Electric spindle angular contact ball bearing pre-tightening force regulating mechanism

An angular contact ball bearing and preload adjustment technology, which is applied to metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve uncontrollable problems, ensure processing quality, improve processing accuracy and processing efficiency, Effect of reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

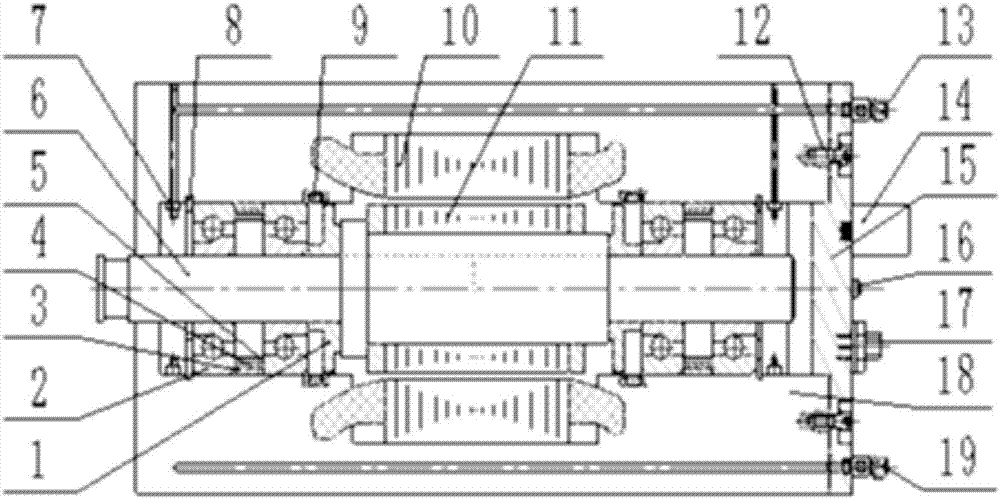

[0032] Such as figure 1 An electric spindle angular contact ball bearing pre-tightening force adjustment mechanism is shown, including an oil baffle ring 1, an angular contact ball bearing 2, a three-layer sleeve, a main shaft 6, an oil injection nozzle 7, a hole elastic retaining ring 8, a non-contact Type temperature sensor 9, stator coil 10, mover coil 11, hexagon socket screw 12, oil nozzle 13, piezoelectric ceramic drive power 14, end cover 15, angular acceleration vibration sensor 16, connector 17, electric spindle housing 18 And water junction 19;

[0033] The mover coil 11 is sleeved on the main shaft 6, the stator coil 10 is installed in the electric spindle housing 18, the main shaft is arranged in the electric spindle housing 18, and the mover coil 11 and the stator coil 10 are There is an air gap between;

[0034] Sleeve the oil baffle ring 1 on both ends of the mover coil 11 on the main shaft 6;

[0035] A pair of angular contact ball bearings 2 are respectively provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com