High pressure gas support flying wheel battery

A flywheel battery and high-pressure gas technology, applied to electrical components, electromechanical devices, electric components, etc., can solve the problems of inability to accurately know the strength and path, high energy consumption of the control system, and difficult control, so as to improve maintainability and reduce Effects on cost, increased efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

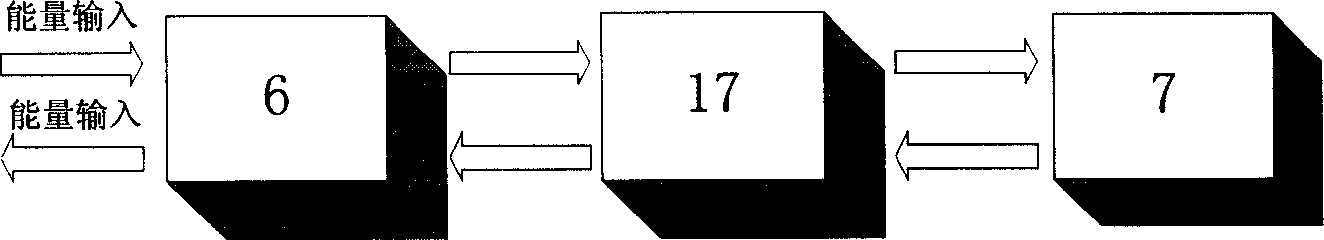

[0030] refer to figure 1 As shown, the energy conversion process of the flywheel energy storage system can be seen from the figure: when charging, the electric energy passes through the power electronic conversion device 6 to drive the motor 17 to drive the flywheel 7 to accelerate the rotation, and the electric energy becomes mechanical energy storage. When discharging, the motor 17 acts as a generator, driven by the flywheel 7 to generate electricity, and the power electronic conversion device 6 outputs electric energy, while the kinetic energy of the flywheel is reduced.

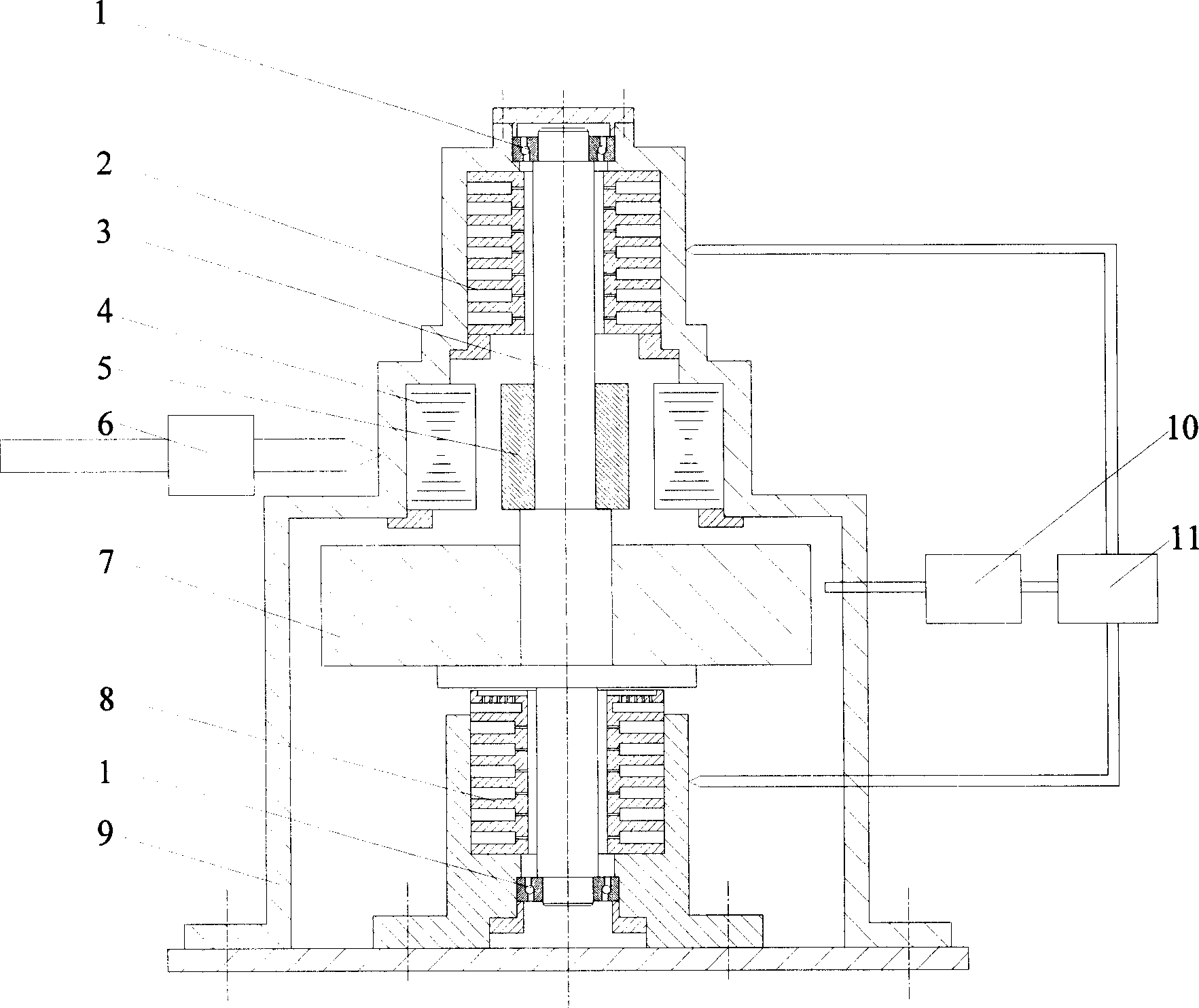

[0031] refer to figure 2 As shown, the present invention includes a sealing shield 9, a main shaft 3 is arranged in the center of the sealing shield 9, the upper and lower ends of the main shaft 3 are in interference fit with the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com