Aluminum alloy formwork inclined-supporting device and construction method

A technology of aluminum alloy formwork and diagonal bracing, which is applied to the joints of formwork/formwork/work frame, the preparation of building components on site, construction, etc. Project quality and other issues, to achieve the effect of good fixing effect, wide application range and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

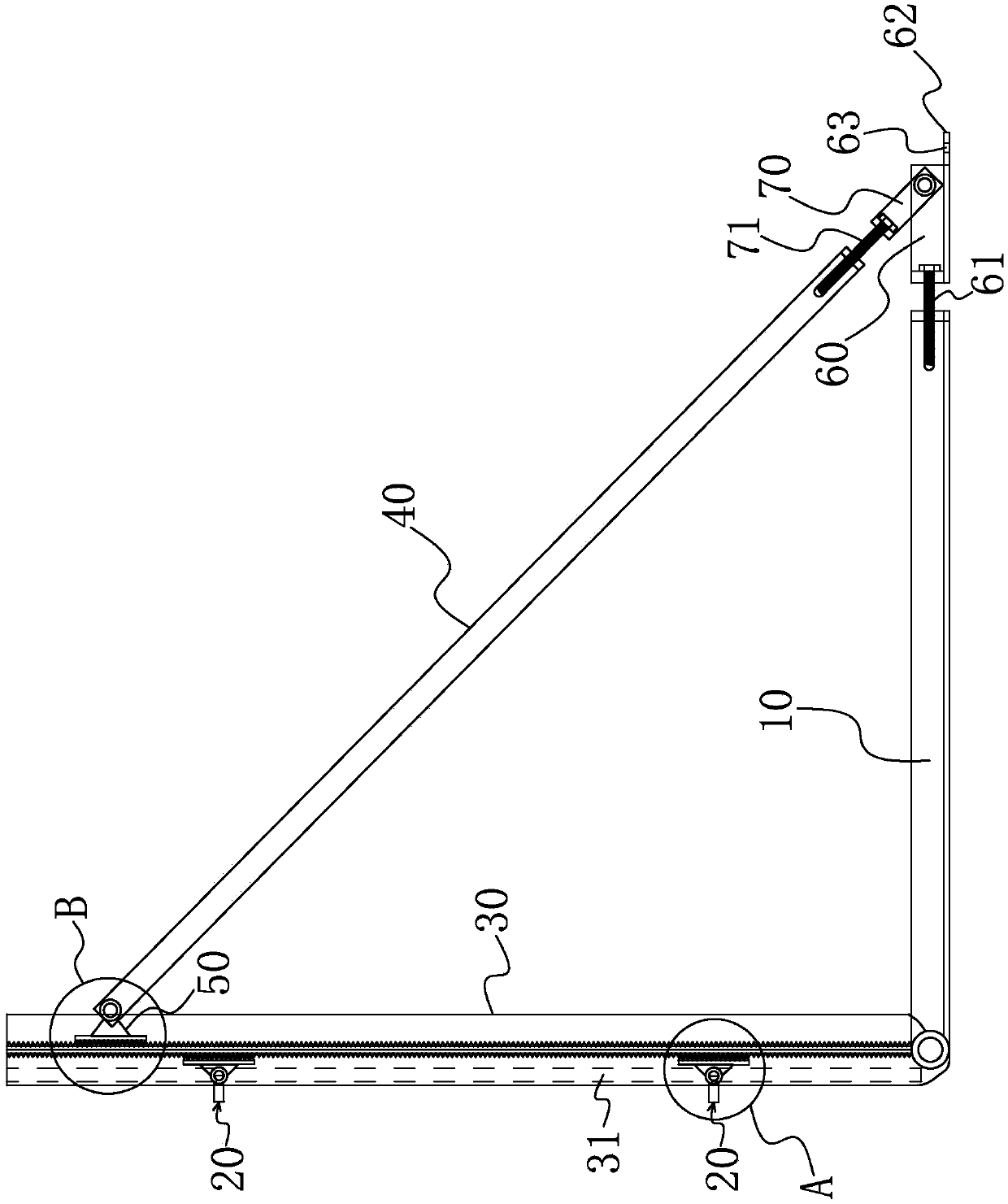

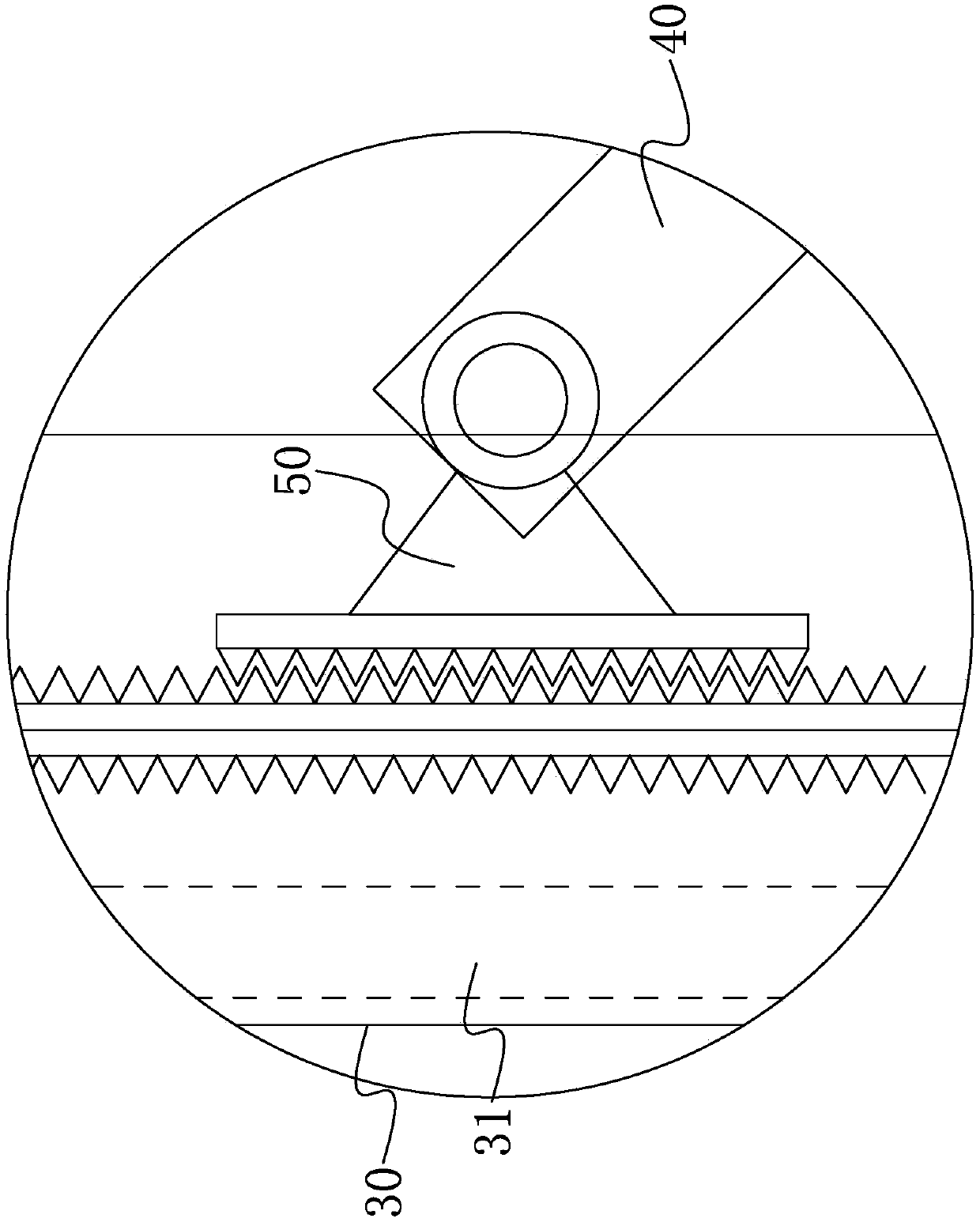

[0042] Such as figure 1 As shown, an aluminum alloy formwork slant bracing device of the present invention includes a horizontal support rod 10 , a support member 20 , a vertical support rod 30 , and an oblique support and adjustment member 50 .

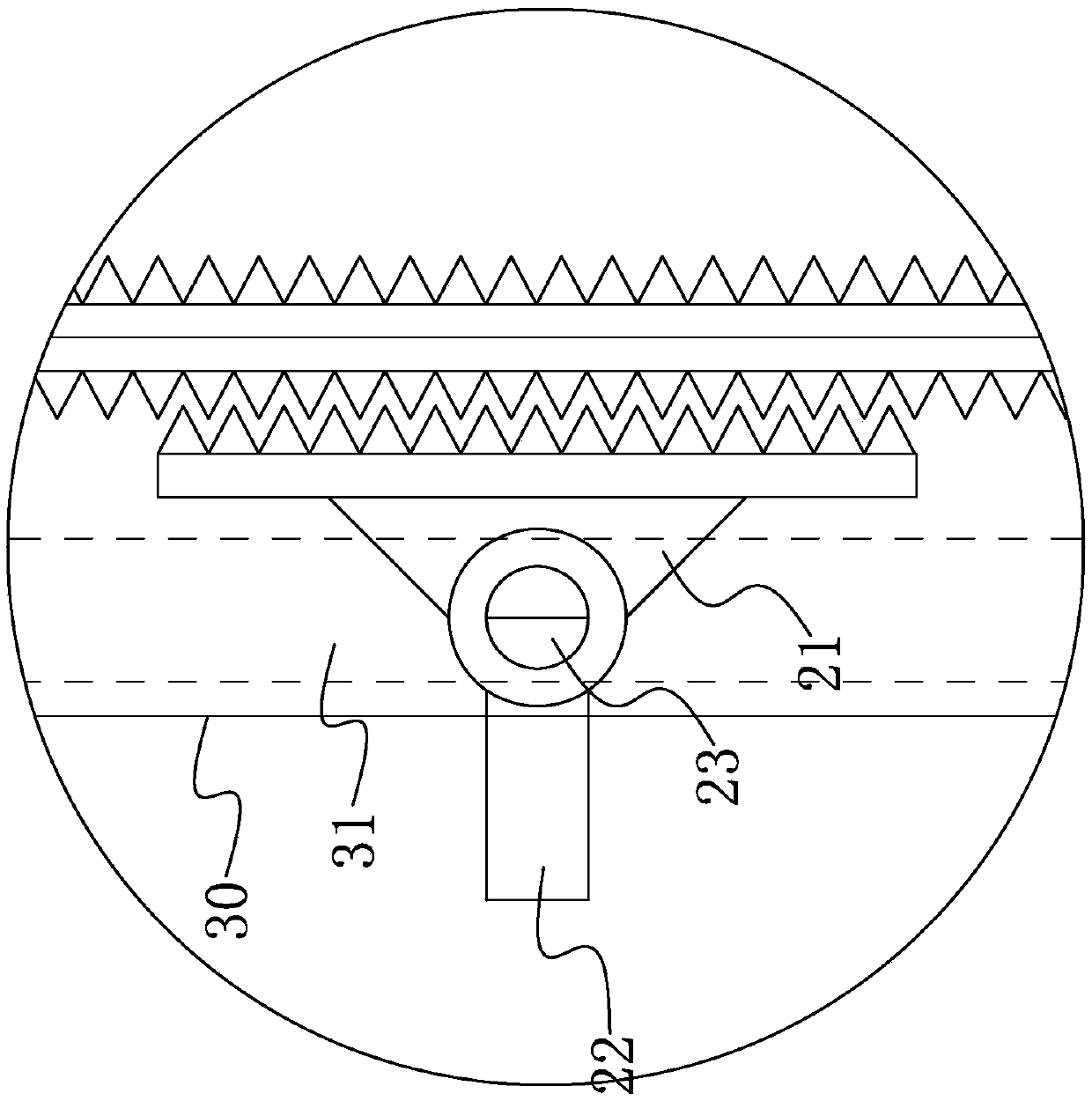

[0043] The horizontal support rod 10 is arranged horizontally and can be fixed with the base surface. The base surface can be the ground or the surface of the building structure. Connection, the two opposite surfaces of the vertical support rod 30 are provided with grooves, the support member 20 has two and is movably connected with the vertical support rod 30, the two support members 20 are all located in the outer groove, the support member 20 can be relatively vertical The su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com