Iron accessory multi-angle bending method

An iron attachment, multi-angle technology, applied in auxiliary devices, feeding devices, positioning devices, etc., can solve problems such as low bending efficiency, achieve high production efficiency, prevent displacement, and improve bending accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

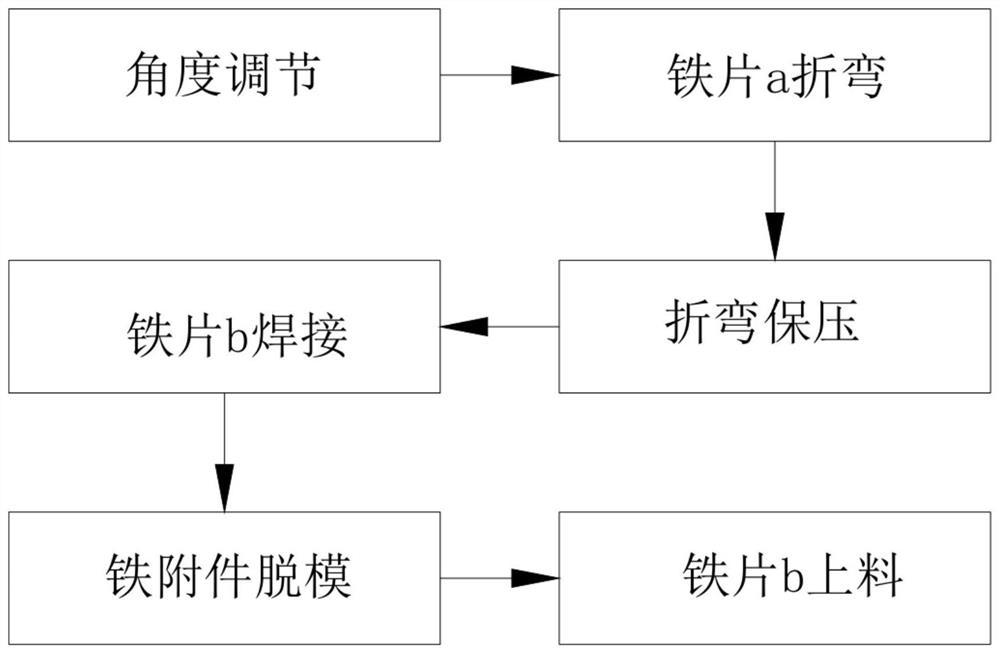

[0041] Such as figure 1 As shown, a multi-angle bending method of an iron accessory comprises the following steps:

[0042] Step 1: Angle adjustment, according to the bending angle, insert the pin 423 into the corresponding limit hole 422 to change the height of the limit frame 421 on the bracket 411 that is matched with the pin 423;

[0043] Step 2: Bending the iron sheet a. After step 1, the lifting device 2 pushes the fixing plate 311 to move down, the pressing plate 3211 contacts the iron sheet a, the fixing plate 311 continues to move down, and the push rod 3111 drives the pressing plate 3211 and The bottom plate 412 rotates at the same time to bend the iron sheet a until the bottom plate 412 conflicts with the limit frame 421;

[0044] Step 3: Bending and maintaining pressure. After step 2, the fixing plate 311 continues to move down, the ejector rod 3111 rotates, and its end moves down along the upper surface of the pressing plate 3211;

[0045] Step 4: Iron sheet b is ...

Embodiment 2

[0059] The present invention also provides a multi-angle bending equipment for iron accessories:

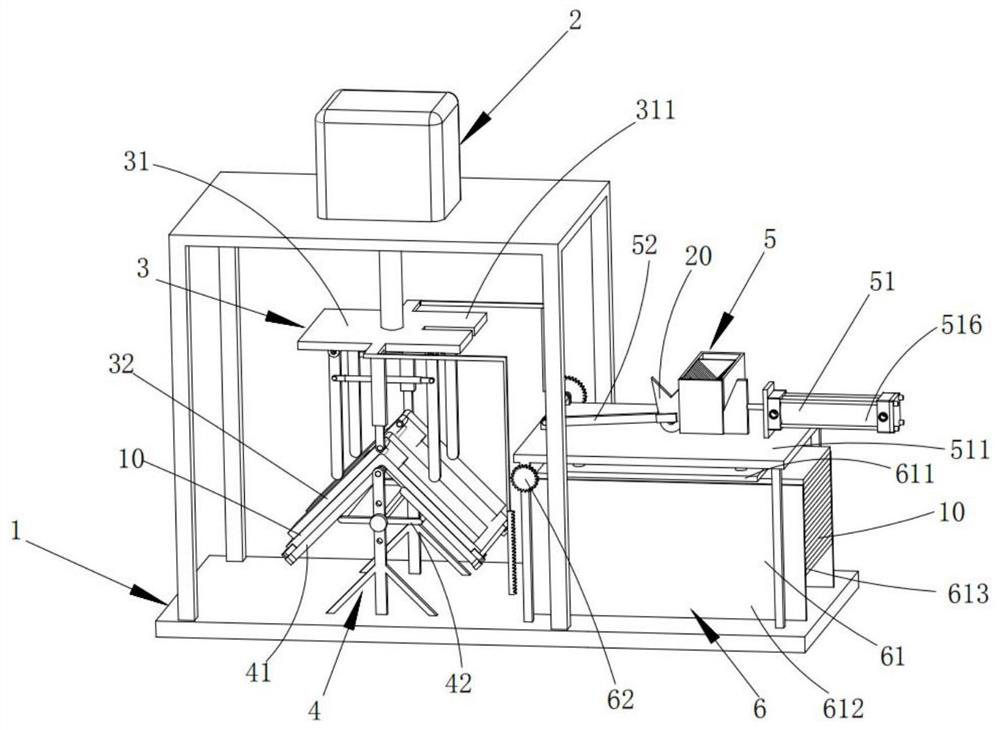

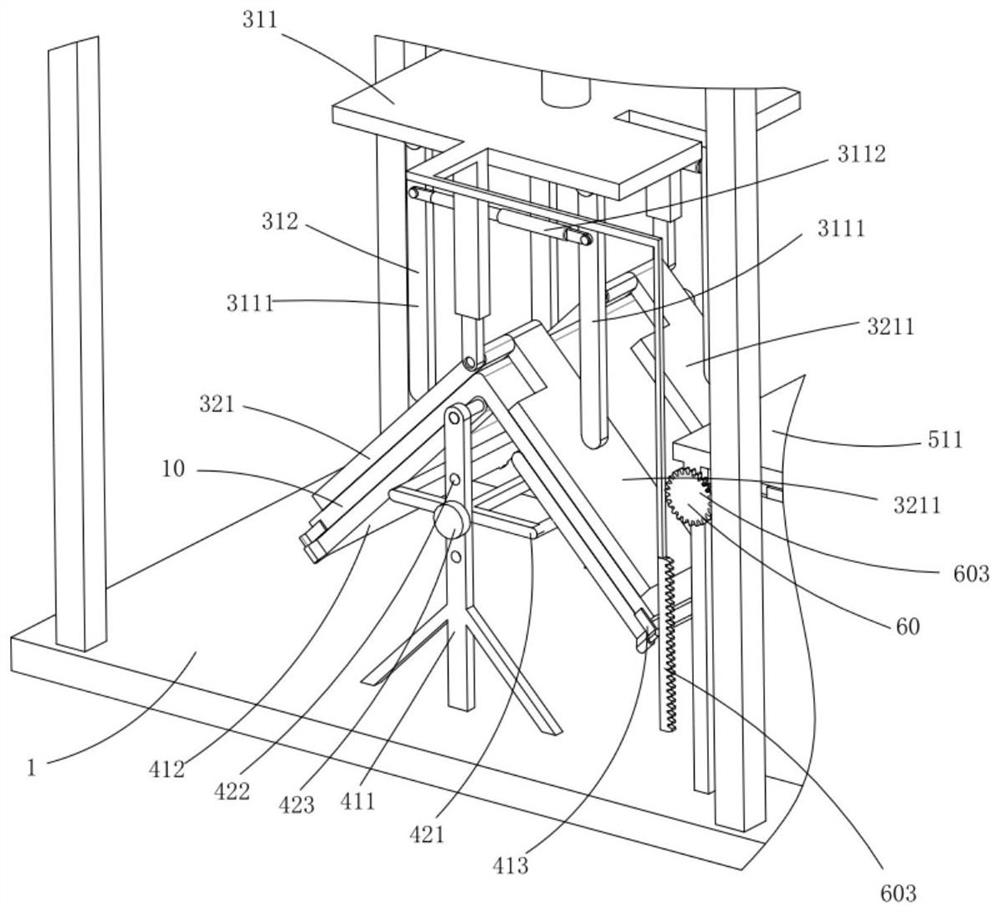

[0060] Such as Figure 2 to Figure 4 As shown, a multi-angle bending equipment for iron accessories includes a base 1 and a lifting device 2 installed on the base 1, and also includes:

[0061] The upper mold 3, the upper mold 3 includes a pressing assembly 31 fixedly connected to the power end of the lifting device 2, and a bend that is arranged under the pressing assembly 31 by sliding up and down and can interfere with the pressing assembly 31 Component 32;

[0062] The lower mold 4, the lower mold 4 includes a positioning assembly 41 installed on the base 1 and forming a bending station 100 with the bending assembly 32, and is arranged under the positioning assembly 41 by sliding up and down and is connected with the positioning assembly 41. Component 41 can interfere with the adjustment component 42 set;

[0063] An assembly device 5, the assembly device 5 includes a feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com