Patents

Literature

48results about How to "Automatic loading and unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

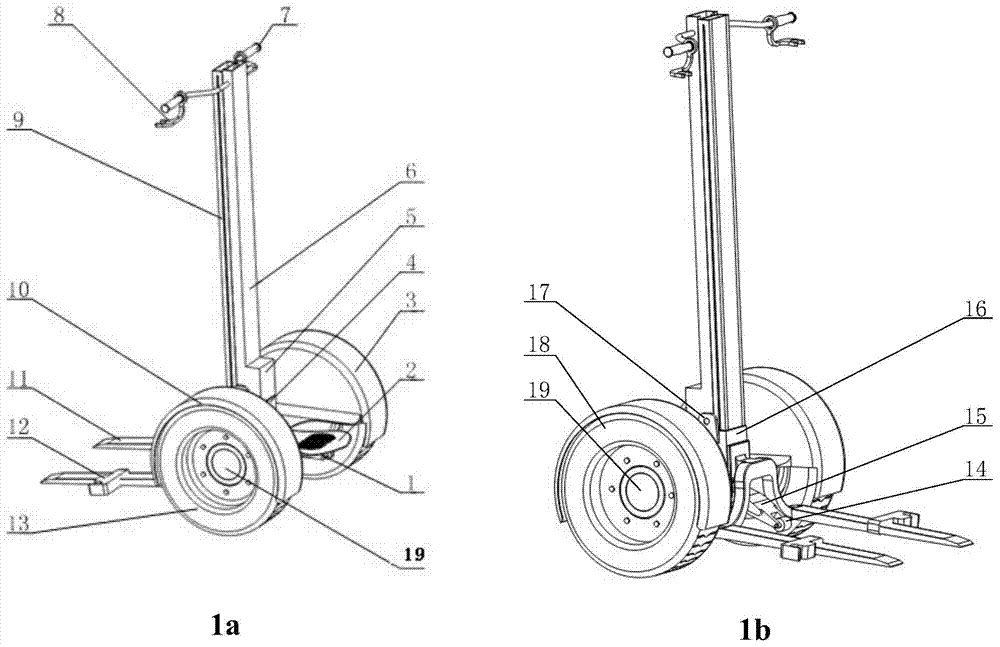

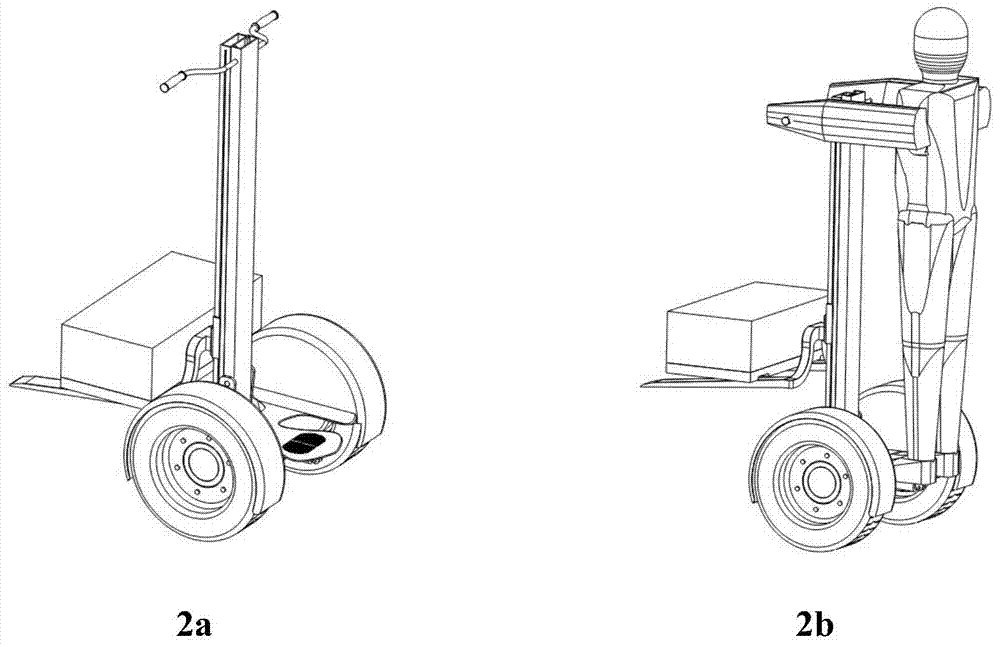

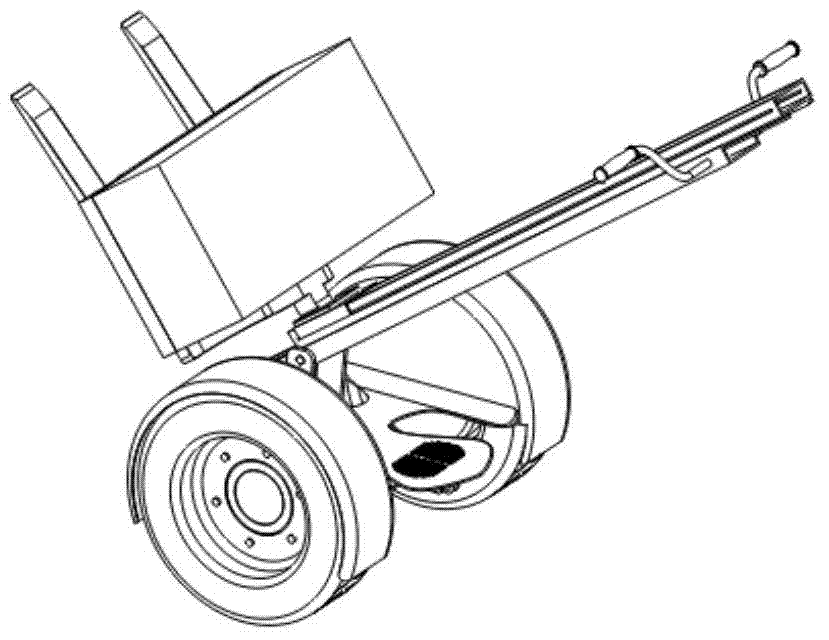

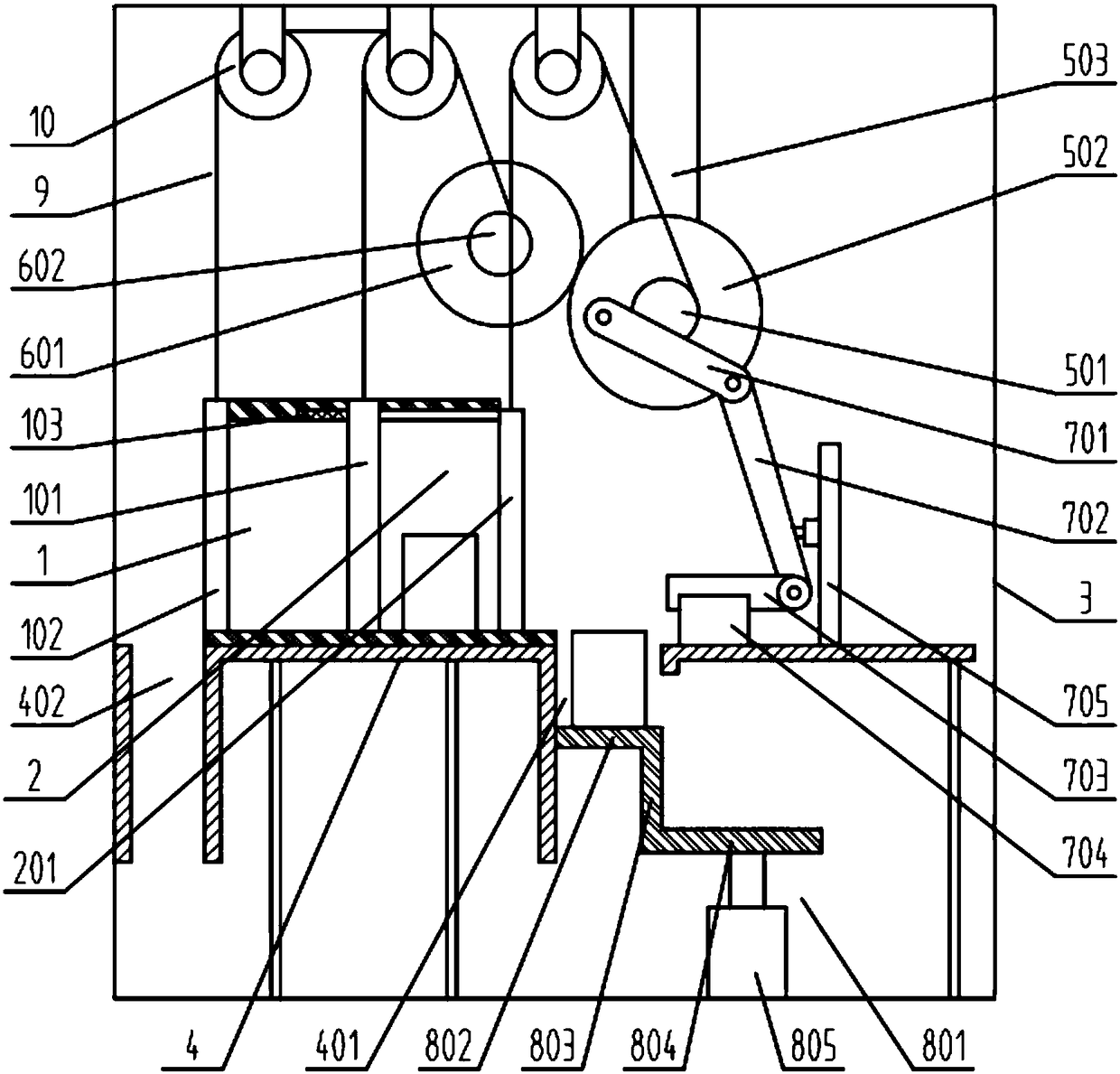

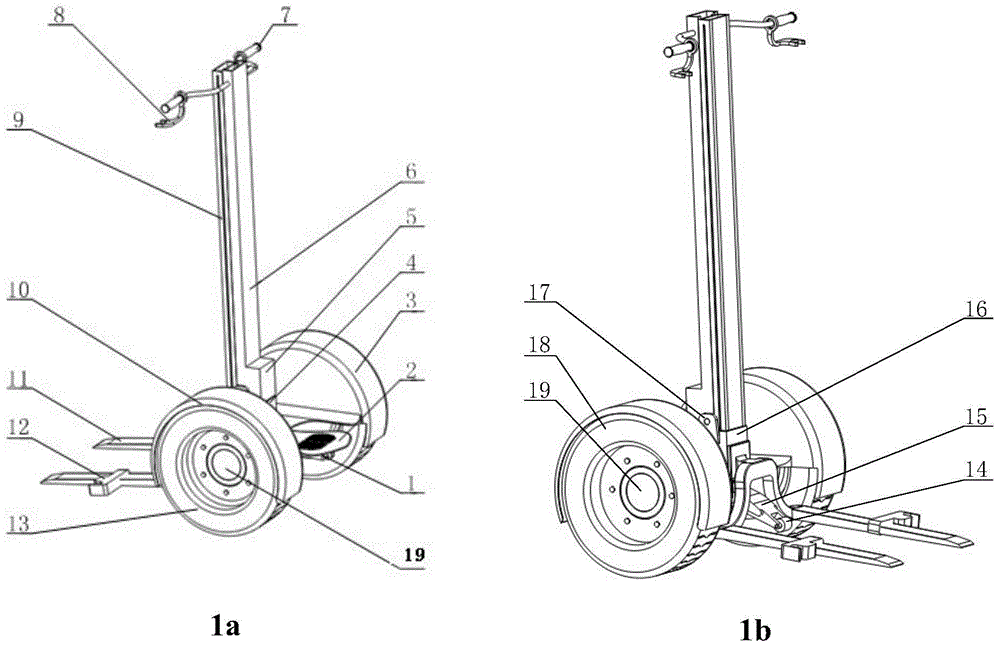

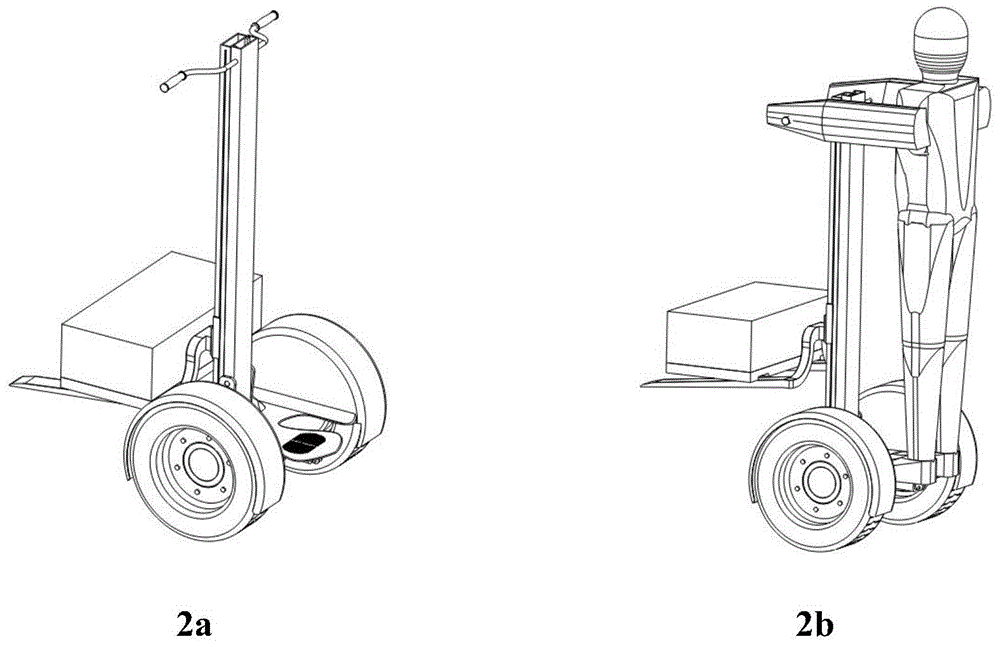

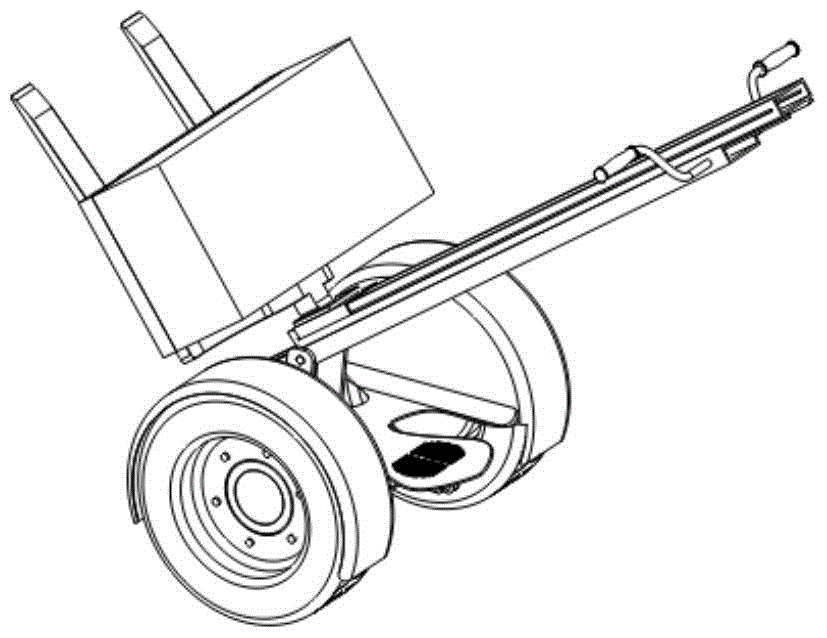

Self-balance multifunctional carrier

InactiveCN104709847AImprove the efficiency of loading and unloading guaranteeSmall bodyLifting devicesLithiumGyroscope

The invention discloses a self-balance multifunctional carrier which comprises a vehicle body, a lifting motor, a wheel drive motor, a motor controller, a winch, a pulley mechanism, a hinge type two-stage lifting portal, a fork, driving wheels, balance supporting legs, a lithium ion storage battery set, an attitude-control gyroscope, a dip angle sensor, a mechanical electric accessory and the like. The self-balance off-road multifunctional carrier has an off-road wheelbarrow work mode and a manual forklift work mode, people can get on and off the carrier by themselves by means of the design of the two-stage lifting portal, people can drive the carrier in the manual forklift mode and a self-balance mode when road environments are good, and the carrier can be assisted and pushed by hands to drive in the off-road wheelbarrow mode when the road environments are bad. The self-balance driving technology and the goods gravity self-adjustment technology are adopted, and flexible switching between the two modes is achieved through the portal toppling structure. The carrier has the advantages that a vehicle body is light, work is flexible, functions are diverse and adaptability is high, and goods loading, unloading and transporting efficiency in field environments can be effectively improved.

Owner:ARCHITECTURAL ENG INST GENERAL LOGISTICS DEPT P L A

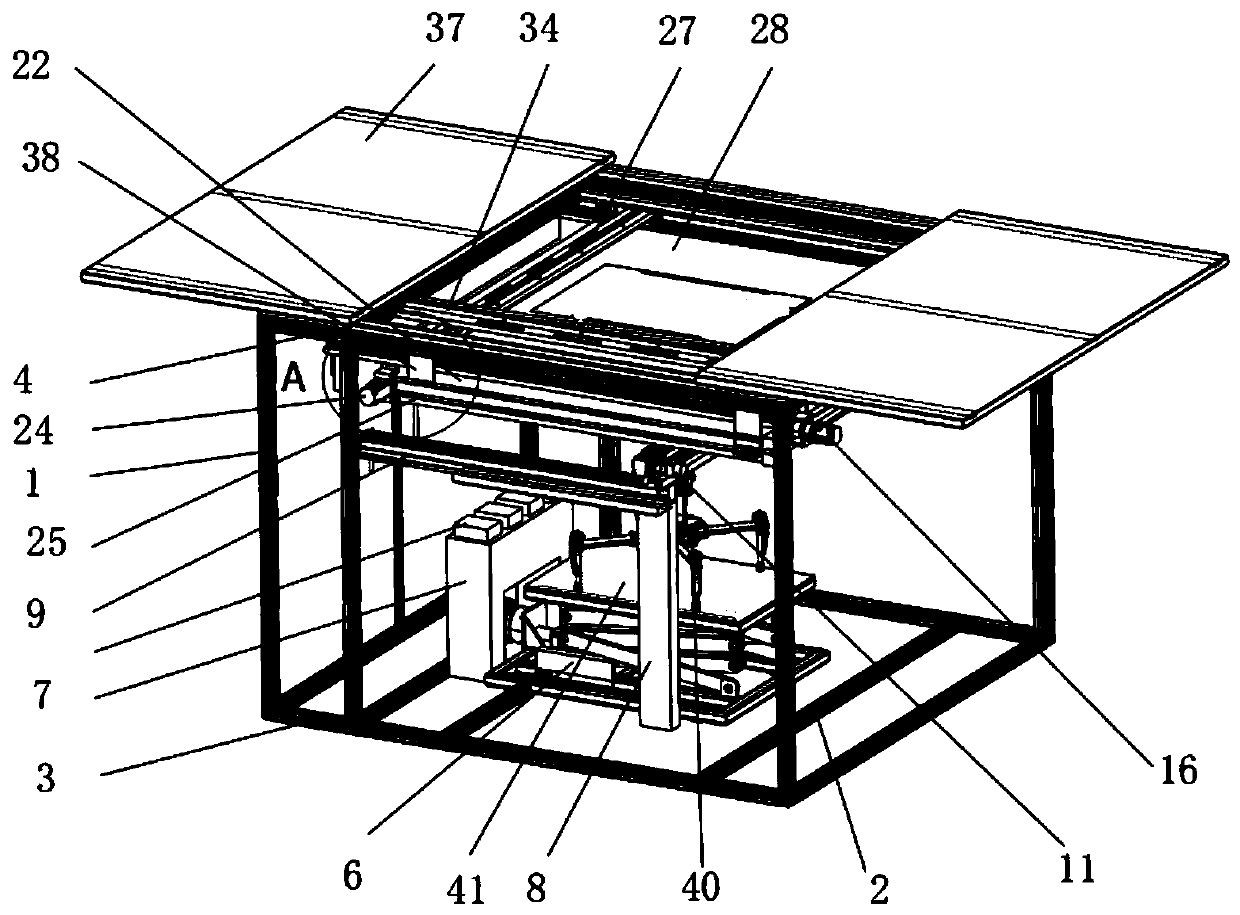

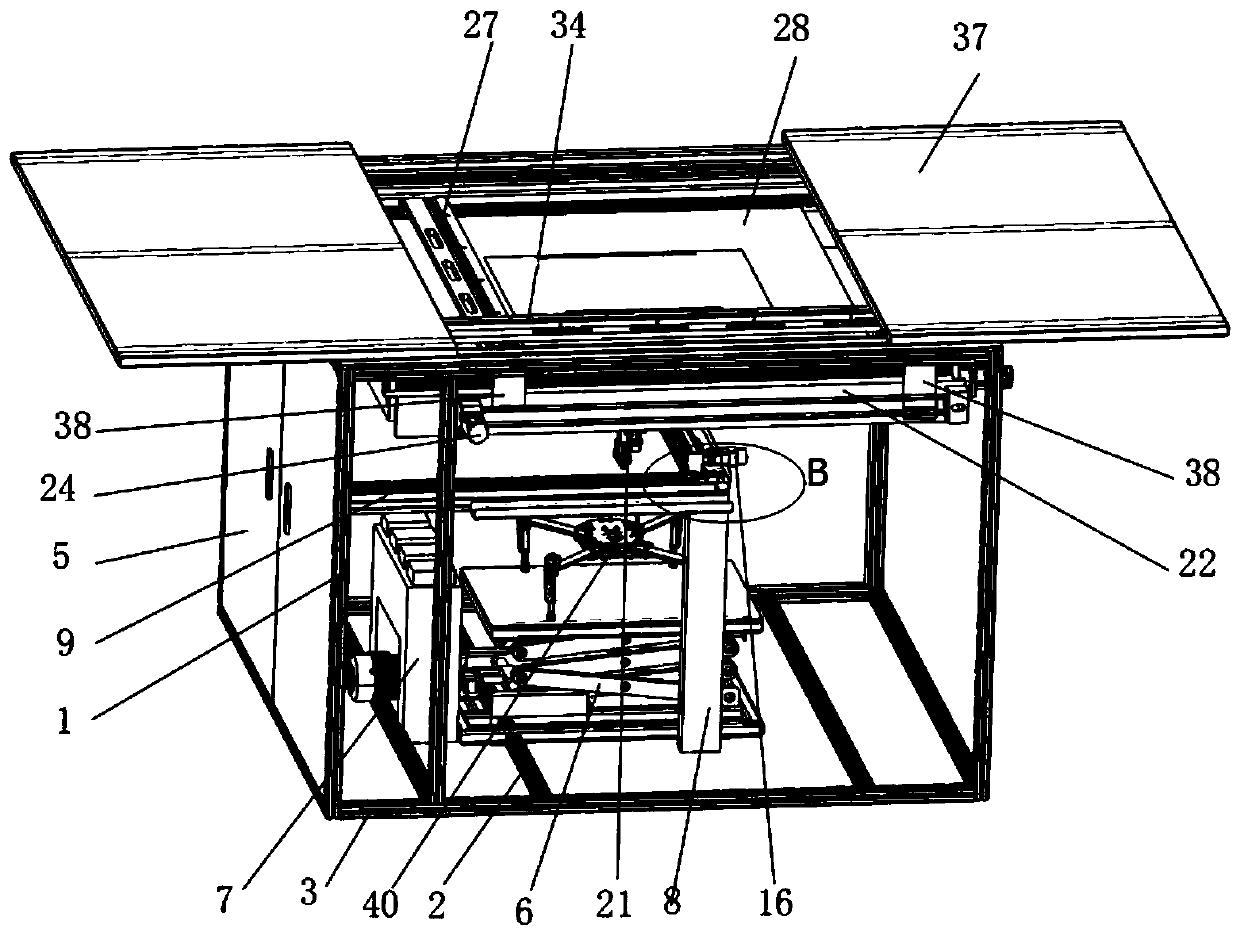

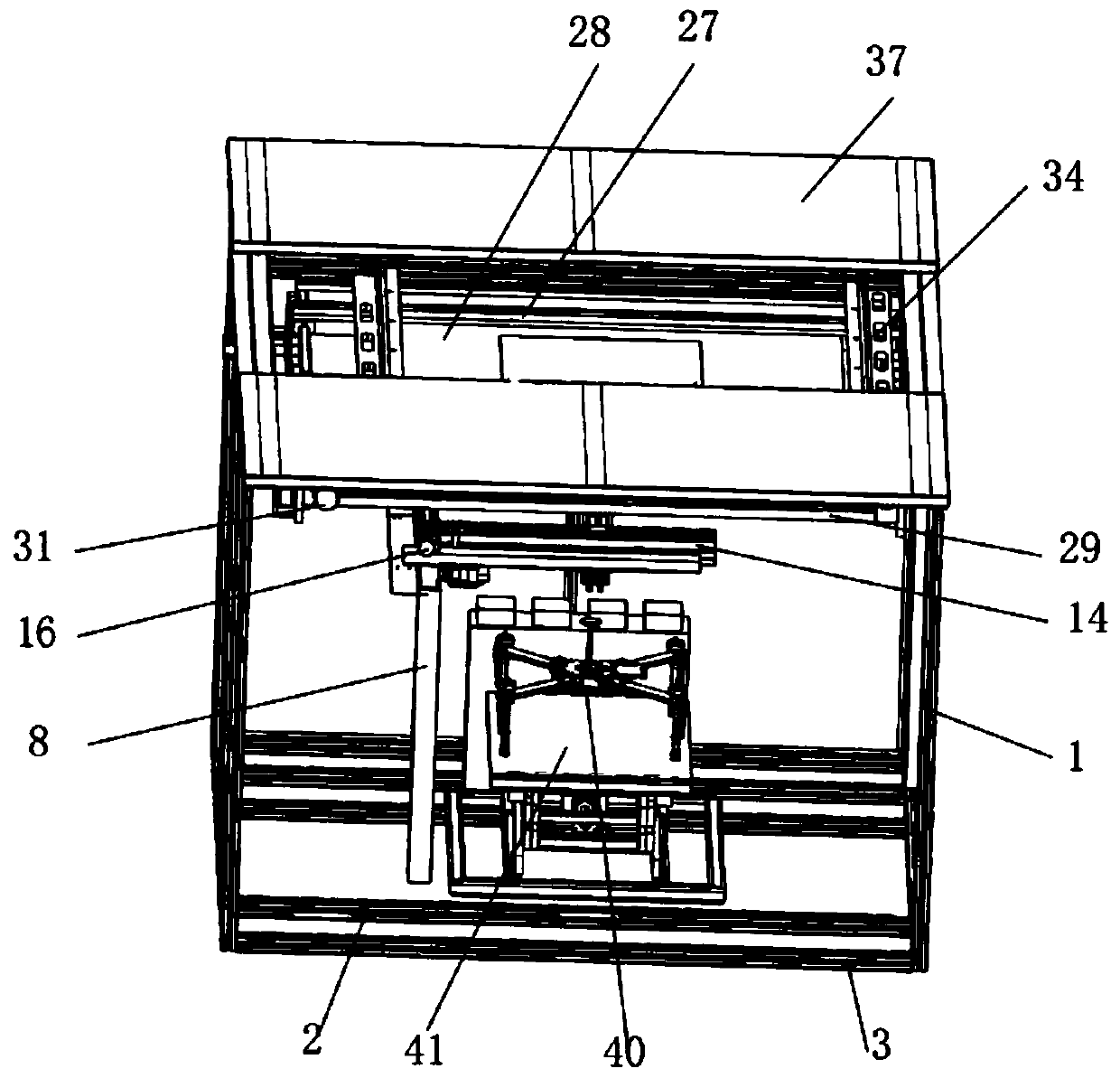

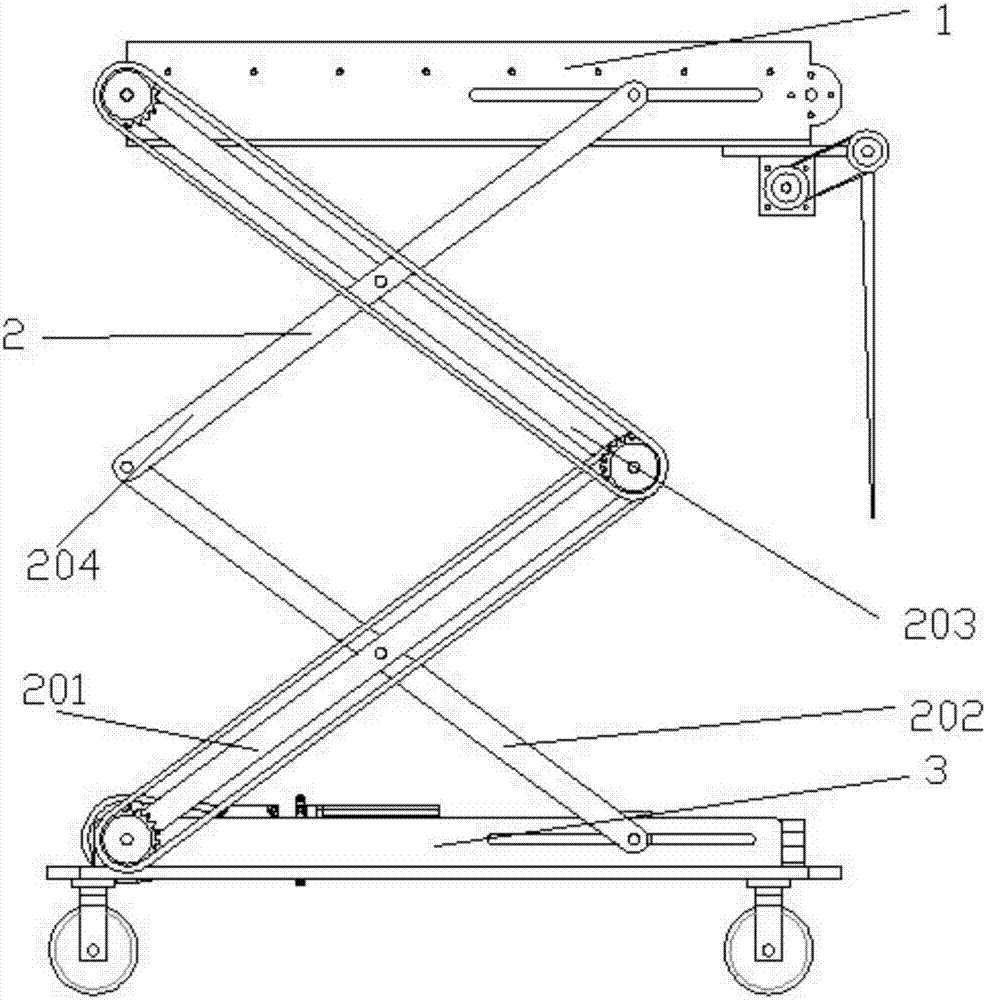

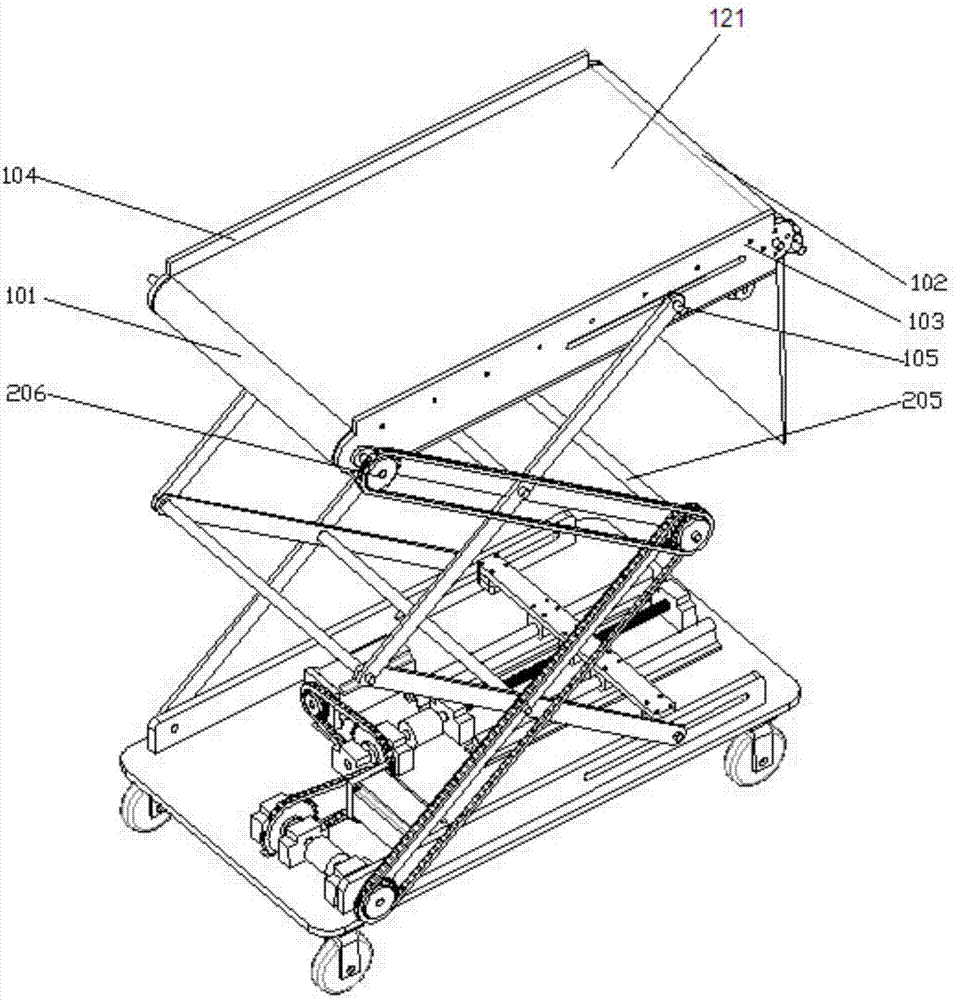

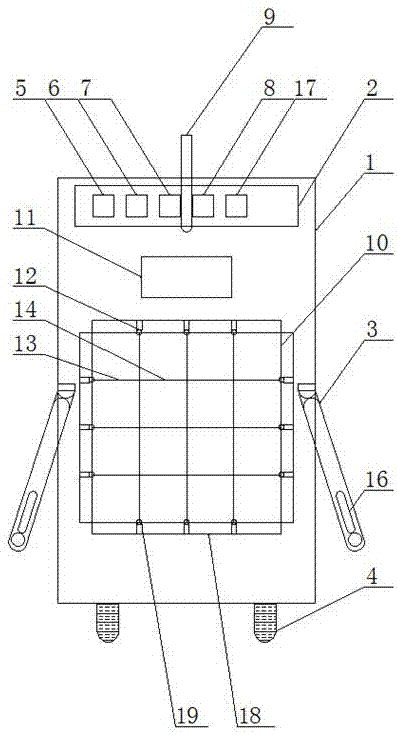

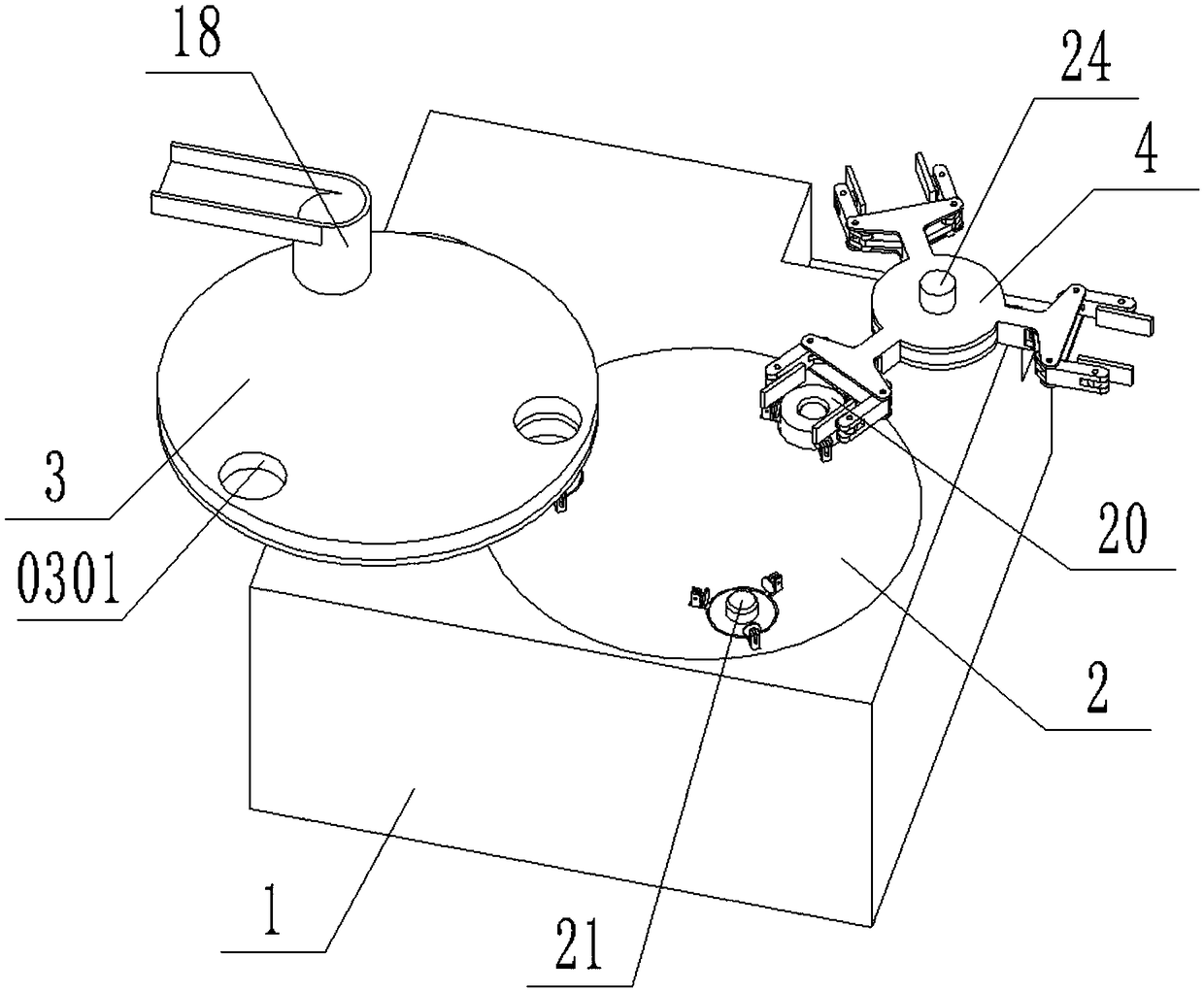

Unmanned aerial vehicle automatic charging hangar

PendingCN110937127AHigh degree of automationReduce labor intensityCharging stationsElectric propulsion mountingMarine engineeringUncrewed vehicle

An unmanned aerial vehicle automatic charging hangar disclosed by the present invention comprises a hangar shell, the hangar shell comprises a support rod, a support column, a support fixing rod and aclosed shell, the support column and the support fixing rod are both arranged on the support rod, and the closed shell is arranged on the support rod and the support column. A battery reloading partcomprises a lifter and a battery loading and unloading part, and the lifter and the battery loading and unloading part are both arranged on the support fixing rod; a centering parts comprise the longitudinal centering part and the transverse centering part, and the longitudinal centering part is arranged on the supporting vertical rod; a warehouse door part comprises a warehouse door sliding groove, a warehouse door sliding rail, a warehouse door plate and a warehouse door power piece, the warehouse door sliding groove and the warehouse door power piece are both arranged on the top end supporting rod, the warehouse door sliding rail is arranged on the warehouse door sliding groove, and the warehouse door plate is arranged on the warehouse door sliding rail. The automatic charging hangar ishigh in automation degree, safe, reliable, capable of remarkably reducing the labor intensity of workers, remarkably reducing the human input and remarkably reducing the operation cost, and suitablefor large-area application and popularization.

Owner:上海赛摩电气有限公司

Multi-angle cabinet type goods lifter

InactiveCN108002291AReduce volumeAvoid disadvantagesConveyorsLifting framesTransmitted powerMechanical engineering

Owner:ZHEJIANG SCI-TECH UNIV

Logistics warehousing method

The invention relates to the field of logistics, in particular to a logistics warehousing method. The logistics warehousing method uses warehousing equipment. The warehousing equipment can protect goods shelves which are loaded through a protective mechanism. A loading mechanism can realize the loading of goods. A moving mechanism can drive the goods to move in the horizontal direction. A pushingmechanism can push the goods out for rapid loading and unloading. A clamping mechanism can clamp and fix the goods. A lifting mechanism can drive the goods up and down and change the position of the goods. Objects are clamped and fixed by a clamping plate in the way that two moving sleeves rotates at a screw and close to each other, the objects with different sizes be clamped, the objects can be clamped in the center, the whole clamping mechanism can be lifted and lowered in the way that a pneumatic sliding block is matched with a pneumatic sliding rail, and the horizontal displacement can bechanged by cooperating a shuttle truck, the goods can be transported to the shelves at a specific position to realize automatic transportation and loading and unloading of the goods.

Owner:王军

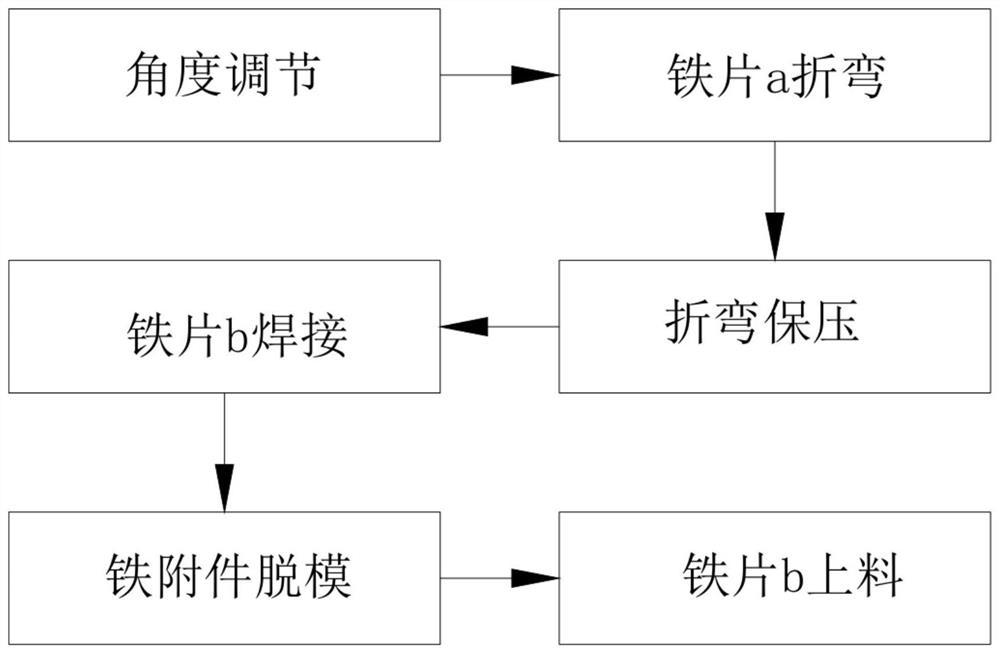

Iron accessory multi-angle bending method

ActiveCN112828084AImprove bending accuracyAvoid displacementMetal-working feeding devicesWelding/cutting auxillary devicesEngineeringMechanical engineering

The invention relates to an iron accessory multi-angle bending method. The method comprises the following steps that angle adjustment is conducted, and a pin is inserted into a corresponding limiting hole according to the bending angle so as to change the height of a limiting frame matched with the pin on a support; an iron sheet a is bent, a fixing plate moves downwards, pressing plates make contact with the iron sheet a, and then ejector rods drive the pressing plates and bottom plates to rotate at the same time to bend the iron sheet a till the bottom plates abut against the limiting frame; bending and pressure maintaining are conducted, the fixing plate continues to move downwards, the ejector rods rotate, and the ends move along the upper surfaces of the pressing plates; an iron sheet b is welded, a transmission assembly a acts to drive a swing arm to rotate, a gripper places the iron sheet b on the iron sheet a, and then the iron sheet a and the iron sheet b are welded to form an iron accessory; a welded part is demolded, the fixing plate moves upwards, the pressing plates and the swing arm rotate and reset, and then a roll shaft rotates to drive the iron sheet a to move to the bottom plate and eject the iron accessory away; and the iron sheet b is fed, and an air cylinder drives the iron sheet b to be clamped into the gripper. By means of the iron accessory multi-angle bending method, continuous production of the iron accessory can be achieved.

Owner:HUZHOU COLLEGE

Tobacco timing temperature control fast baking device

InactiveCN110250554AAvoid accumulationImprove uniformityTobacco preparationEngineeringTemperature control

The invention discloses a tobacco timing temperature control fast baking device. According to the tobacco timing temperature control fast baking device, automatic loading and unloading can be realized, automatic turning and leveling can be realized, stacking is prevented, uniformity of baking is improved, meanwhile, the spacing between the lower end surface of a leveling and turning assembly and the upper end surface of a transport assembly are adjustably arranged to facilitate adjustments of the leveling and turning thickness of the leveling and turning assembly to the tobacco so that during baking, the turning and levelingoperations of the tobacco are achieved through sliding back and forth along a guiding sliding groovein a reciprocate mode, during different reciprocating sliding, the adjustment of different leveling thicknesses can be realized, uniform leveling of different thicknesses can be realized, baking of tobacco in each layer is realized,and uniformity of baking is improved.

Owner:ANHUI SCI & TECH UNIV

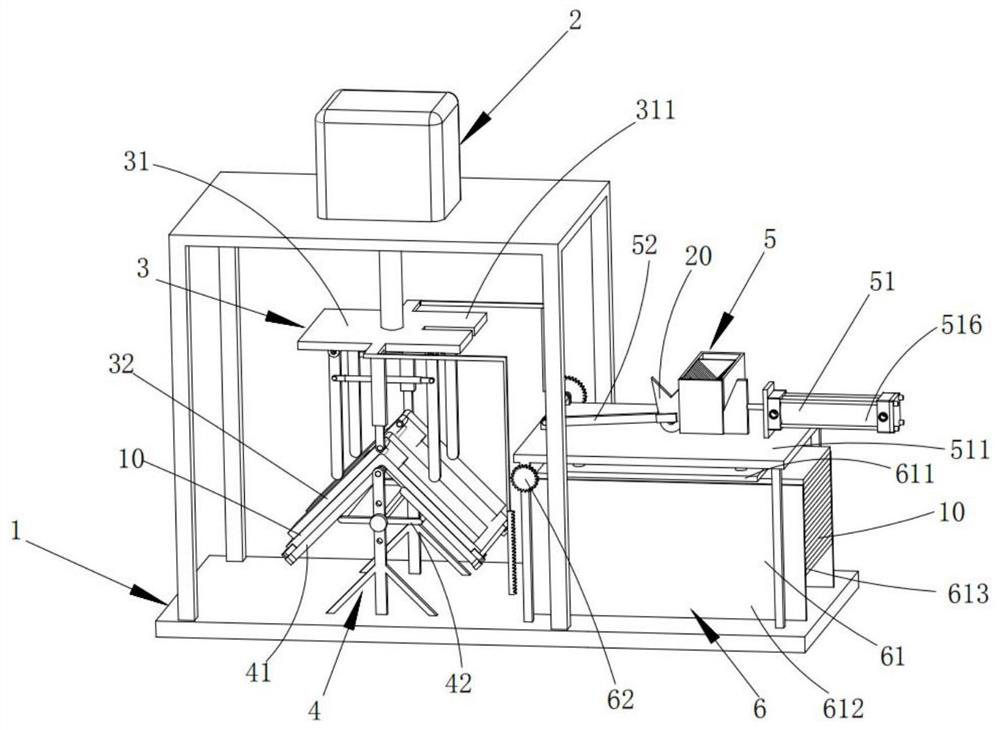

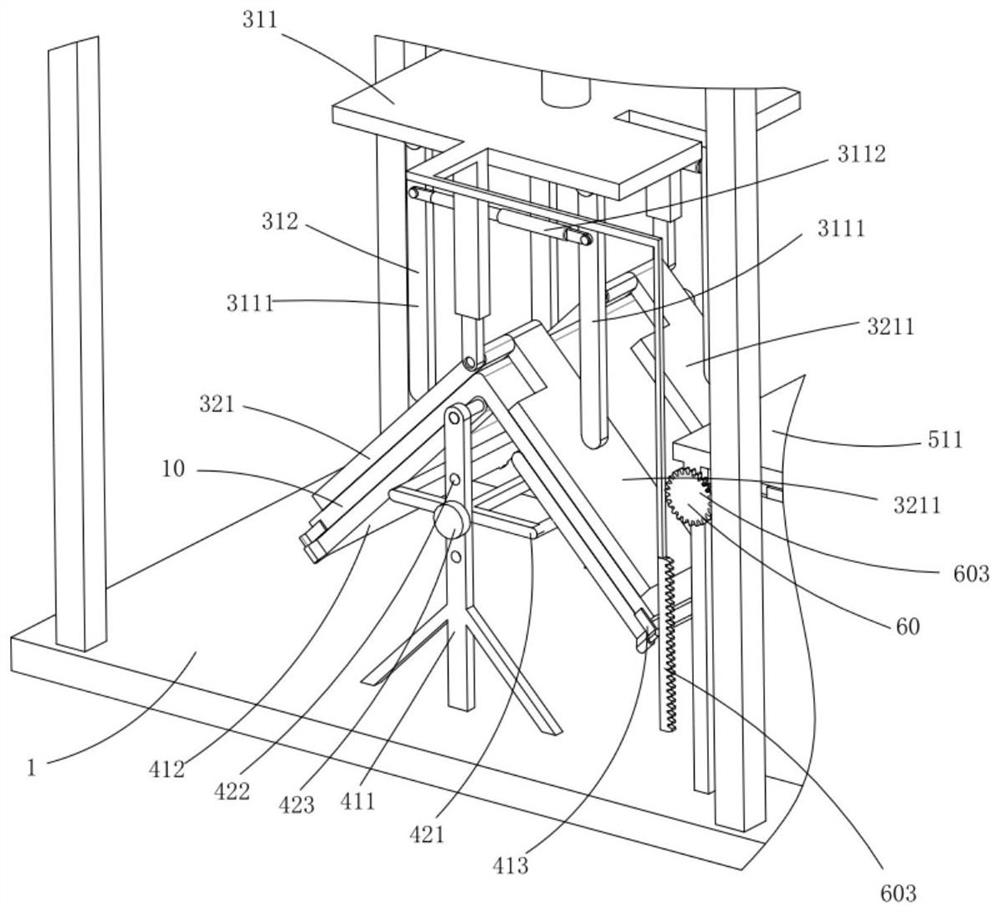

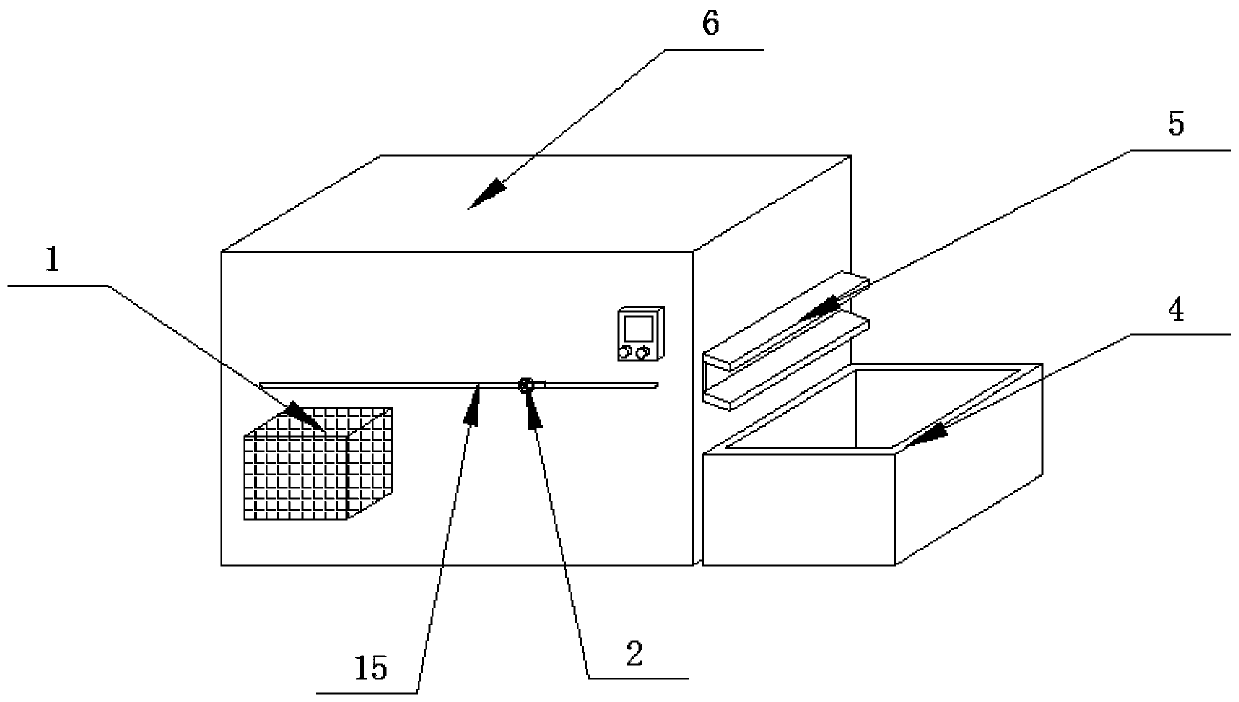

Sheet metal part bending forming equipment

ActiveCN112845704AImprove assembly accuracyImprove the pressing effectShaping toolsMetal-working feeding devicesEngineeringPhysics

The invention provides sheet metal part bending forming equipment. The equipment comprises a base, lifting equipment, an upper mold, a lower mold, an assembling device and a feeding device, wherein the upper mold comprises a pressing assembly and a bending assembly; the lower mold comprises a positioning assembly and an adjusting assembly; the assembling device comprises a feeding assembly and a conveying assembly; and the feeding device comprises a storage assembly and a driving assembly. According to the sheet metal part bending forming equipment, the bending assembly and the positioning assembly are driven through downward movement of the pressing assembly to rotate to carry out bending and pressure maintaining on an iron sheet a, and meanwhile, the pressing assembly is matched with the conveying assembly and the driving assembly to achieve part assembling and feeding and discharging work, so that the technical problem that in the prior art, pressure maintaining cannot be carried out on a bent sheet metal part is solved.

Owner:HUZHOU COLLEGE

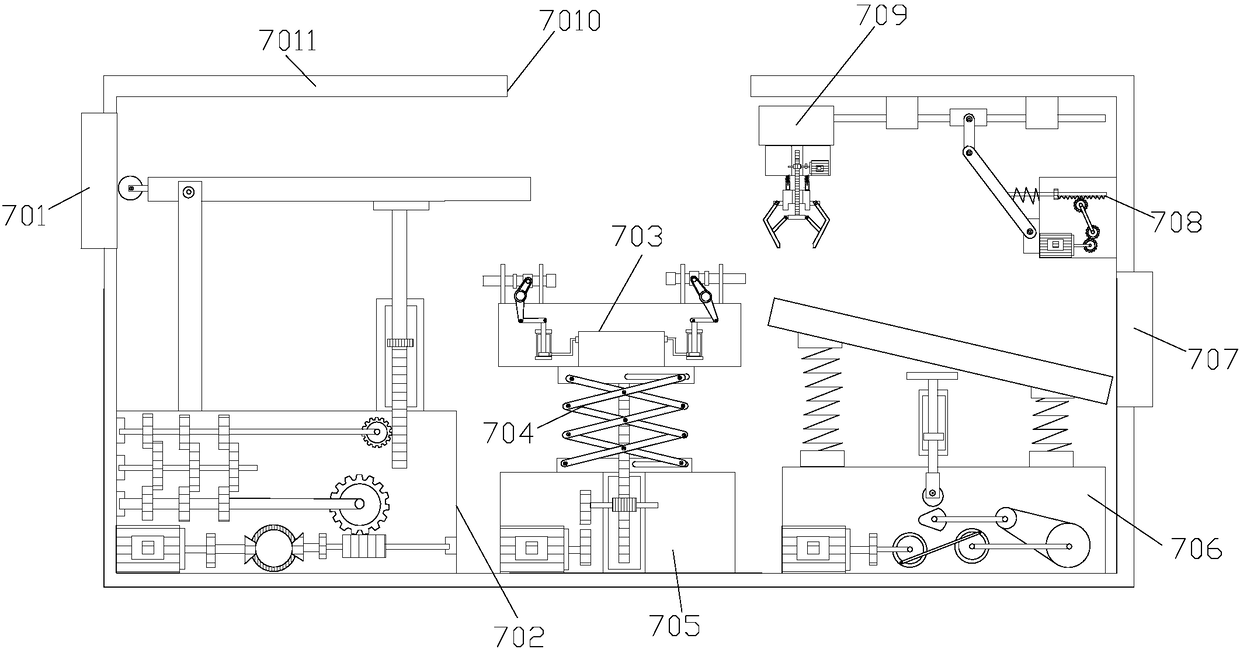

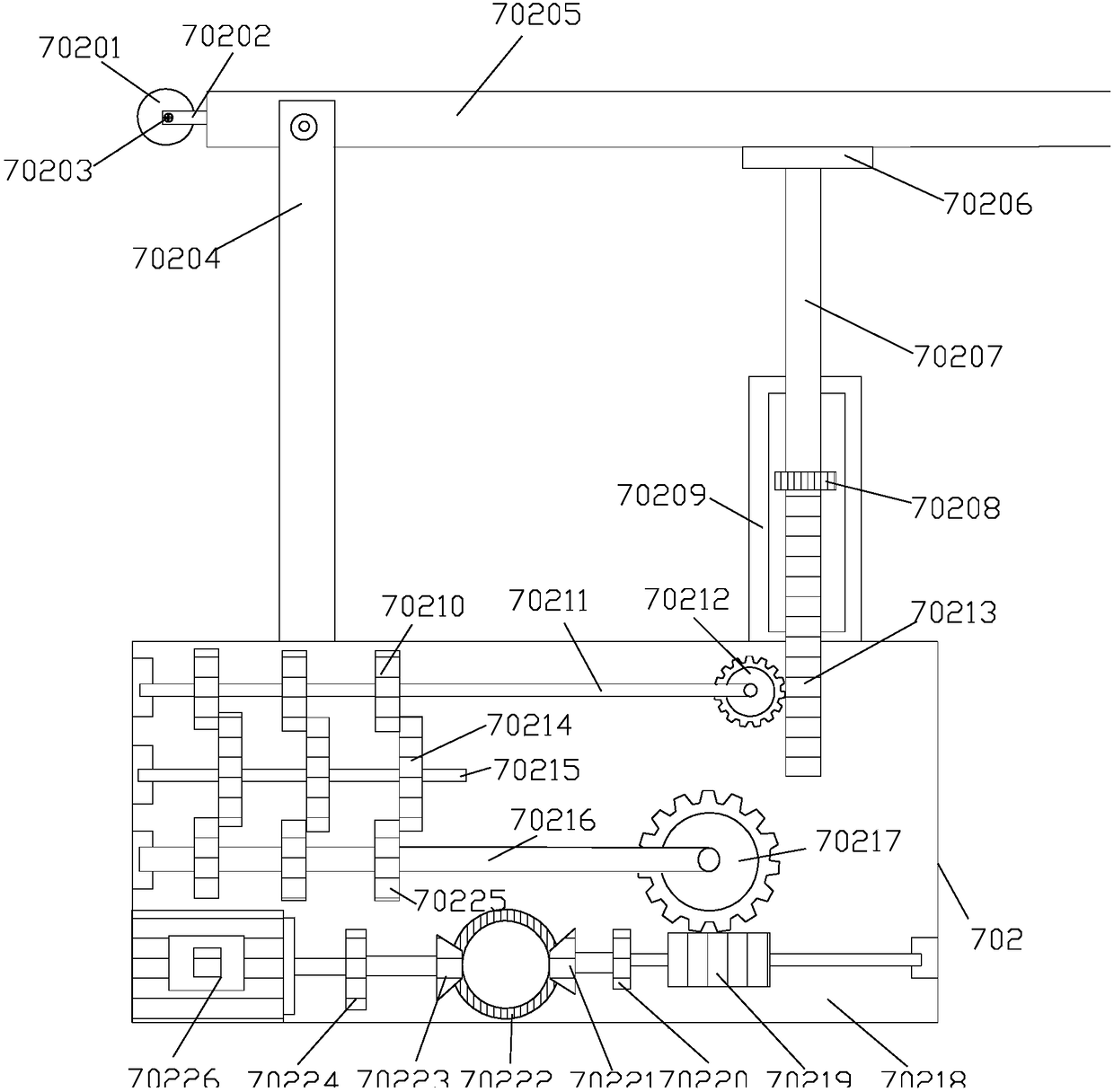

Intelligent carrying equipment capable of changing storage space freely and work method thereof

ActiveCN107497696AAutomatic loading and unloadingAutomatic distributionSortingControl roomMarine navigation

The invention discloses intelligent carrying equipment capable of changing the storage space freely. The intelligent carrying equipment comprises a box body, a control chamber, a grabbing device and movement devices. The control chamber comprises a processor, a drive device, a navigation device and a storage device, wherein the storage device is connected with the processor and used for storing information of express parcels. The information of the express parcels comprises the consignee addresses and the telephone numbers of recipients. The box body comprises a camera, a storage rack and an RFID label printer. The storage rack comprises a plurality of storage units. The storage units comprise first storage unit bodies and second storage unit bodies. Each storage unit comprises a rotation device, a first storage plate, a second storage plate and a first electric sliding rail, wherein the first electric sliding rail is connected under the first storage plate, and the second storage plate is connected with the first electric sliding rail. The rotation devices and the first electric sliding rails are driven by the drive device. The RFID label printer is connected with the processor and driven by the drive device. The grabbing device comprises RFID recognizers, and the RFID recognizers are connected with the processor and used for recognizing RFID labels.

Owner:上海孚迅机器人有限公司

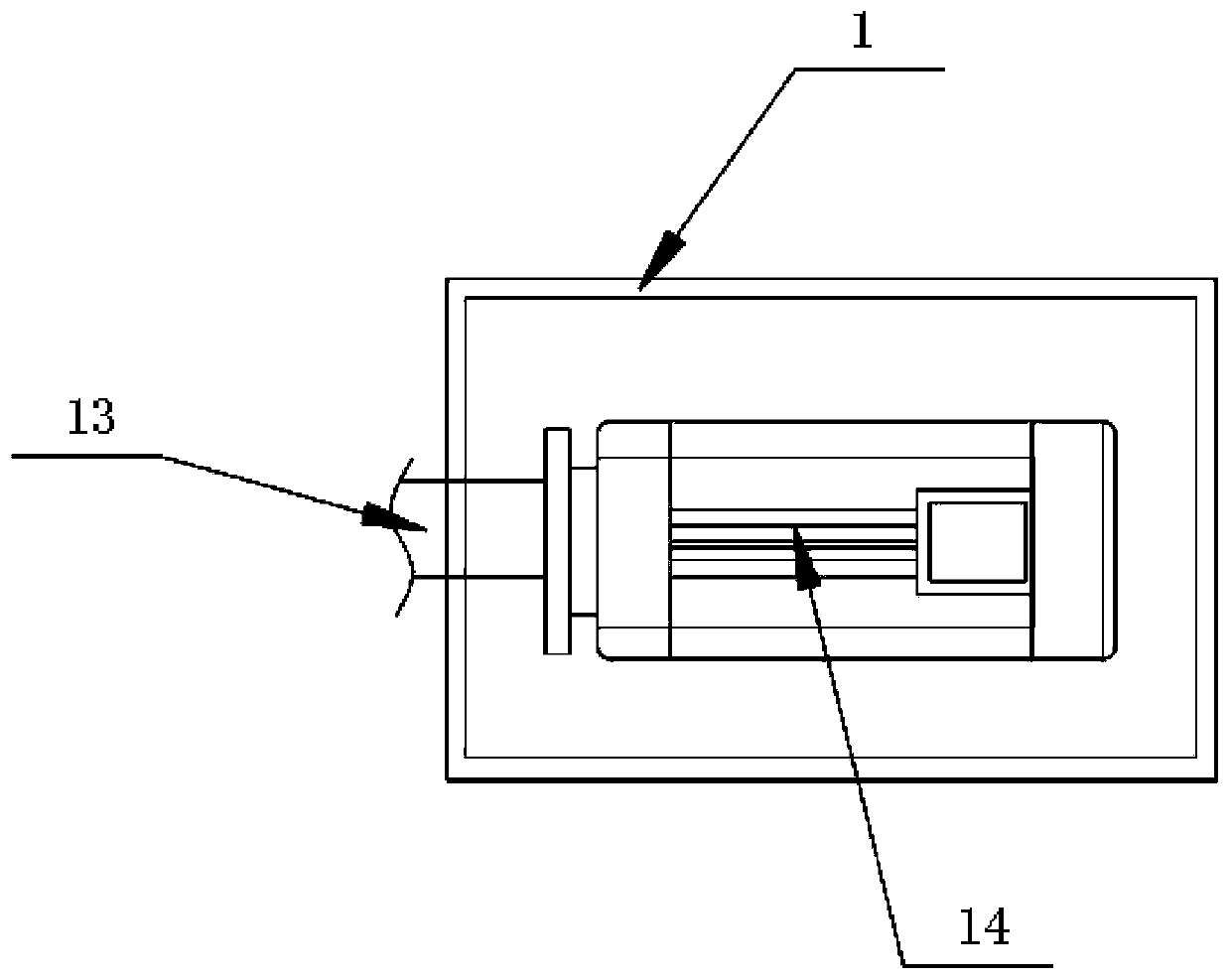

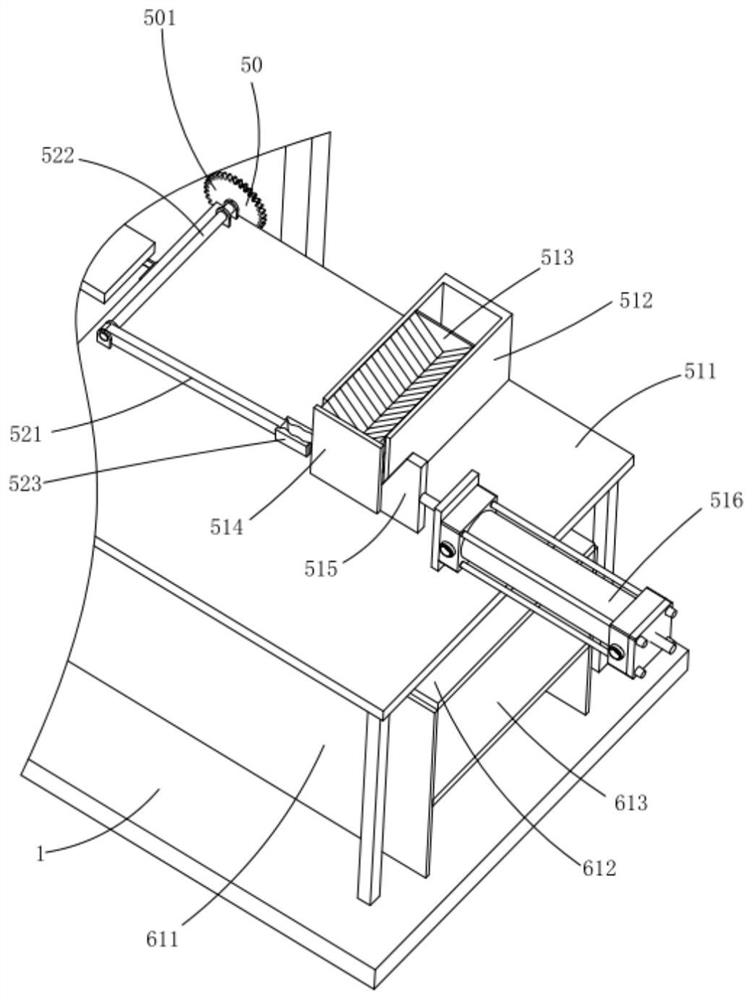

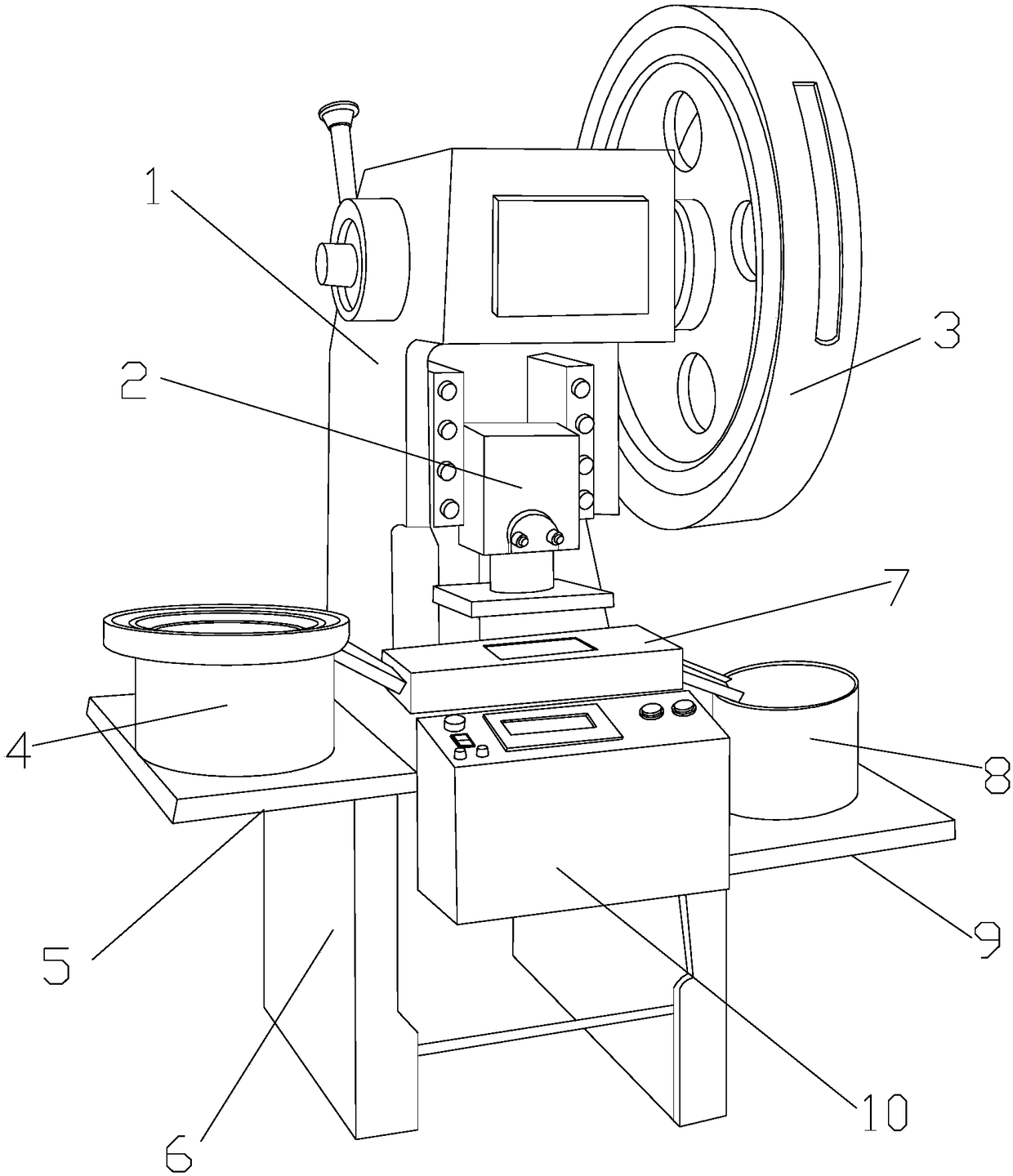

Assembly line laser marking device for bearing model

InactiveCN108944065ARealize automatic loading and unloadingRealize automatic unloadingTypewritersTransmission beltElectrical connection

The invention provides an assembly line laser marking device for a bearing model. The device comprises a machine body, a marking workbench and a grabbing block; a group of part installation fixing plates are fixedly connected to a left side of a top part of the machine body; top parts of the part installation fixing plates are axially connected with a group of part installation work plates, and agroup of part inlet openings are arranged behind top parts of the part installation work plates; the part inlet openings are fixedly connected with an incoming part assembly line; a group of unloadingtransmission belts are wound around outer sides of unloading driven pulley wheels and unloading driving pulley wheels; a group of driven pulley wheels are fixedly and coaxially connected to a top part of a driving toothed wheel, a group of transmission belts are wound around outer sides of the driven pulley wheels and driving pulley wheels, a motor is in common electrical connection with an external control device and an external power source. The device is accurate in positioning and is capable of automatic clamping, movement or rotation can be prevented during marking processes, marking position changes can be prevented, automatic loading and unloading can be realized, labor costs can be lowered and work efficiency can be improved.

Owner:新昌县奔力机械有限公司

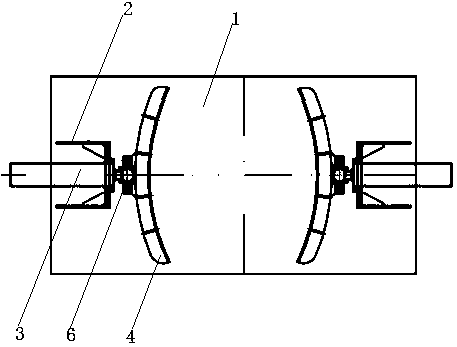

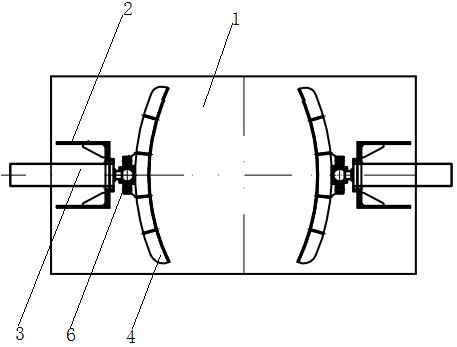

Ton bag extruding machine

The invention discloses a ton bag extruding machine which comprises a base, wherein supporting plate assemblies are fixed on two sides of the top face of the base; hydraulic cylinders are fixed on thetwo supporting plate assemblies; extrusion plates are disposed between the two supporting plate assemblies; pulleys are disposed on bottoms of two sides of the extrusion plates; telescopic ends of the hydraulic cylinders extend to inner sides of the supporting plate assemblies and are fixed to outer sides of the extrusion plates by bulb flanges; the hydraulic cylinders are connected to a hydraulic station by a push oil pipe and a return oil pipe respectively; pressure adjustment valves are disposed on the push oil pipe and the return oil pipe; an oil pump motor and a pressure display meter are disposed on the hydraulic station; a horizontal sway range of the two extrusion plates is 2-3 DEG; axes of the two hydraulic cylinders are located at the same center line; and the two extrusion plates have a horn mouth structure which decreases in size from top to bottom.

Owner:GARSONI FERTILIZER PINGYUAN

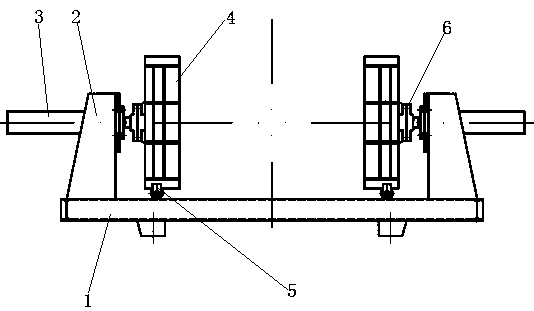

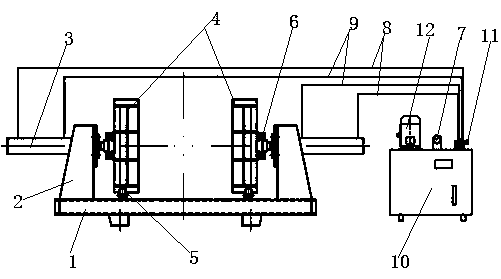

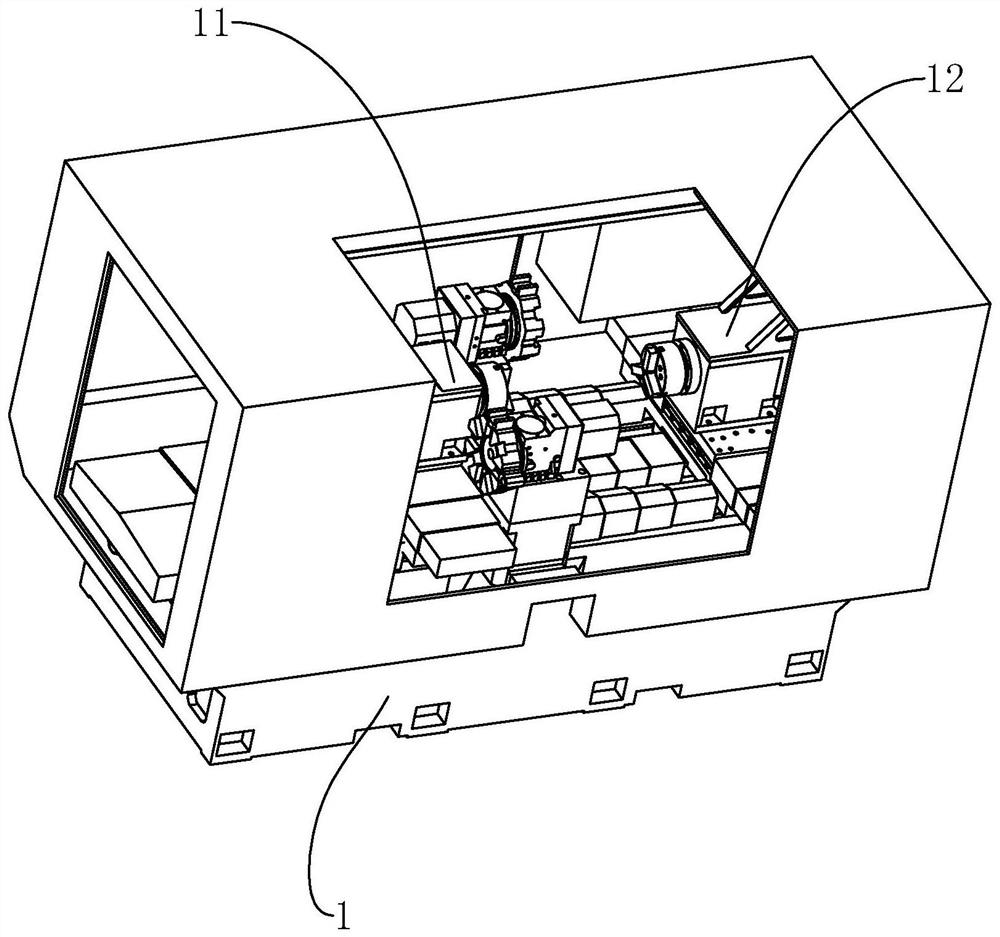

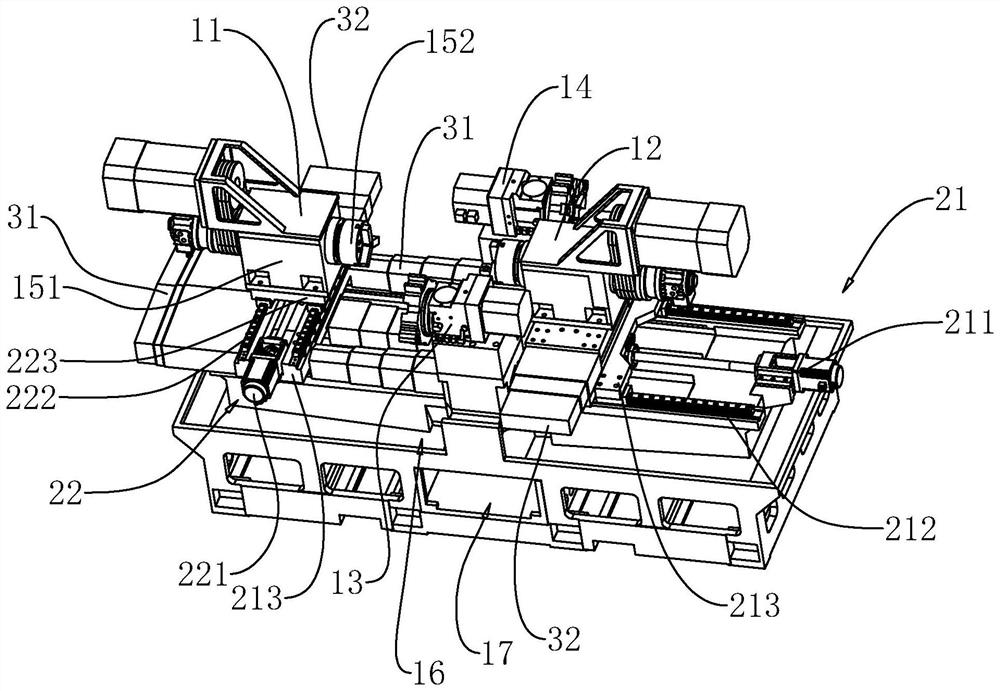

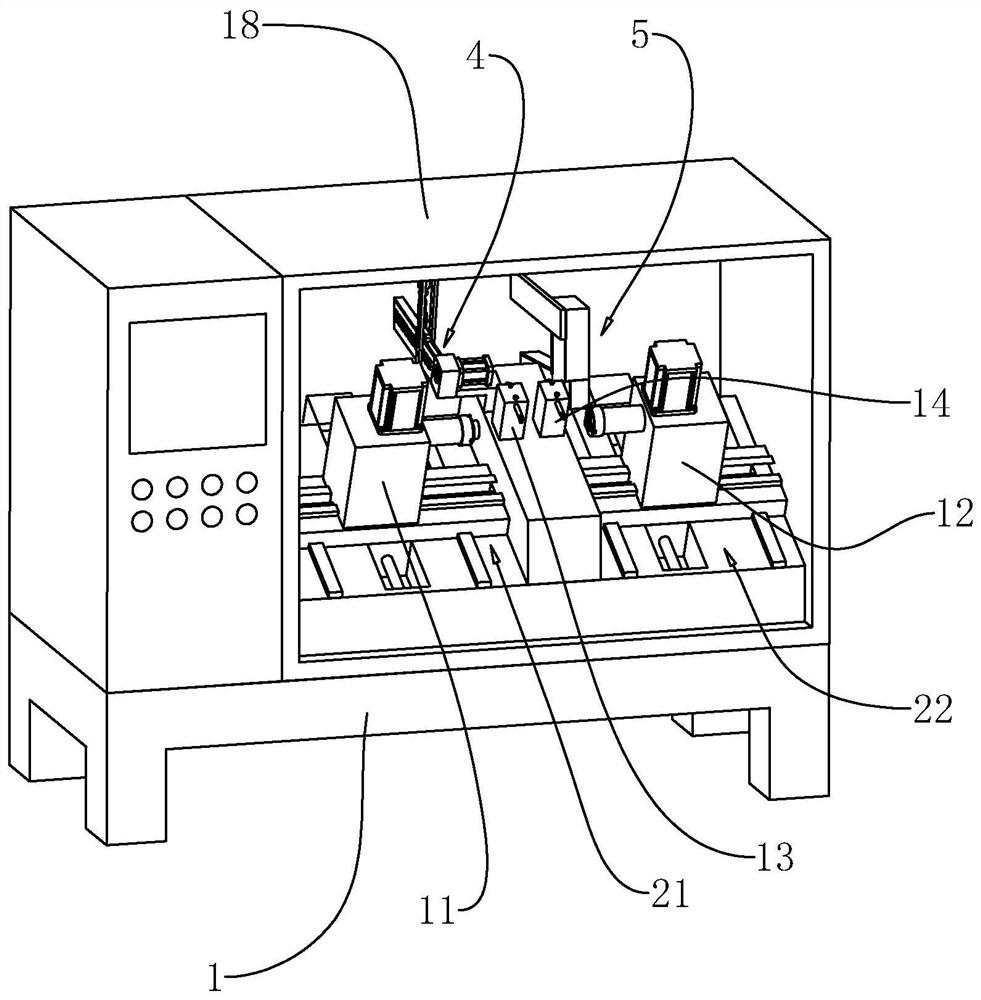

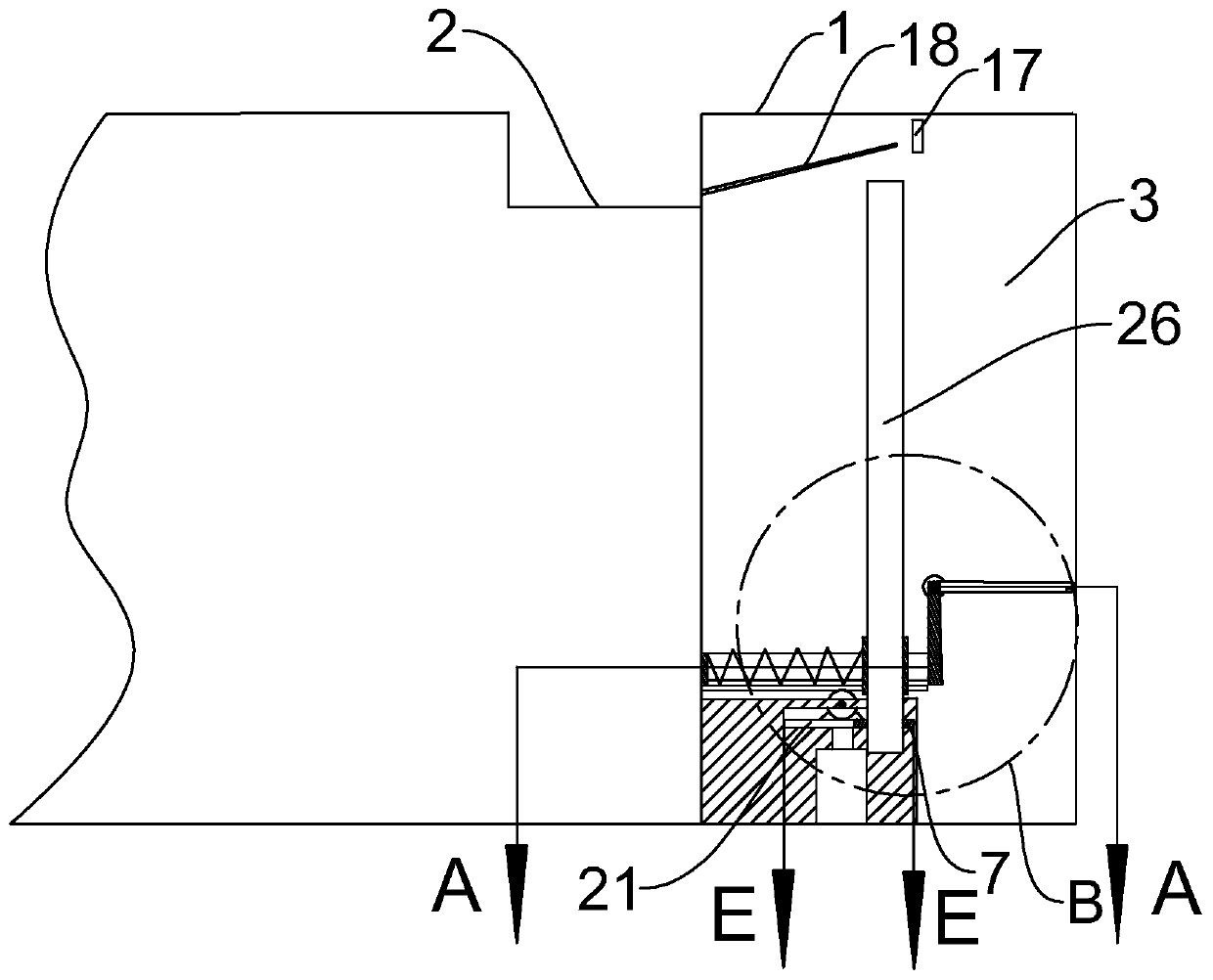

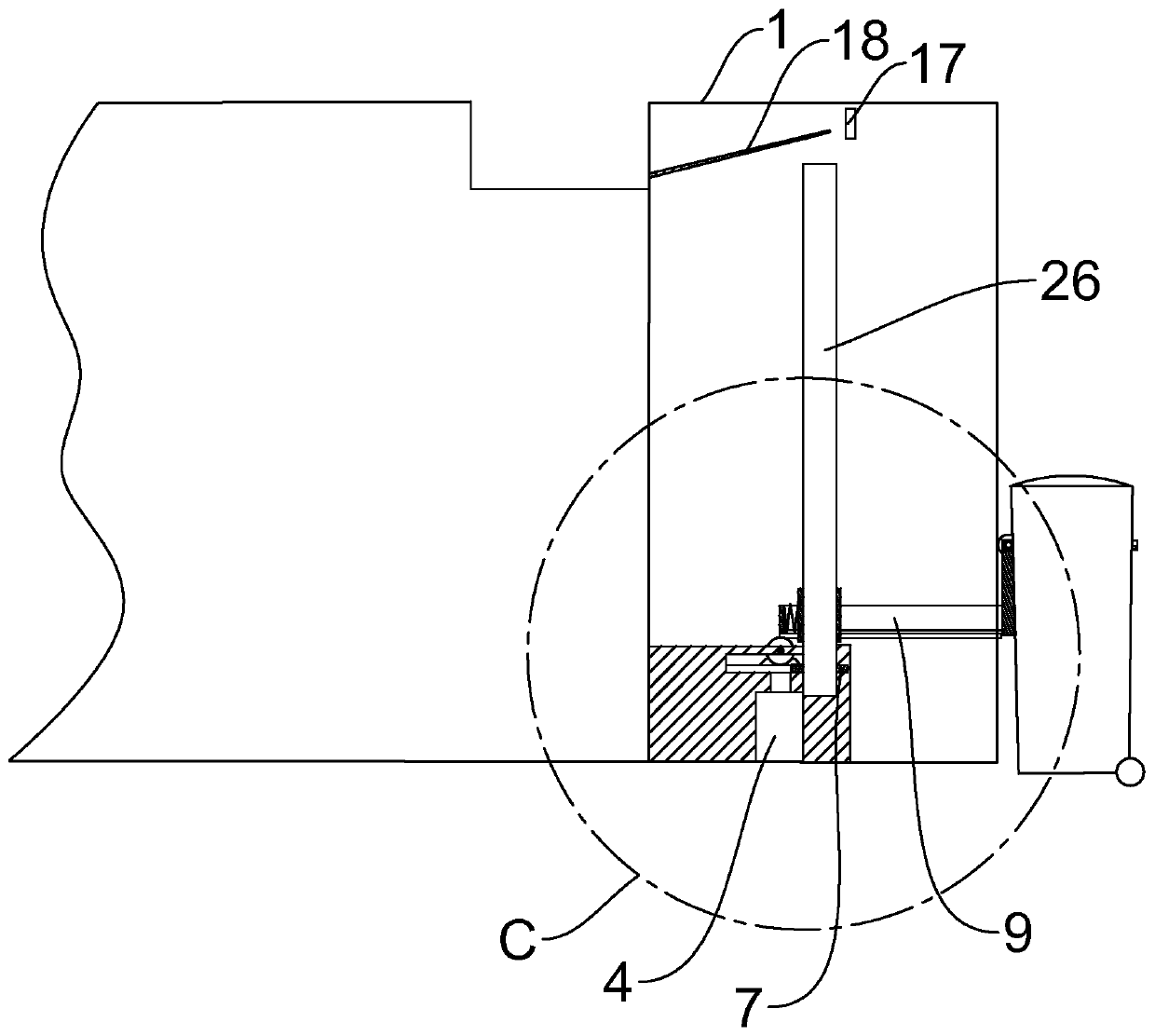

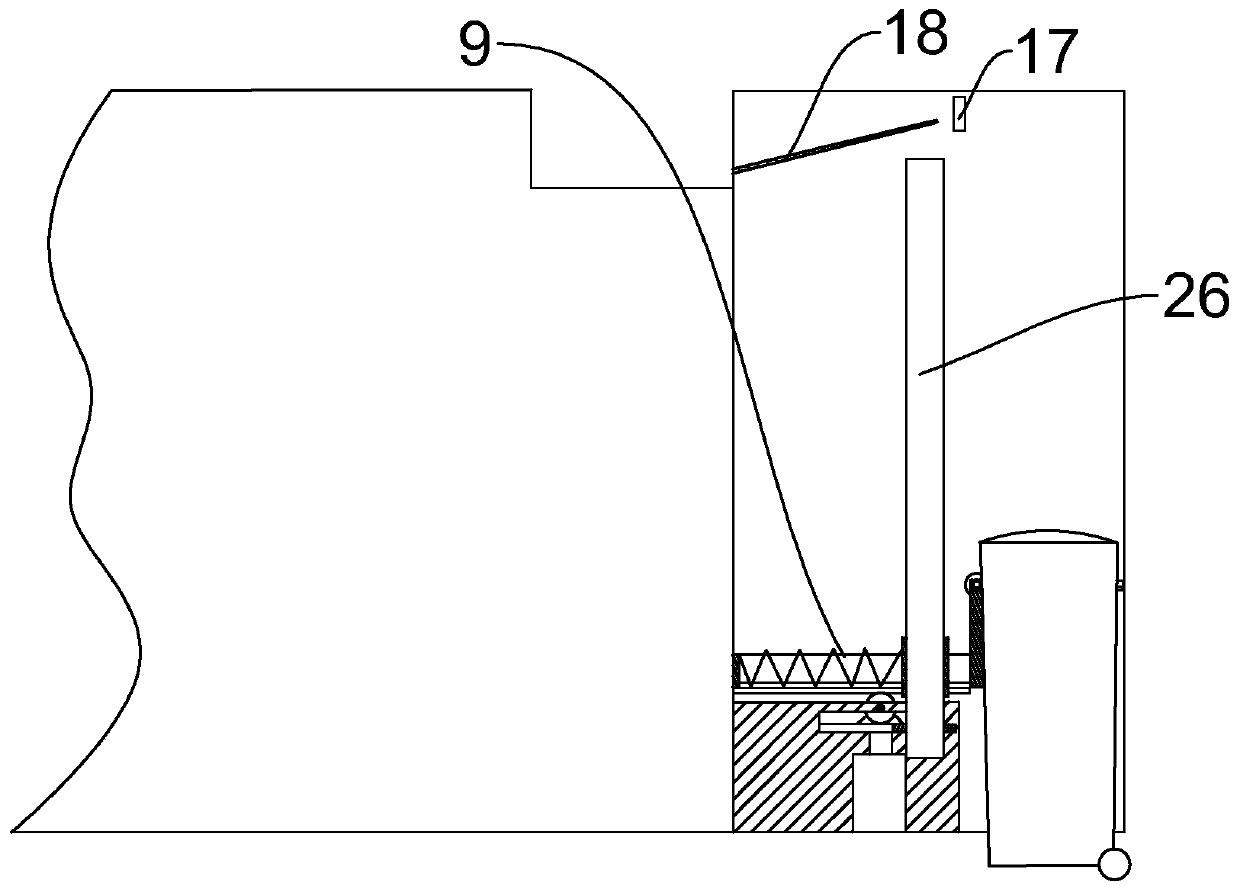

Double-position machining numerical control machine tool

ActiveCN111957987AEasy to operateAutomatic loading and unloadingAutomatic conveying/guiding stockAuxillary equipmentNumerical controlEngineering

The invention relates to a double-position machining numerical control machine tool and relates to the field of numerical control machine tools. The double-position machining numerical control machinetool comprises a machine base. A first clamping device and a second clamping device are symmetrically arranged on the machine base. The first clamping device and the second clamping device each comprise a three-jaw chuck and a fixed base, and the three-jaw chuck is mounted on the fixed base. A first tool turret and a second tool turret are arranged on the machine base. The first tool turret is paired with the first clamping device for use. The second tool turret is paired with the second clamping device for use. The machine base is further provided with a first moving device and a second moving device. The first moving device is used for driving the first clamping device to move. The second moving device is used for driving the second clamping device to move. The double-position machiningnumerical control machine tool has the effect of being easy to operate.

Owner:浙江震环数控机床股份有限公司

Side-mounted garbage truck

The invention discloses a side-mounted garbage truck. The side-mounted garbage truck comprises a vehicle body, a working tank is arranged at the right end of the vehicle body, an inclined plate fixedat the front end and the rear end of the working tank is arranged at the upper end of the working tank, a garbage inlet located at the left upper part of the working tank is formed in the upper end ofthe vehicle body, and a stepping motor is arranged inside the lower end of the vehicle body; and the output shaft of the stepping motor is connected with a first disc in a keyed mode and a first conical gear positioned above the first disc, a half ring gear is arranged at the left front end of the first disc, a lifting mechanism matched with the half ring gear is arranged at the right front end of the first disc, and a second conical gear is meshed with the front end of the first bevel gear. The side-mounted garbage truck has the advantages that an environmental sanitation garbage can is fixed or loosened through stretchable racks, can be automatically turned over through the stretchable racks, a driver does not get off the truck, the sanitation garbage can can be automatically loaded andunloaded, garbage can be poured into the garbage truck, and time and labor are saved.

Owner:杜行国

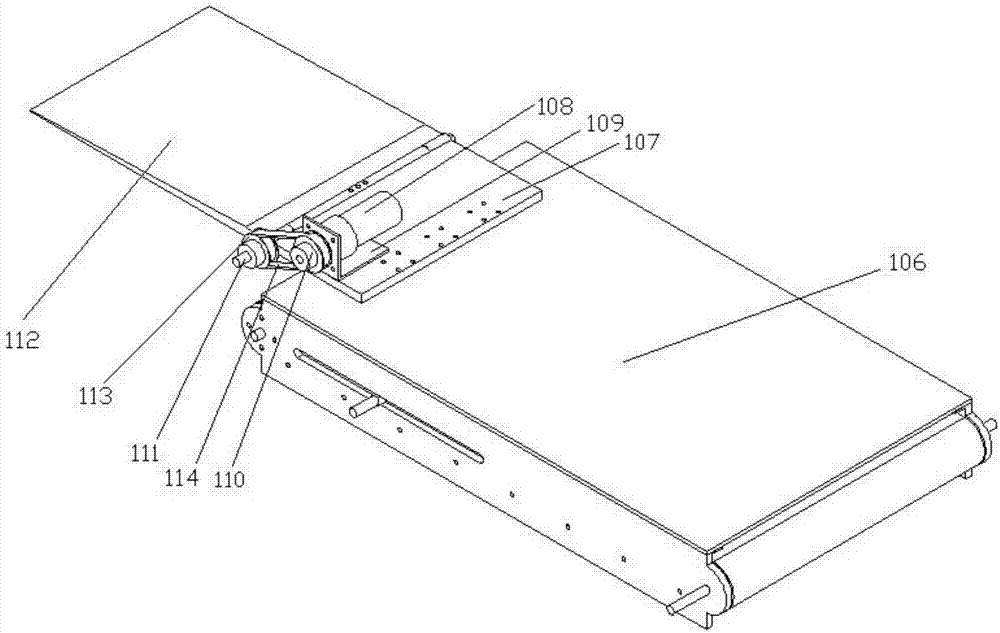

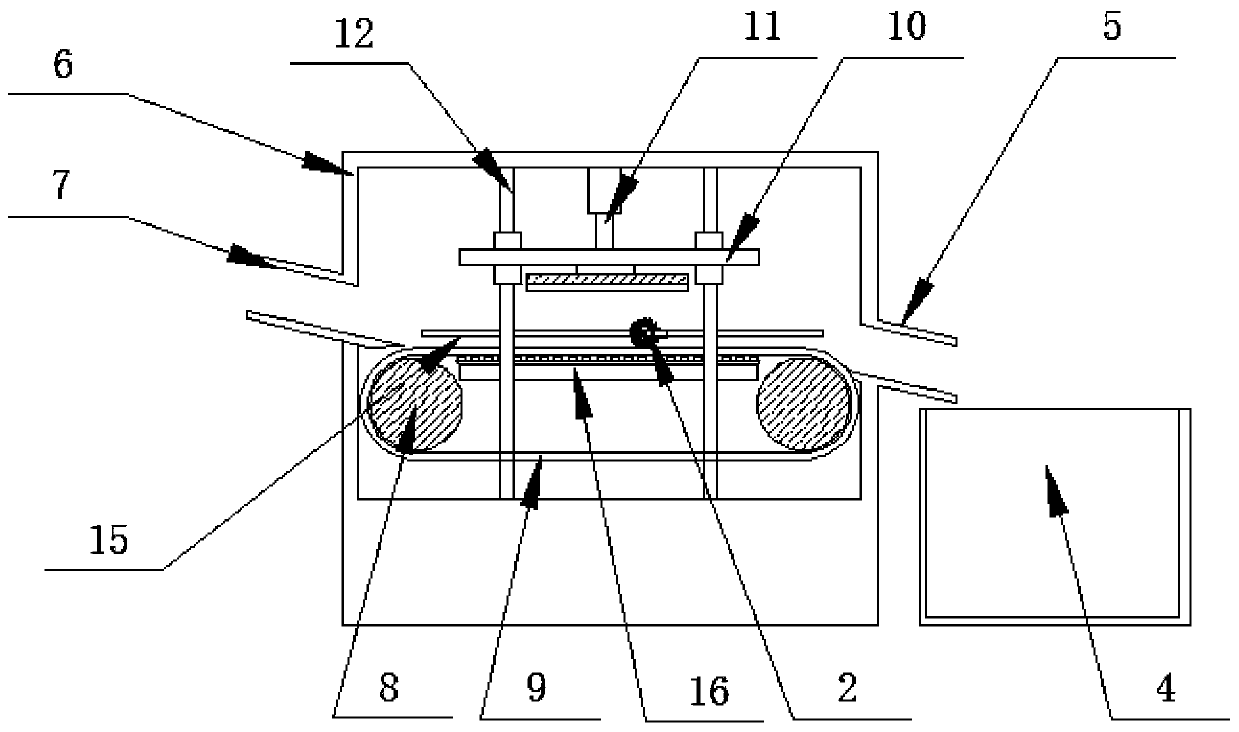

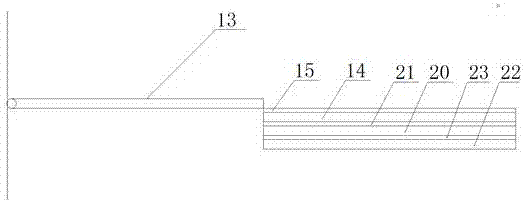

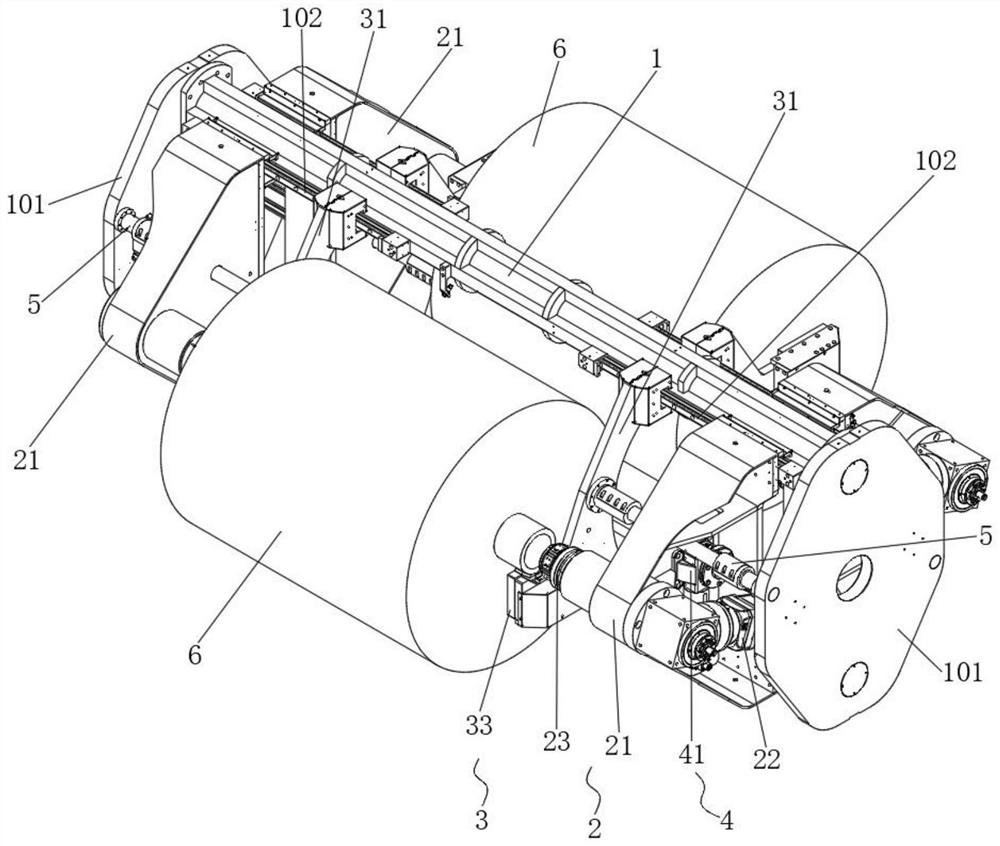

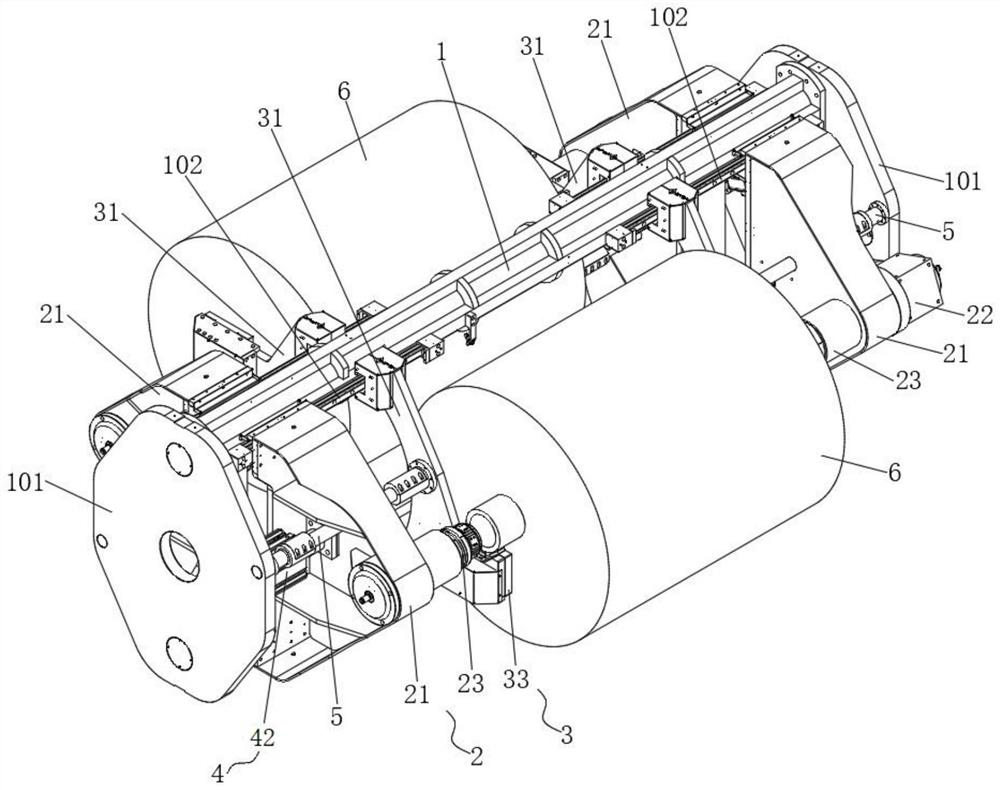

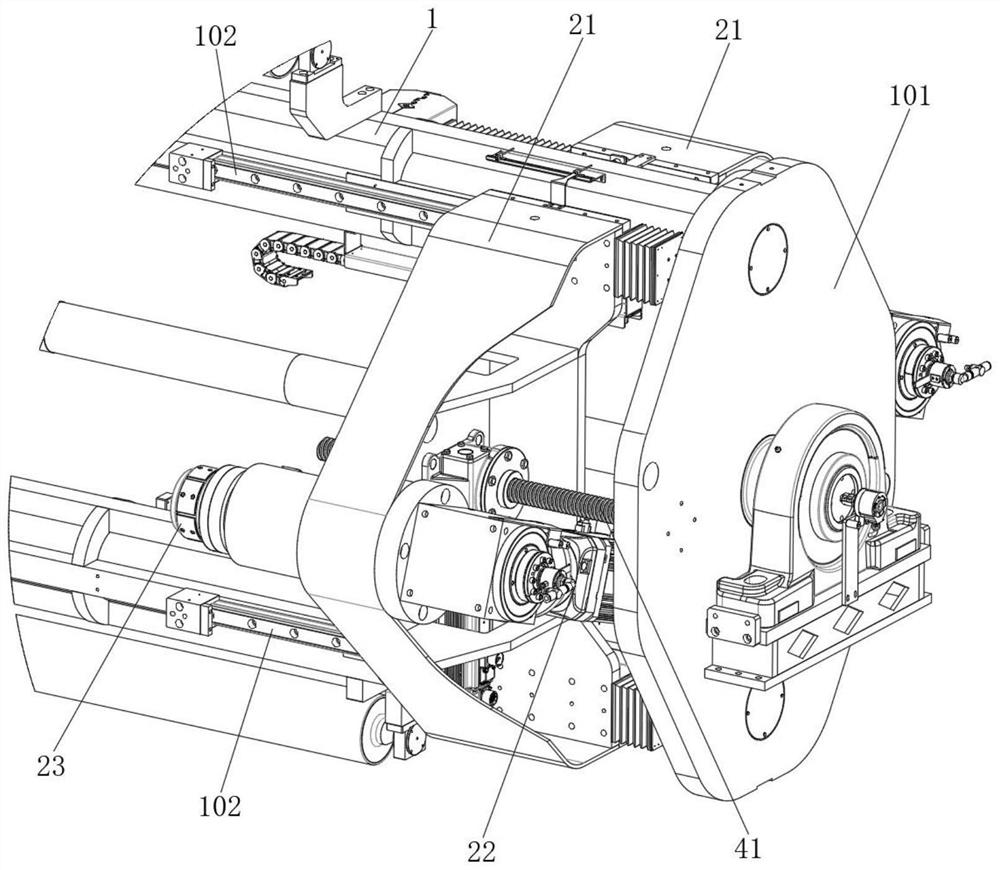

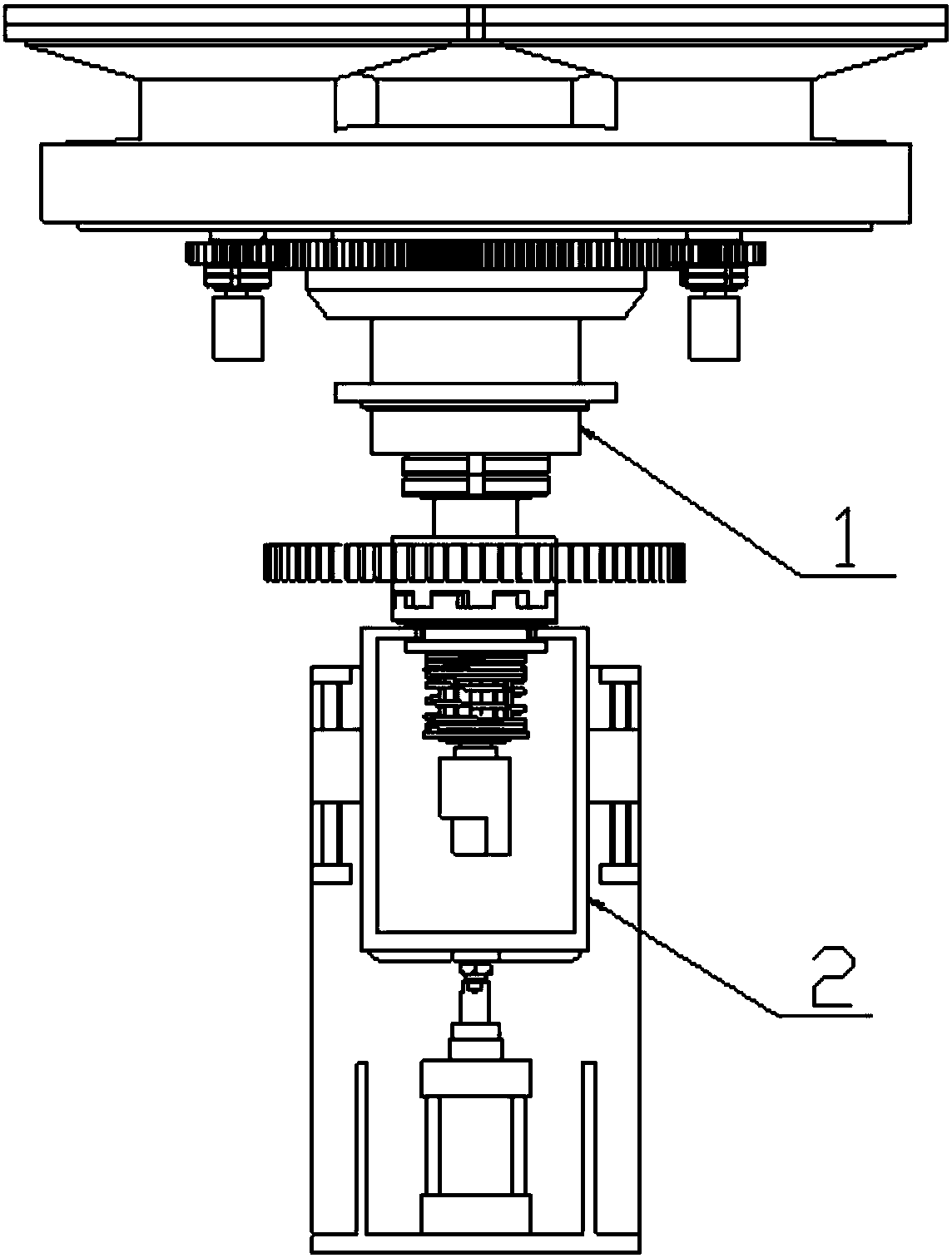

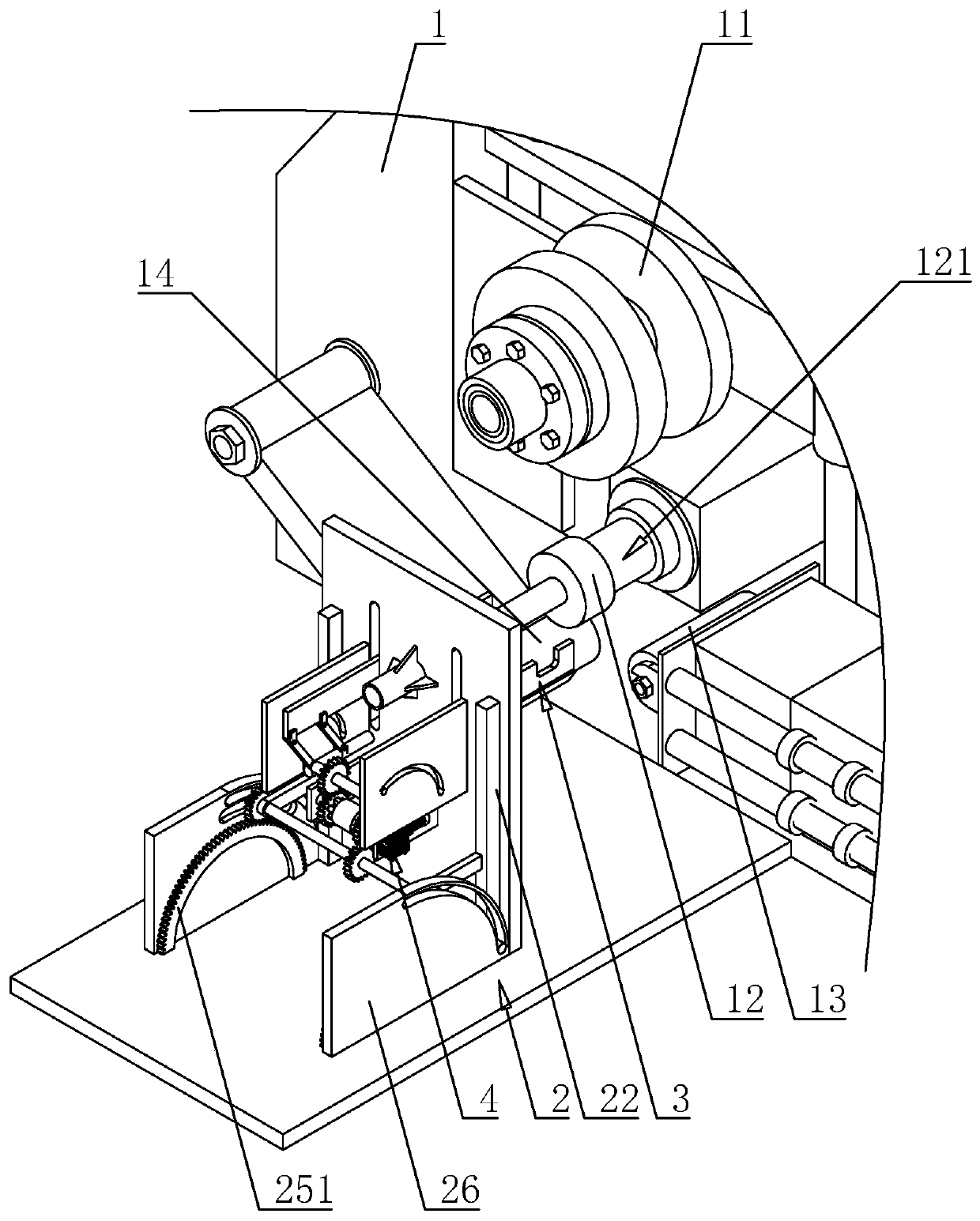

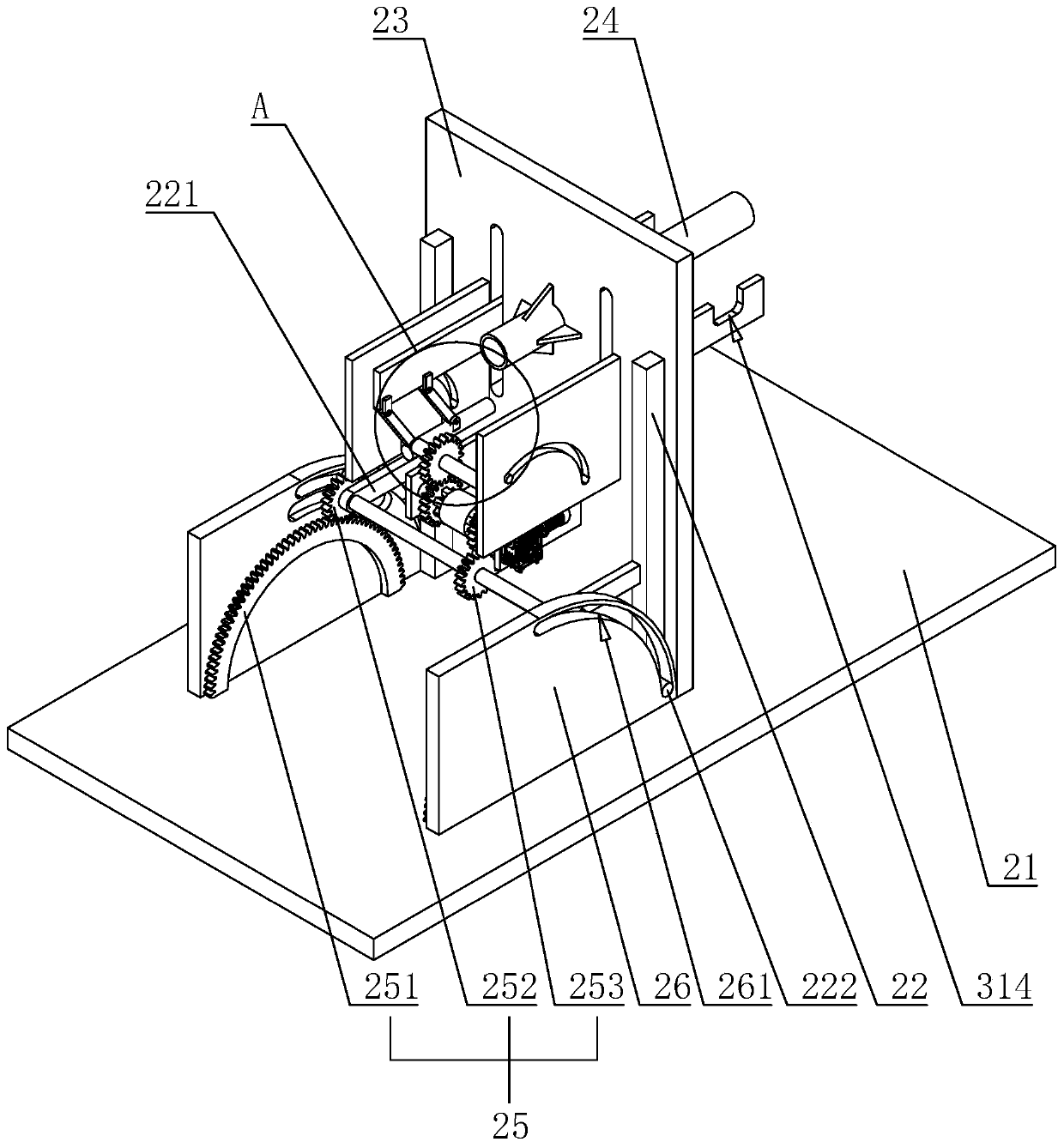

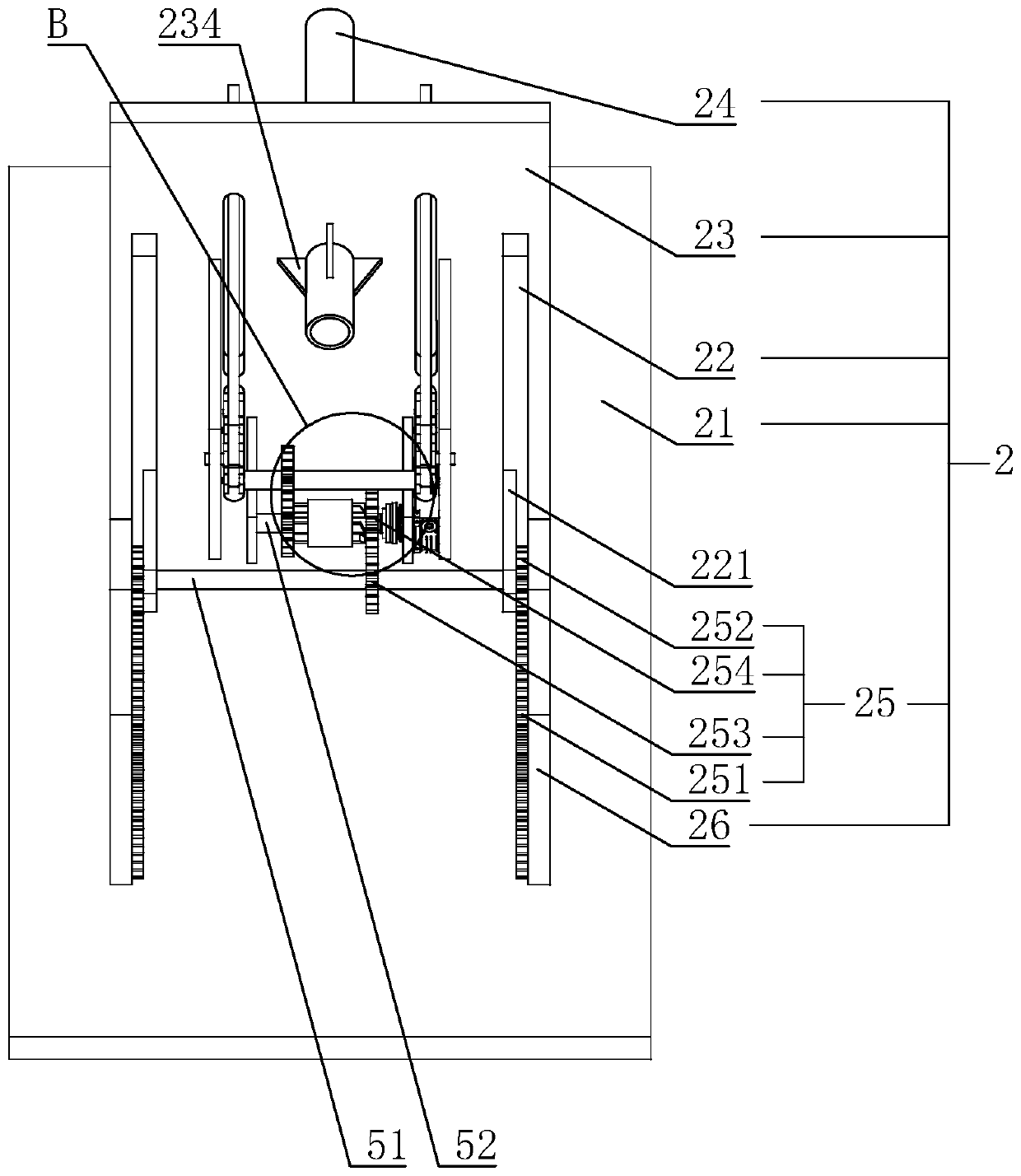

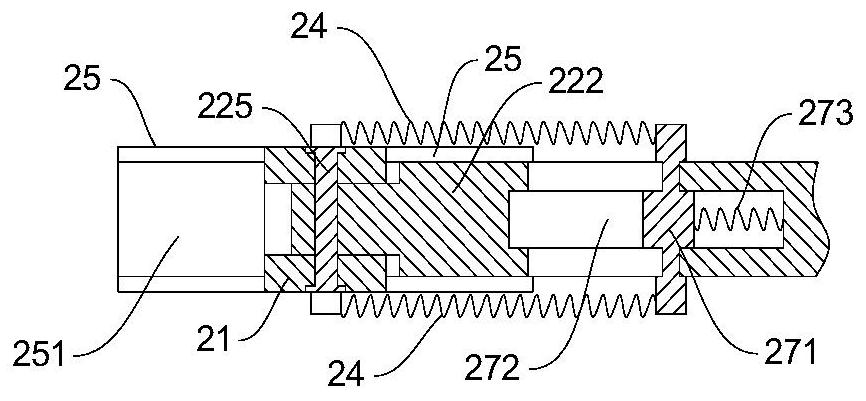

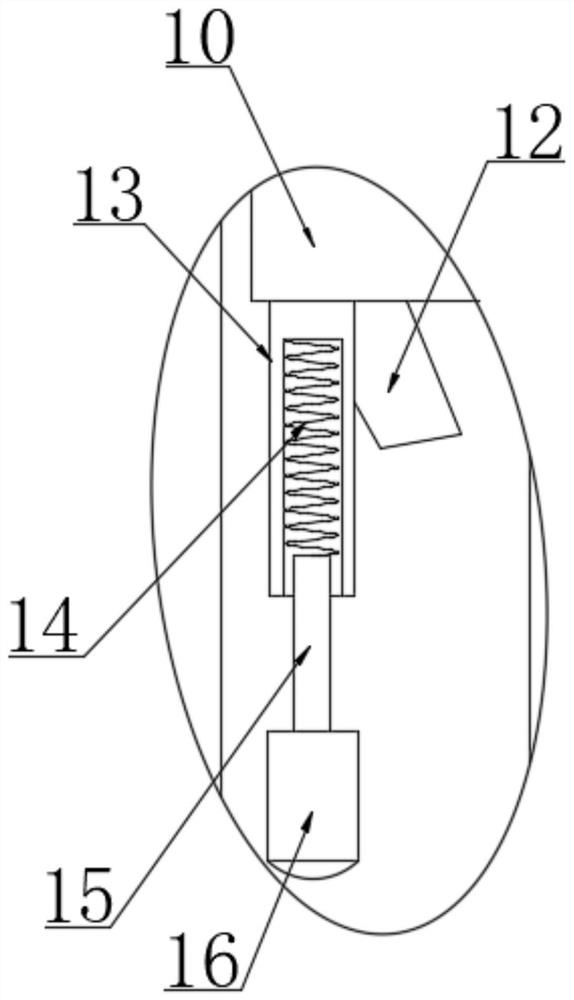

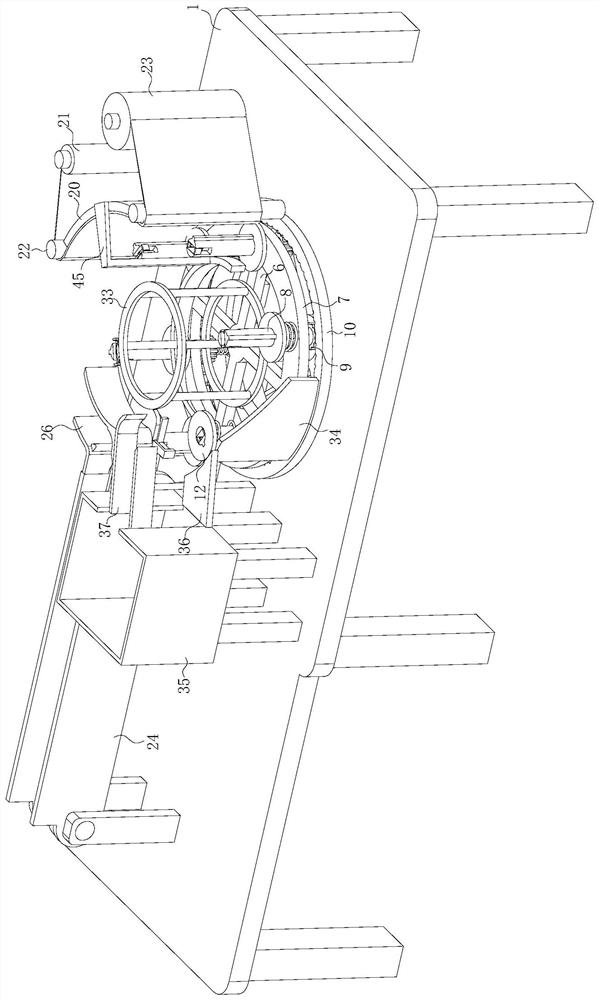

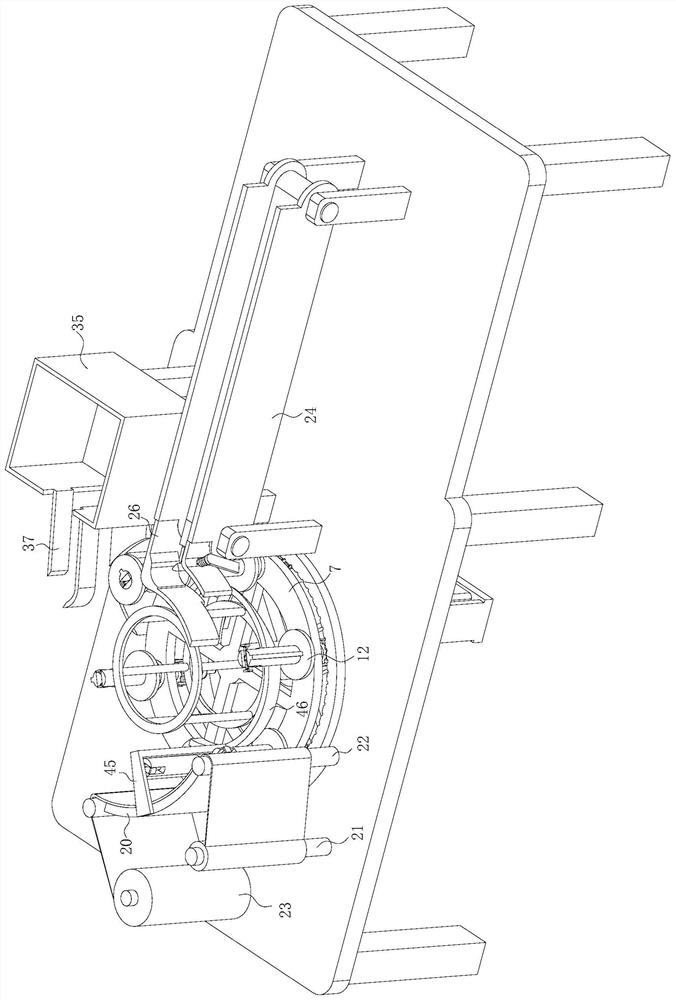

Winding and unwinding mechanism

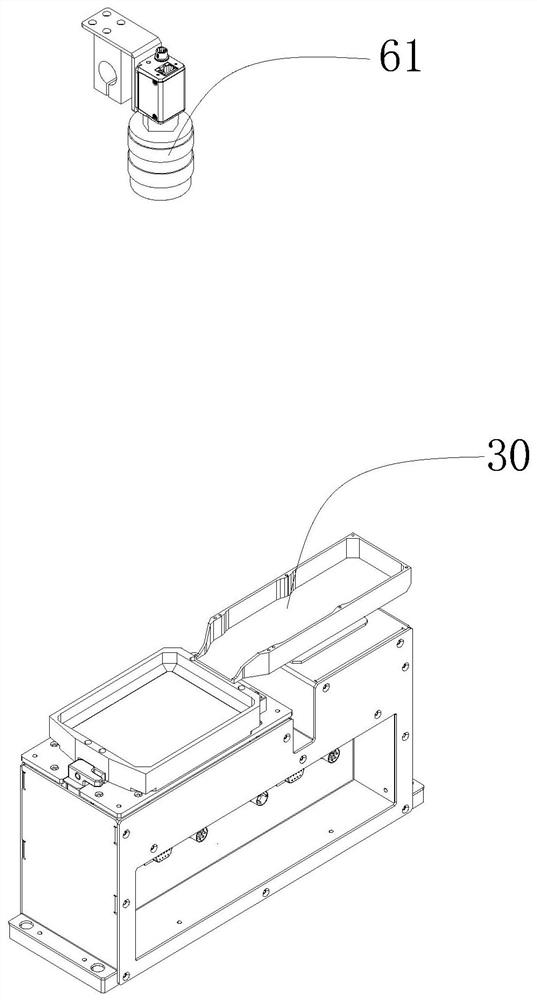

PendingCN114291663AGood detachmentGuaranteed positioning accuracyWebs handlingStructural engineeringMechanical engineering

The invention discloses a winding and unwinding mechanism. The winding and unwinding mechanism comprises a support, a winding assembly and a reel positioning and supporting assembly. The winding assembly and the reel positioning and supporting assembly are both arranged on the support, and the positions of the winding assembly and the reel positioning and supporting assembly on the support are adjustable in the axial direction of winding and unwinding of a material reel. When material rolls are fed and discharged, the reel positioning and supporting assembly serves as an auxiliary mechanism for feeding and discharging operation, manual feeding and discharging or automatic feeding and discharging can be met, the fed and discharged material rolls are accurately positioned and supported, the feeding and discharging speed of the material rolls is increased, and the production efficiency is improved. And a reel clamp in the winding assembly can conveniently and accurately clamp or loosen a reel to accurately position, so that the production efficiency is improved, the winding and unwinding stability and uniformity of the coil stock are improved, and the quality of the coil stock is ensured. In addition, the winding and unwinding mechanism is wide in winding and unwinding applicability to material rolls with different widths and sizes.

Owner:HUIZHOU YINGHE TECH

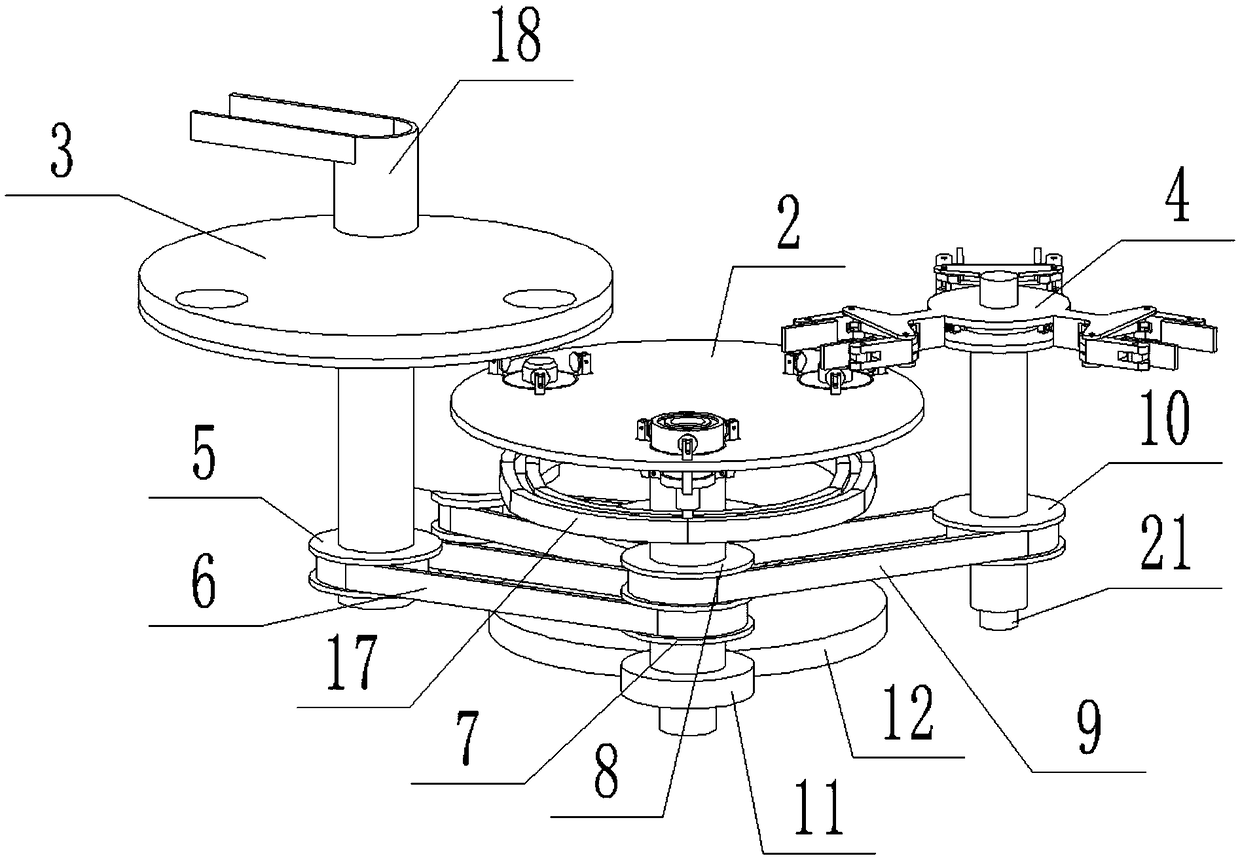

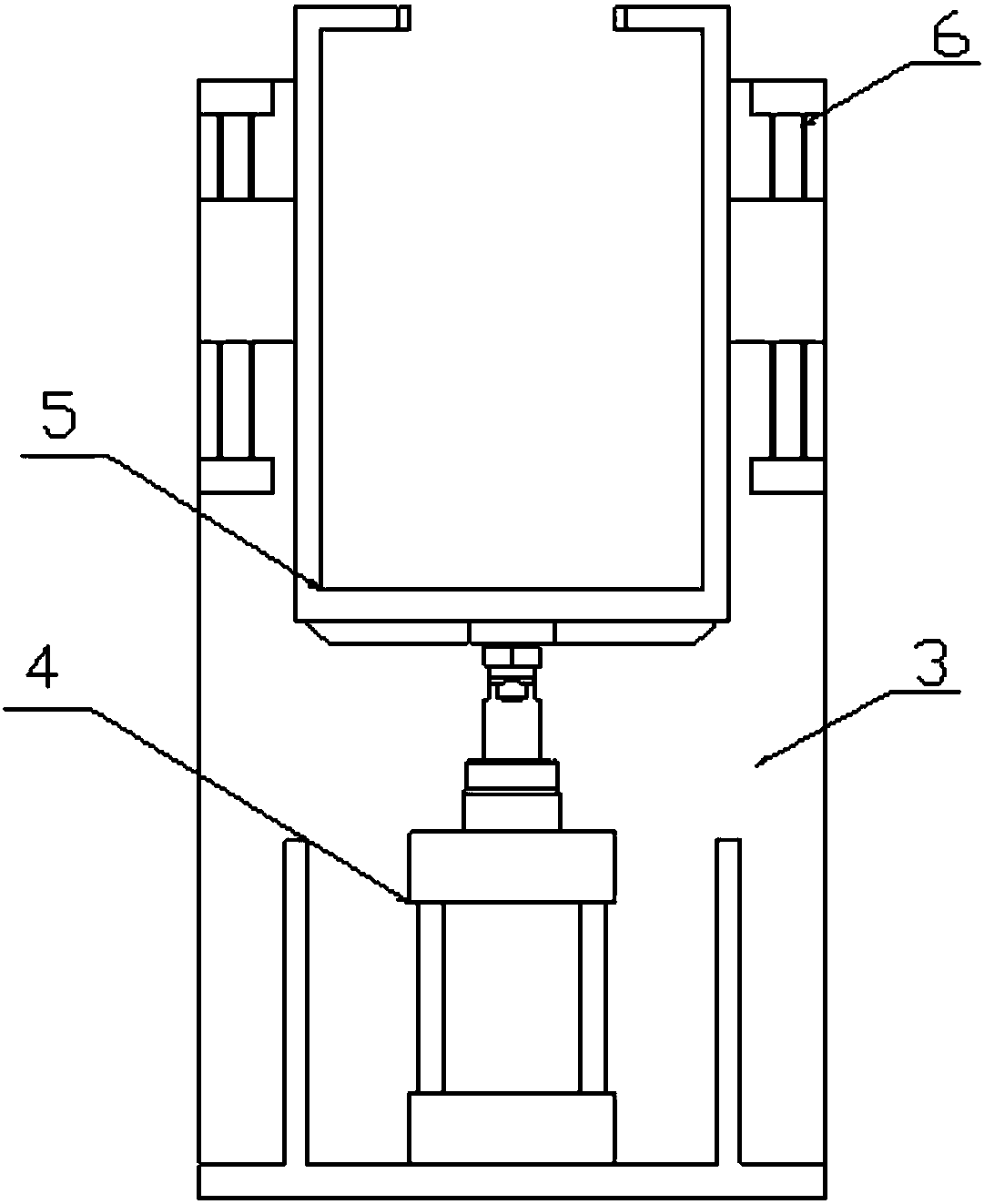

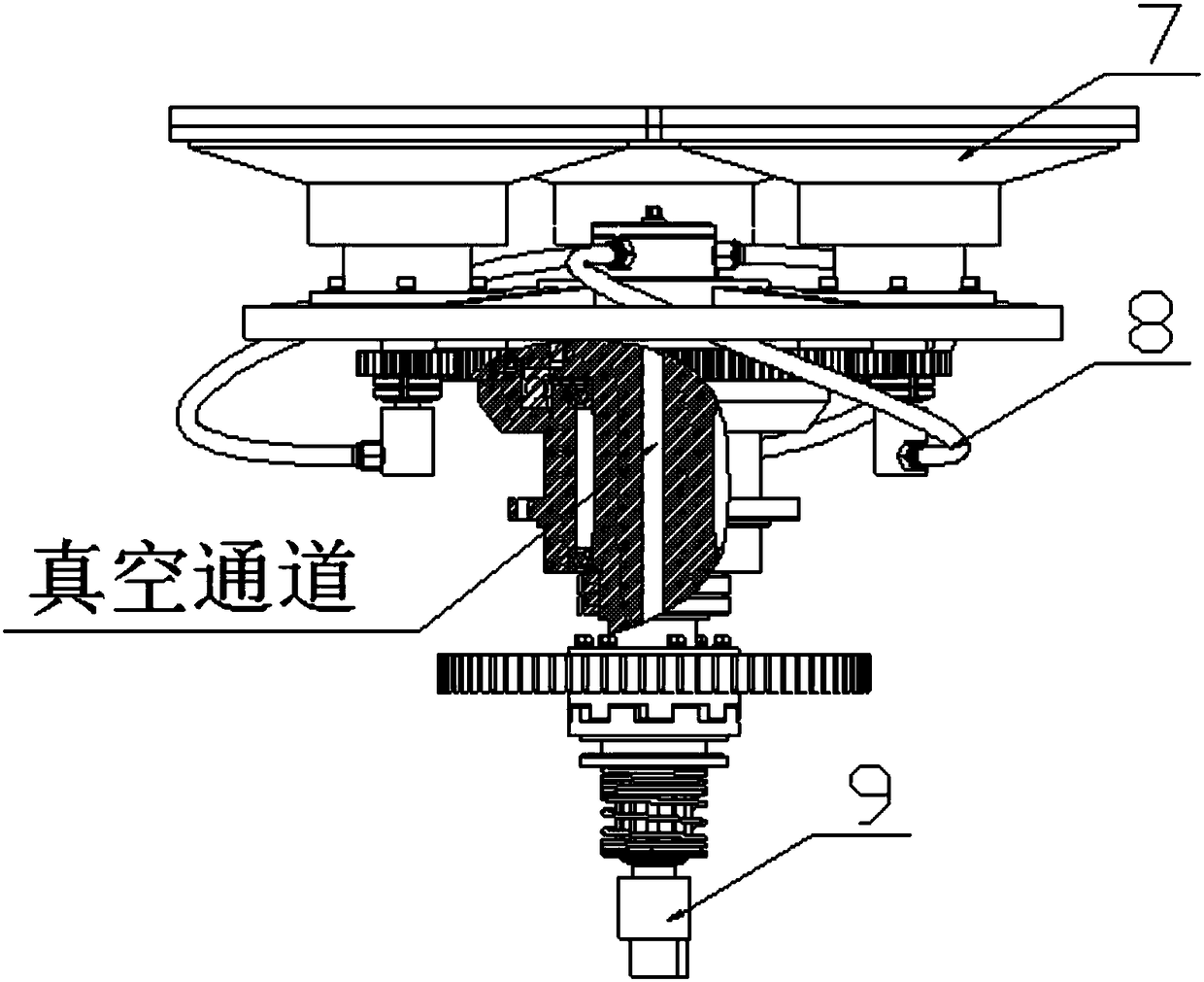

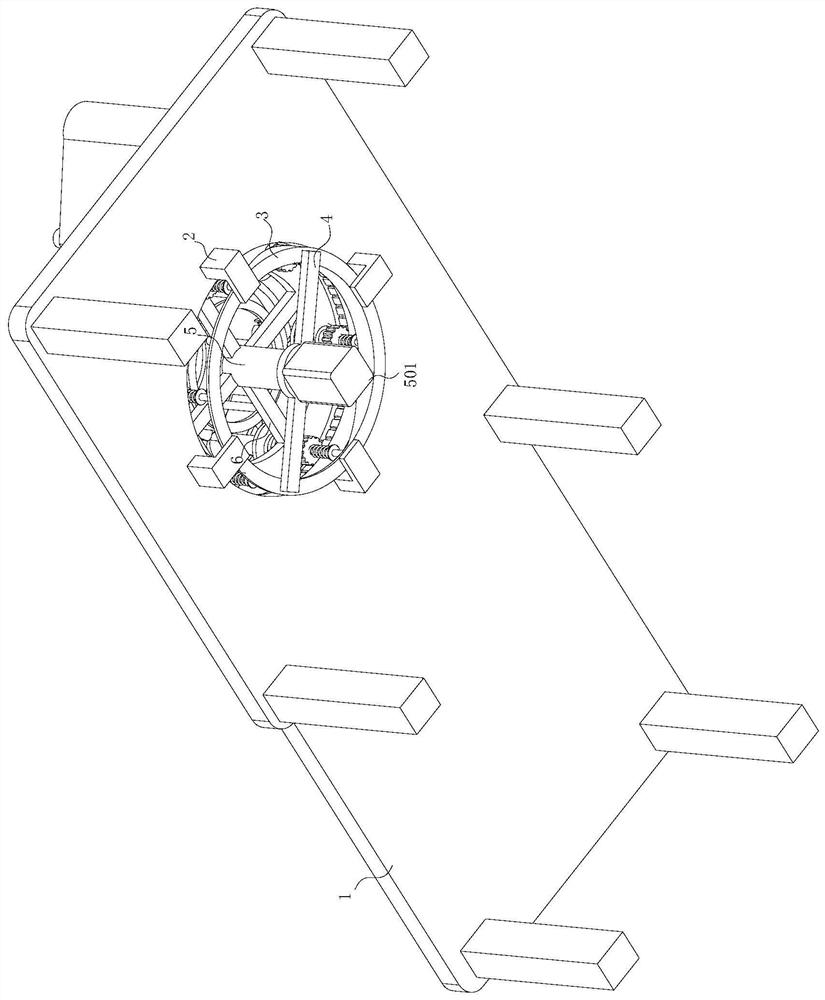

Station starting and stopping device for continuous curved surface polishing machine

PendingCN108214243ASatisfy manual loading and unloadingAutomatic loading and unloadingGrinding drivesGrinding machinesClutchRetaining ring

The invention discloses a station starting and stopping device for a continuous curved surface polishing machine. The machine comprises a station unit, a gear claw clutch device and a vacuum suction device, wherein the station unit comprises rotary assemblies, a sealing cover, mounting plates, supporting seats, a station transmission shaft, station driven gears, bearings, round nuts, bearing pressing covers, station driving gears, elastic retaining rings for a shaft, combining sleeves, compression springs and spring seats, wherein the gear claw clutch device comprises an air cylinder base, a separating air cylinder, a separating claw and linear sliding rails; and the vacuum suction device comprises a vacuum sucker, and a vacuum tube and a rotary joint. According to the invention, manual feeding and discharging can be met, and automatic feeding and discharging can also be met, so that the purpose of continuously polishing under the condition of no shutdown can be achieved, and the utilization rate and the production efficiency of equipment can be greatly improved.

Owner:HUNAN YUJING MACHINE

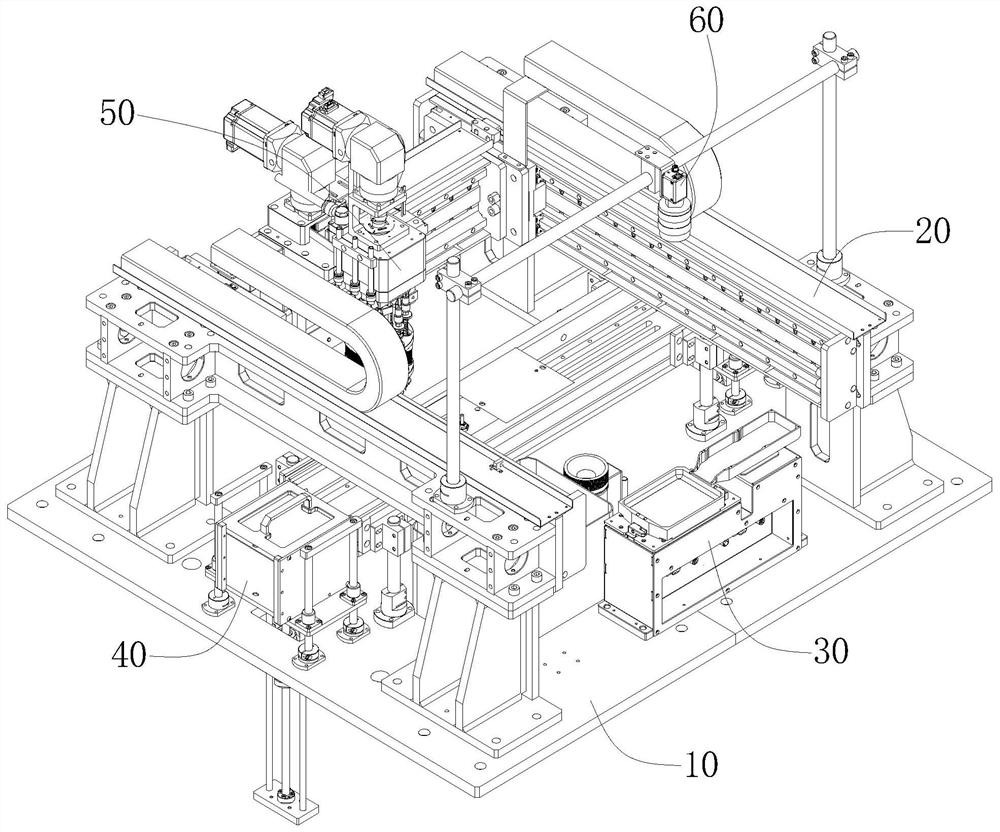

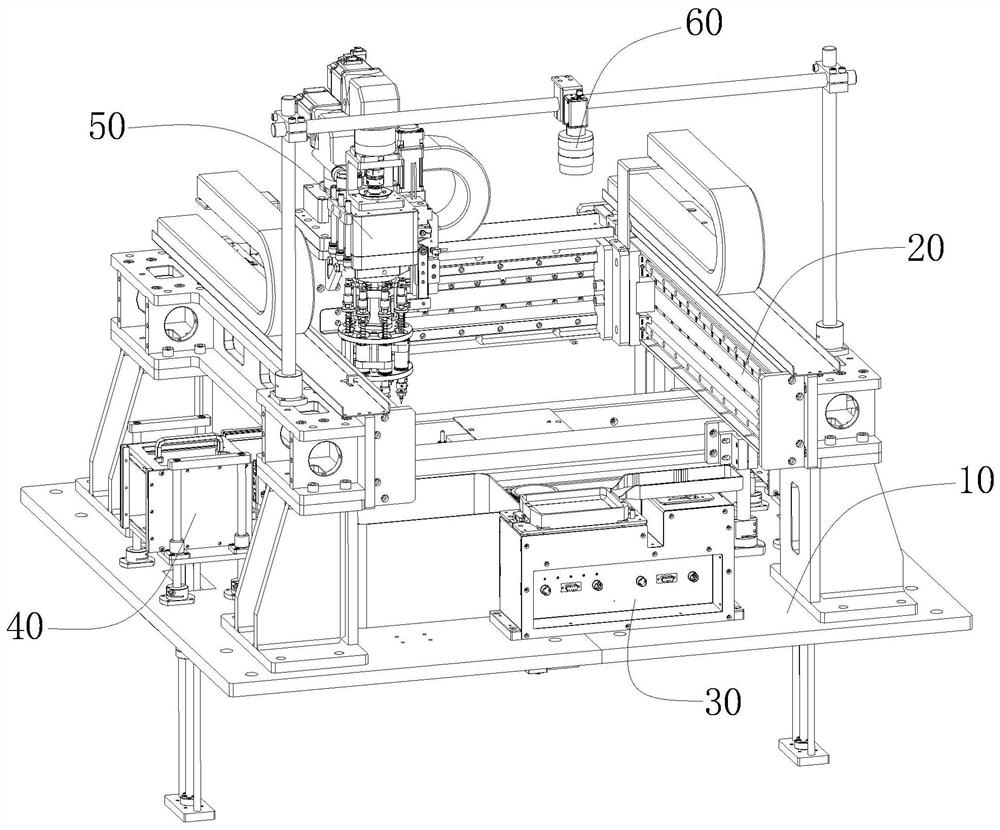

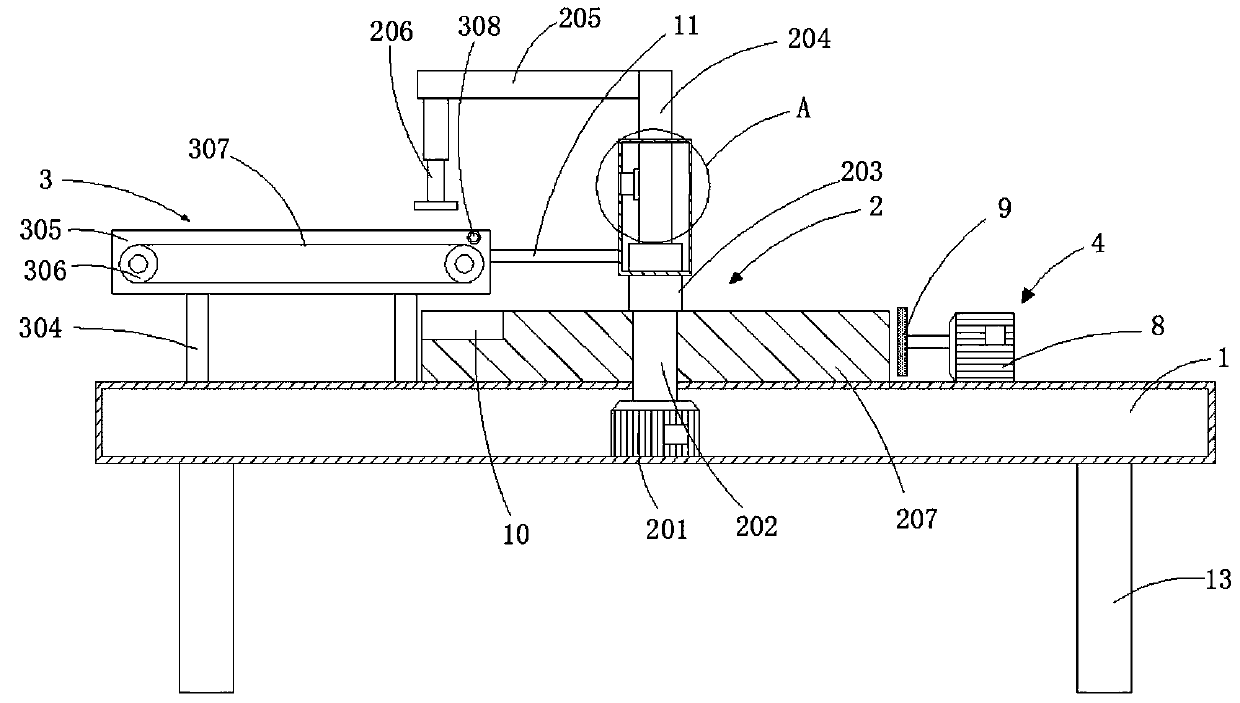

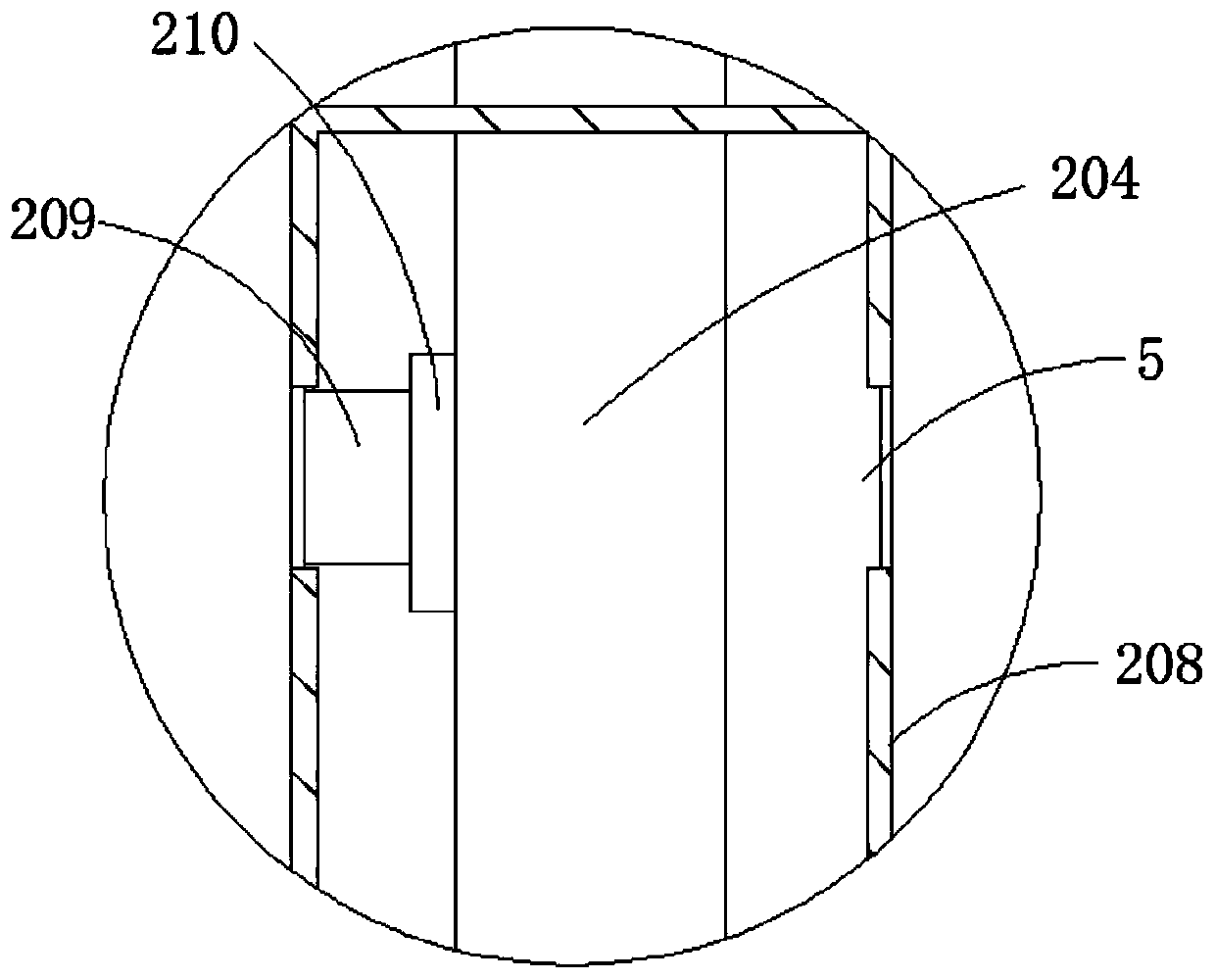

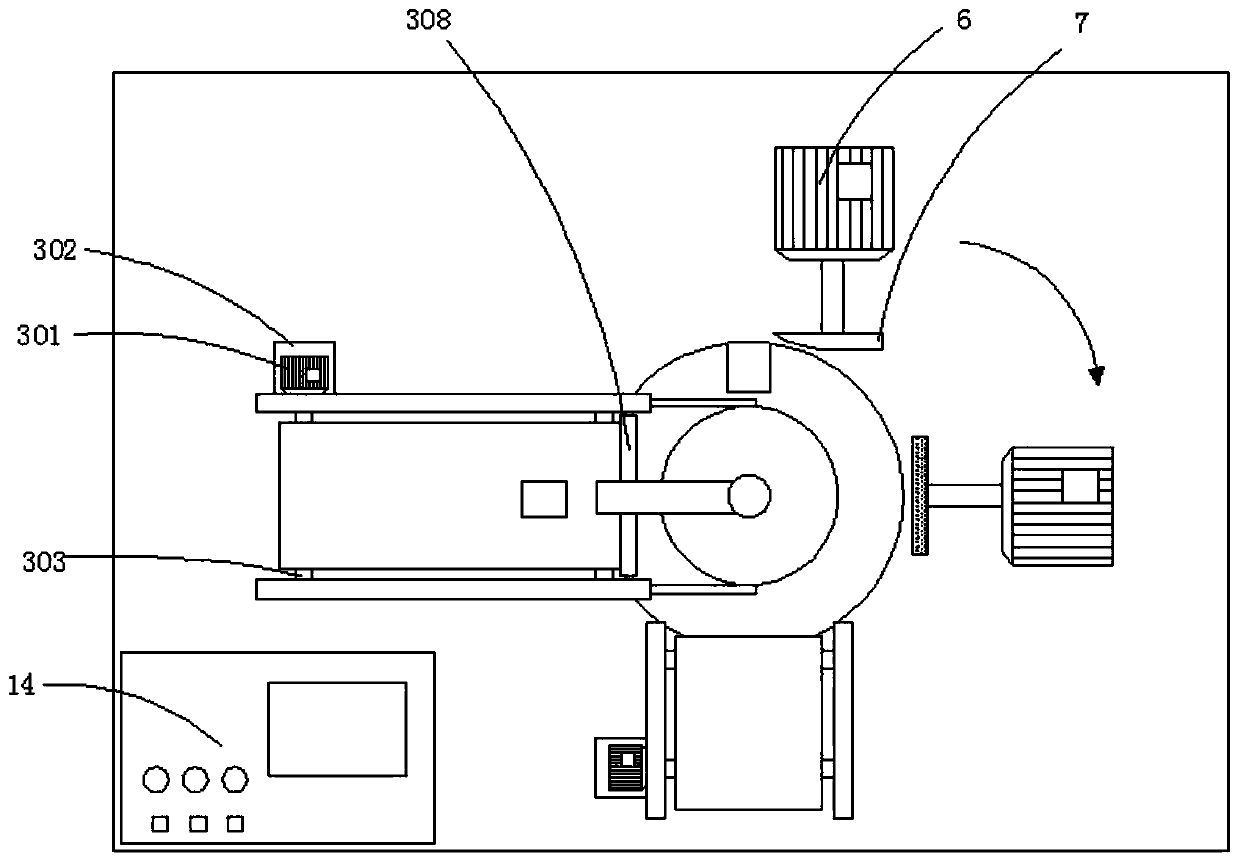

High-speed flexible sorting and arranging equipment

The invention discloses high-speed flexible sorting and arranging equipment. The high-speed flexible sorting and arranging equipment comprises a machine base, wherein a flexible feeding mechanism, a feeding and discharging bin mechanism and a high-speed linear motion module are separately arranged on the machine base; the high-speed linear motion module comprises an X-axis guide rail and Y-axis guide rails arranged at two ends of the X-axis guide rail; two ends of the X-axis guide rail are connected with the Y-axis guide rails separately; a mounting base is arranged on the X-axis guide rail; aturret-type working head is arranged on the mounting base; and the high-speed linear motion module further comprises a first motion mechanism used for driving the X-axis guide rail to move on the Y-axis guide rails and a second motion mechanism used for driving the mounting base to move on the X-axis guide rail. According to the equipment, through the arrangement of the turret-type working head,compared with an in-line working head, the turret-type working head has the advantages of being small in size and low in unit working head cost, automatic feeding and discharging are achieved throughthe feeding and discharging bin mechanism, the feeding and discharging efficiency is high, and the overall efficiency of the equipment is high.

Owner:成都云绎智创科技有限公司

Efficient plate arc edge cutting and grinding device

InactiveCN111070061AHigh degree of automationImprove processing efficiencyGrinding machinesGrinding feedersGrindingStructural engineering

The invention provides an efficient plate arc edge cutting and grinding device and relates to the field of plate processing equipment. The efficient plate arc edge cutting and grinding device comprises a workbench, a rotary loading and unloading mechanism, a transportation mechanism and a cutting and grinding mechanism. A rotating disc is rotationally connected to the top end of a rotating shaft.A sleeve is fixedly connected to the top of the rotating shaft. A lifting rod is movably connected to the top of the sleeve. A connecting rod is fixedly connected to one side of the lifting rod. A vacuum sucker is mounted at the end, away from the lifting rod, of the connecting rod. The outer sides of the sleeve and the lifting rod are sleeved with a limiting sleeve. A limiting sliding way is formed on the inner wall of the limiting sleeve. A limiting rod is fixedly connected to the outer side of the lifting rod through a rotating block. According to the efficient plate arc edge cutting and grinding device, by arranging the rotary loading and unloading mechanism, through the cooperation of the limiting rod, the limiting sleeve and the lifting rod, the connecting rod moves up and down alongwith the track of the limiting sliding way while rotating along with the rotating shaft, so that loading and unloading of plates are achieved automatically, the automation degree of the device is increased, and the machining efficiency of plate cutting and grinding is improved.

Owner:湖州飞祥智能办公设备股份有限公司

Automobile part automatic annealing device

ActiveCN108285956ASave electricitySimple automatic loading and unloadingFurnace typesHeat treatment furnacesDrive wheelEngineering

Owner:宁波鑫神泽汽车零部件有限公司

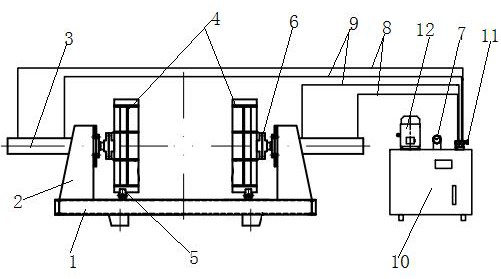

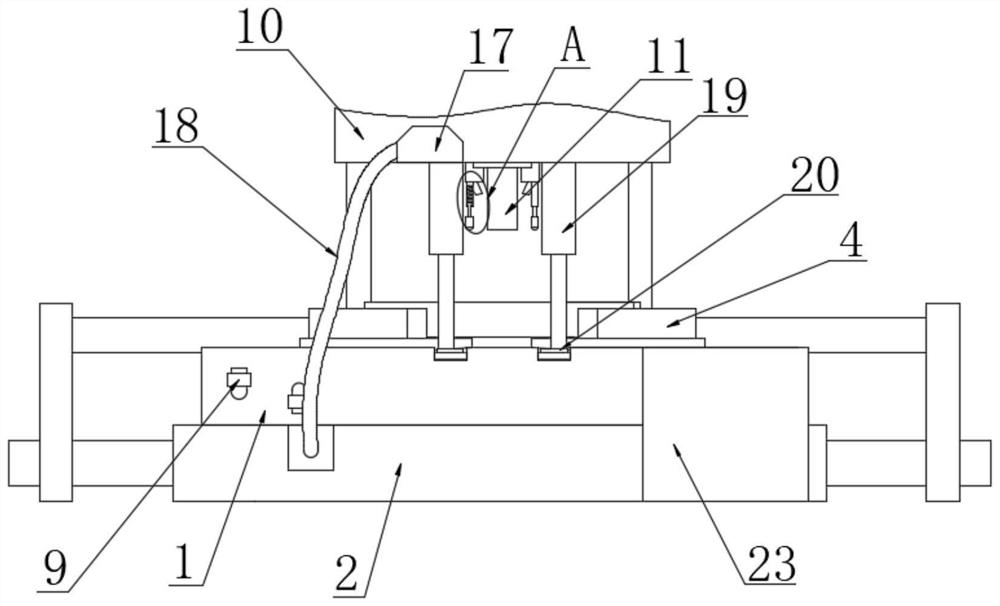

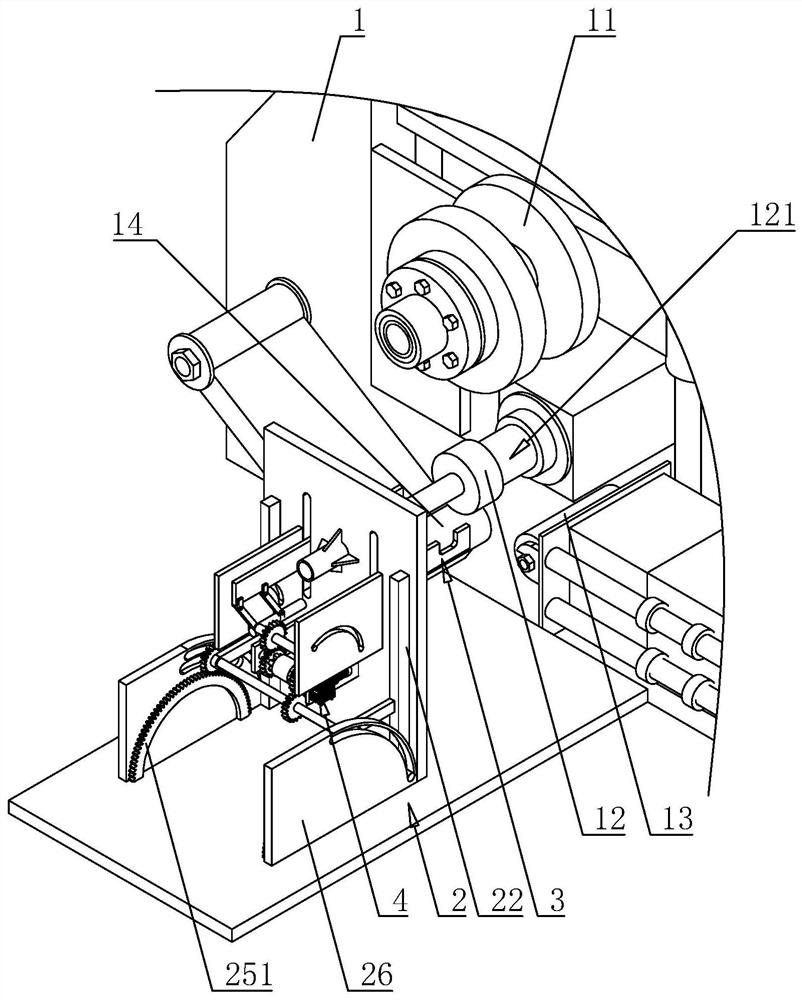

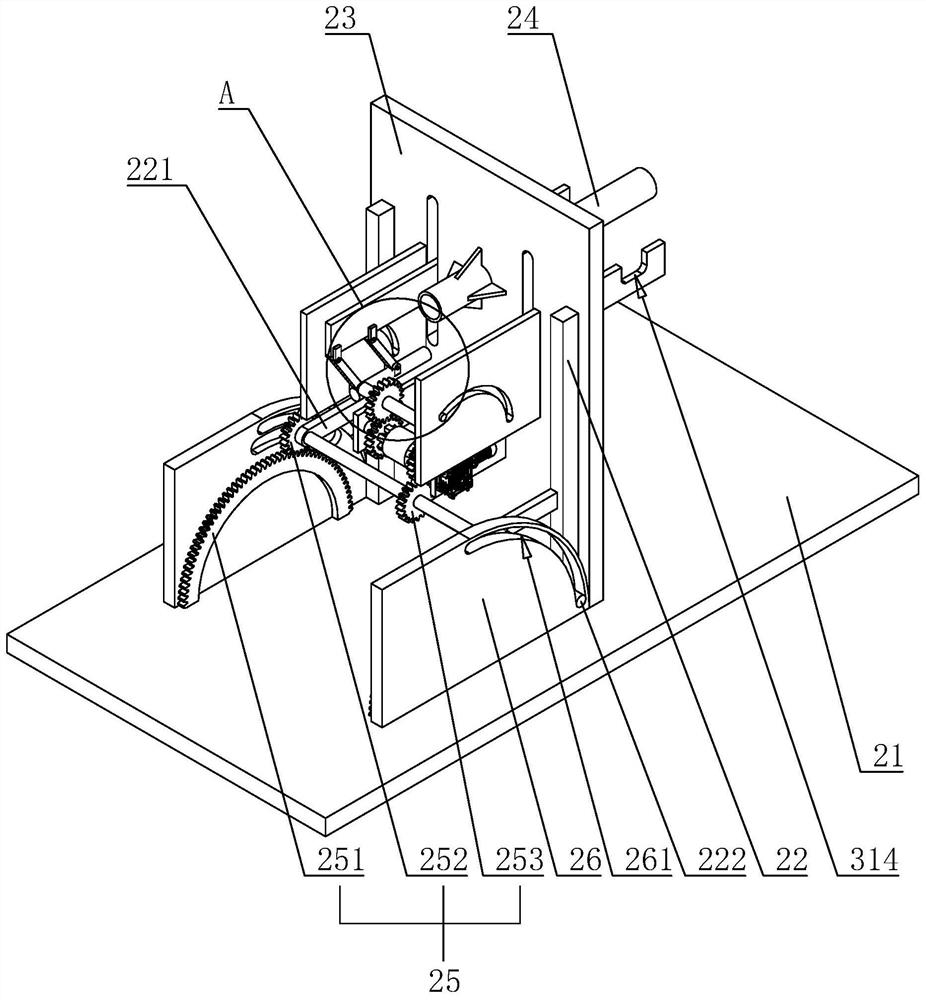

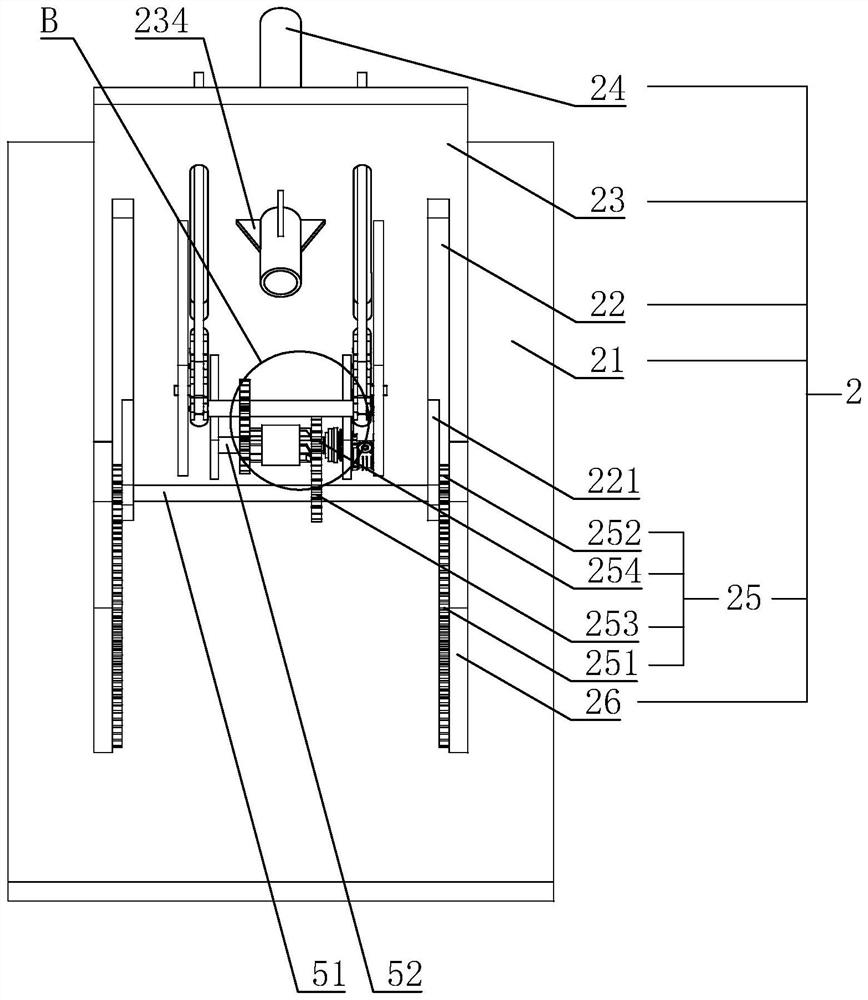

Vertical ring rolling mill capable of automatic feeding and discharging

ActiveCN110935824AExtend your lifeEasy to unloadMetal-working feeding devicesMetal rollingStructural engineeringMachining

The invention relates to a vertical ring rolling mill capable of automatic feeding and discharging and relates to the technical field of hot forging machining. The ring rolling mill comprises a rack;a grinding roller, a core roller, a guide roller and a measuring roller are arranged on the rack; an annular die cavity used for rolling a flange blank is formed in the peripheral surface of the coreroller; a connecting shaft is coaxially and fixedly connected to the end, away from the rack, of the core roller; a supporting device and a feeding and discharging device are further arranged at the end, close to the core roller, of the rack; and the supporting device comprises a base, a supporting arm, a discharging plate and a first shaft sleeve; the feeding and discharging device comprises a feeding and discharging mechanism; the feeding and discharging mechanism comprises a first rotating rod, a second rotating rod and a feeding arm; and a driving device used for driving the supporting device and the feeding and discharging device is further arranged on the discharging plate. The supporting device and the feeding and discharging device can be directly driven to operate step by step through the driving device, automatic feeding and discharging of the vertical ring rolling mill can be achieved while a mandrel is protected, and the mill is simple and convenient.

Owner:山东凯杰锻造股份有限公司

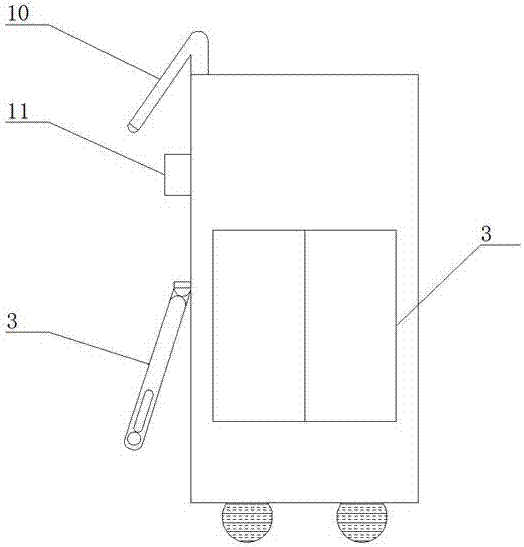

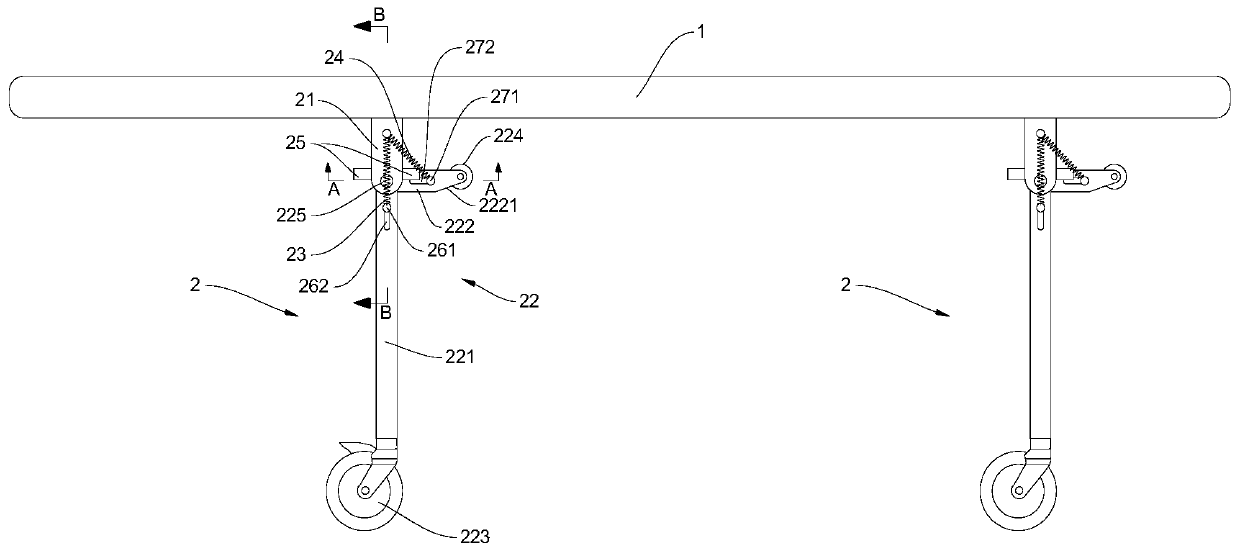

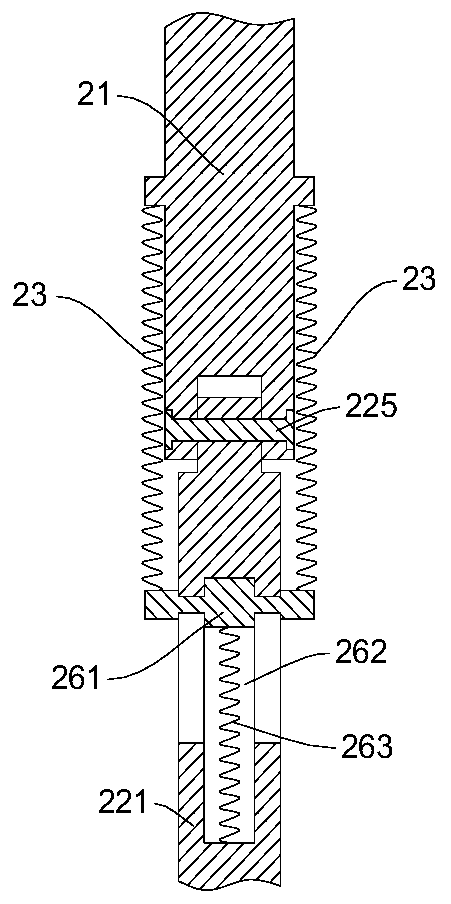

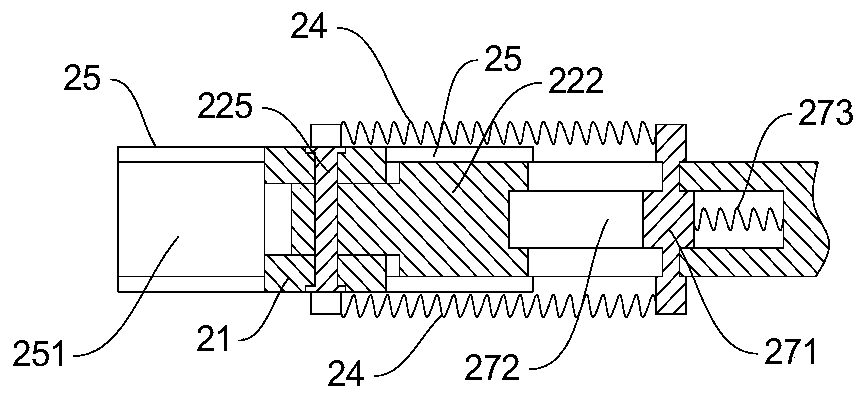

Ambulance stretcher combination capable of getting on and off automatically

The invention discloses an ambulance stretcher combination capable of getting on and off automatically. The ambulance stretcher combination capable of getting on and off automatically comprises a stretcher and an ambulance. The stretcher comprises a vehicle frame and four sets of supporting leg wheel set arranged on the lower part of the vehicle frame. Each supporting leg wheel set comprises a fixed supporting leg, a rotating supporting leg, a first tension spring and a second tension spring, the upper ends of the fixed supporting legs are fixed to the bottom of the vehicle frame, and horizontal supporting members are arranged on the front side and the back side of the lower part of the fixed supporting legs. The rotating supporting legs comprise vertically arranged main supporting legs and side supporting legs vertically connected to the front sides of the upper ends of the main supporting legs. A connecting part of the main supporting legs and the side supporting legs is connected tothe lower ends of the fixed supporting legs through a rotating shaft. First casters are arranged at the lower ends of the main supporting legs, second casters are installed at the front ends of the side supporting legs, the first tension springs are fixed between the fixed supporting legs and the main supporting legs, the second tension springs are connected between the fixed supporting legs andthe side supporting legs, and a blocking member is arranged on the side, close to a vehicle door, of a bottom plate of a carriage of the ambulance. The ambulance stretcher combination capable of getting on and off automatically can enable the stretcher to get on and off more conveniently and reliably.

Owner:黄驰越

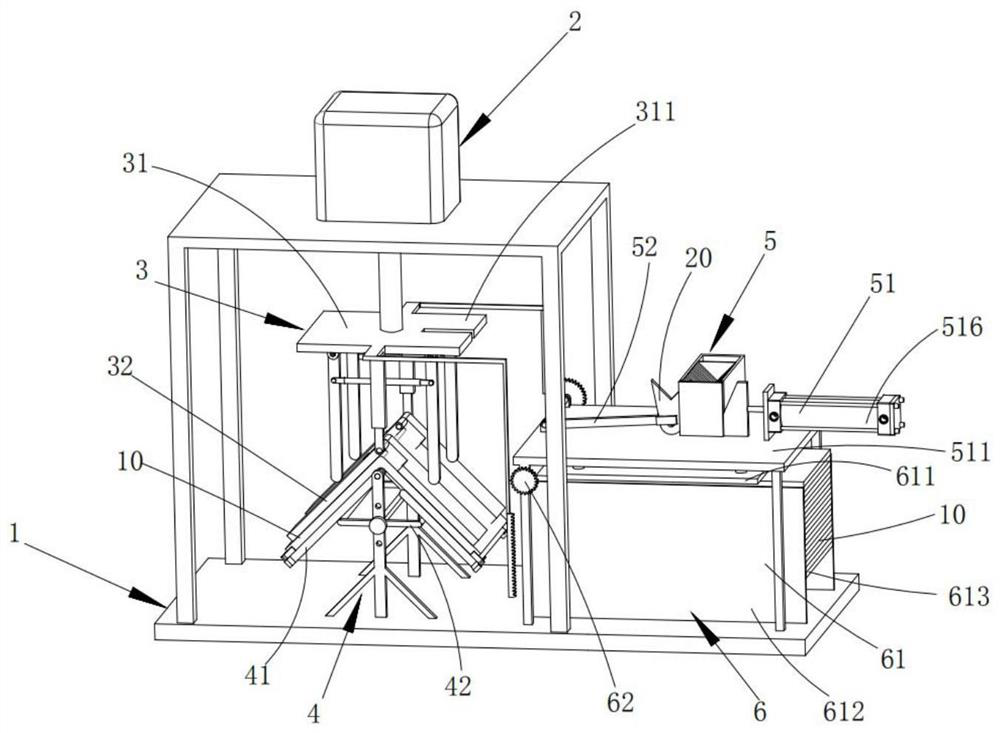

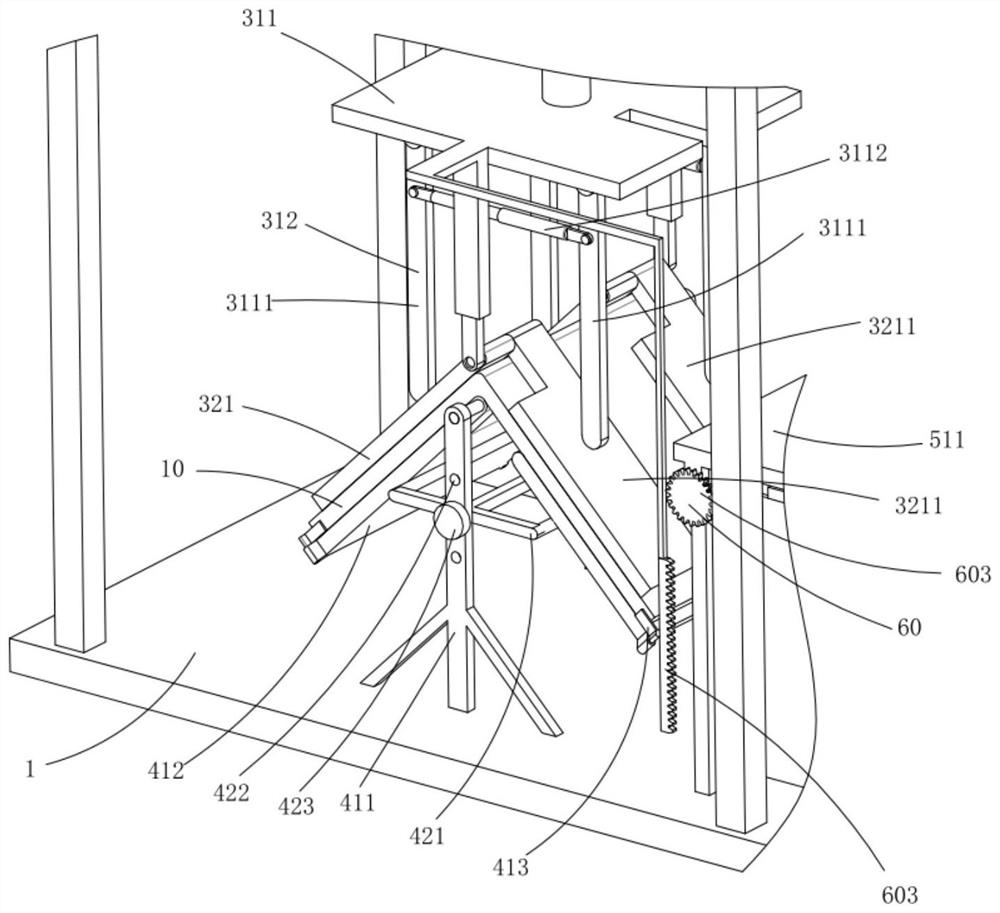

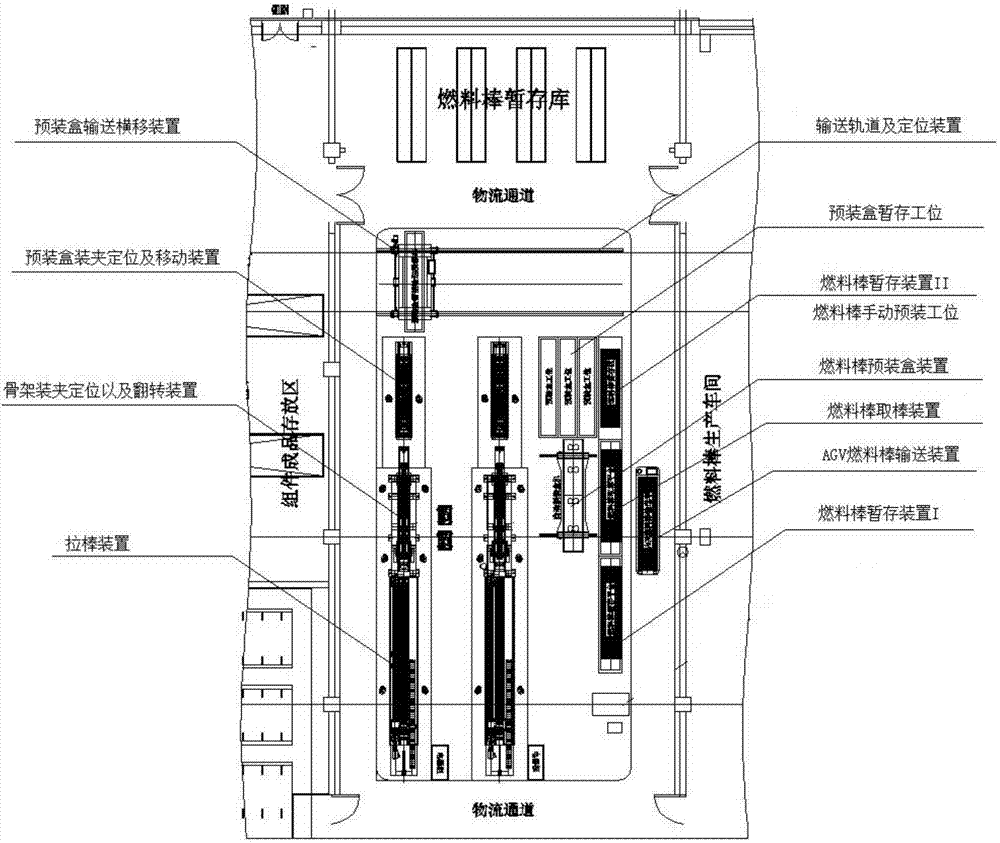

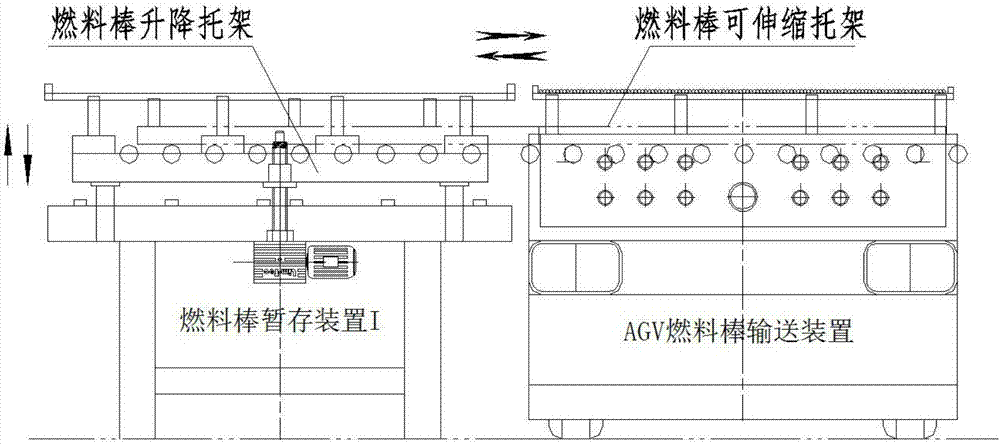

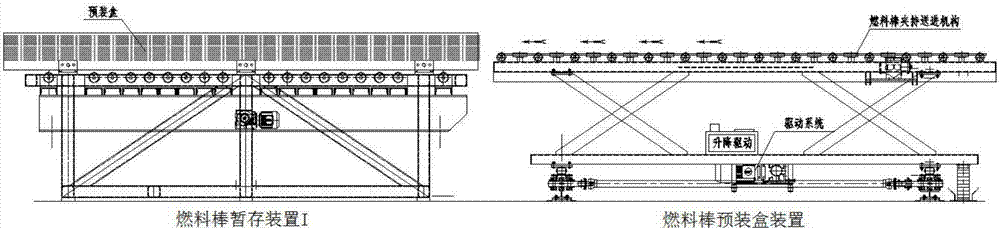

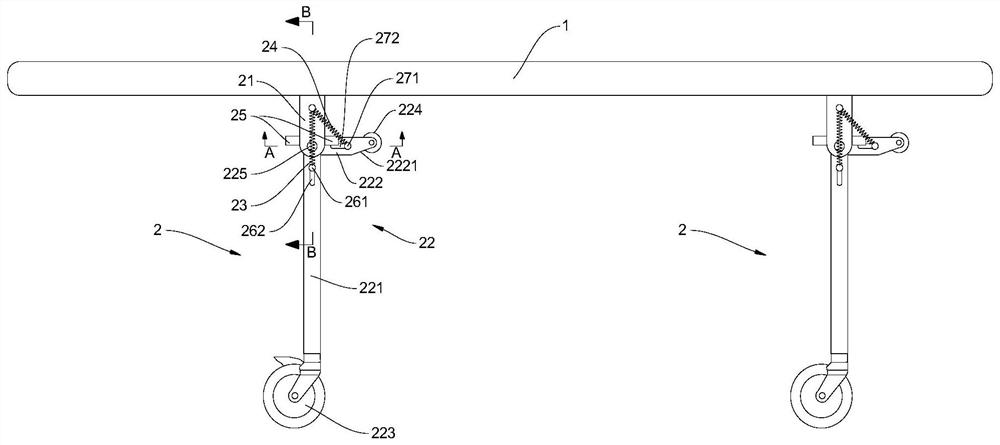

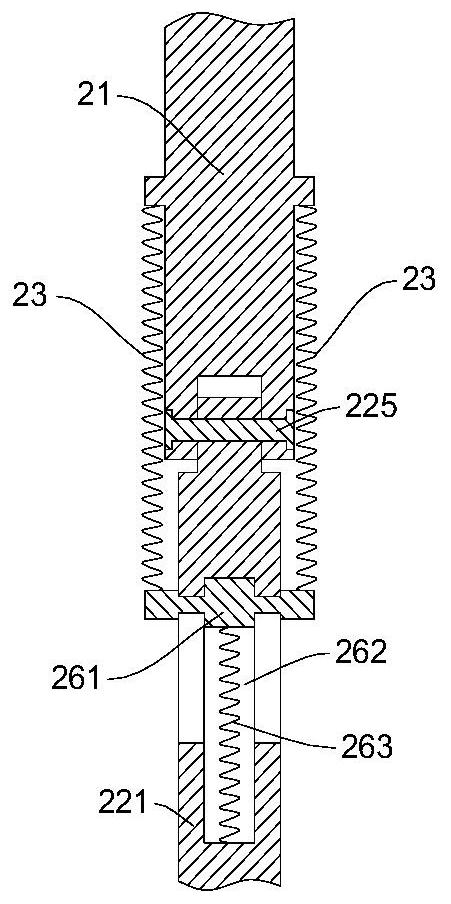

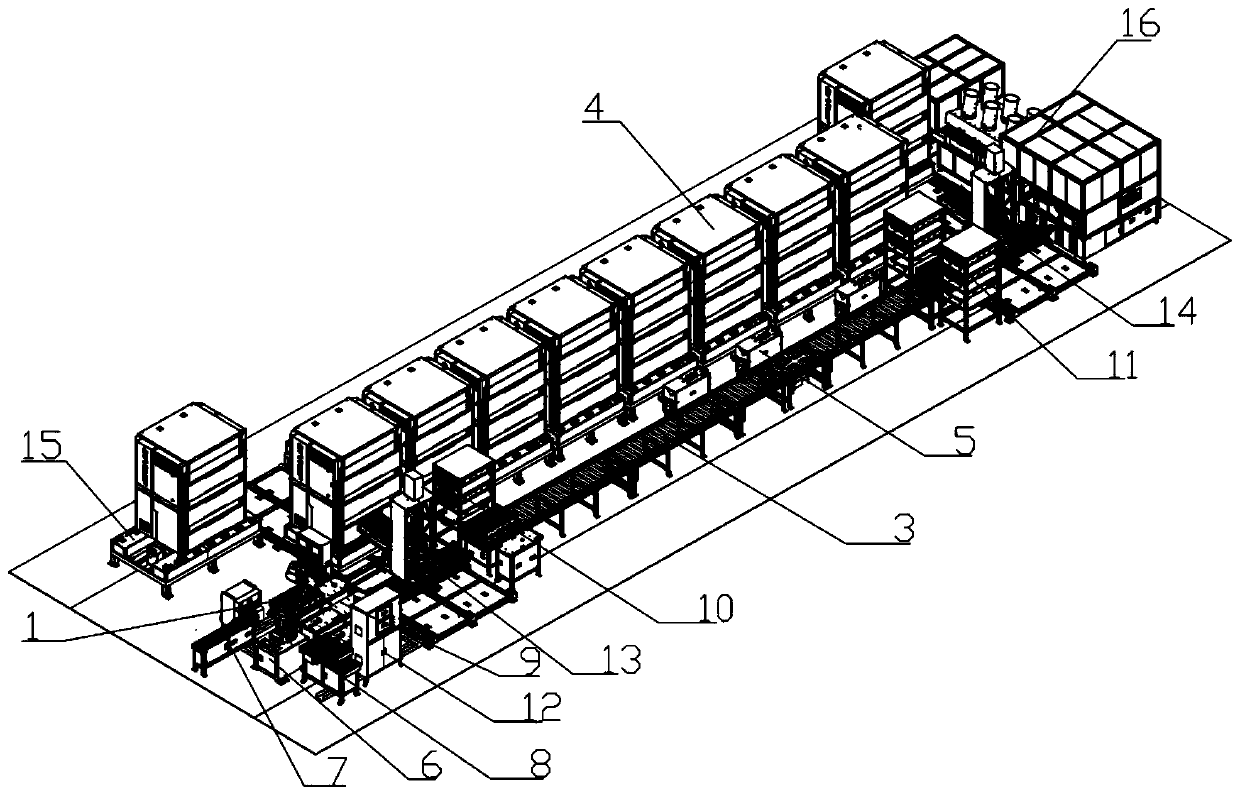

Novel nuclear fuel assembly rod pulling production system

ActiveCN107274945AAutomatic loading and unloadingImprove efficiencyNuclear energy generationReactors manufactureWorkloadPull technology

The invention relates to a novel nuclear fuel assembly rod pulling production system, and belongs to the field of nuclear fuels. The system comprises a fuel rod temporary storage device I, a fuel rod picking device, a fuel rod prepackaged box device, a fuel rod temporary storage device II, a prepackaged box conveying and traversing device, a prepackaged box clamping, positioning and moving device, a skeleton clamping, positioning and overturning device and a rod pulling device, wherein the fuel rod temporary storage device I, the fuel rod picking device, the fuel rod prepackaged box device and the fuel rod temporary storage device II are sequentially connected, the prepackaged box conveying and traversing device, the prepackaged box clamping, positioning and moving device, the skeleton clamping, positioning and overturning device and the rod pulling device are sequentially connected, and the prepackaged box conveying and traversing device moves between the fuel rod temporary storage device II and the prepackaged box clamping, positioning and moving device. The system obviously improves the mechanization degree of a nuclear fuel assembly rod pulling technology, reduces the workload, reduces the labor intensity of workers, and improves the quality of nuclear fuel assemblies.

Owner:CMCU ENG

Ambulance stretcher combination with automatic loading and unloading

ActiveCN110464556BAutomatic loading and unloadingEasy to get on and offStretcherVehicle frameSimulation

The invention discloses an ambulance stretcher combination capable of getting on and off automatically. The ambulance stretcher combination capable of getting on and off automatically comprises a stretcher and an ambulance. The stretcher comprises a vehicle frame and four sets of supporting leg wheel set arranged on the lower part of the vehicle frame. Each supporting leg wheel set comprises a fixed supporting leg, a rotating supporting leg, a first tension spring and a second tension spring, the upper ends of the fixed supporting legs are fixed to the bottom of the vehicle frame, and horizontal supporting members are arranged on the front side and the back side of the lower part of the fixed supporting legs. The rotating supporting legs comprise vertically arranged main supporting legs and side supporting legs vertically connected to the front sides of the upper ends of the main supporting legs. A connecting part of the main supporting legs and the side supporting legs is connected tothe lower ends of the fixed supporting legs through a rotating shaft. First casters are arranged at the lower ends of the main supporting legs, second casters are installed at the front ends of the side supporting legs, the first tension springs are fixed between the fixed supporting legs and the main supporting legs, the second tension springs are connected between the fixed supporting legs andthe side supporting legs, and a blocking member is arranged on the side, close to a vehicle door, of a bottom plate of a carriage of the ambulance. The ambulance stretcher combination capable of getting on and off automatically can enable the stretcher to get on and off more conveniently and reliably.

Owner:黄驰越

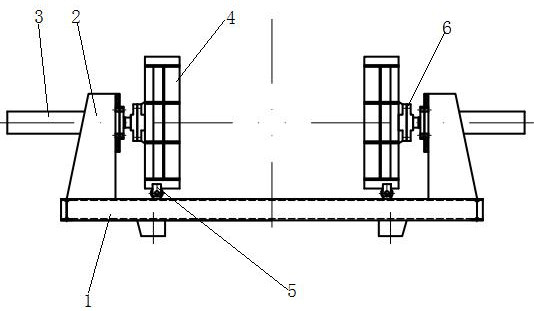

Digital controlled lathe loading and unloading device

InactiveCN108580932AAutomatic loading and unloadingImprove work efficiencyMetal working apparatusEngineeringMechanical engineering

The invention discloses a digital controlled lathe loading and unloading device which structurally comprises a digital controlled lathe body, a digital controlled lathe machining seat, a runner, a loading seat, a loading seat support plate, a bottom support, a digital controlled lathe loading and unloading mechanism, an unloading seat, an unloading seat support plate and a PLC, wherein the digitalcontrolled lathe machining seat is movably connected onto the surface of the front end of the digital controlled lathe body; the other end of the digital controlled lathe body is connected with the runner; the digital controlled lathe body is welded on the surface of the upper end of the bottom support; thedigital controlled lathe loading and unloading mechanism is arranged on the surface of theupper end of the bottom support; the loading seat is connected onto one end of the digital controlled lathe loading and unloading mechanism and is arranged on the surface of the upper end of the loading seat support plate; and the loading seat support plate is welded onto one end of the bottom support. The digital controlled lathe loading and unloading device is provided with the digital controlled lathe loading and unloading mechanism, so that the digital controlled lathe loading and unloading device can automatically load and unload a workpiece during the using process to overcome the defectthat the workpiece is loaded and unloaded through manual operation and effectively improve the working efficiency of the device and is high in practicality.

Owner:金舒宁

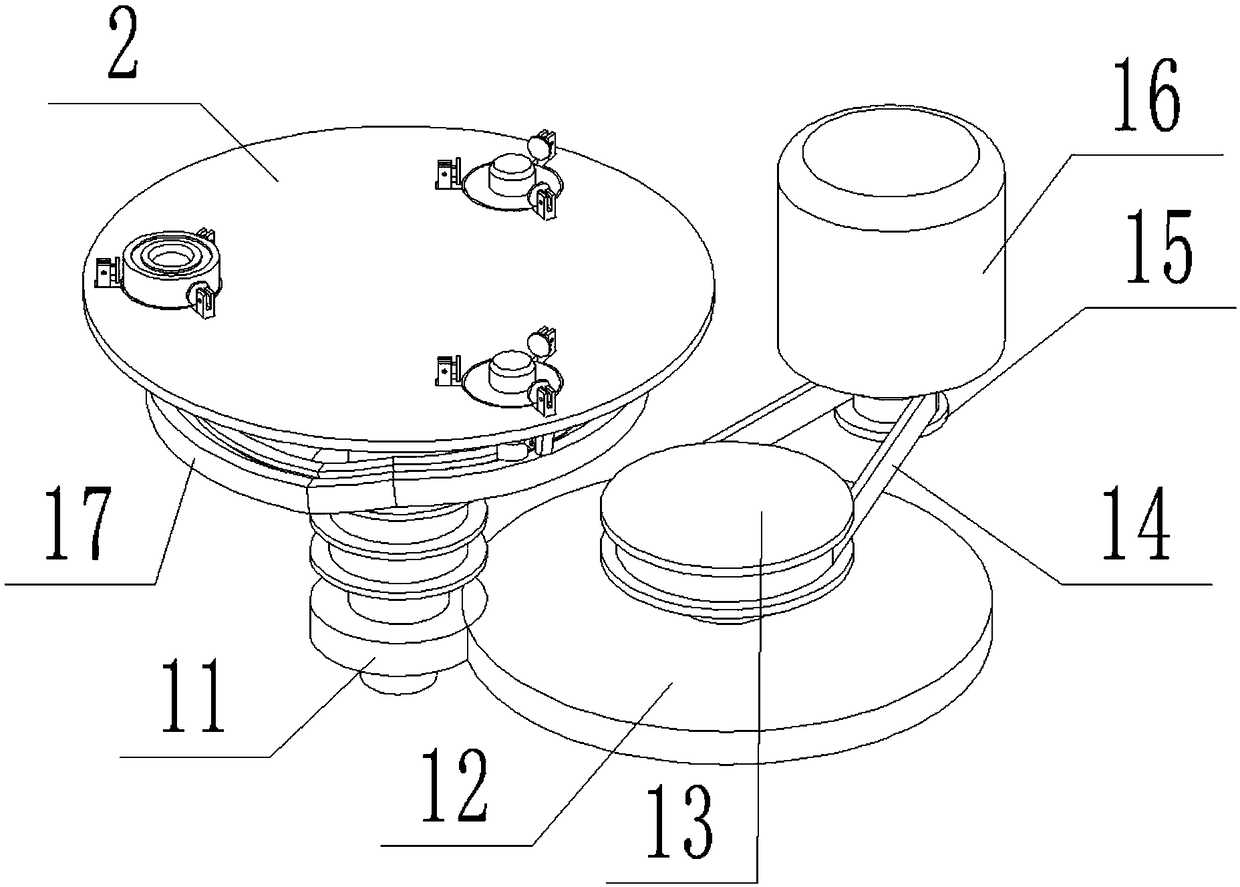

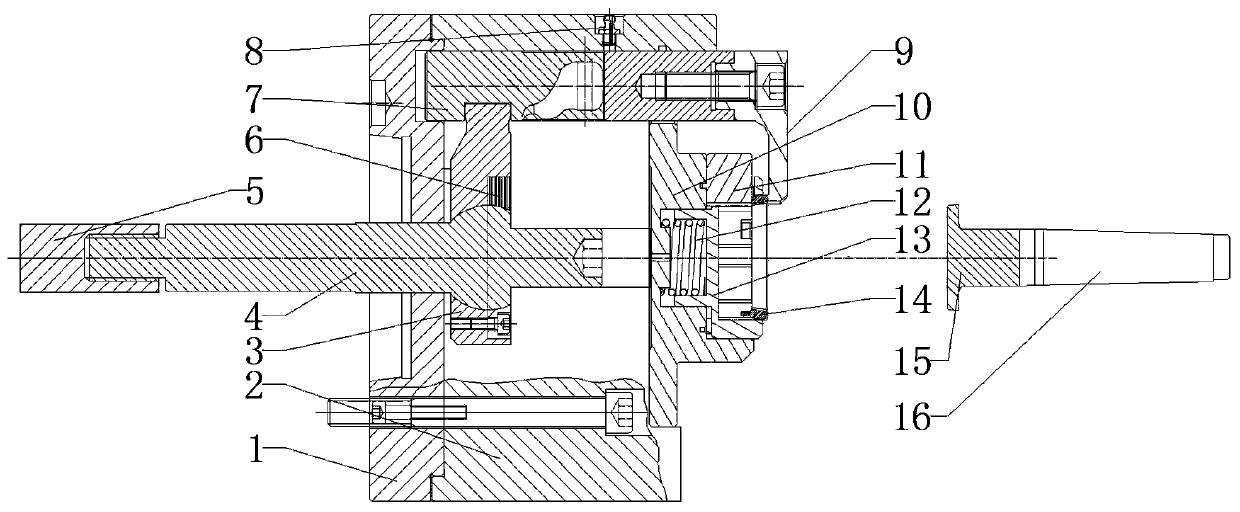

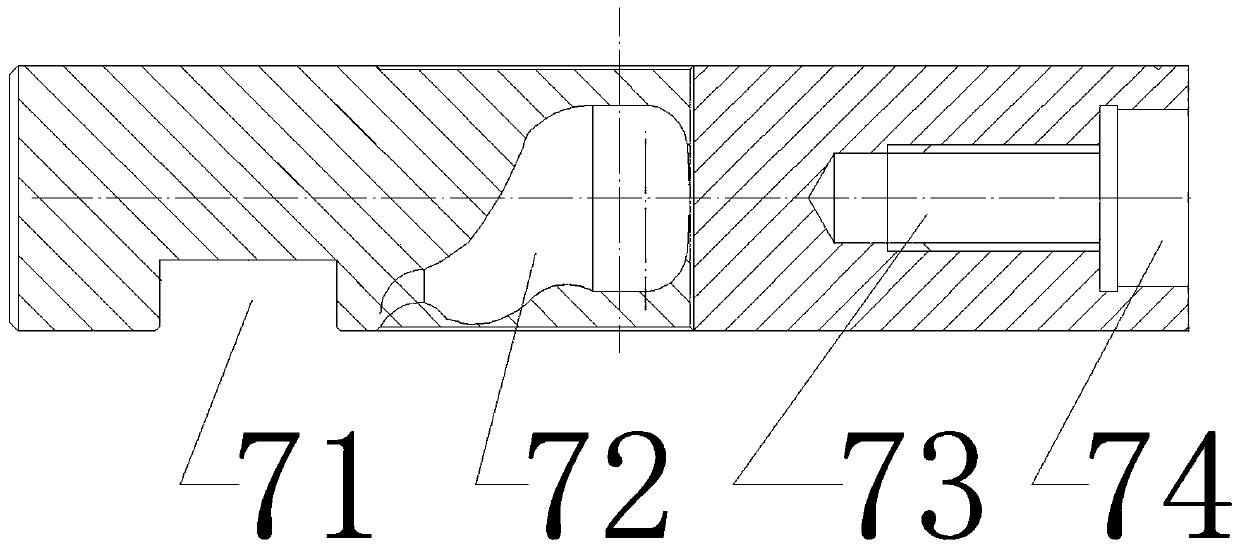

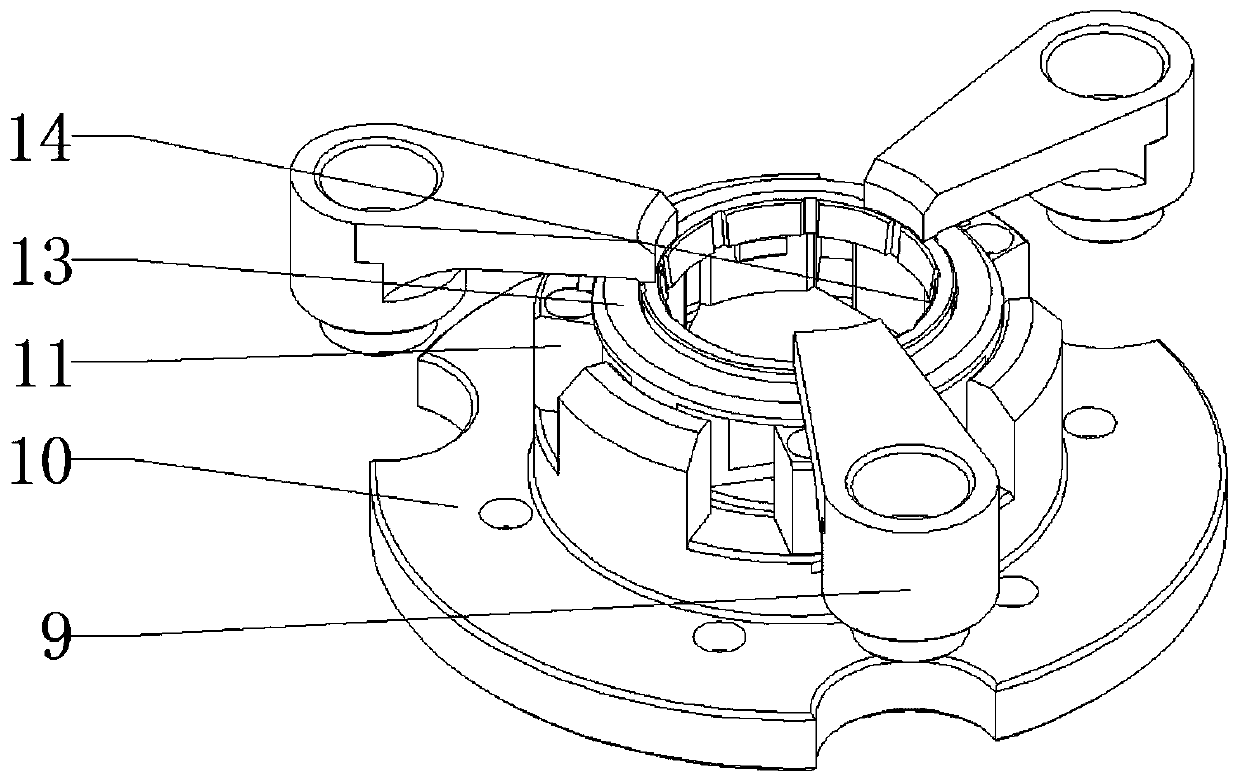

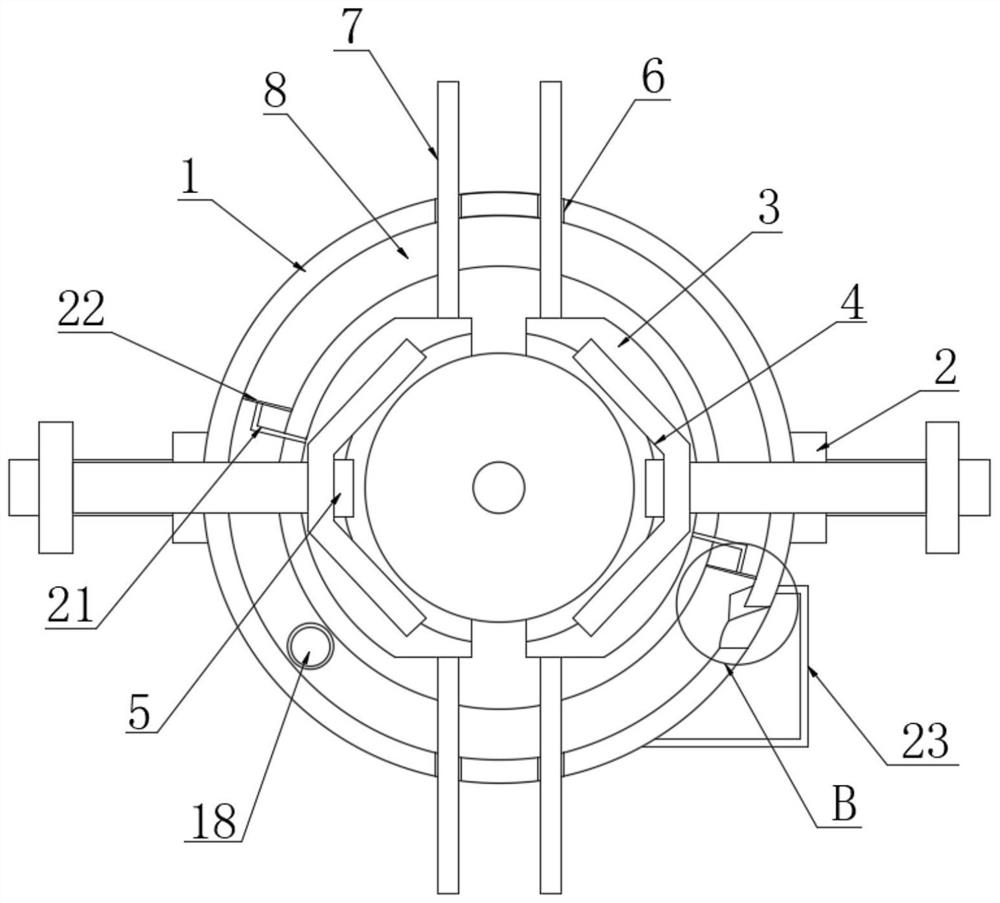

A composite fixture for processing the inner ring of a synchronizer gear ring

ActiveCN108296986BQuality improvementAutomatic loading and unloadingGrinding work supportsSynchronizerEngineering

The invention discloses a synchronizer gear ring inner ring machining composite clamp which comprises a connection disc, a disc body, a floating supporting disc, a floating spherical pull rod, a mainshaft pull rod, a supporting disc limiting block, a workpiece pull rod, an anti-rotation pin, a pressing plate, a clamp base, an axial positioning block, a pressing spring, a floating positioning bodyand other components. The connection disc is connected with the disc body, the floating supporting disc and the workpiece pull rod are arranged in the disc body, the anti-rotation pin is installed outside the disc body and abuts against the outer surface of the workpiece pull rod, the floating supporting disc is installed on the floating spherical pull rod through the supporting disc limiting block, and the floating spherical pull rod is connected with the main shaft pull rod on a machine tool. A floating type pulling finger-shaped clamping disc and a floating self-centering clamp are adopted, axial pressing force acts on the product end face, it is ensured that synchronizer inner ring product key important characters meet client drawing quality requirements, a machined synchronizer gearring product is reliable in quality, and automatic feeding and discharging requirements can be met.

Owner:WUHAN KYOWA SYNCHRONIZER RING

A big bag extrusion machine

ActiveCN109794314BAutomatic loading and unloadingGrain treatmentsHydraulic cylinderElectric machinery

The invention discloses a ton bag extruding machine which comprises a base, wherein supporting plate assemblies are fixed on two sides of the top face of the base; hydraulic cylinders are fixed on thetwo supporting plate assemblies; extrusion plates are disposed between the two supporting plate assemblies; pulleys are disposed on bottoms of two sides of the extrusion plates; telescopic ends of the hydraulic cylinders extend to inner sides of the supporting plate assemblies and are fixed to outer sides of the extrusion plates by bulb flanges; the hydraulic cylinders are connected to a hydraulic station by a push oil pipe and a return oil pipe respectively; pressure adjustment valves are disposed on the push oil pipe and the return oil pipe; an oil pump motor and a pressure display meter are disposed on the hydraulic station; a horizontal sway range of the two extrusion plates is 2-3 DEG; axes of the two hydraulic cylinders are located at the same center line; and the two extrusion plates have a horn mouth structure which decreases in size from top to bottom.

Owner:GARSONI FERTILIZER PINGYUAN

Drilling temperature control equipment based on gear machining and use method of drilling temperature control equipment

PendingCN114083023AQuick fix limitDo not delay the drilling processPositioning apparatusMetal working apparatusTemperature controlGear wheel

The invention discloses drilling temperature control equipment based on gear machining and a use method of the drilling temperature control equipment. A machining base is included. A clamping mechanism is arranged on one side of the machining base. A drilling mechanism and a temperature control mechanism are arranged at the top of the machining base. The clamping mechanism comprises a double-rod air cylinder fixed to one side of the machining base. One end of a piston rod of the double-rod air cylinder is fixedly connected with a clamping disc. And the top of the clamping disc is fixedly connected with a clamping frame. The invention relates to the technical field of gear machining. The drilling temperature control equipment based on gear machining and the use method thereof are provided. When the gear is machined, the gear can be quickly fixed and limited; the temperature control effect is adjusted by measuring the temperature of the gear in real time during drilling; cooling is conducted through the cutting fluid, and the cutting fluid can be recycled and reused after heat exchange; the temperature control effect is better, and the normal gear drilling machining process is not delayed.

Owner:安徽一本精工科技有限公司

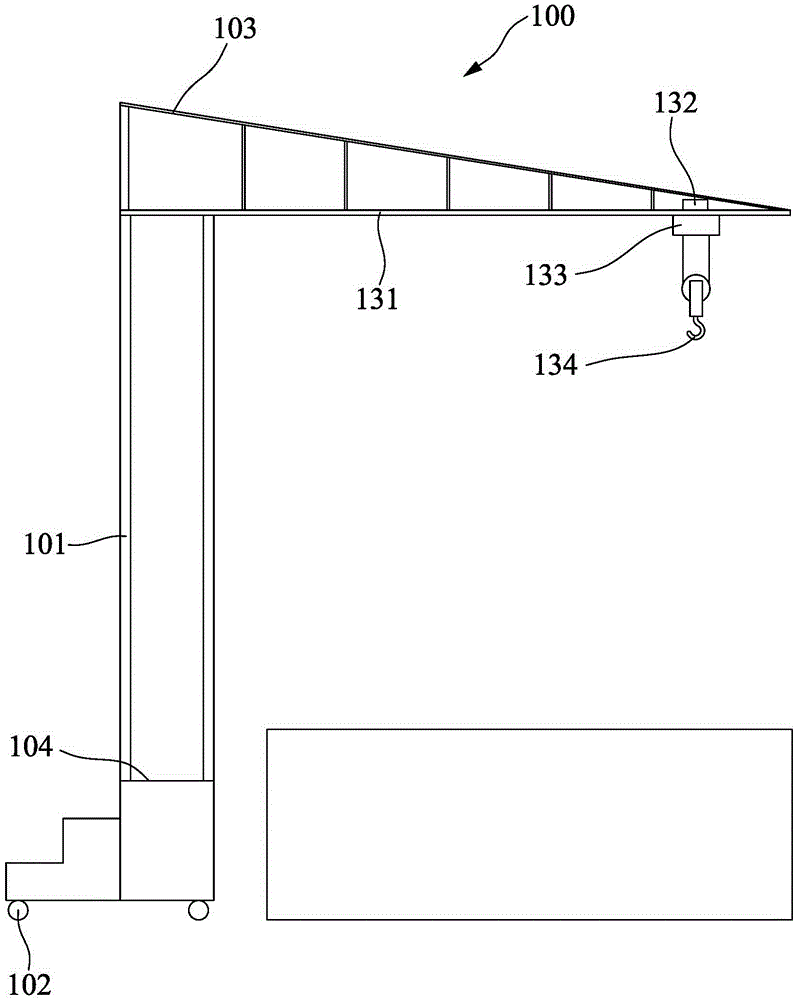

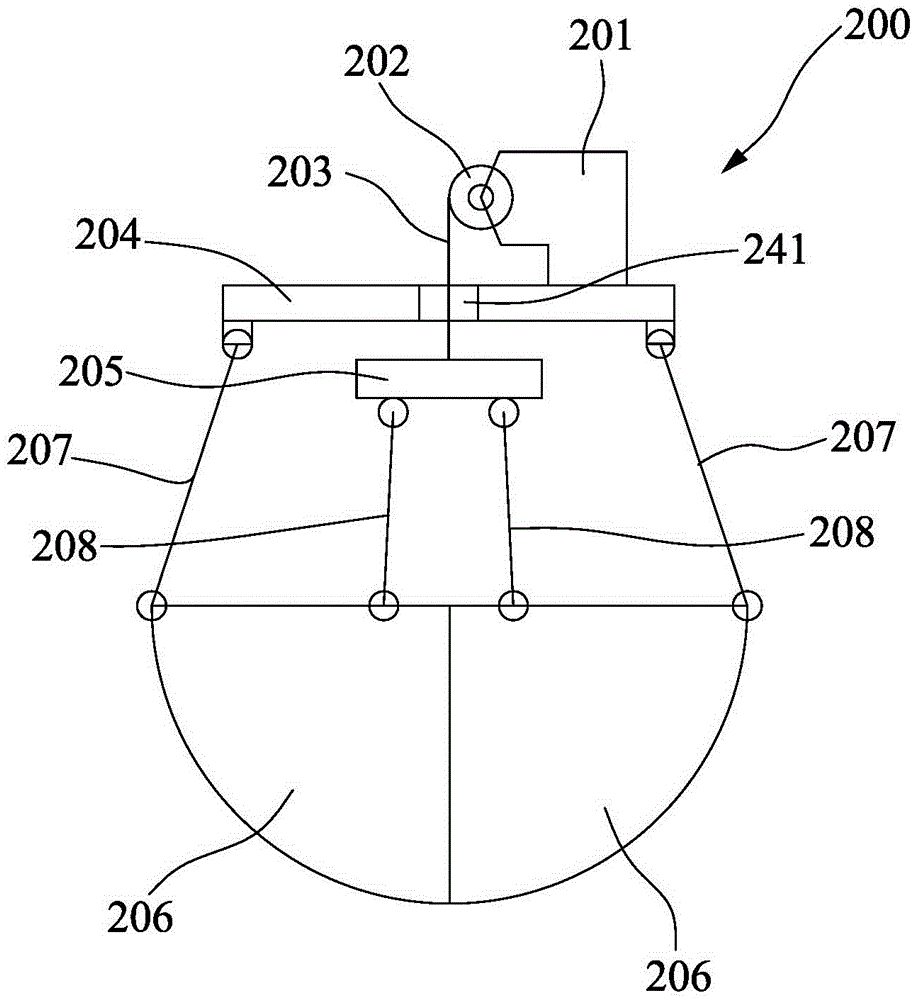

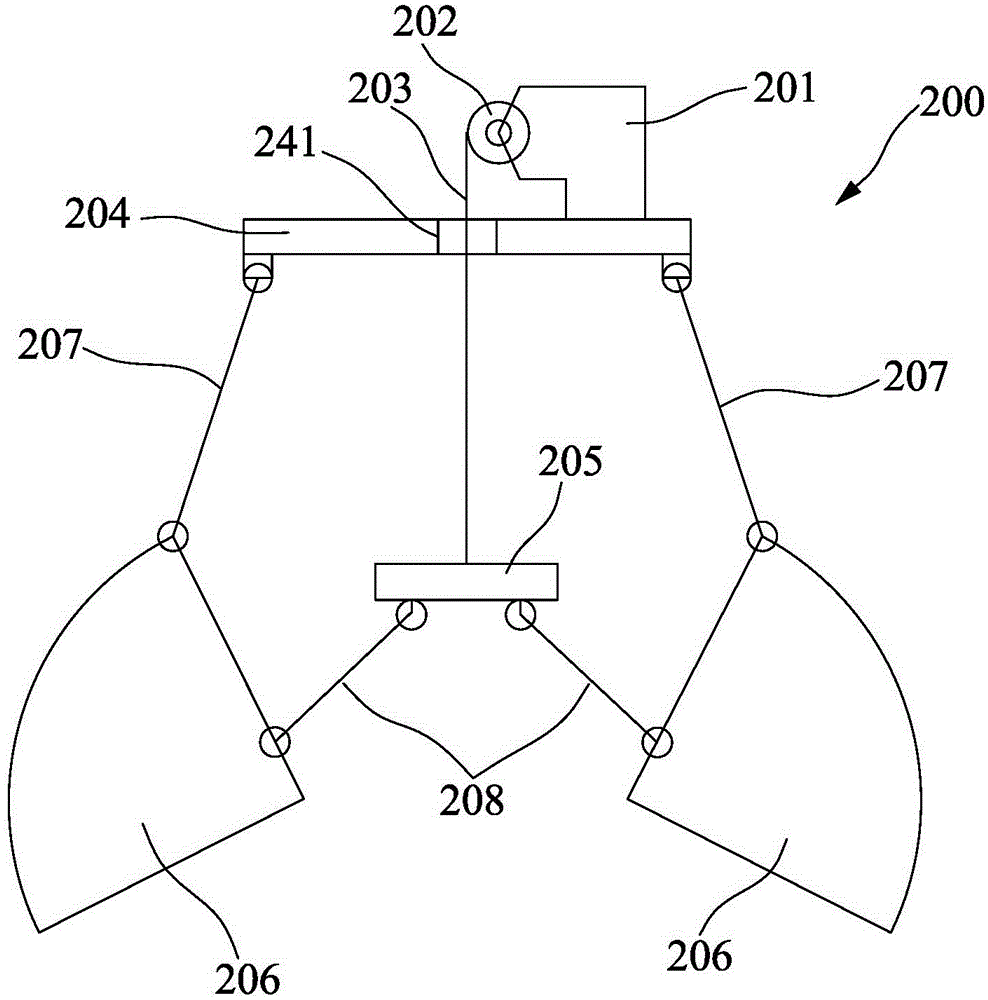

Simple operating system special for fresh ginger soaking pool

InactiveCN105110204AKeep it workingAvoid troubleCranesLoad-engaging elementsTransmission beltEngineering

The invention discloses a simple operating system special for a fresh ginger soaking pool. A movement operation device comprises a supporting frame, rollers and a traveling crane. The supporting frame is installed beside the soaking pool, the rollers are installed at the bottom of the supporting frame, and a traveling crane rail is installed at the top of the supporting frame; a driving motor and a crane are installed on the rail, and a lifting hook is suspended below the crane; a mechanical grab bucket is composed of a grab bucket motor, a rotating wheel, a transmission belt, a main plate, a driven plate and a bucket, wherein the main plate is suspended on the lifting hook, the grab bucket motor and the rotating wheel are installed on the main plate, the grab bucket motor and the rotating wheel are transmitted, the driven plate is located below the main plate, and the rotating wheel is wound with the transmission belt; one end of the transmission belt is fixed to the rotating wheel, and the other end of the transmission belt penetrates a penetrating hole in the main plate to be fixed to the driven plate; and the bucket is composed of two semi bucket bodies in a buckled manner, the outer tops of the two semi bucket bodies and the outer end of the main plate are pivoted with the two ends of an outer connecting rod, and the inner tops of the two semi bucket bodies and the outer end of the driven plate are pivoted to the two ends of an inner connecting rod. By means of the system, the aim of automatically and rapidly loading, unloading and fishing fresh ginger is achieved.

Owner:FUJIAN YOUCHUANG AGRI DEV CO LTD

A self-balancing multifunctional transport vehicle

InactiveCN104709847BImprove the efficiency of loading and unloading guaranteeSmall bodyLifting devicesDrive wheelGyroscope

The invention discloses a self-balance multifunctional carrier which comprises a vehicle body, a lifting motor, a wheel drive motor, a motor controller, a winch, a pulley mechanism, a hinge type two-stage lifting portal, a fork, driving wheels, balance supporting legs, a lithium ion storage battery set, an attitude-control gyroscope, a dip angle sensor, a mechanical electric accessory and the like. The self-balance off-road multifunctional carrier has an off-road wheelbarrow work mode and a manual forklift work mode, people can get on and off the carrier by themselves by means of the design of the two-stage lifting portal, people can drive the carrier in the manual forklift mode and a self-balance mode when road environments are good, and the carrier can be assisted and pushed by hands to drive in the off-road wheelbarrow mode when the road environments are bad. The self-balance driving technology and the goods gravity self-adjustment technology are adopted, and flexible switching between the two modes is achieved through the portal toppling structure. The carrier has the advantages that a vehicle body is light, work is flexible, functions are diverse and adaptability is high, and goods loading, unloading and transporting efficiency in field environments can be effectively improved.

Owner:ARCHITECTURAL ENG INST GENERAL LOGISTICS DEPT P L A

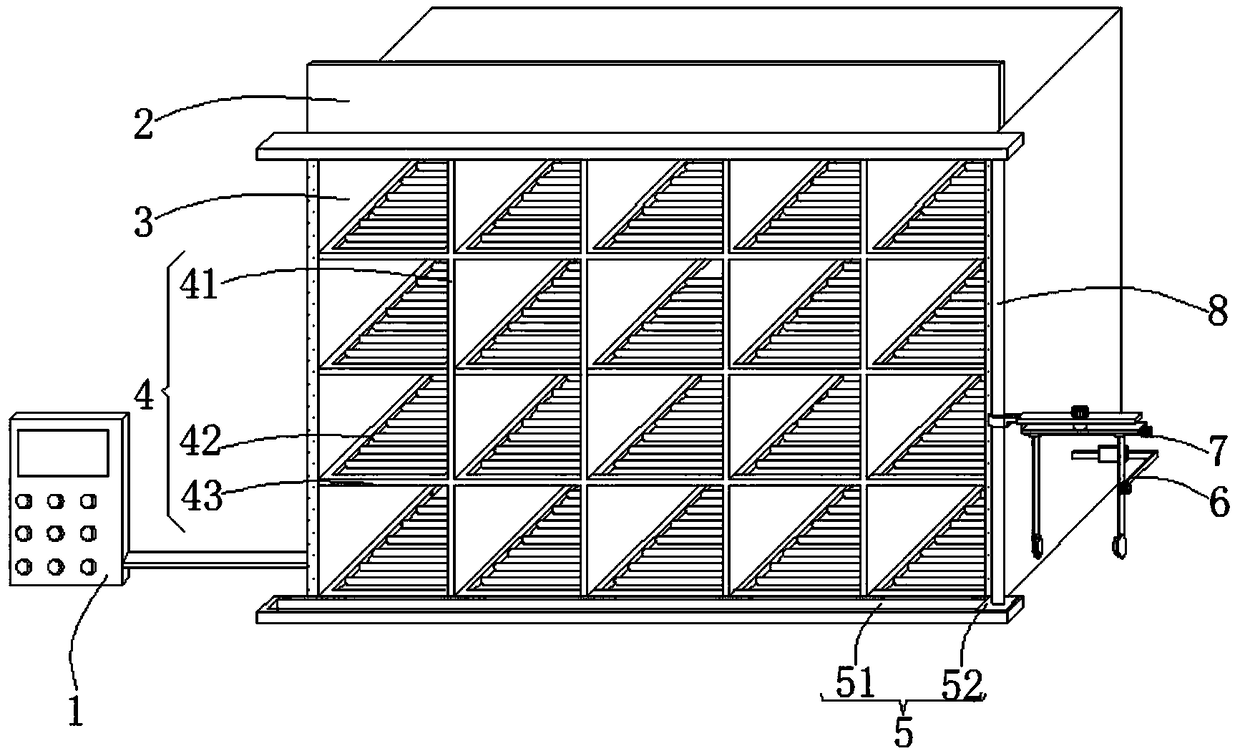

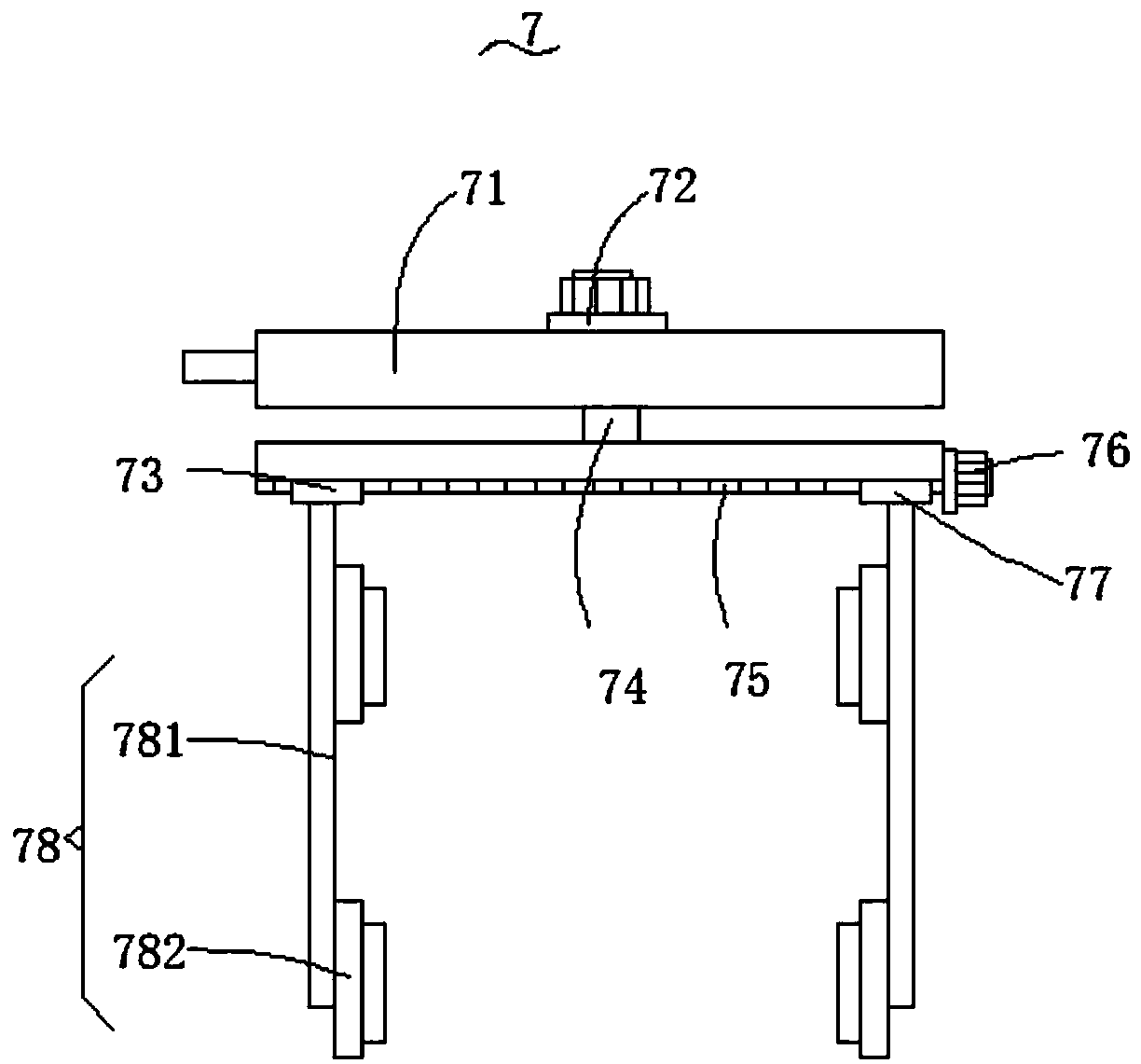

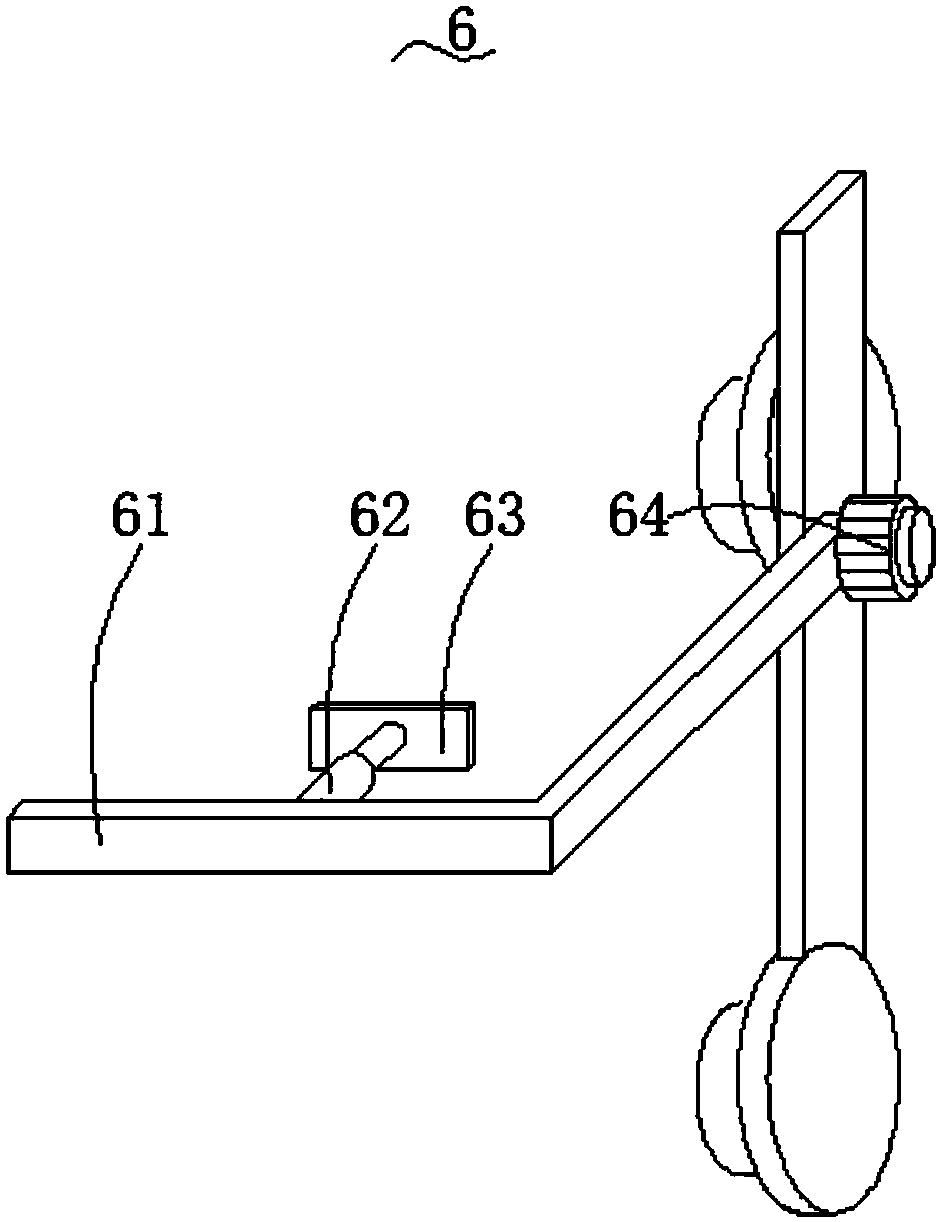

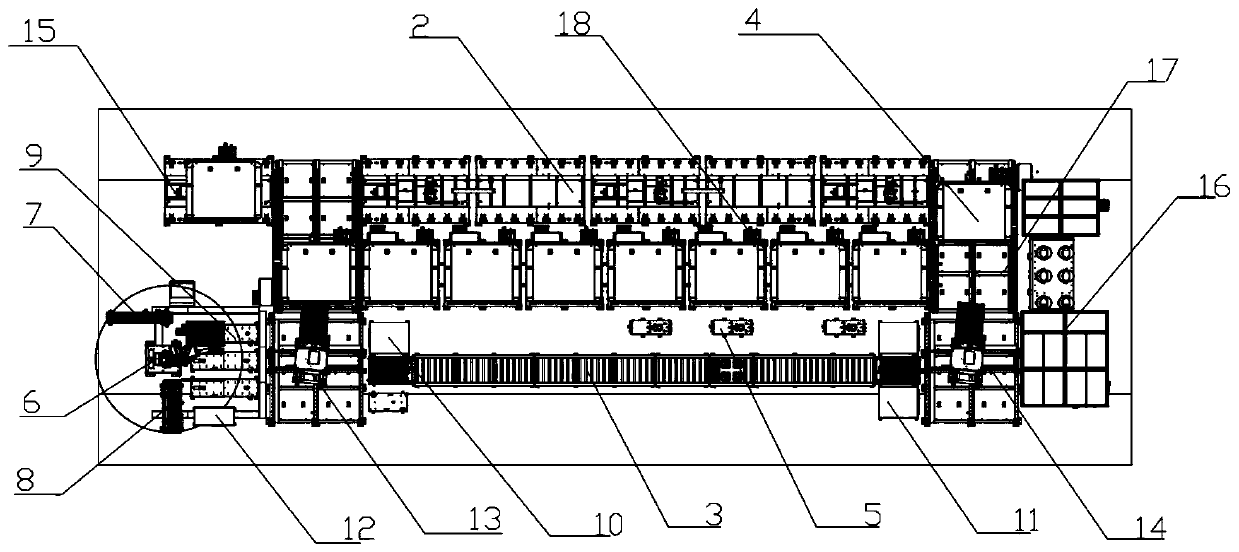

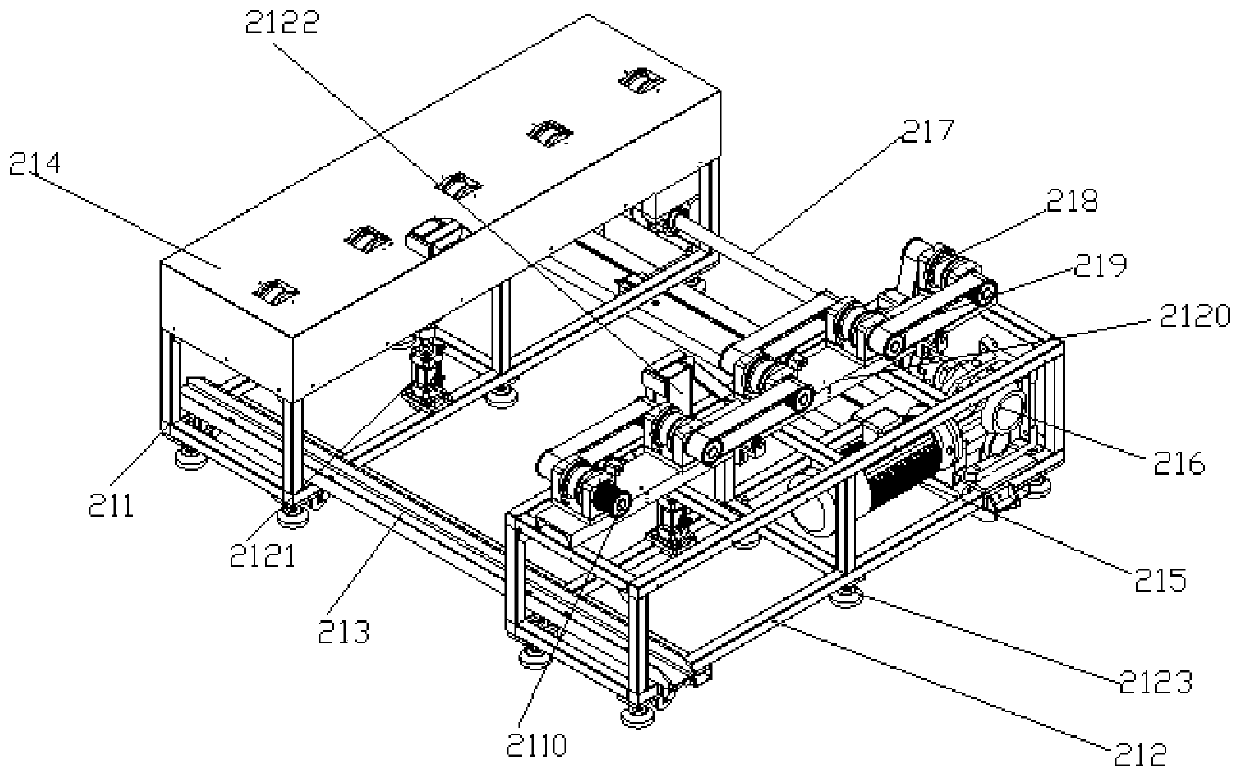

Circulation Furnace Type Lithium Battery Automatic Baking System

ActiveCN107462068BAchieve dryingAchieving processing powerPrimary cell manufactureFinal product manufactureControl engineeringEngineering

The invention discloses a circulating furnace body type lithium battery automatic baking system, which is characterized in that it includes a circulating moving line, a drying furnace, a manipulator and a cooling furnace assembly, the circulating moving line includes a plurality of box moving mechanisms, and the box The body moving mechanism is connected end to end to form the circulating moving line, at least one of the drying furnaces is installed on the circulating moving line; Fixture unloading manipulators are respectively arranged at both ends of the circulating moving line, and the drying furnace is set on the circulating moving line, moves circularly on the circulating moving line, and respectively enters the fixture feeding manipulator and the Describe the working space of the fixture blanking manipulator. The invention can greatly reduce the contact time of the lithium battery with air after drying, and automatically complete the drying and cooling process of the lithium battery.

Owner:深圳市新伟创实业有限公司

Full-automatic multifunctional side labeling machine

ActiveCN113479441AAutomatic loading and unloadingSmooth rotationLabelling short rigid containersLabelling machinesGear wheelBottle

The invention discloses a full-automatic multifunctional side labeling machine in the technical field of multifunctional side labeling machines. The full-automatic multifunctional side labeling machine comprises a processing table, wherein the bottom of the processing table is fixedly connected with a first extrusion ring through four L-shaped connecting blocks, and the bottom of the first extrusion ring is fixedly connected with a first connecting plate. According to the full-automatic multifunctional side labeling machine, when the side faces of round bottles are labeled, a feeding mechanism is used for conveying the round bottles, the round bottles sleeve first sliding rods when the first sliding rods move to the bottom of the feeding mechanism in cooperation with rotation of a first rotating shaft, the falling round bottles are clamped in cooperation with a clamping mechanism, and the round bottles can stably rotate under the action of first gears and an inner gear ring, so that the sliding between the round bottles and a labeling mechanism is avoided, it is ensured that the labels can be tightly attached to the side walls of the round bottles, and wrinkles caused by labeling are avoided; and the round bottles are taken out in cooperation with a material taking mechanism after labeling is completed, so that feeding and discharging of the round bottles are automatically realized, persons do not need to take the round bottles, and the full-automatic multifunctional side labeling machine is convenient and rapid.

Owner:东莞市欧尚自动化设备科技有限公司

A vertical ring rolling machine with automatic loading and unloading

ActiveCN110935824BExtend your lifeEasy to unloadMetal-working feeding devicesMetal rollingEngineeringMachine

The invention relates to a vertical ring rolling machine with automatic loading and unloading, and relates to the technical field of hot forging processing. A ring-shaped die groove for rolling flange blanks is arranged on the surface, the end of the core roller away from the frame is coaxially connected with a connecting shaft, and the end of the frame close to the core roller is also provided with a support device and a loading and unloading device. The support device includes a base, a support arm, a feeding plate and a first bushing; the loading and unloading device includes a loading and unloading mechanism, and the loading and unloading mechanism includes a first rotating rod, a second rotating rod and a feeding arm; It is used to drive the supporting device and the driving device of the loading and unloading device. The invention can directly drive the operation of the support device and the loading and unloading device step by step through the driving device, and can realize the automatic loading and unloading of the vertical ring rolling machine while protecting the mandrel, which is simple and convenient.

Owner:山东凯杰锻造股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com