Vertical ring rolling mill capable of automatic feeding and discharging

An automatic loading and unloading and ring rolling machine technology, which is applied in the field of hot forging processing, can solve the problems of reducing the operating space of the mandrel and making it difficult to load and unload the ring rolling machine, so as to prolong the life, protect the core roll and avoid burning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

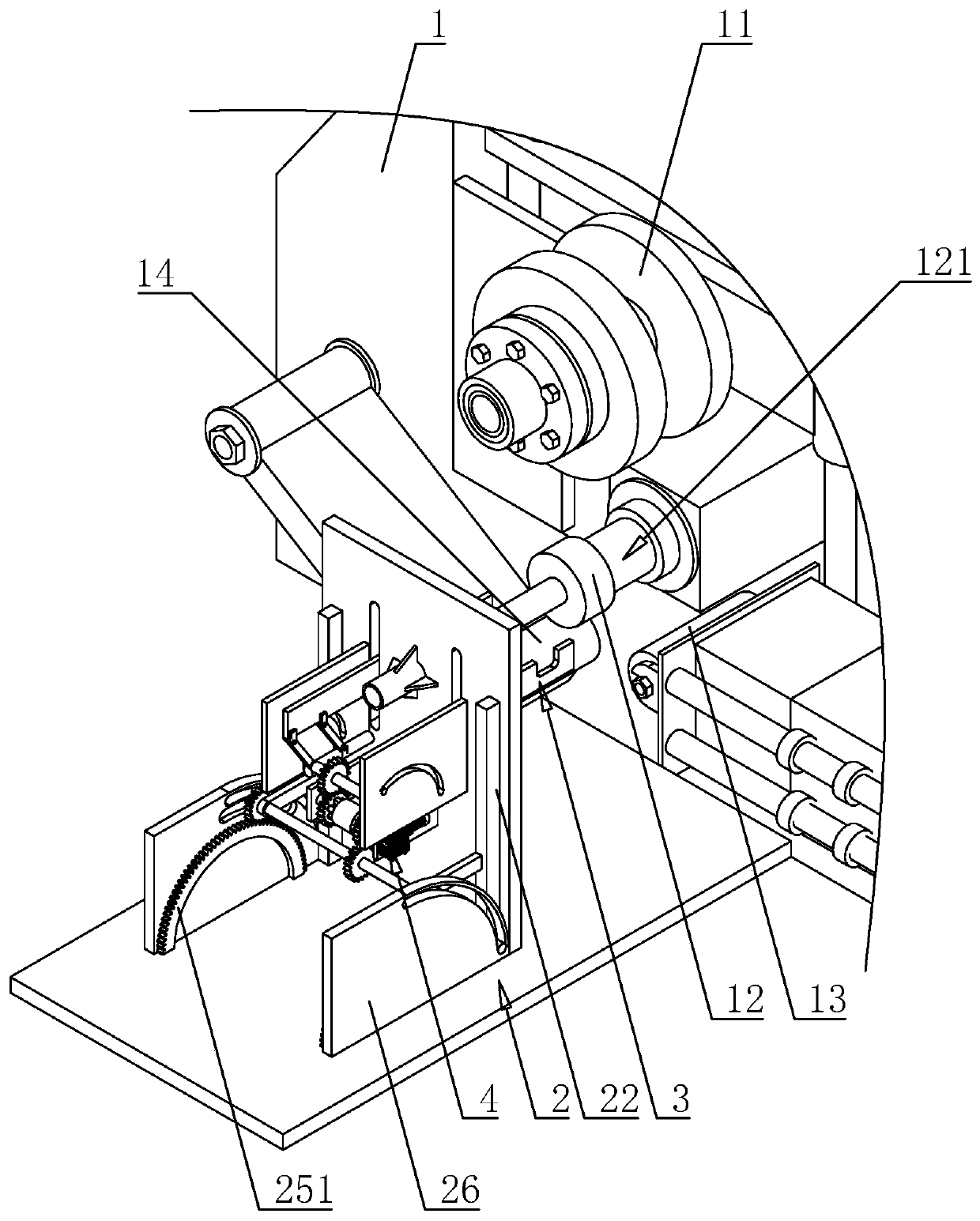

[0041] refer to figure 1 , the present embodiment proposes a vertical ring rolling machine with automatic loading and unloading, including a frame 1 on which a rolling roller 11 , a core roller 12 , a guide roller 13 and a measuring roller 14 are rotatably connected. The outer peripheral surface of the core roll 12 is provided with an annular die groove 121 for rolling the flange blank, and the end of the core roll 12 away from the frame 1 is integrally formed with a connecting shaft 122 (such as Figure 4 shown). One end of the frame 1 close to the core roll 12 is also provided with a supporting device 2 for supporting the core roll 12 and a loading and unloading device 3 for automatically loading and unloading the core roll 12 .

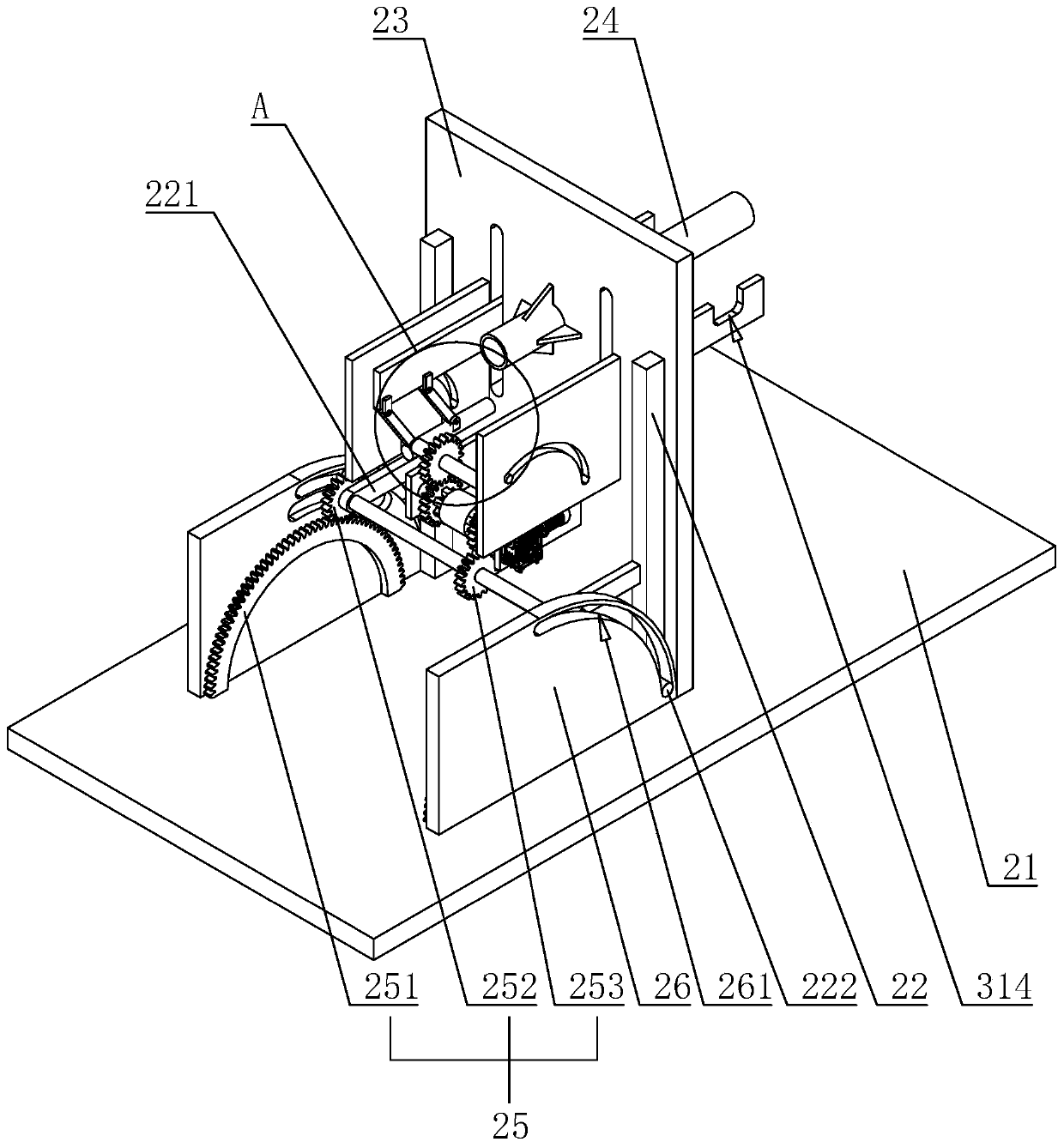

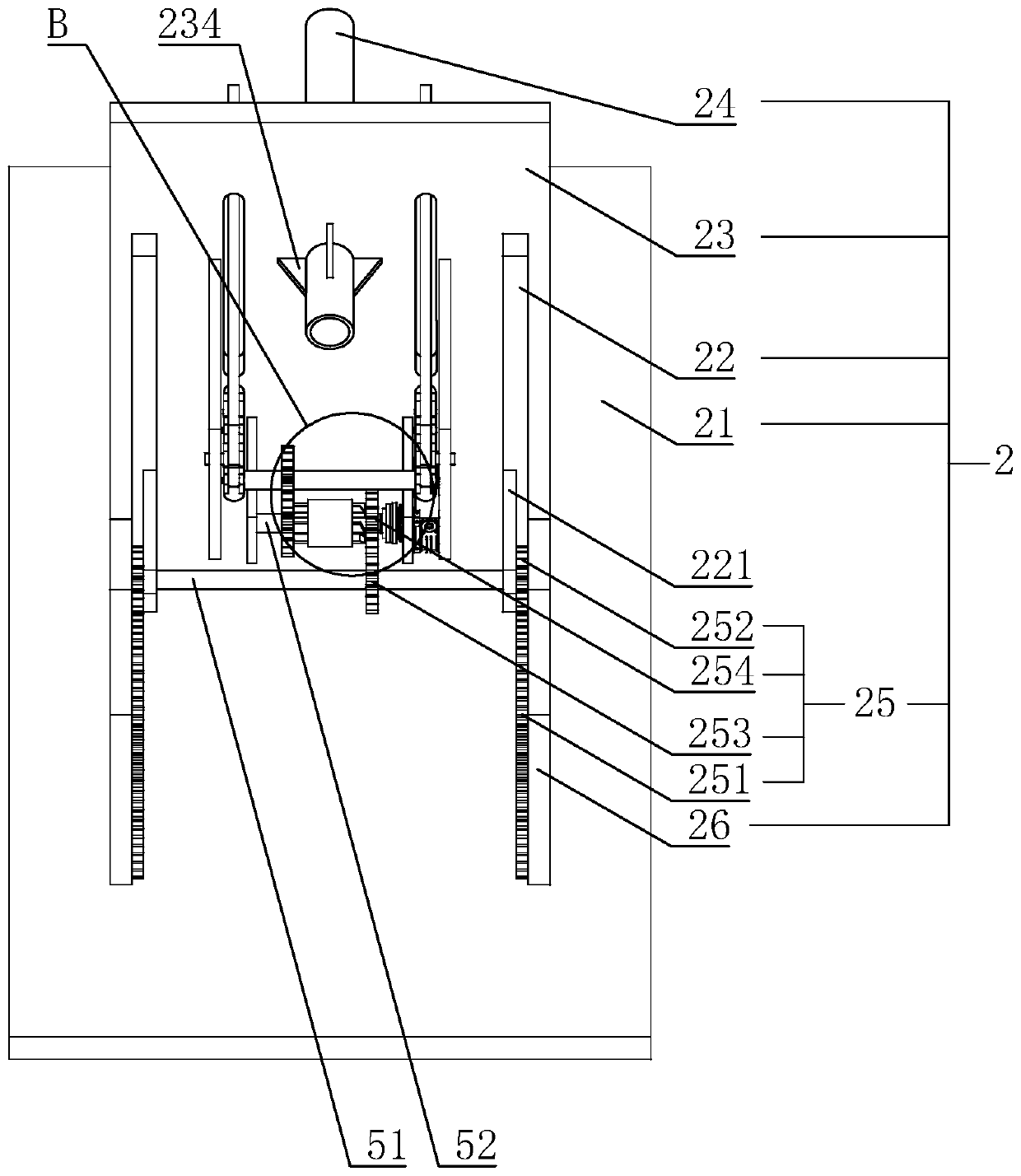

[0042] refer to figure 2 and image 3 , the support device 2 includes a base 21 , a support arm 22 , a discharge plate 23 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com