Novel nuclear fuel assembly rod pulling production system

A technology for nuclear fuel assemblies and production systems, applied in nuclear engineering, nuclear power generation, and manufacturing reactors, etc., can solve problems such as the inability to meet the needs of the vigorous development of nuclear power, the low output of nuclear fuel assemblies, and the slow development of nuclear power. The effect of improving efficiency, improving stability and equipment reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

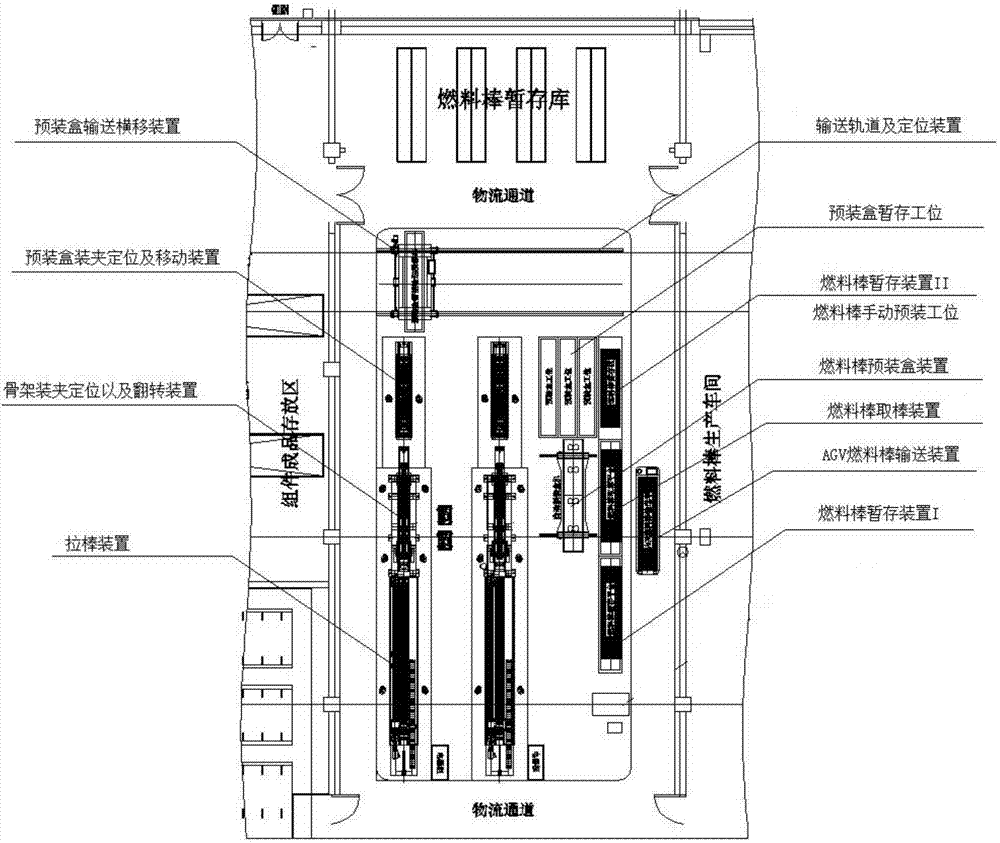

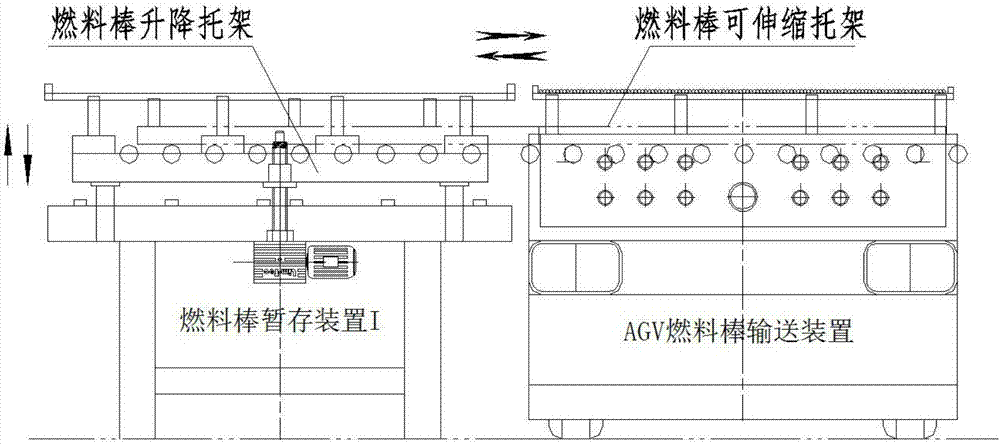

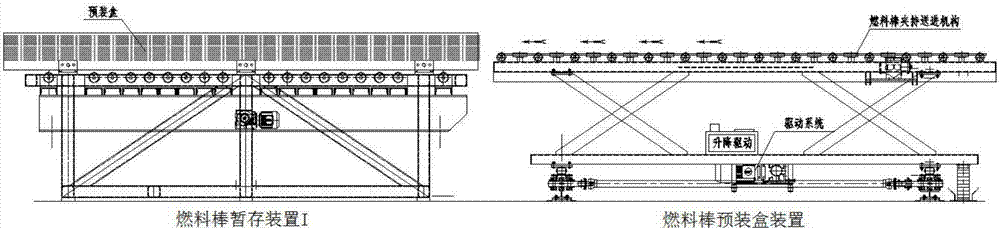

[0035] Such as figure 1 As shown, the new nuclear fuel assembly pull rod production system includes fuel rod temporary storage device I, fuel rod removal device, fuel rod pre-packaging device, fuel rod temporary storage device II, pre-packaging box conveying and moving device, pre-packing box Clamping and positioning and moving device, skeleton clamping and positioning and turning device, and rod pulling device, in which the fuel rod temporary storage device I, the fuel rod removal device, the fuel rod pre-packaging device, and the fuel rod temporary storage device II are connected in sequence. The box loading and clamping positioning and moving device, the skeleton clamping and positioning and turning device, and the rod pulling device are connected in sequence, and the prepackaged box conveying and traversing device moves between the fuel r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com