Station starting and stopping device for continuous curved surface polishing machine

A polishing machine and station technology, which is used in grinding drive devices, grinding machine parts, grinding/polishing equipment, etc., can solve problems such as low production efficiency, reduced product yield, and easy slippage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

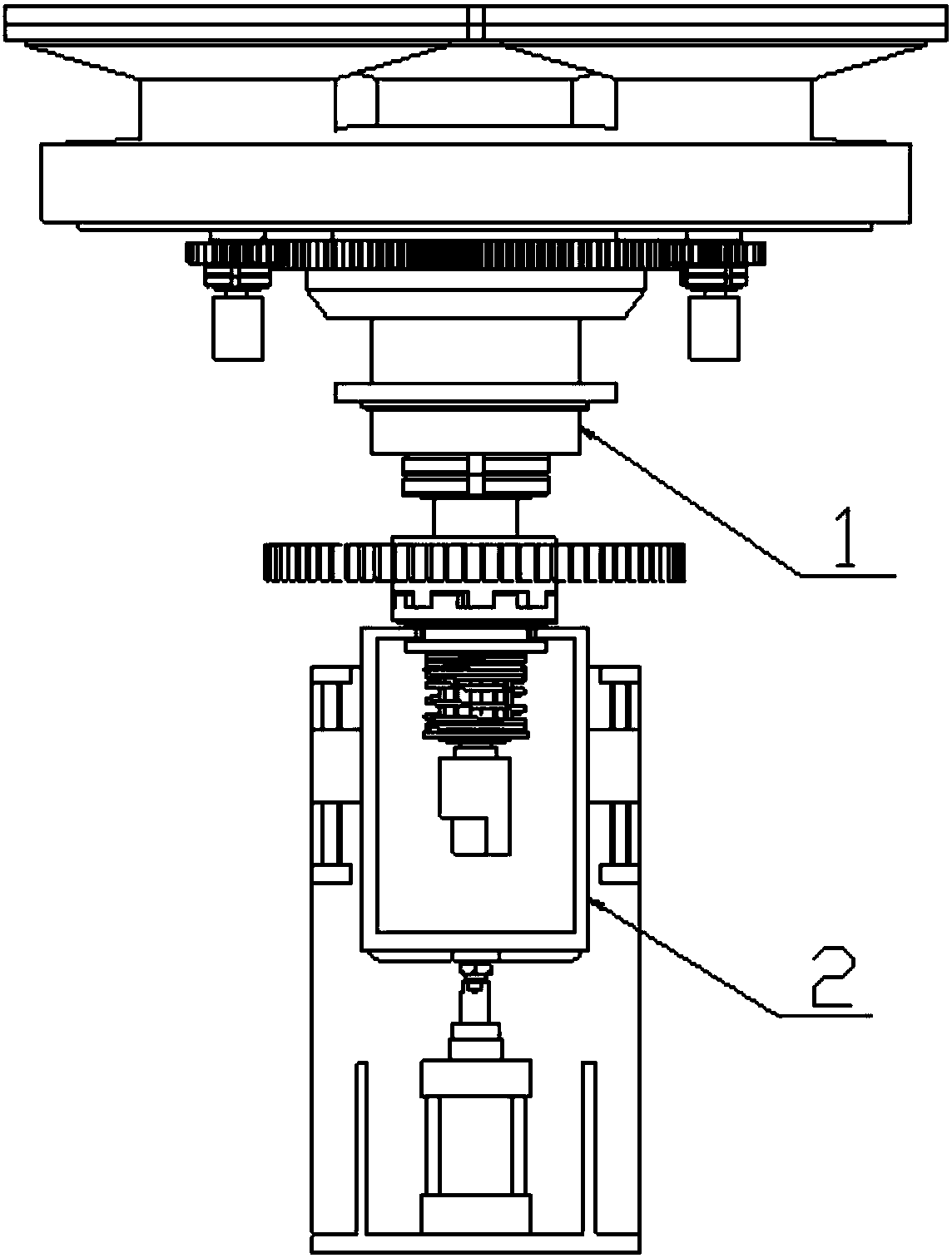

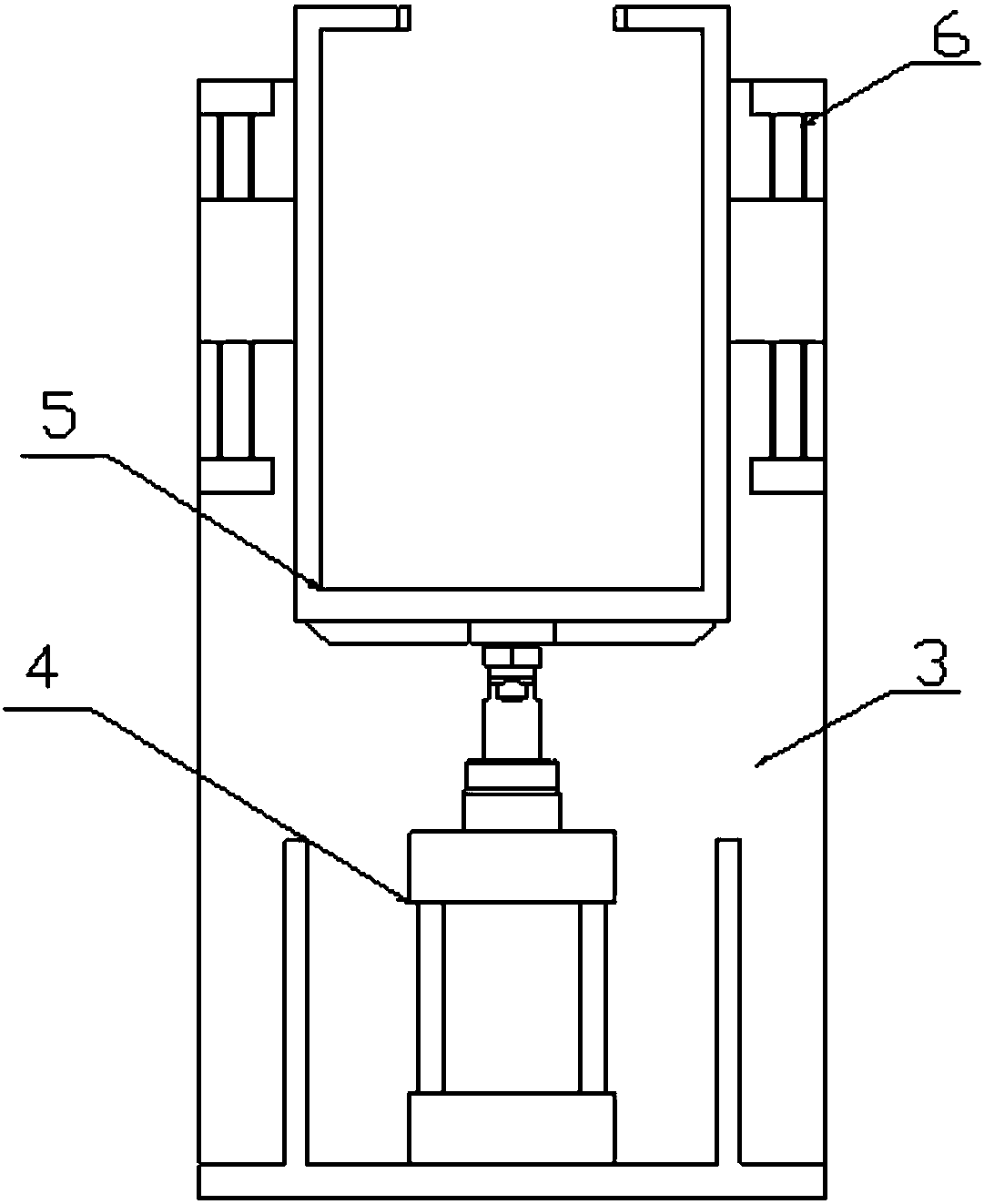

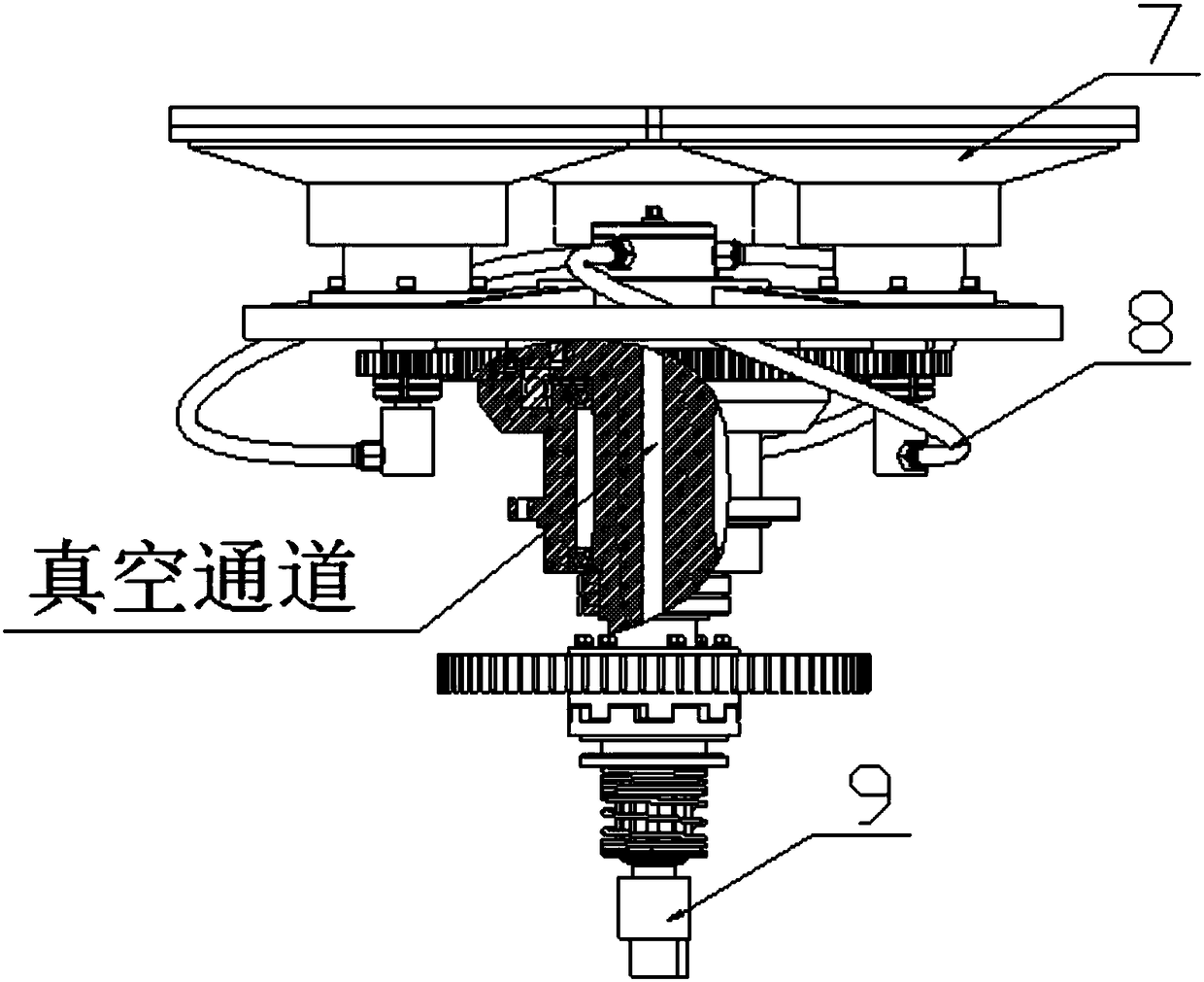

[0022] Referring to the accompanying drawings, the station start-stop device for a continuous curved surface polishing machine includes a station unit 1, a claw clutch device 2 and a vacuum adsorption device;

[0023] The station unit 1 refers to an individual unit that can independently complete the polishing operation. The station unit 1 includes a number of rotary components 10, a sealing cover 12, a mounting plate 11, a support seat 18, a station transmission shaft 13, and a station driven gear. 14. Bearing 17, round nut 19, bearing gland 20, station driving gear 16, shaft circlip 23, coupling sleeve 15, compression spring 21 and spring seat 22; the rotary assembly 10 is fixed to the mounting plate 11 Connected, the sealing cover 12 and the mounting plate 11 are all fixedly connected with the transmission shaft of the station with screws, and the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com