Winding and unwinding mechanism

A technology for winding and unwinding rolls and reels, which is applied in the field of coil material unwinding and unwinding equipment, can solve problems such as poor alignment accuracy of reels, low loading and unloading efficiency, and affecting the quality of coil materials, so as to ensure quality, improve stability and uniformity , the effect of enhancing security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

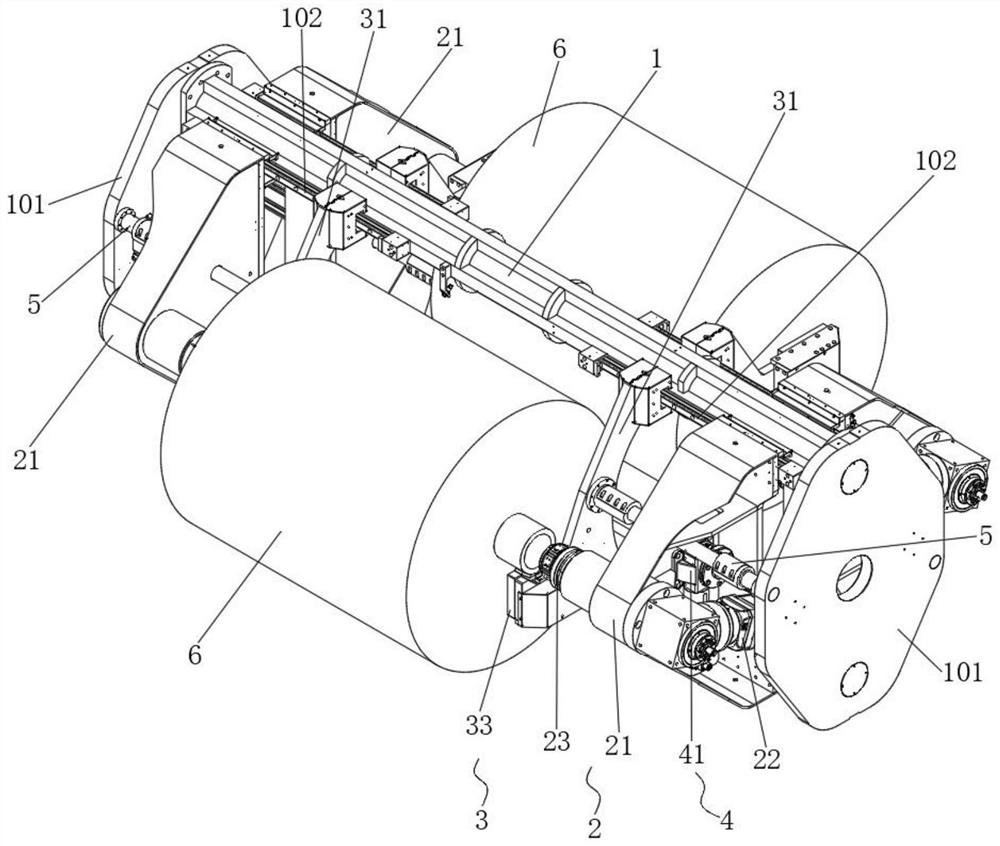

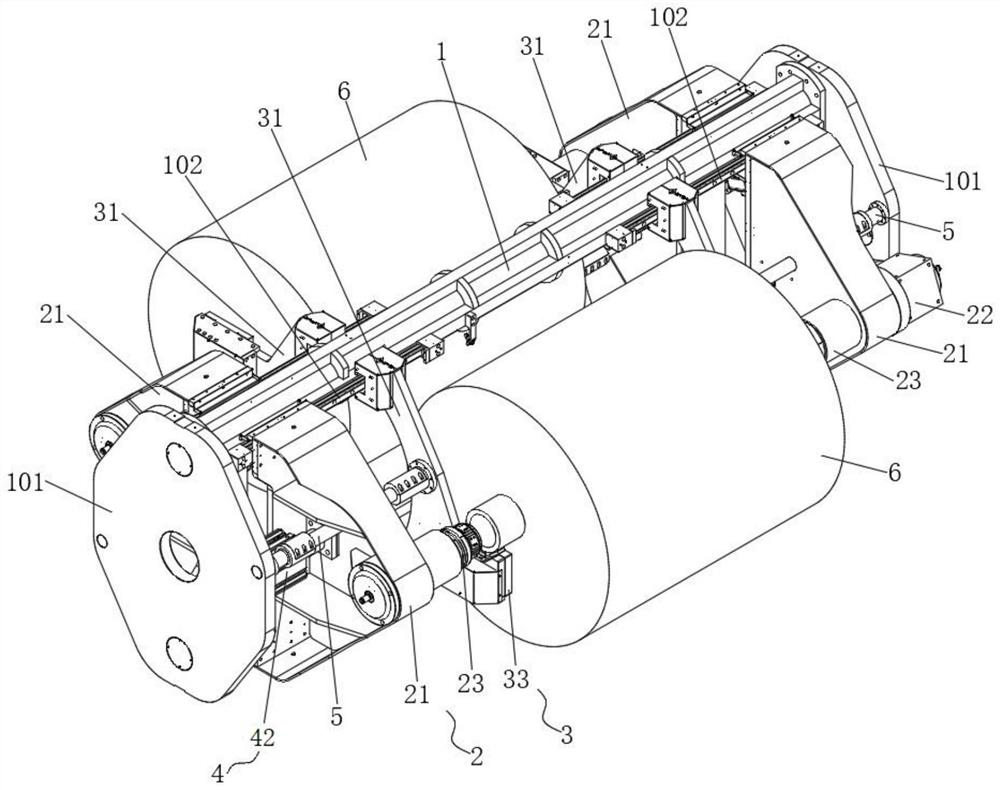

[0037] For the winding and unwinding mechanism of the present invention, please refer to figure 1 and figure 2 As shown, it is a schematic diagram of the axial structure of the winding and unwinding mechanism from the first direction and the second direction respectively, and the first direction and the second direction can be specifically the right front side direction and the left front side direction as shown in the figure.

[0038] The winding and unwinding mechanism is provided with a support 1, and the support 1 has a beam running along the left and right directions, and side plates 101 are fixedly connected to the left and right ends of the beam. In addition, a winding assembly 2 and a reel positioning support assembly 3 are arranged on the support 1 . Wherein, the winding assembly 2 and the reel positioning support assembly 3 are connected to the beam of the bracket 1, and the positions of the winding assembly 2 and the reel positioning support assembly 3 on the brac...

Embodiment 2

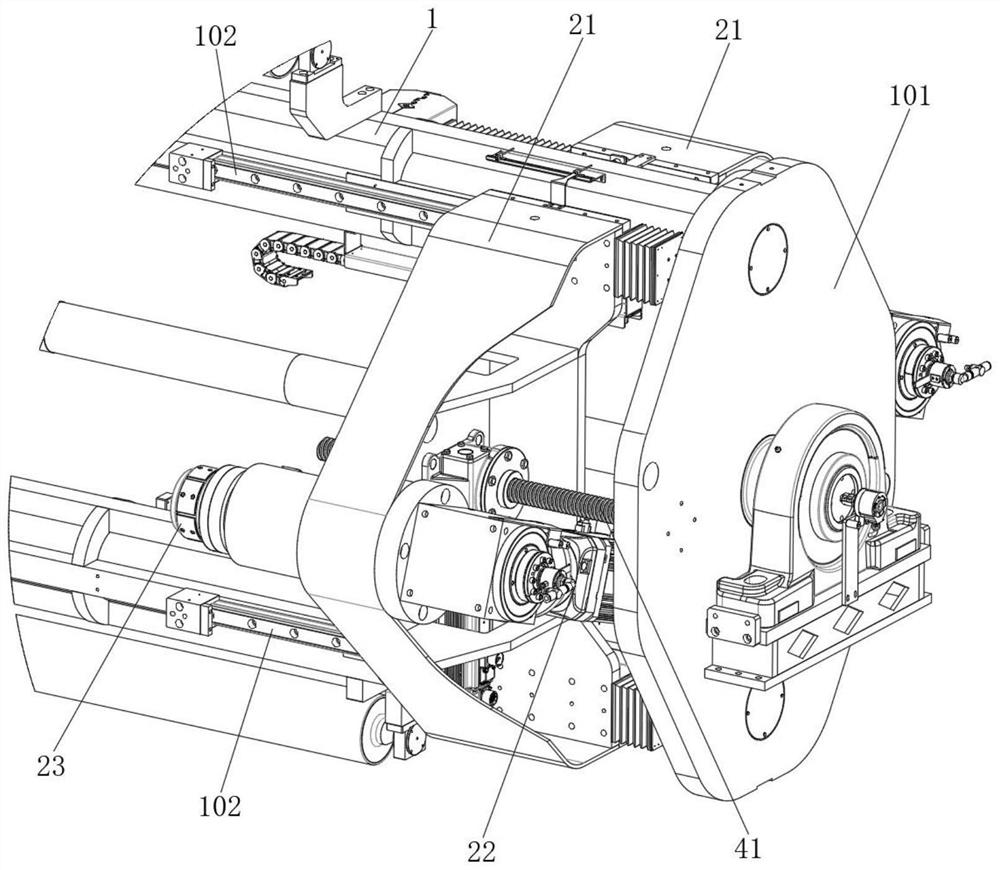

[0046] This embodiment is the same as Embodiment 1. Further, see image 3 As shown, in the retracting and unwinding mechanism of this embodiment, the winding assembly 2 further includes a first support arm 21, wherein the rotating drive member 22 and the reel clamp 23 are both arranged on the first support arm 21; and, the first support arm 21 The support arm 21 is connected to the beam of the bracket 1 and can move left and right relative to the beam of the bracket 1 for adjustment.

[0047] In the specific embodiment shown, a slide rail 102 along the left-right direction is arranged on the crossbeam of the bracket 1, and the first support arm 21 is slidably arranged on the slide rail 102 through a slider, and can move along the slide rail 102 Adjust the position left and right.

[0048] Optionally, the first support arm 21 has a V-shaped arm structure, the support 1 at least includes vertically arranged beams, the slide rails 102 are arranged on the vertically arranged bea...

Embodiment 3

[0053] This embodiment is the same as Embodiment 1 or Embodiment 2. further, please see figure 1 and figure 2 As shown, in the winding and unwinding mechanism of this embodiment, the reel positioning support assembly 3 further includes a second support arm 31 . Moreover, the second support arm 31 is connected to the crossbeam of the bracket 1 , and can move left and right relative to the crossbeam of the bracket 1 .

[0054] In the specific embodiment shown, a slide rail 102 along the left-right direction is provided on the crossbeam of the bracket 1, and the second support arm 31 is slidably arranged on the slide rail 102 through a slider, and can move along the slide rail. 102 moves to adjust the left and right positions.

[0055] Optionally, the second support arm 31 has a V-shaped arm structure, and the support 1 at least includes vertically arranged beams, on which the slide rails 102 are arranged, and the support bracket 33 and the lifting drive member 32 are both pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com