Assembly line laser marking device for bearing model

A laser marking equipment and pipeline technology, applied in typewriters, printing and other directions, can solve the problems of inaccurate positioning and low work efficiency, and achieve the effect of improving work efficiency, facilitating unloading operations, and saving labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

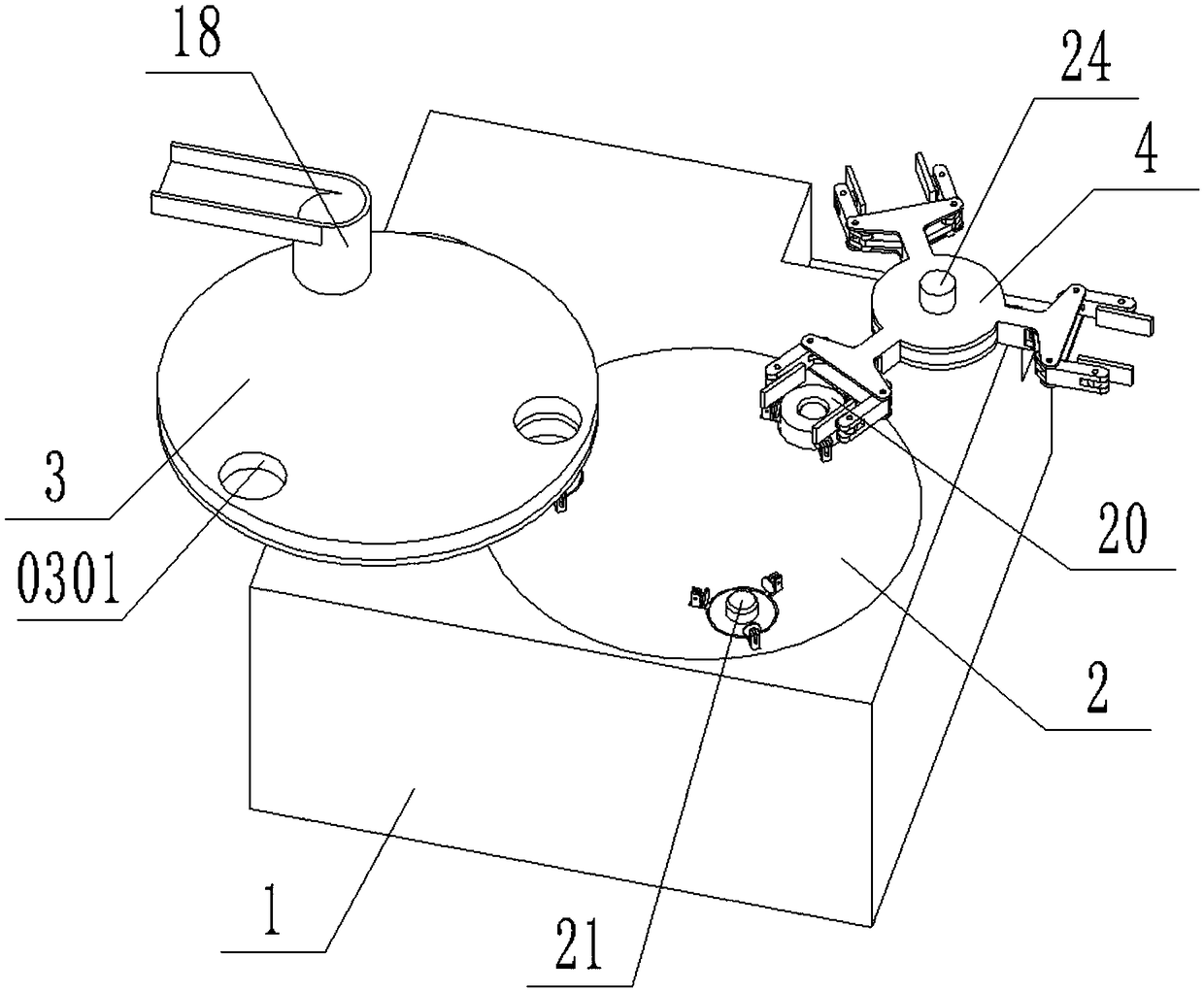

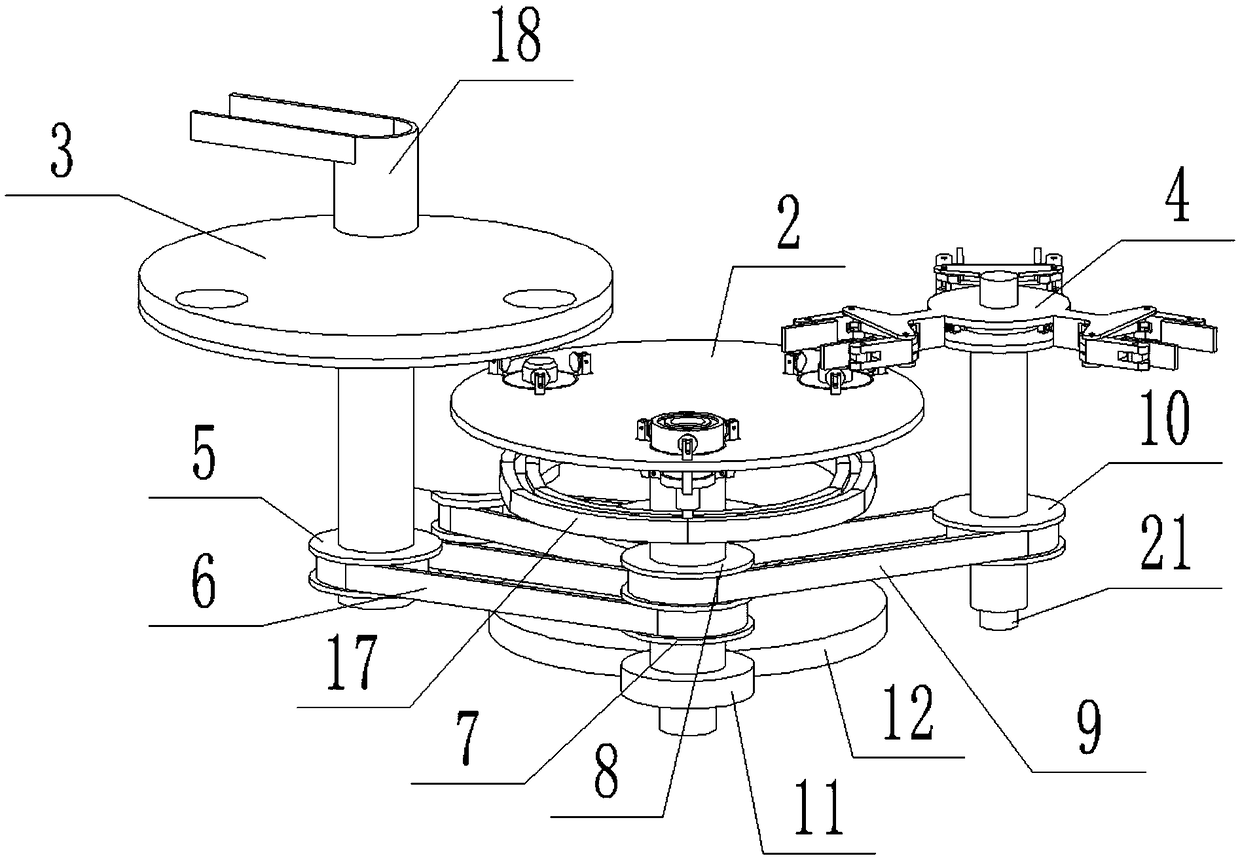

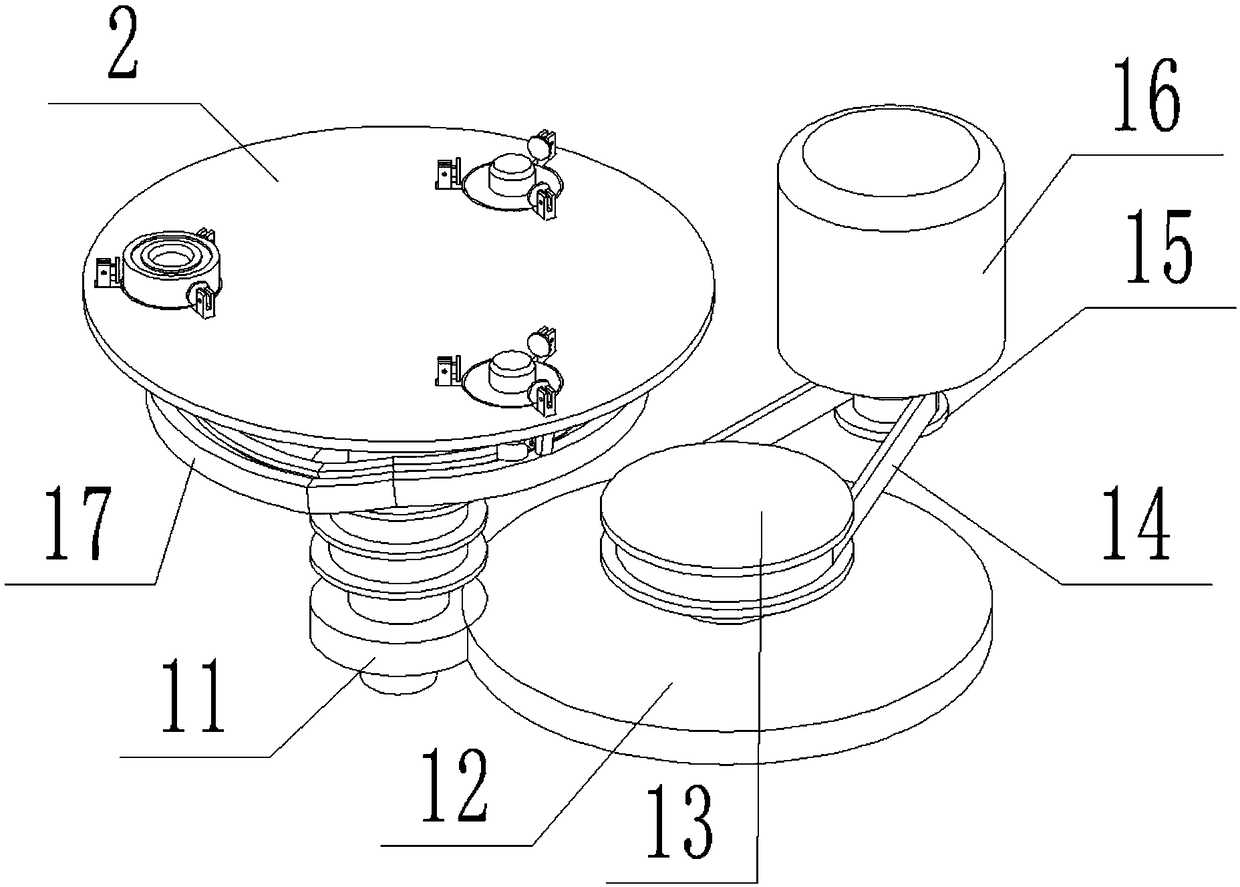

[0033] as attached figure 1 To attach Figure 8 Shown:

[0034]The invention provides an assembly line laser marking equipment for bearing models, including: a body 1, a marking workbench 2, a loading work plate 3, a pick-up hole 0301, a fixing table for an unloading manipulator 4, and a loading follower Pulley 5, loading drive belt 6, loading driving pulley 7, unloading driving pulley 8, unloading driving belt 9, unloading driven pulley 10, driven gear 11, driving gear 12, driven pulley 13 , drive belt 14, driving pulley 15, motor 16, workbench slideway 17, inlet 18, fixing plate 19, mounting hole 1901, pulling rod 20, guide wheel 2001, lifting platform 2002, tensioning block 21 , positioning table 2101, clamping lever 22, clamping block 23, unloading fixed shaft 24, cam 2401, roller 25, spring 26, push rod 27, connecting rod 28, grabbing lever 29 and grabbing block 30; Fuselage 1 The left side of the top is fixedly connected with an assembly fixing plate 19; the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com