Intelligent carrying equipment capable of changing storage space freely and work method thereof

A storage space and intelligent handling technology, applied in the field of handling machinery, can solve the problems of reduced delivery efficiency, inability to maximize the utilization of storage space, and unreasonable utilization of elevator space, so as to improve handling efficiency, rational use, and reasonable The effect of storing empty space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

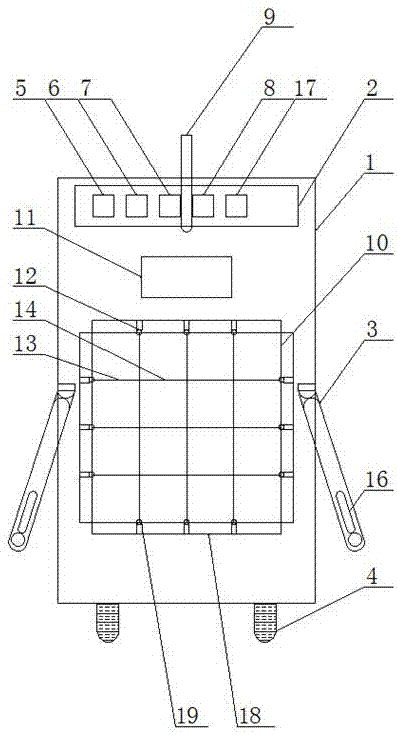

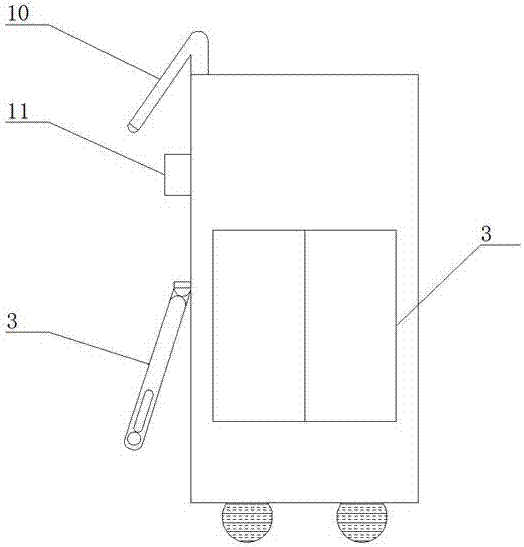

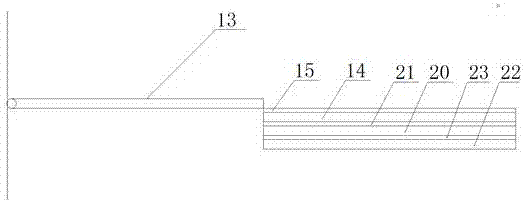

[0047] like figure 1 , 2, 3, an intelligent handling device that can freely change the storage space, includes a box body 1, a control room 2, a grabbing device 3 and a moving device 4, and the control room 2 includes a processor 5, a driving device 6, a navigation device 7 and a storage device 8, the driving device 6 is connected to the processor 5, the navigation device 7 is connected to the processor 5, and is used to set the walking route of the handling equipment, and the storage device 8 is connected to the processor 5. Described processor 5 is connected, is used for storing courier information, and described courier information comprises receiving address and addressee phone, and described cabinet 1 comprises camera 9, storage rack 10 and RFID label printer 11, and described camera 9 is connected with the processor 5, and is used to take the picture of the delivery receipt of the courier and send it to the processor 5, and the storage rack 10 is used to place the couri...

Embodiment 2

[0054] like Figure 5 As shown, a working method of an intelligent handling device that can freely transform the storage space includes the following working steps:

[0055] a) The camera 9 captures the picture in front of the handling equipment and sends it to the processor 5;

[0056] b) the processor 5 outputs a grabbing signal to the driving device 6, and the driving device 6 drives the grabbing device 3 to grab the express delivery;

[0057] c) the processor 5 extracts the courier information from the picture sent by the camera 9 and saves it to the storage device 8, and the courier information includes the recipient address and the recipient's phone number;

[0058] d) The processor 5 outputs a posting signal to the driving device 6, and the driving device 6 drives the RFID label printer 11 to print the RFID label and paste it on the surface of the express item, and attach the RFID label to the express item Establish a one-to-one correspondence with the recipient addre...

Embodiment 3

[0074] like Figure 7 As shown, step d also includes:

[0075] The processor 5 saves the relationship established between the RFID tag and the delivery address of the courier to the storage device 8;

[0076] The processor 5 sends the RFID tag information to the RFID identifier 16 .

[0077] Step h also includes:

[0078] The processor 5 imports the delivery address into the navigation device 7, and the navigation automatically generates a walking route and sends it to the processor 5;

[0079] The processor 5 outputs a walking signal to the driving device 6, and the driving device 6 drives the mobile device 4 to walk according to the walking route;

[0080] The navigation device 7 sends an address signal to the processor 5 after the handling equipment arrives at the receiving address;

[0081] The processor 5 extracts from the storage device 8 the RFID tag that establishes a relationship with the delivery address and sends it to the RFID identifier 16 .

[0082] Specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com