Double-position machining numerical control machine tool

A CNC machine tool and double-station technology, applied in the field of CNC machine tools, can solve problems such as cumbersome operation and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

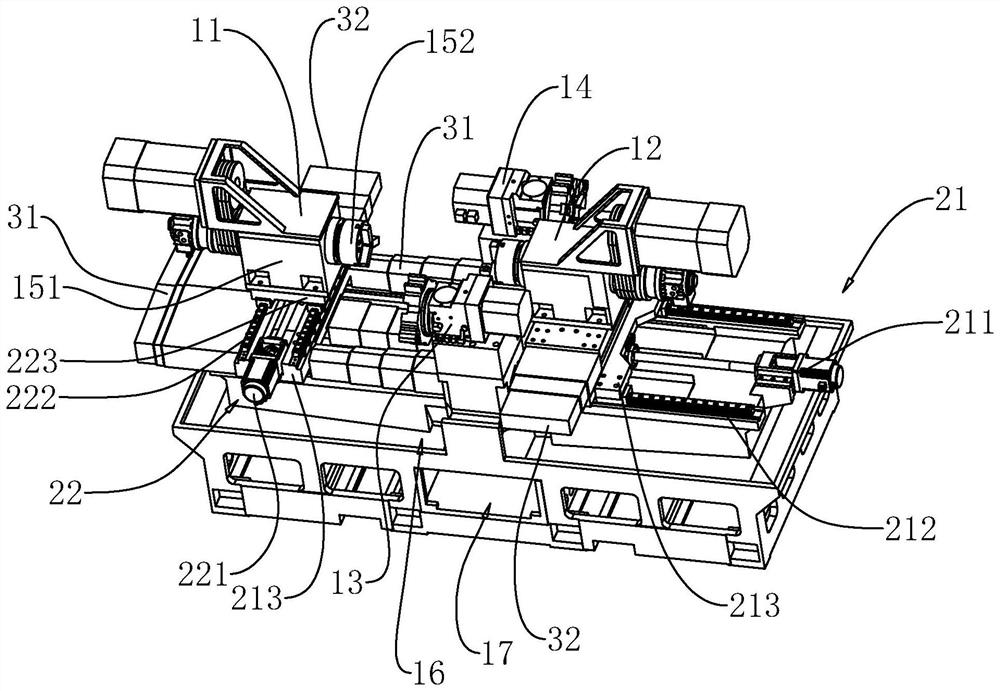

[0041] refer to figure 1 with figure 2 , the lateral movement mechanism includes a first drive member 211, a first slide rail 212 and a first slide table 213 slidingly connected with the first slide rail 212, the first drive member 211 is fixedly installed on the base 1, and the first drive member 211 It is a linear slide table. In this embodiment, a screw-type linear slide table is used. The first slide rail 212 is fixedly installed on the machine base 1. There are two first slide rails 212 located on both sides of the first driving member 211. , the first driving member 211 is used to drive the first slide table 213 to move back and forth laterally, the longitudinal movement mechanism is installed on the first slide table 213, the lateral movement mechanism also includes a first telescopic cover assembly 31, and the first telescopic cover assembly 31 is located at the first slide table 213. Two sides of a sliding platform 213 are used to cover the first driving member 211 ...

Embodiment 2

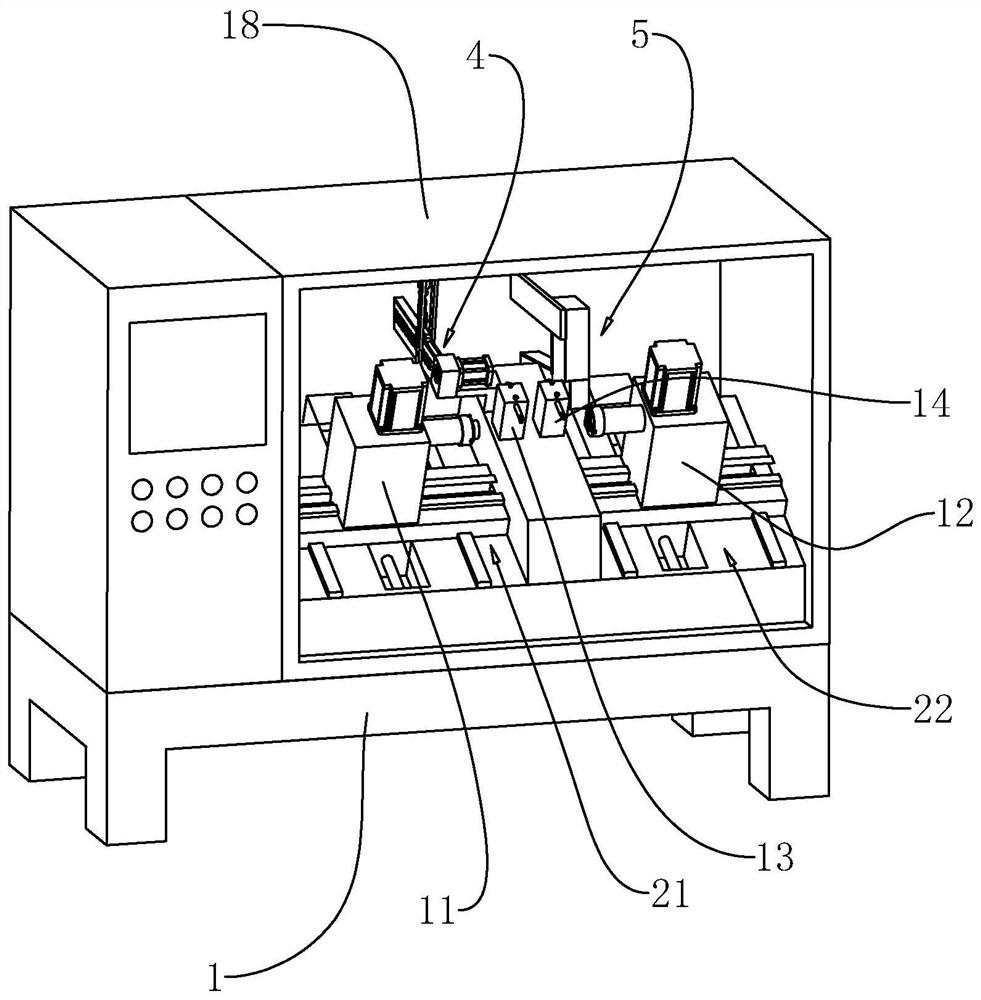

[0046] refer to image 3 with Figure 4 , in this embodiment, the workpiece is cylindrical or annular, and the first turret 13 and the second turret 14 are located on the same side of the machine base 1, and the machine base 1 is fixedly connected with a protective box 18, and on the machine base 1 Also be provided with feeding device 4, feeding device 4 comprises conveying mechanism and storage mechanism, and conveying mechanism comprises conveying material plate 41, is provided with the conveying groove 411 that is used to convey workpiece on the conveying material plate 41, and conveying material plate 41 is inclinedly arranged, The material storage mechanism includes a material storage block 45 on which a material storage tank 451 is arranged. The material storage block 45 is located below the conveying material plate 41 and the material storage tank 451 communicates with the conveying tank 411 . The conveying material plate 41 is inclined towards the material storage blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com