Automobile part automatic annealing device

A technology for auto parts and annealing devices, which is applied to heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve the problems of high production cost of automatic annealing devices, unfavorable industrial promotion and application, etc., to shorten the process temperature time, reduce heat consumption, and reduce heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

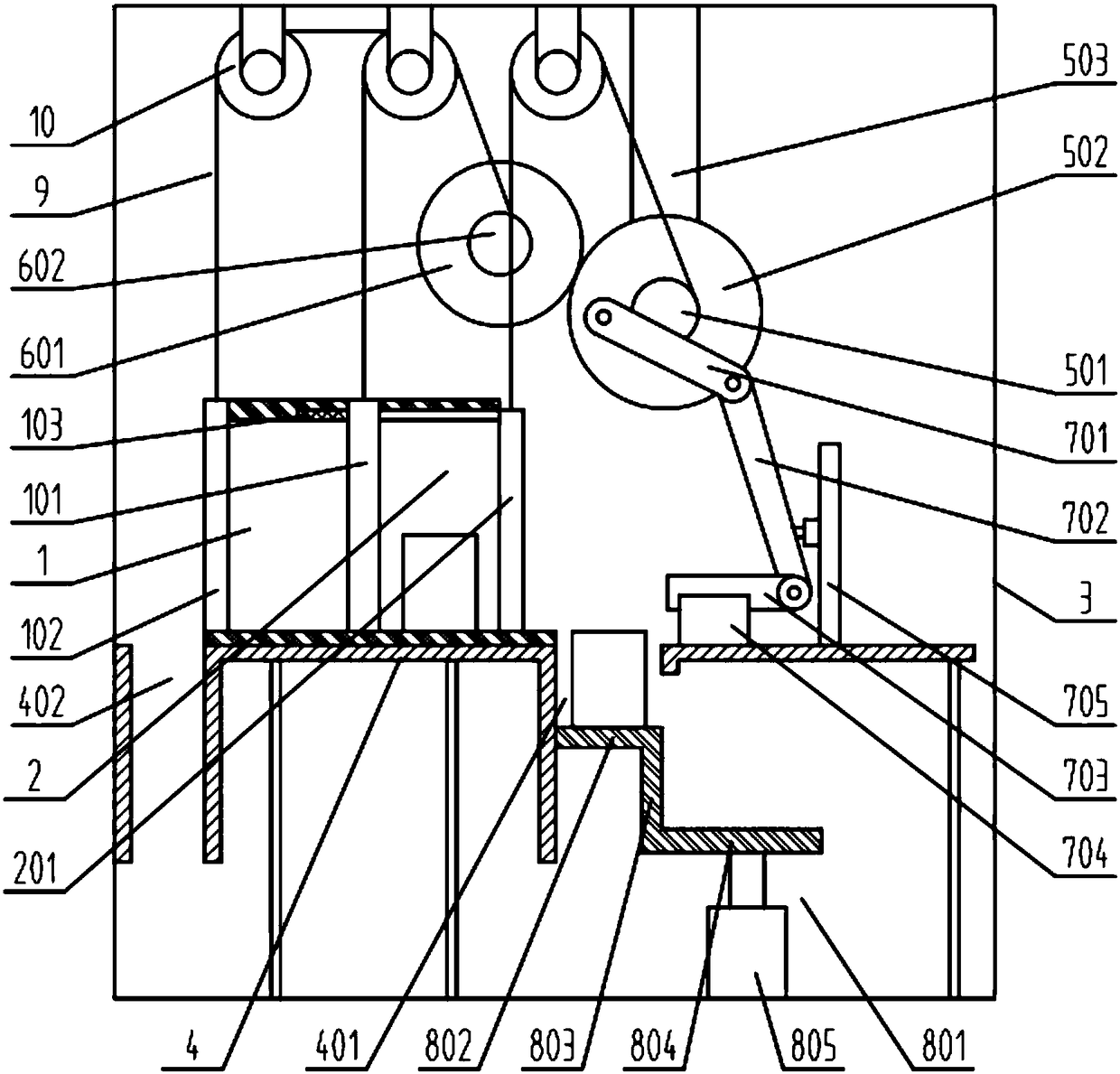

[0020] The reference signs in the accompanying drawings of the description include: working chamber 1, feed door 101, discharge door 102, elastic member 103, feed cavity 2, push door 201, box body 3, base 4, feed chute 401, discharge Material trough 402, first rotating shaft 501, driving runner 502, first support rod 503, first transmission wheel 601, second rotating shaft 602, first connecting rod 701, second connecting rod 702, horizontal push rod 703, Limiting slot 704 , vertical rod 705 , lifting platform 801 , first horizontal part 802 , vertical part 803 , second horizontal part 804 , power cylinder 805 , transmission rope 9 , steering wheel mechanism 10 .

[0021] Such as figure 1 As shown, the automatic annealing device for auto parts includes a box body 3 with an annealing chamber. The annealing chamber includes a working chamber 1 and a feeding chamber 2 with e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com