Patents

Literature

42results about How to "Reduce calorie consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultra cleaning of combustion gas including the removal of CO.sub.2

ActiveUS7641717B2Efficiently and emissionLow costUsing liquid separation agentEmission preventionCombustionCelsius Degree

Owner:GENERAL ELECTRIC TECH GMBH

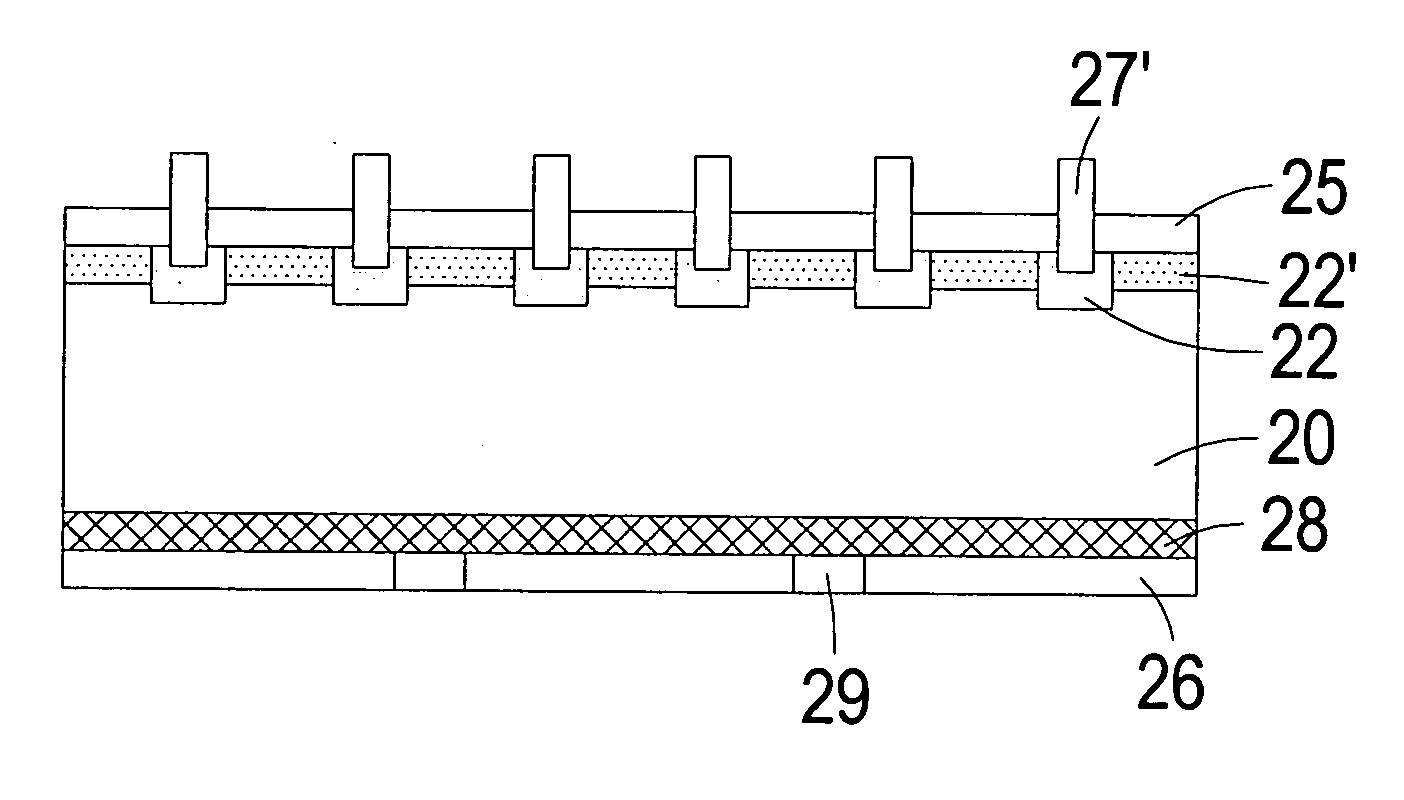

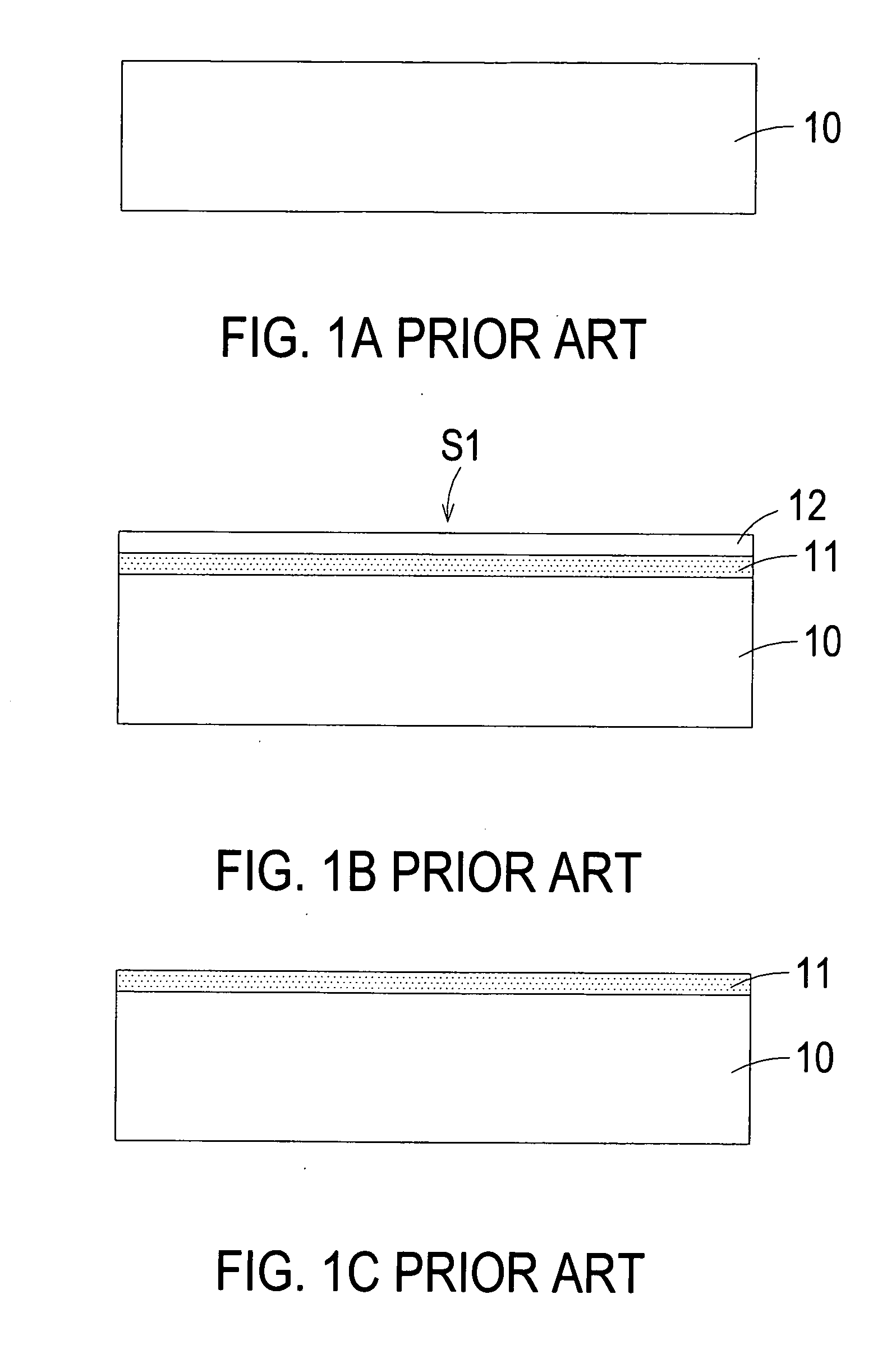

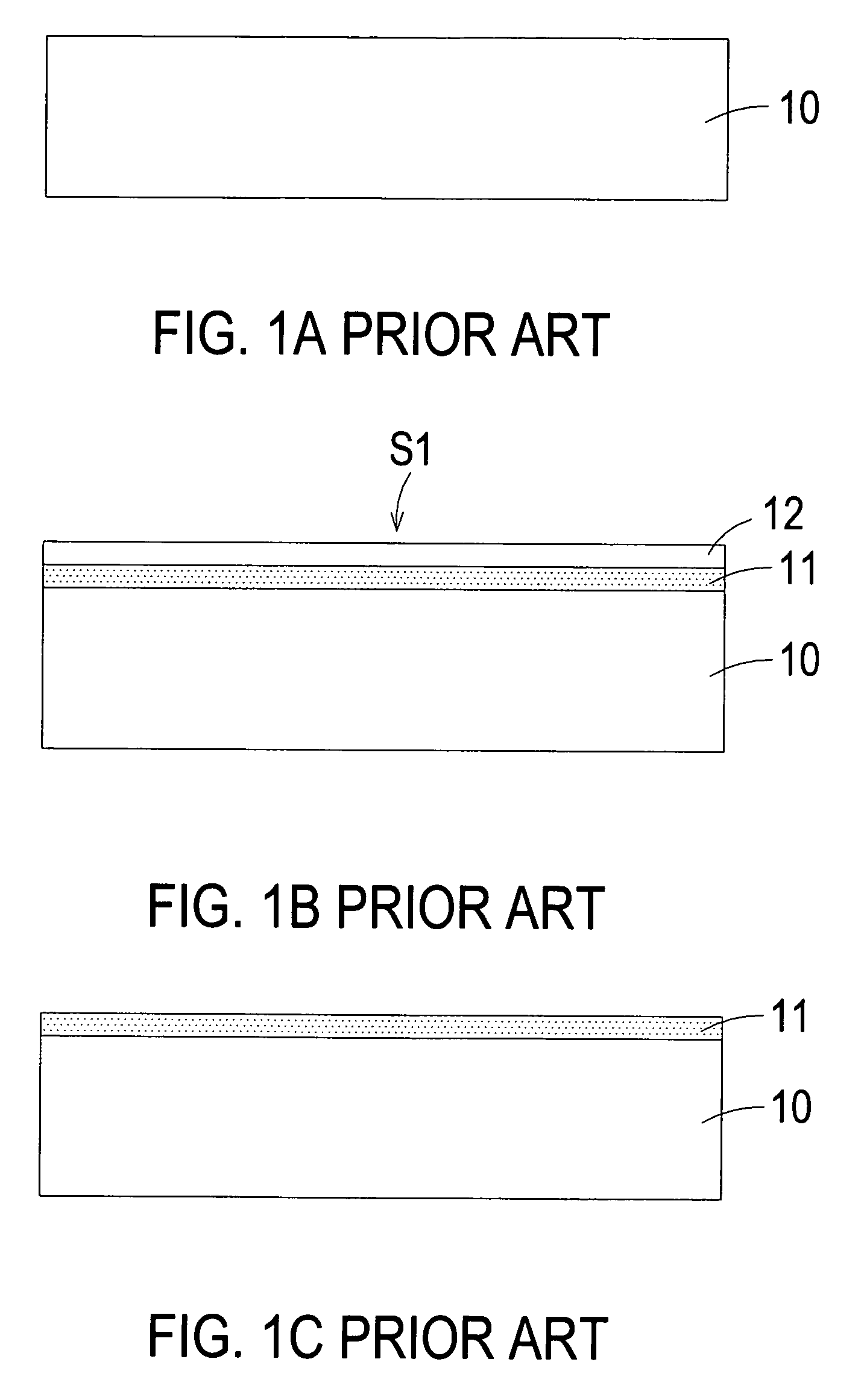

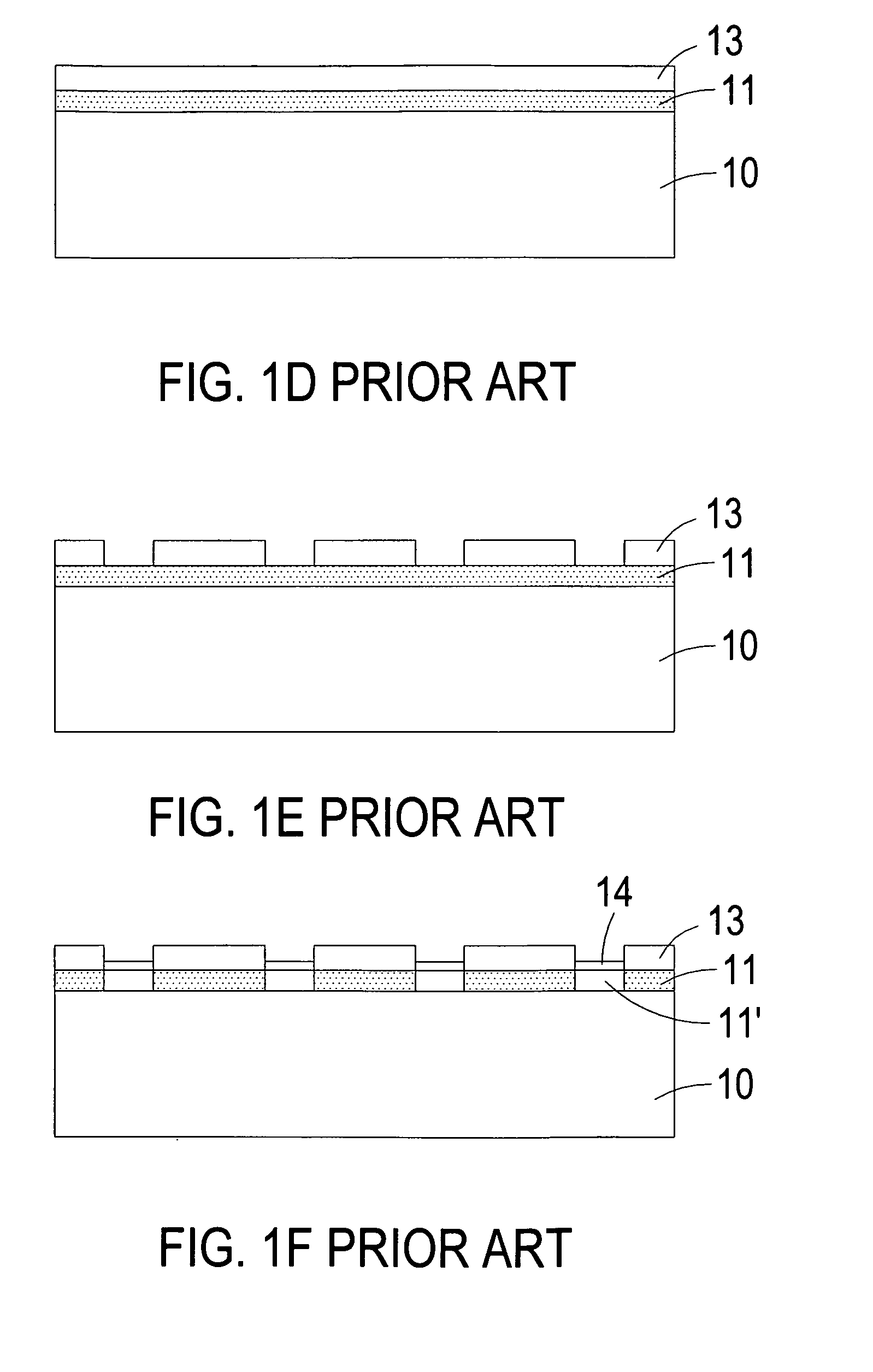

Process of manufacturing solar cell

InactiveUS20100015750A1Avoid damageReduce calorie consumptionFinal product manufactureSemiconductor/solid-state device manufacturingAmorphous siliconSolar cell

A process of manufacturing a solar cell is disclosed. The process comprises steps of (a) providing a semiconductor substrate, (b) forming a dielectric layer with amorphous silicon structure on the semiconductor substrate, (c) partially removing the dielectric layer with amorphous silicon structure to expose parts of the semiconductor substrate, (d) simultaneously forming a heavily doped region on a surface of the exposed semiconductor substrate and a lightly doped region on a surface of the unexposed semiconductor substrate using the dielectric layer with amorphous silicon structure as a translucent barrier layer, (e) removing the dielectric layer with amorphous silicon structure, (f) forming an anti-reflection coating on the semiconductor substrate, and (g) forming a first electrode on the anti-reflection coating and coupled with the heavily doped region.

Owner:MOSEL VITELIC INC

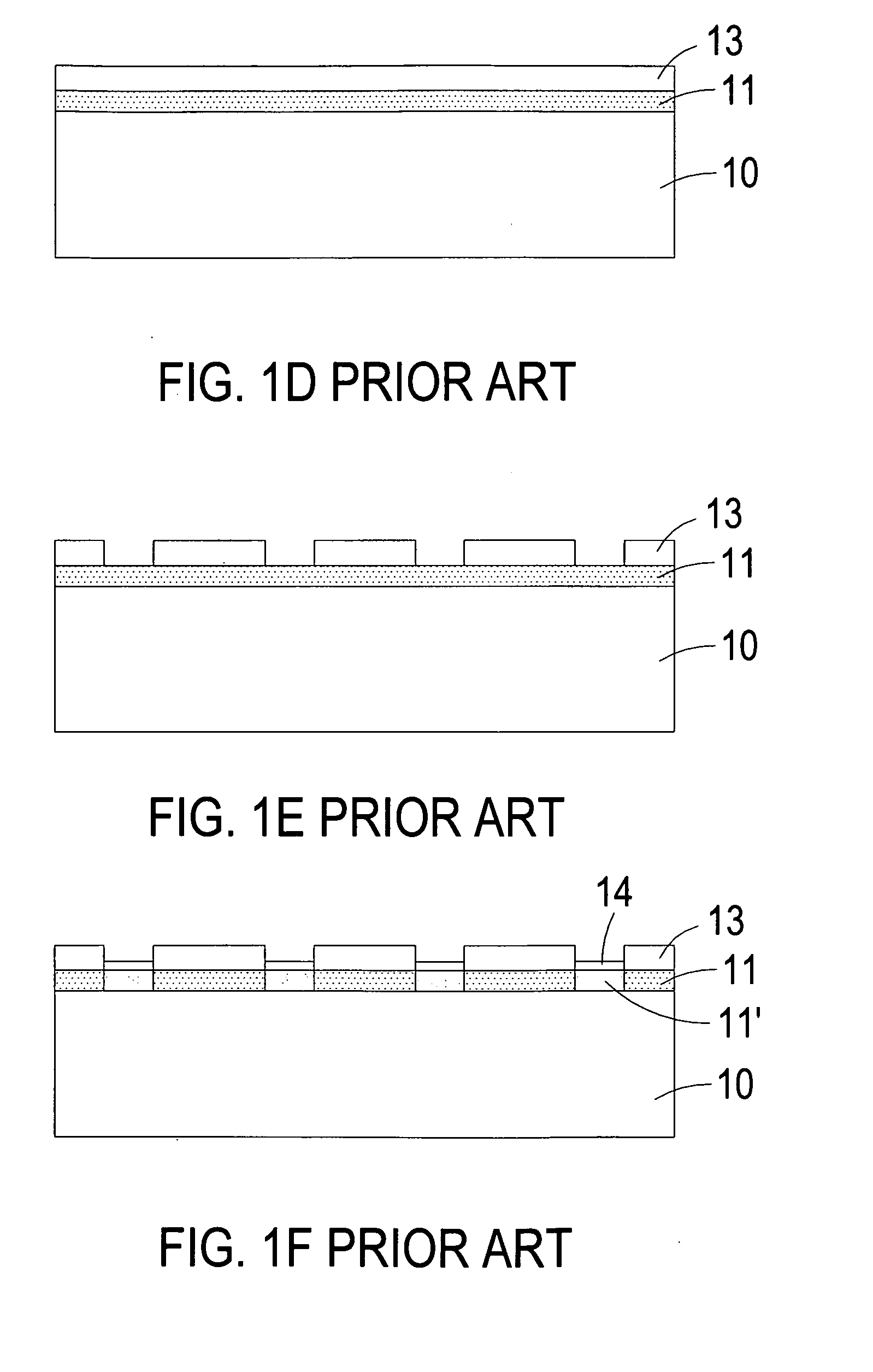

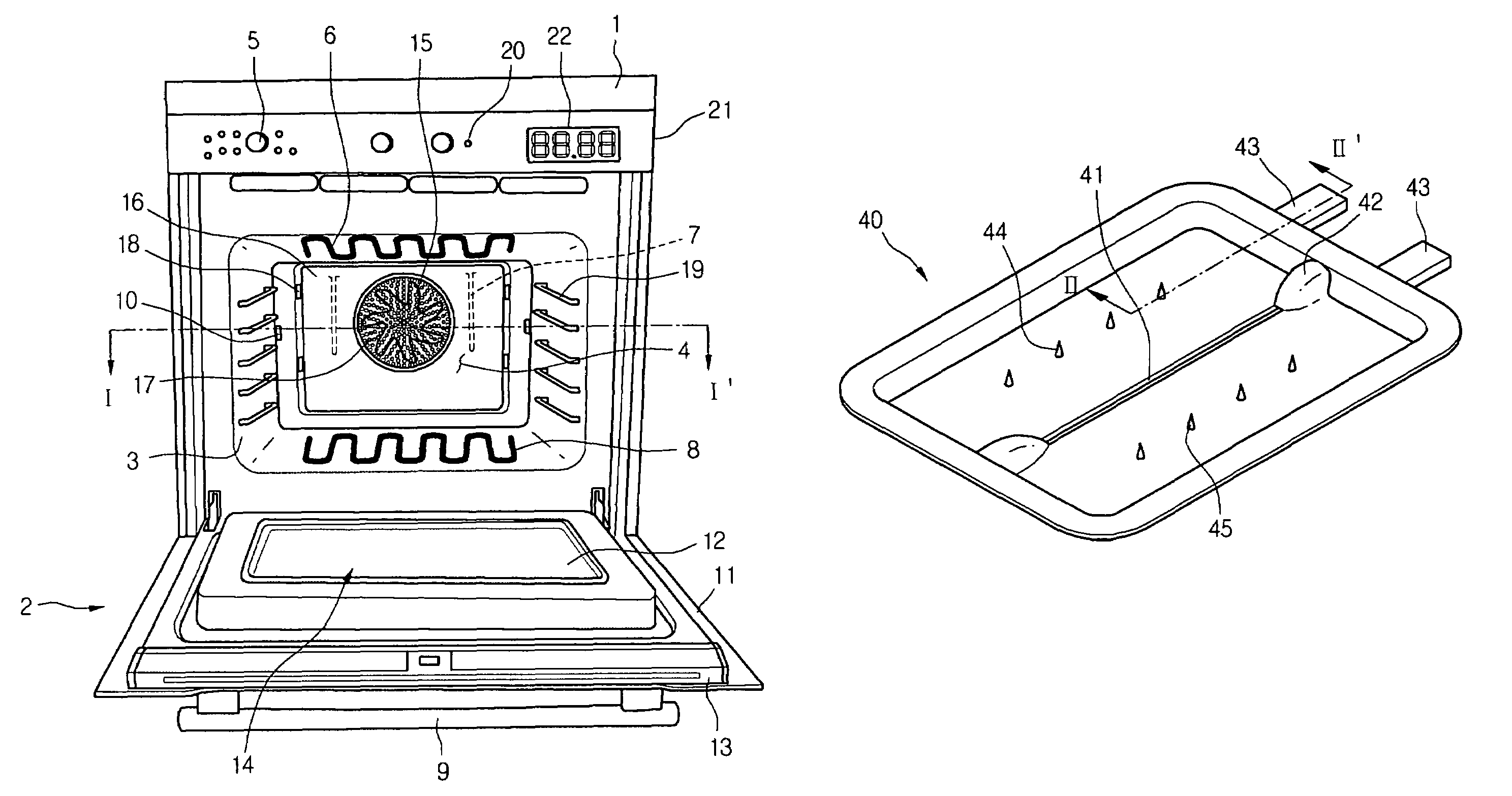

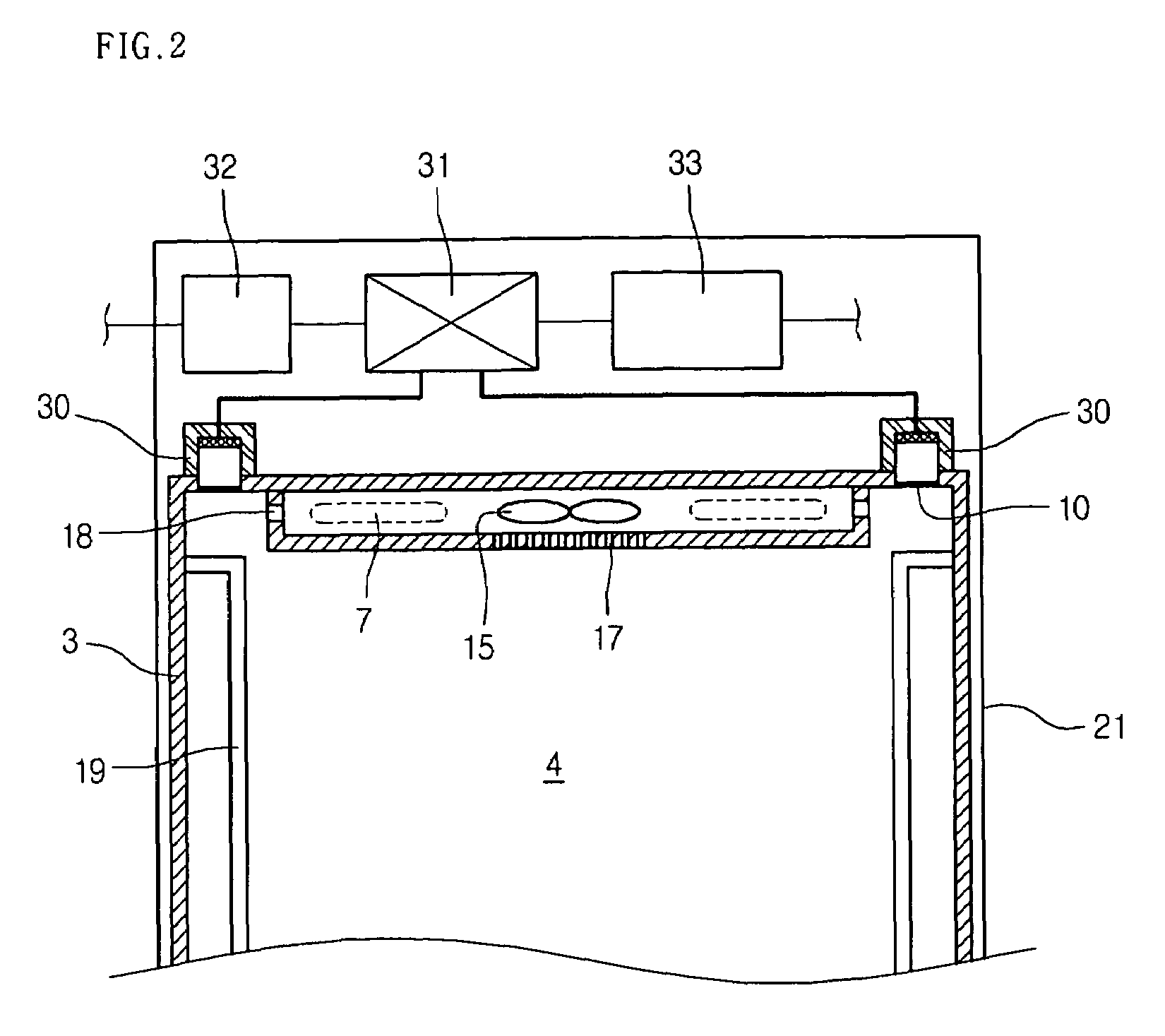

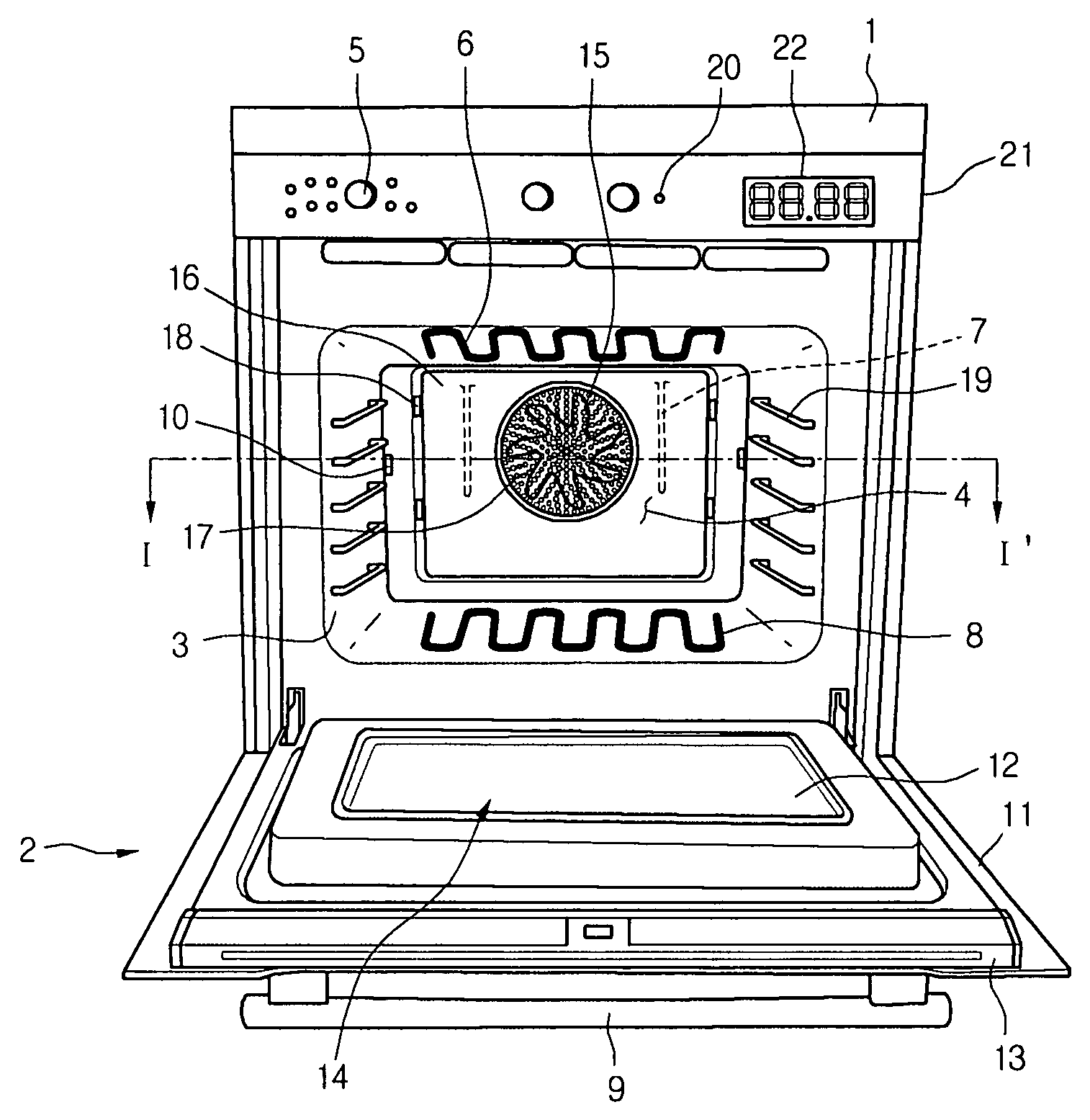

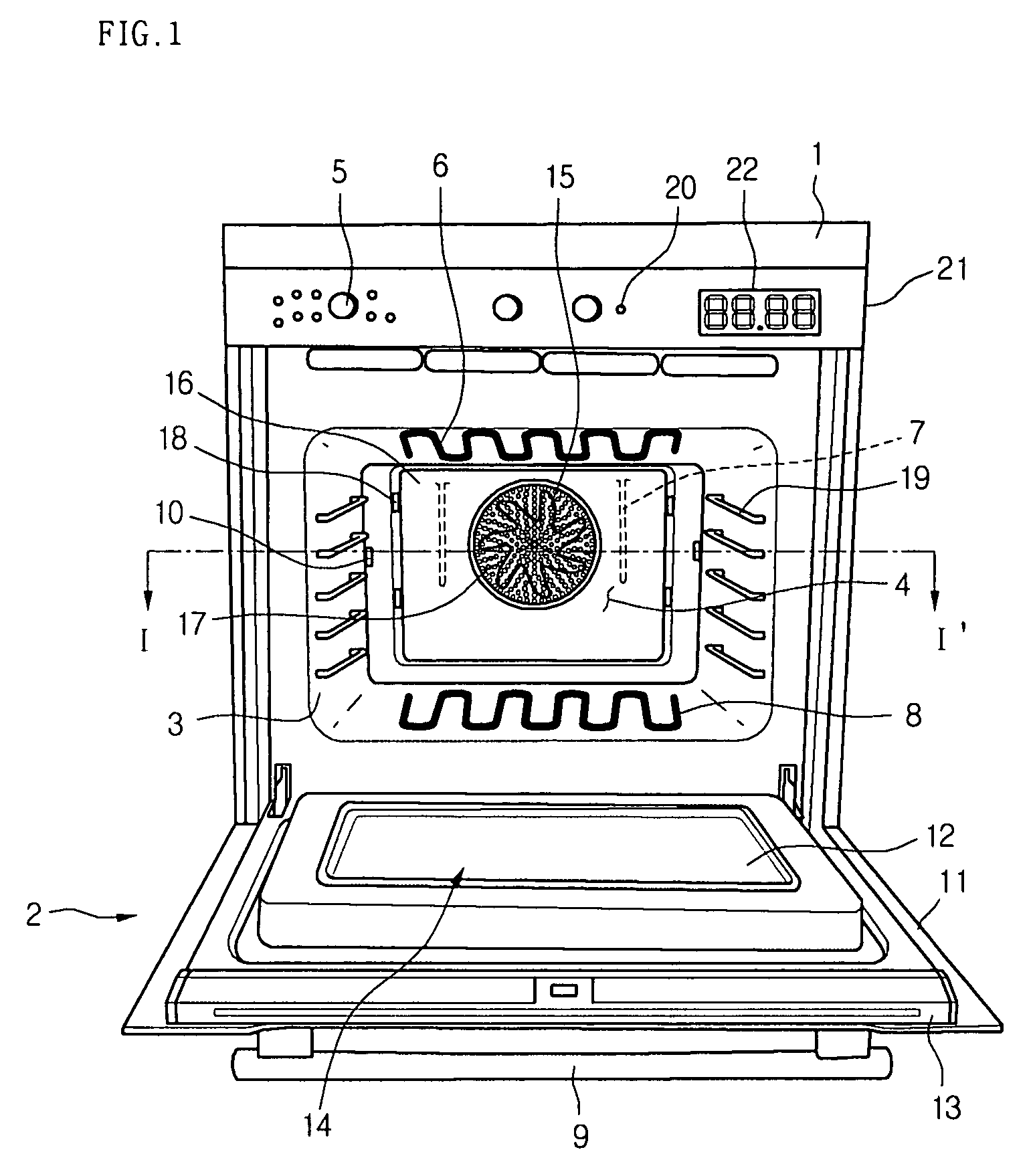

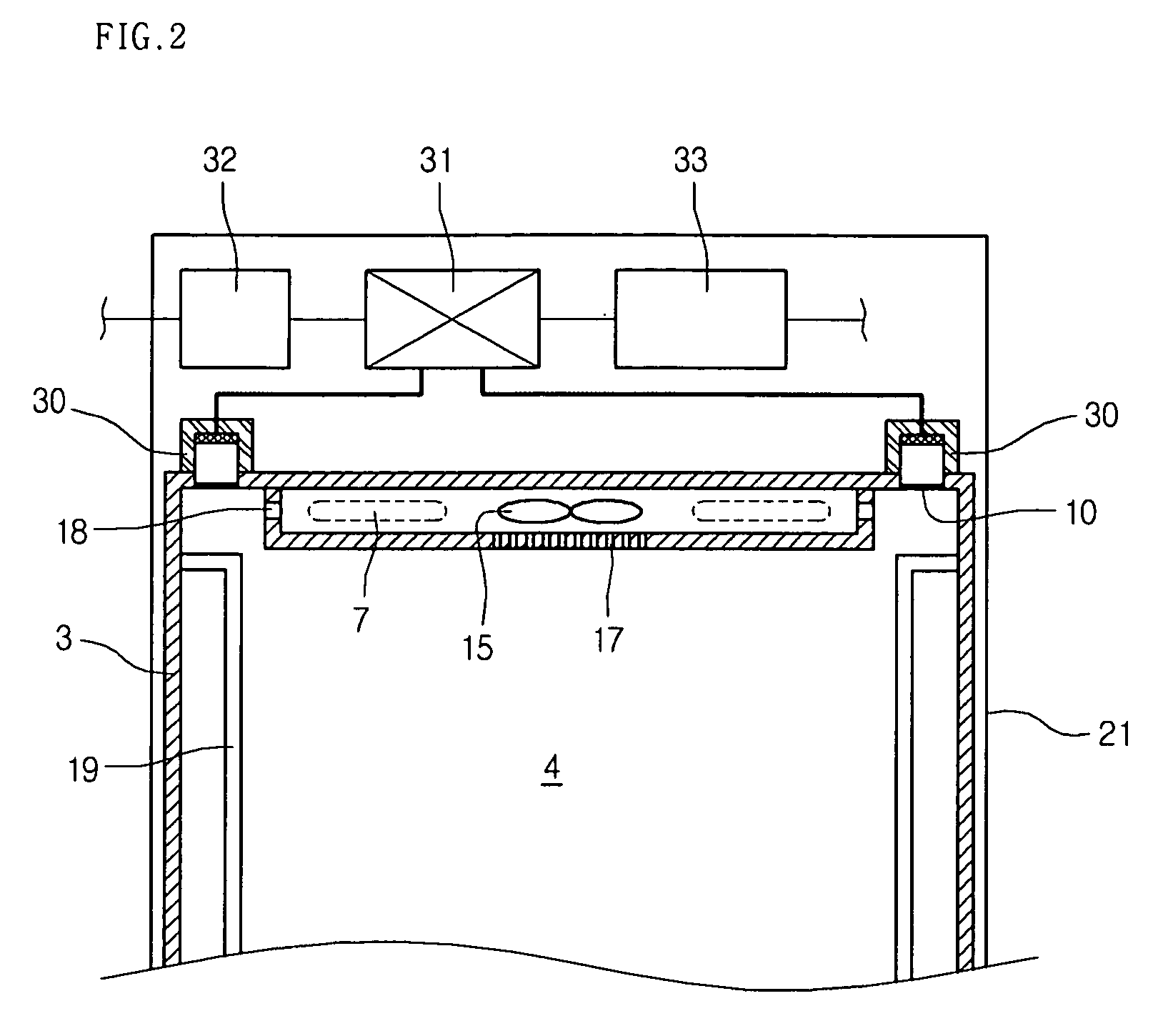

Oven and heating unit of oven

InactiveUS7368685B2Avoid insufficient heatingIncrease heatMilk preparationStoves/ranges foundationsEngineeringProcess engineering

Owner:LG ELECTRONICS INC

A method for drying large-capacity lithium-ion power battery cells

ActiveCN104142045BShorten heating timeFast heatingFinal product manufactureDrying solid materials without heatPower batteryManufacturing technology

The invention discloses a method for drying large-capacity lithium-ion power battery cells, and belongs to the technical field of lithium battery production and manufacturing. The method comprises the following steps: (1) placing the battery cell to be dried in a drying furnace, heating to raise the temperature of the furnace, and evacuating to a relative vacuum degree ≤ -99.0; (2) evacuating the vacuum to a relative vacuum degree of - 5.0~-85.0; (3) Run the blower equipment in the drying furnace to keep warm; (4) Vacuumize to a relative vacuum degree ≤ -99.0 and continue to vacuumize; (5) Sequentially perform (2), (3), (4 ) steps to cycle. The method of the invention utilizes the dry and wet hot gas convection state and the vacuum state in the furnace to dry the battery cells alternately, which can effectively reduce the moisture content of the battery cells with a small number of cycles, improve the drying rate and efficiency of the battery cells, and reduce the circulating gas Dosage and reduce calorie consumption.

Owner:中创新航科技(江苏)有限公司

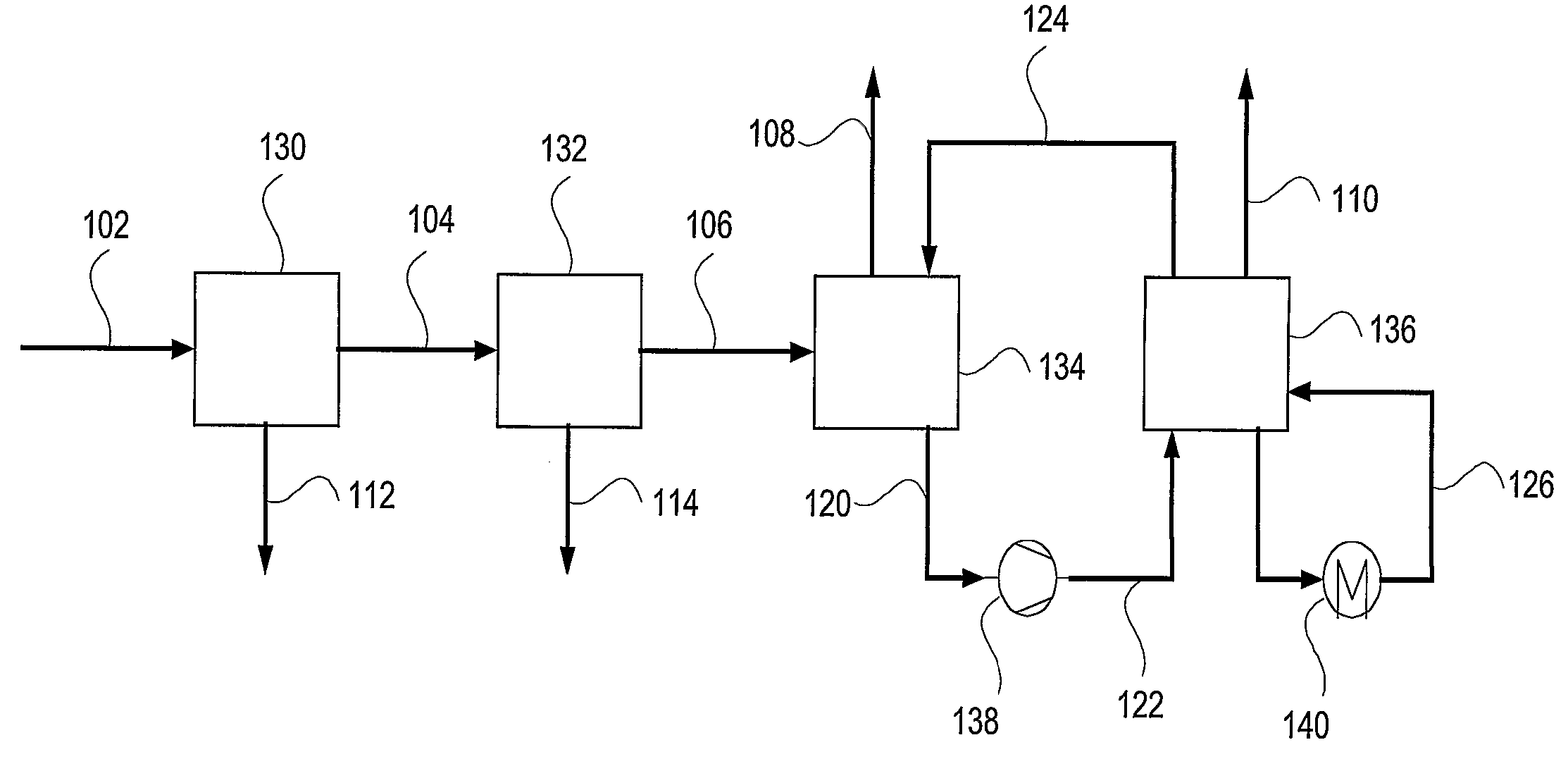

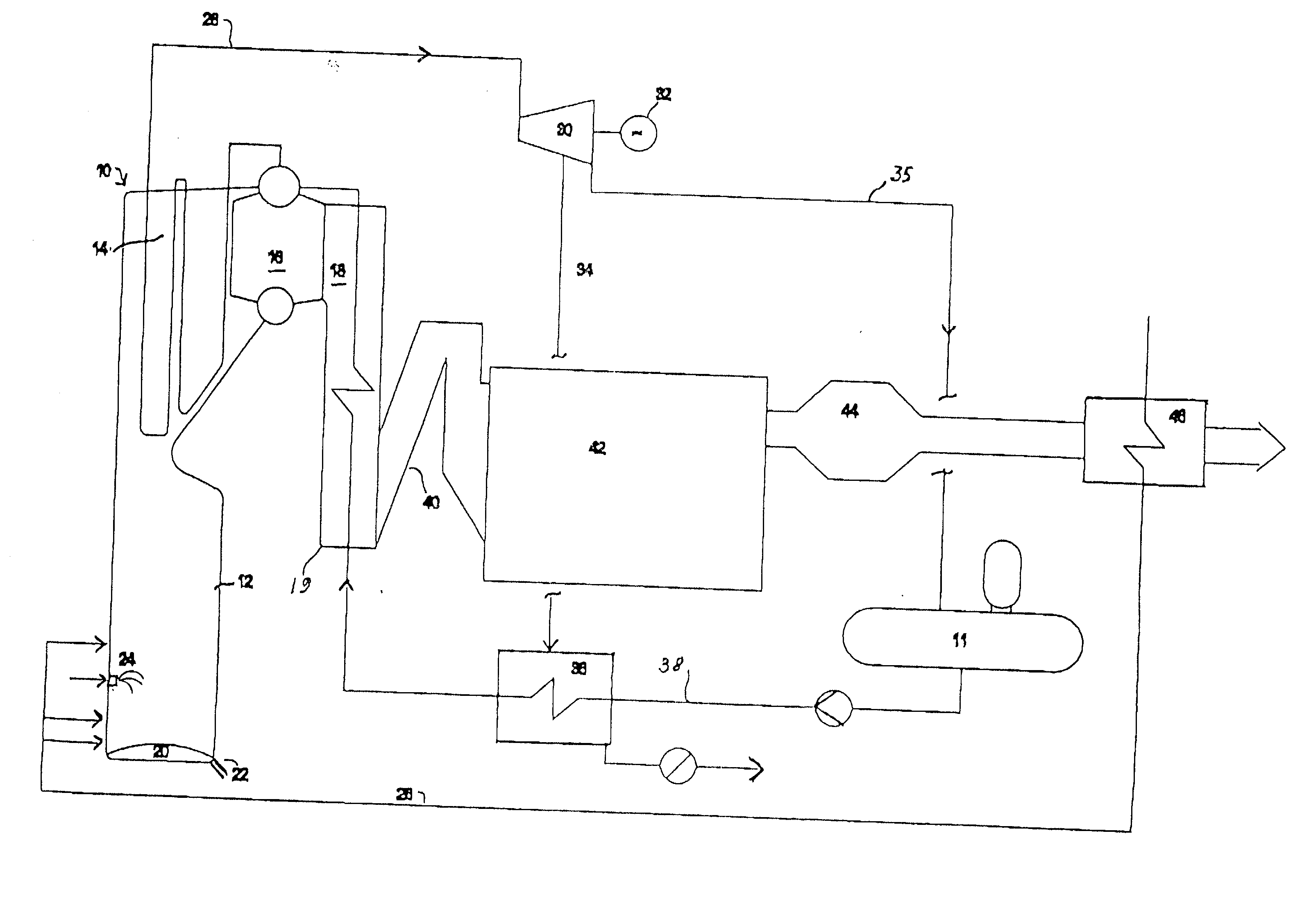

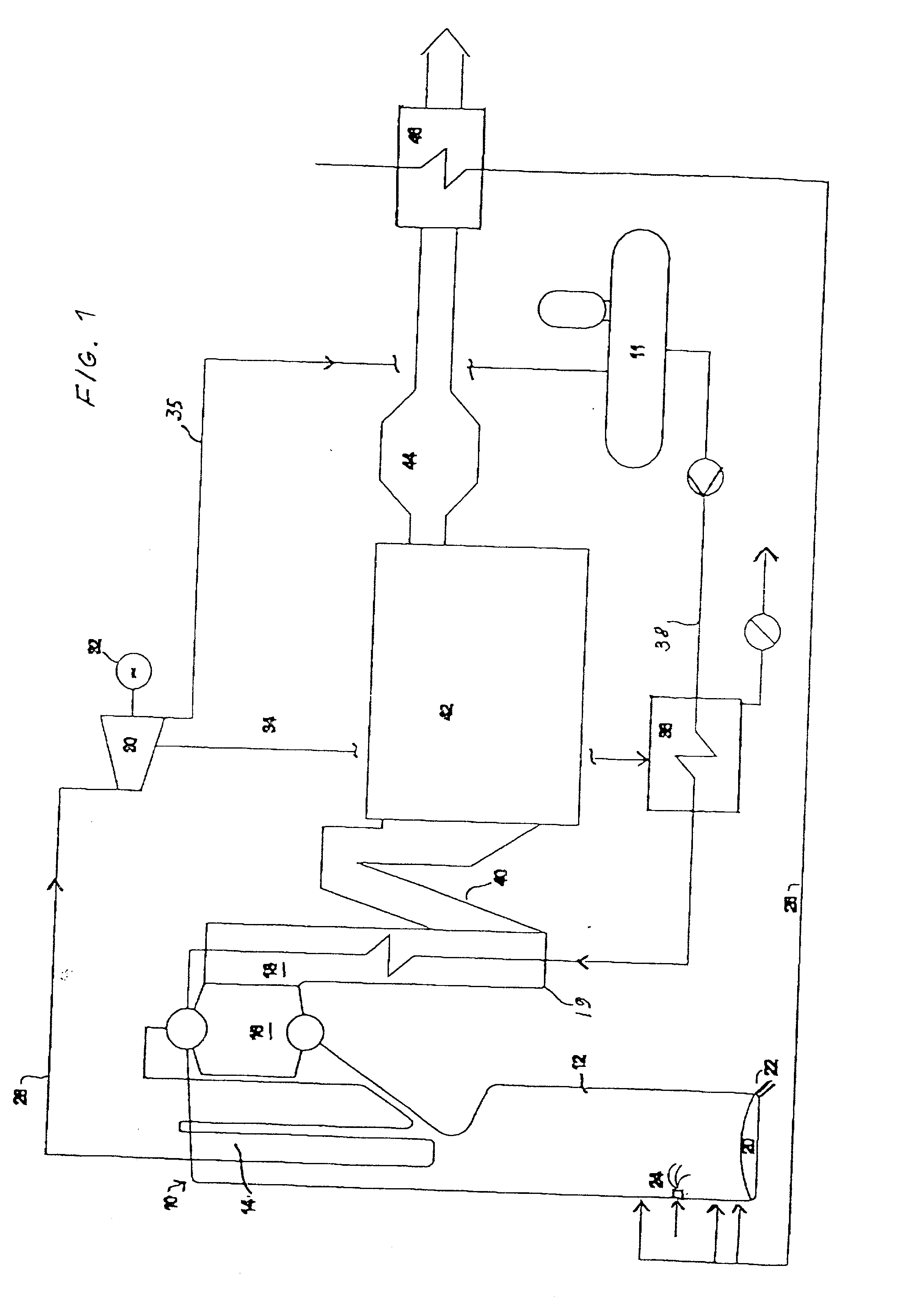

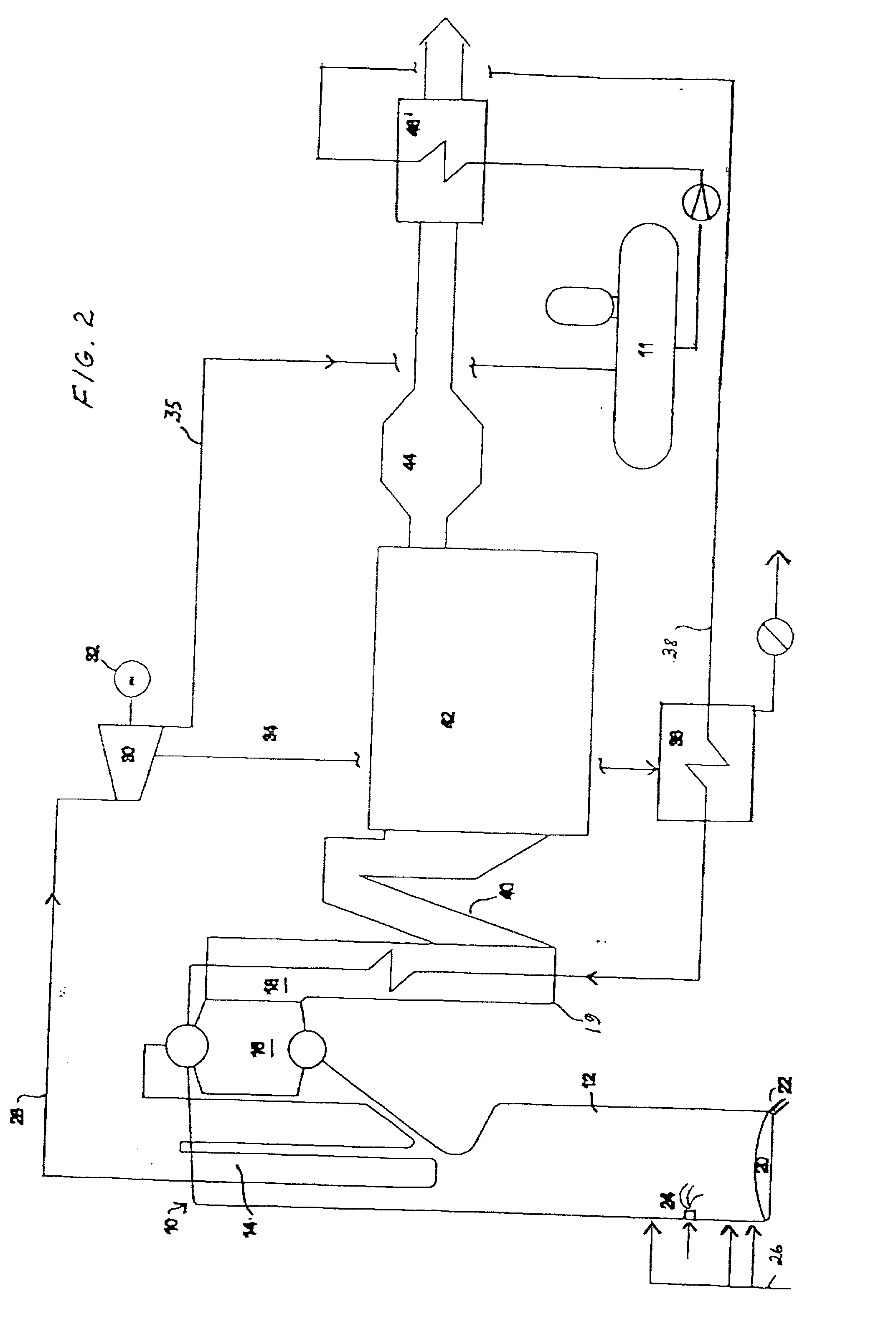

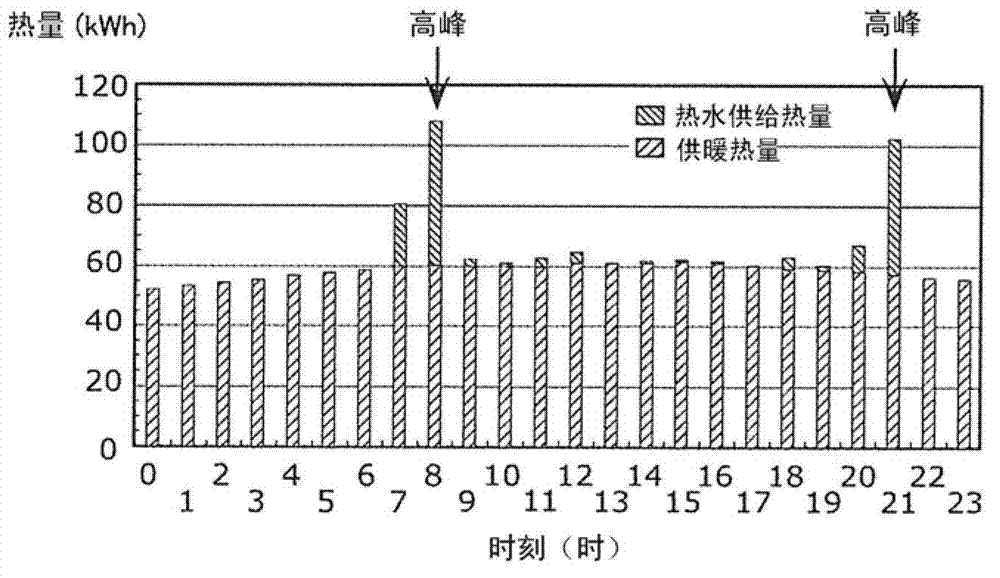

Method and arrangement for producing electrical energy at a pulp mill

InactiveUS20020194849A1Improve power production efficiencyElectrical efficiencyPulp liquors combustionSteam generation using steam absorptionSuperheaterEconomizer

The invention relates to a method and an arrangement in the production of electric energy in a boiler plant of a pulp mill. Black liquor having a dry solids content of more than 80% and combustion air are fed into a furnace of a recovery boiler for combusting black liquor and recovering chemicals contained therein. The flue gases generated in the combustion are led into an economizer of the recovery boiler, in which economizer the feed water for the boiler is heated, and after the economizer to gas cleaning. The feed water is led from the economizer onto the steam-generating bank at a temperature below the saturation temperature and further into a superheater to produce steam having a pressure of more than 80 bar. The steam is led from the recovery boiler to a steam turbine to produce electricity. The temperature of the feed water being led into the economizer is regulated by means of bleed steam of the turbine so that the flue gases exit the economizer at a temperature of more than 250° C. and that after the economizer the flue gases are cleaned in at least a hot electrostatic precipitator and the cleaned flue gases are cooled by the combustion air or the feed water.

Owner:ANDRIZ OY

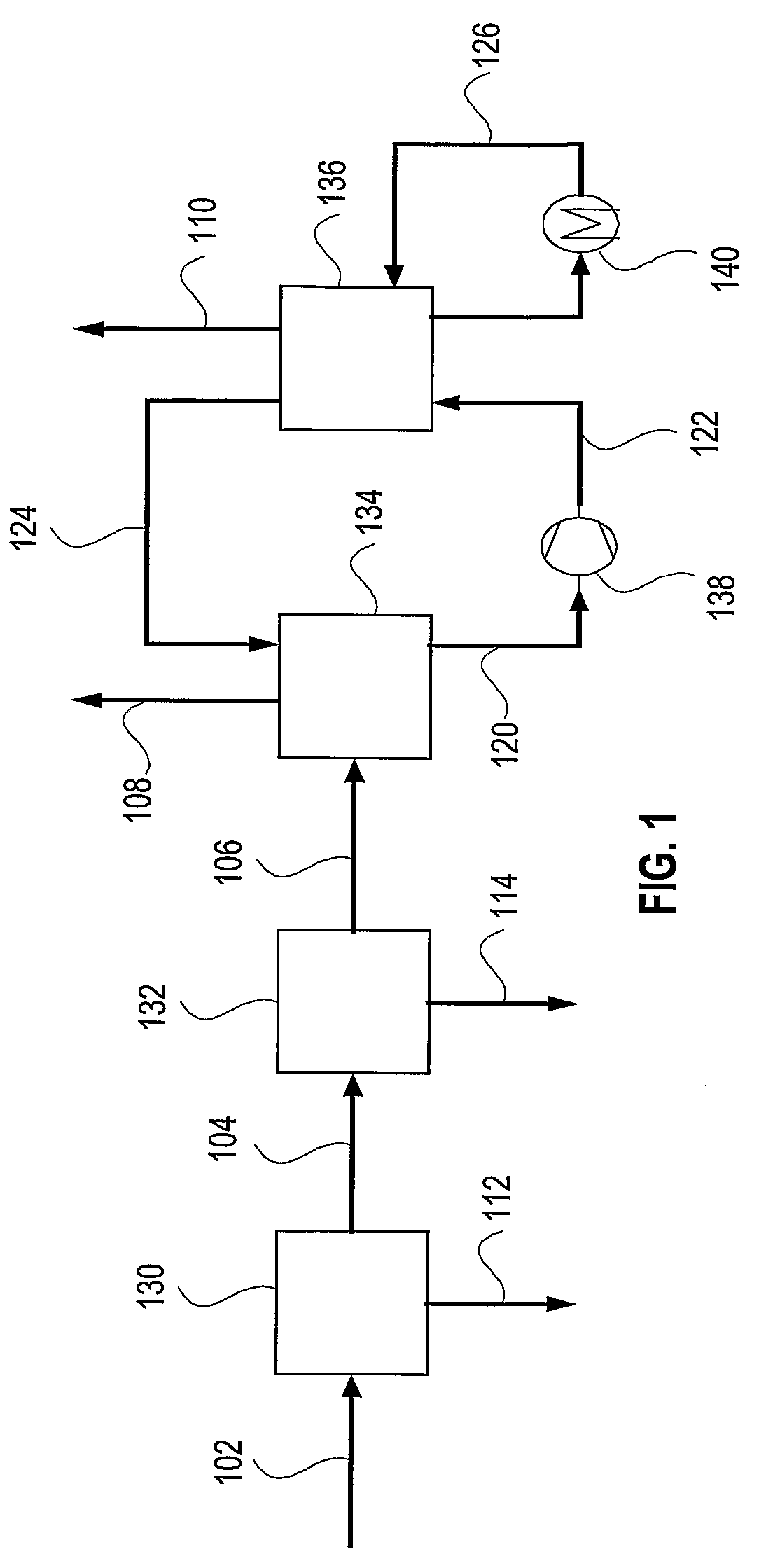

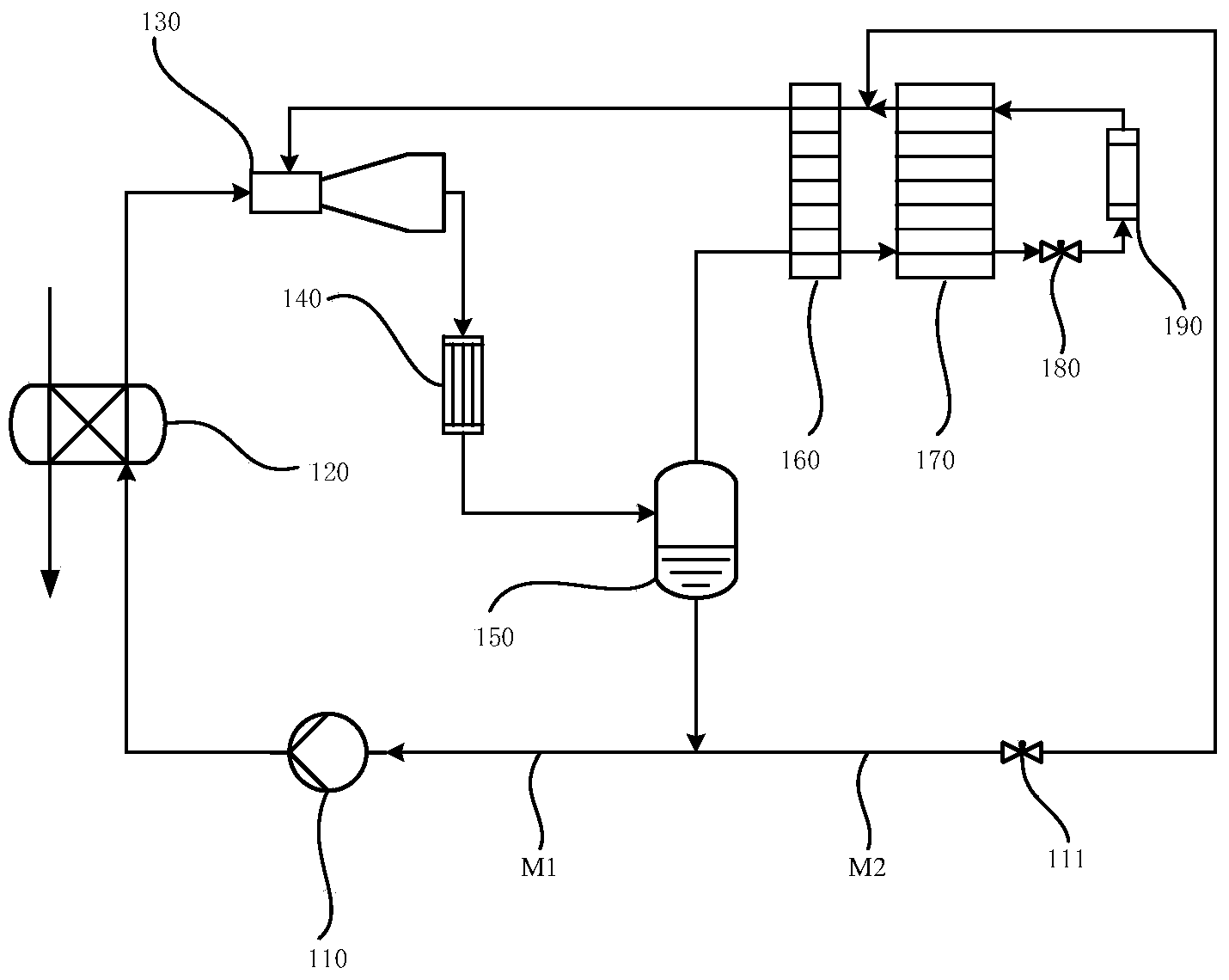

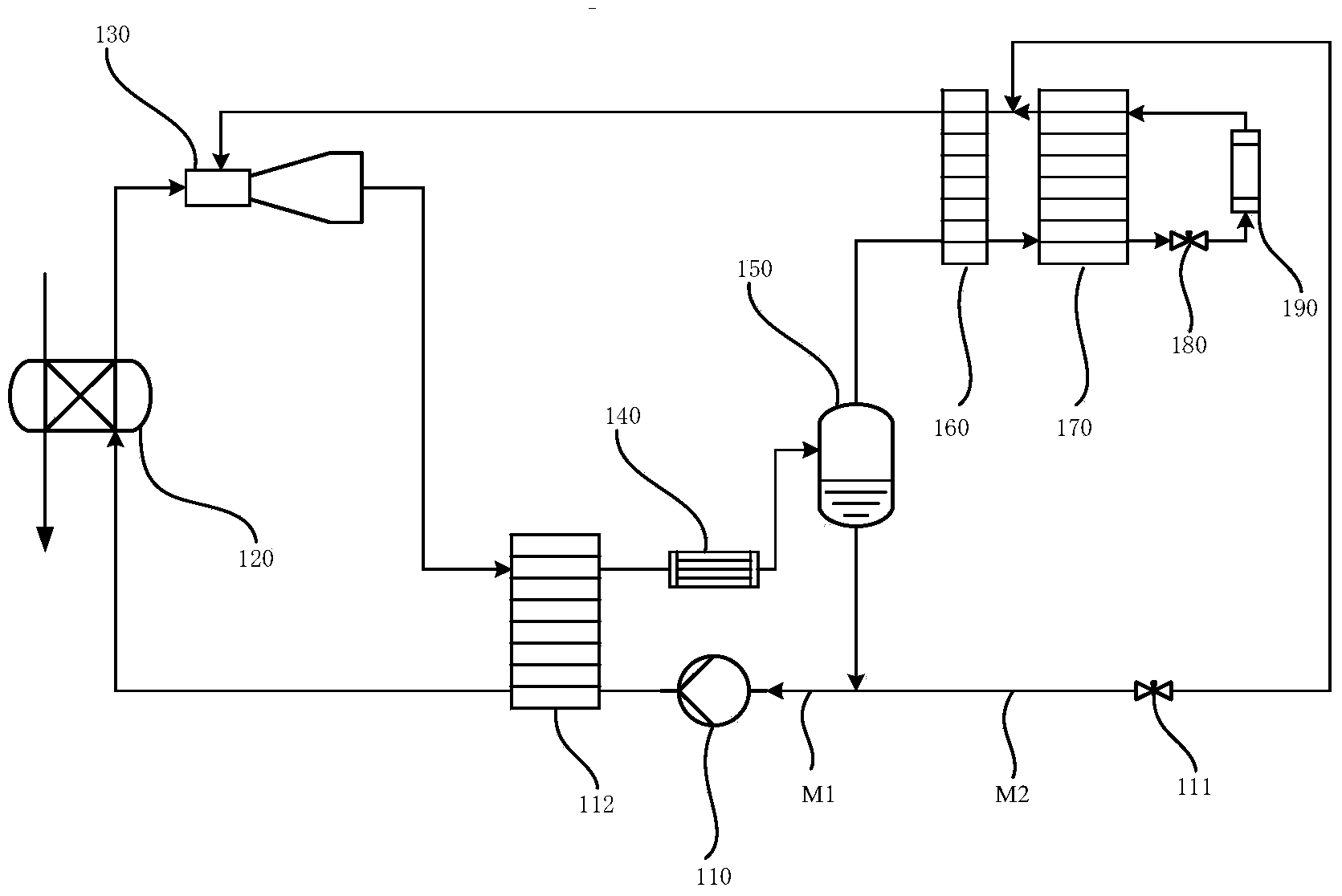

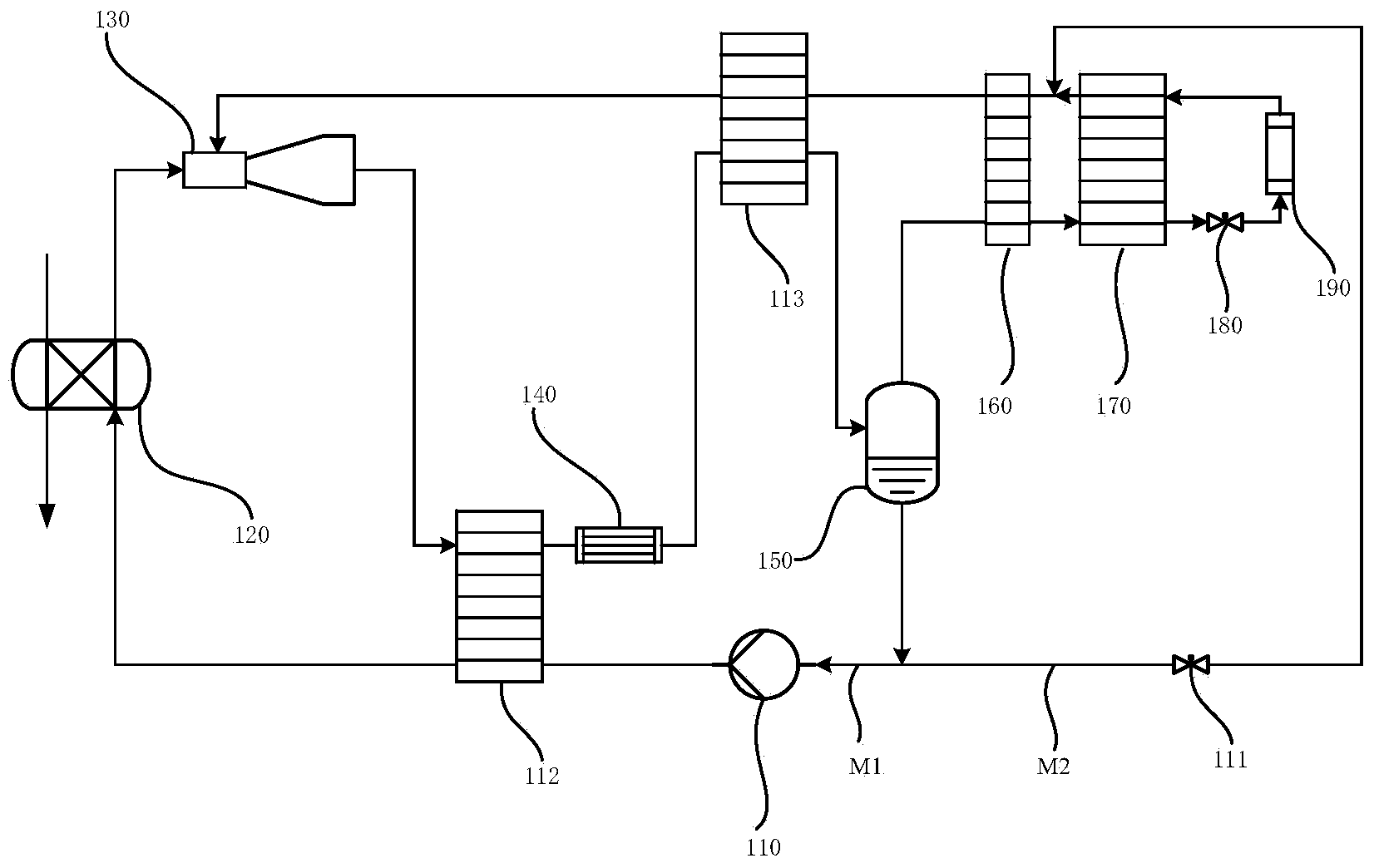

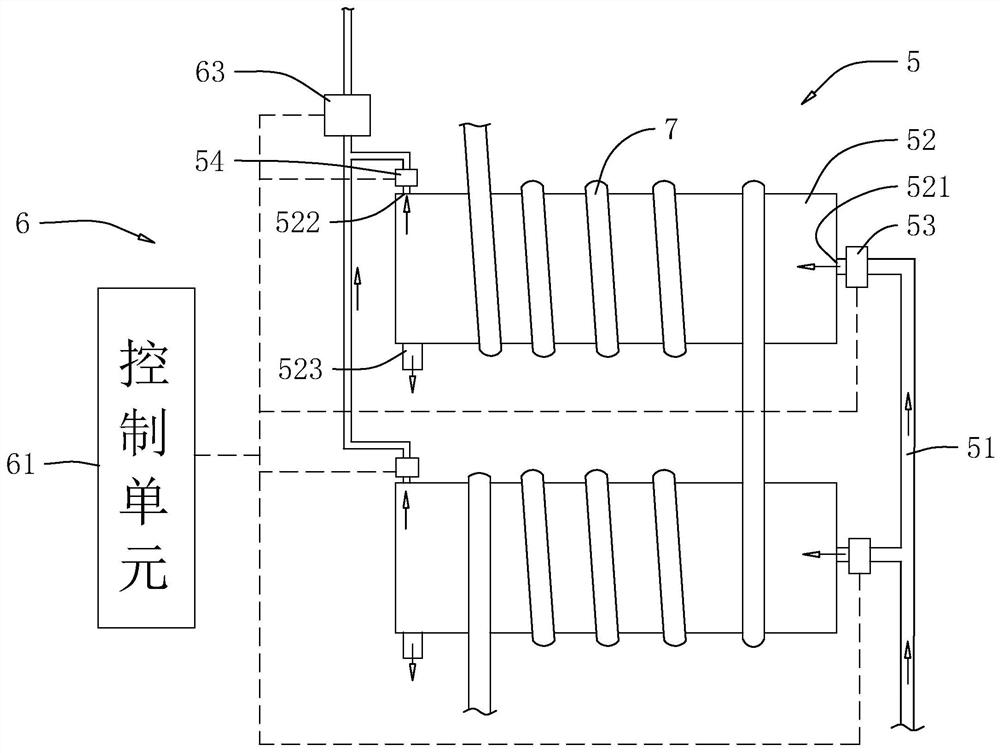

Mixed working medium low-temperature refrigerating cycle system driving ejector through waste heat

ActiveCN104019579ASignificant energy-saving effect of the systemReduce calorie consumptionClimate change adaptationFluid circulation arrangementProcess engineeringThrottle

A mixed working medium low-temperature refrigerating cycle system driving an ejector through waste heat comprises a drive pump, a steam generator, the ejector, a condenser, a gas-liquid separator, a first returning heat exchanger, a second returning heat exchanger, a first throttling valve and an evaporator. A mixing working medium liquid-phase component is pressurized through the pump and then enters the steam generator to become high-temperature and high-pressure gas, and the high-temperature and high-pressure gas enters the ejector to eject the mixing working medium throttling refrigerating fluid; the gas enters the condenser to be cooled into gas-liquid fluid, the gas-liquid fluid is separated, a gas-phase component enters the returning heat exchanger throttling valve, the low temperature is generated, the heat of the gas-phase component is absorbed by the evaporator , the gas-phase component enters the returning heat exchangers, the temperature is reset, and then the gas-phase component is ejected by the ejector. The liquid-phase working medium is divided into two parts, one part is throttled and enters the returning heat exchangers to provide precooling, the working medium and the gas-phase working medium are mixed to be ejected by the ejector, and the other part enters the pump to be pressurized to serve as ejecting fluid to finish circulation. According to the mixed working medium low-temperature refrigerating cycle system, the high-temperature and high-pressure steam generated by waste heat is completely utilized for driving the ejector to eject the throttled working medium, and therefore efficient, energy-saving and low-temperature refrigerating can be achieved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

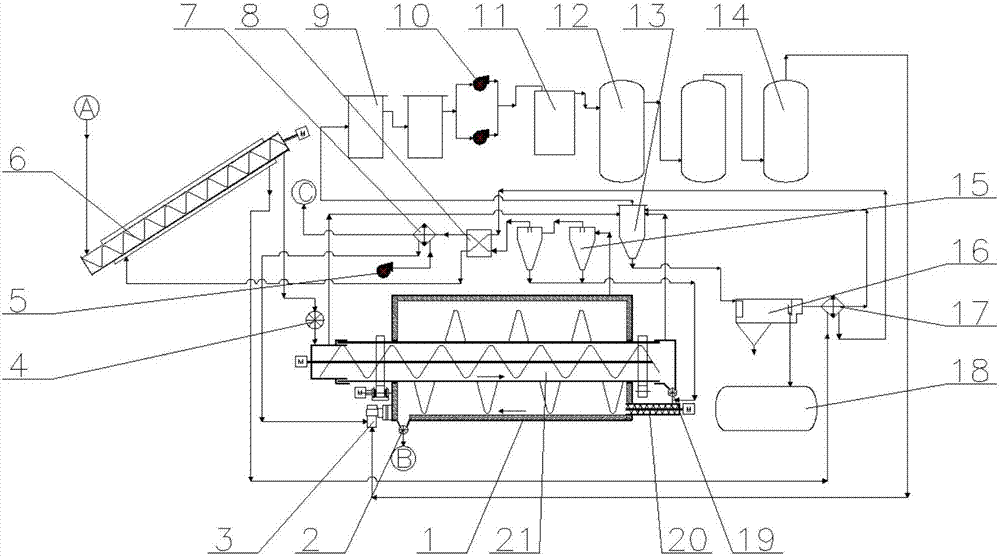

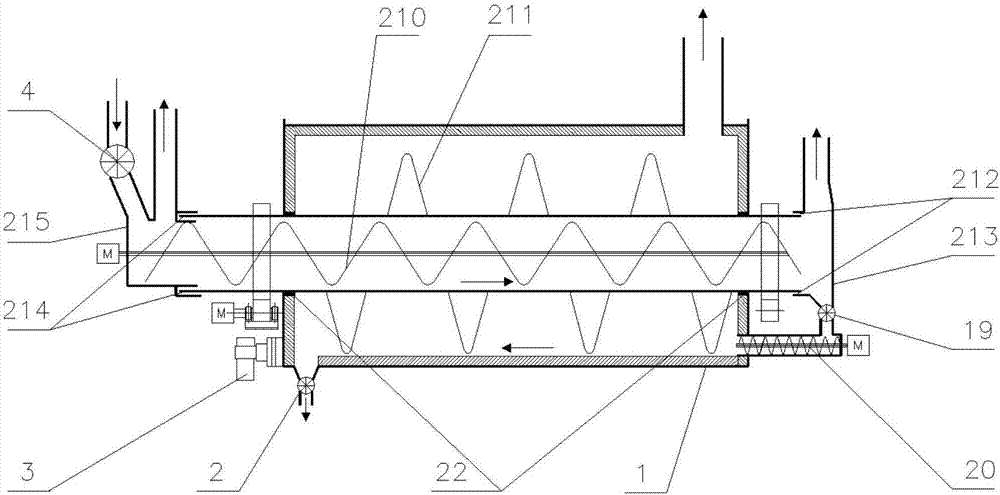

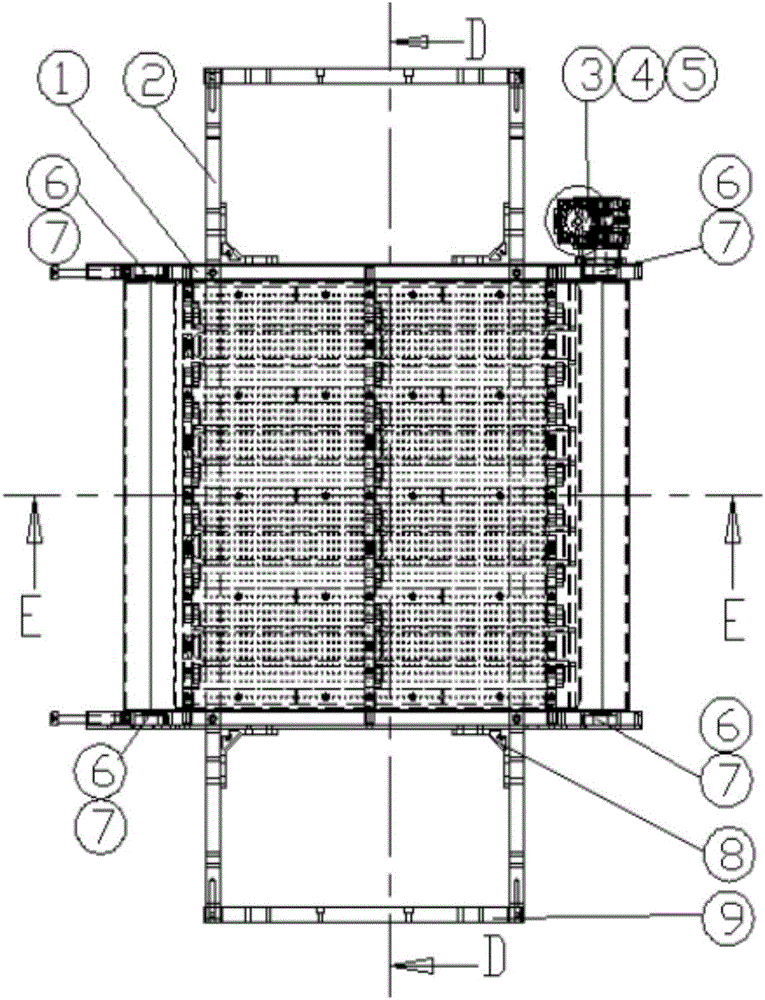

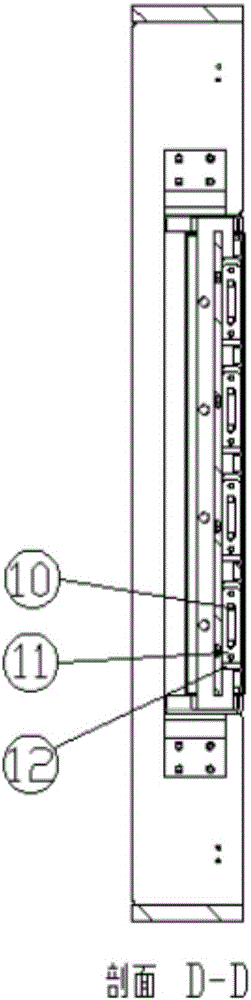

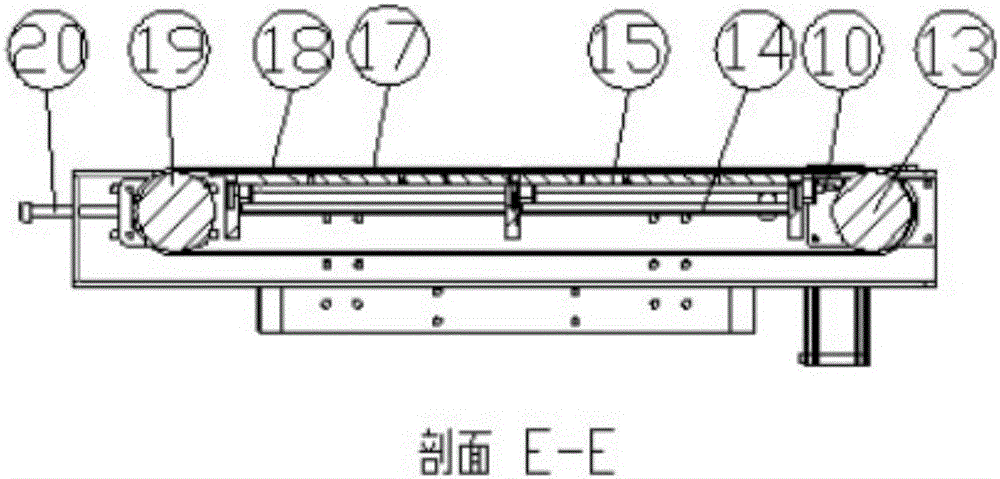

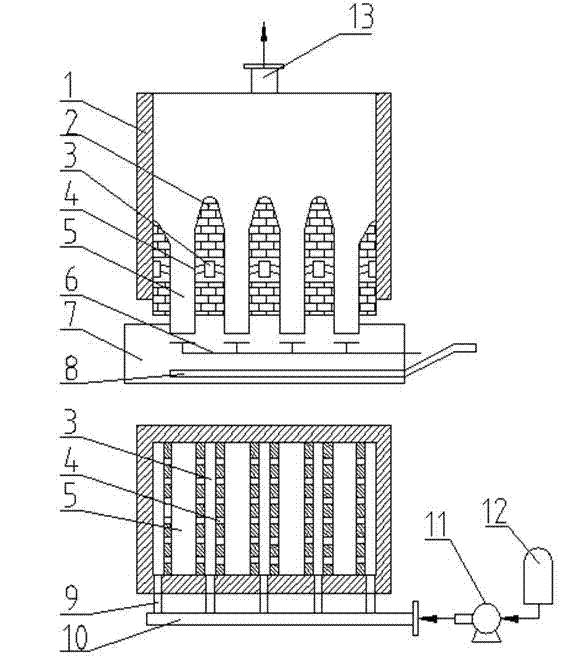

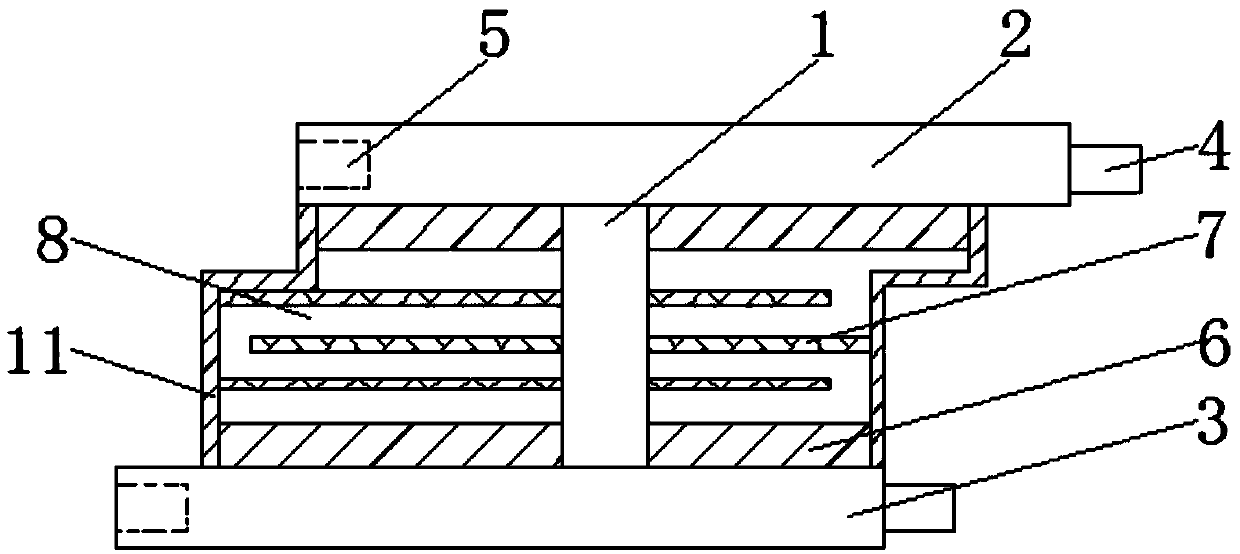

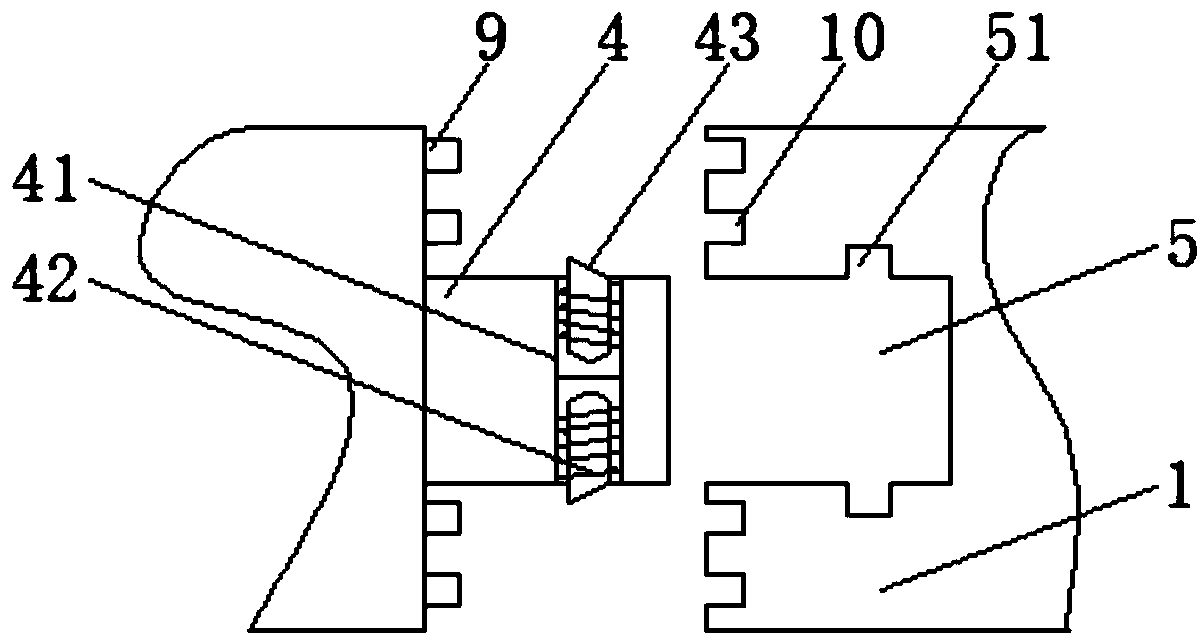

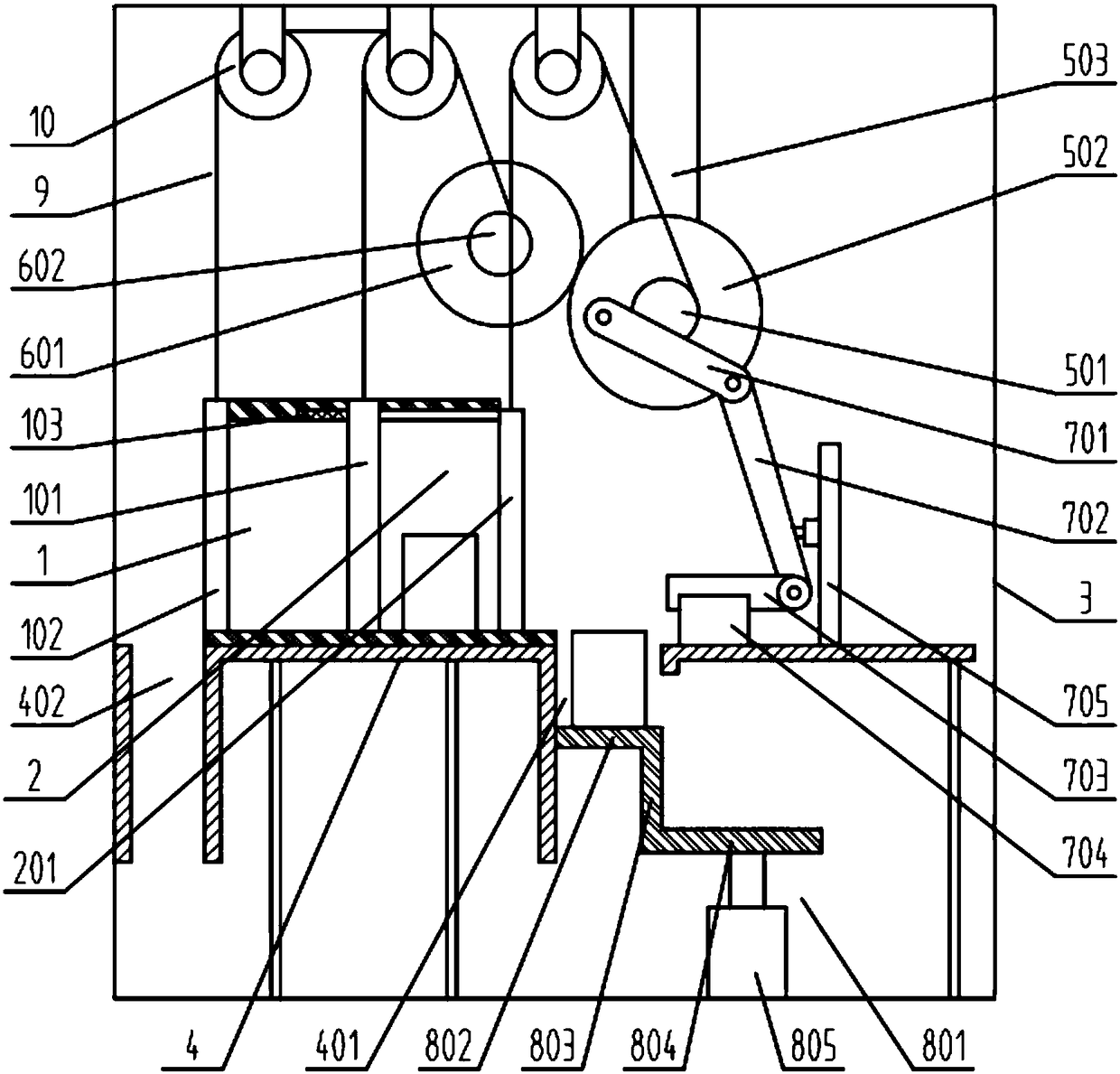

Indirect thermal cracking and ash combustion smelting furnace and treatment method thereof

ActiveCN107120656ASimple structureReduce calorie consumptionIncinerator apparatusCombustion chamberNitrogen gas

The invention belongs to the technical field of organic solid waste treatment, and particularly relates to an efficient and energy-saving indirect thermal cracking and ash combustion smelting furnace with a wide utilization range. The efficient and energy-saving indirect thermal cracking and ash combustion smelting furnace comprises a rotary thermal cracking and ash combustion smelting furnace body and a rotary barrel / rotary kiln sealing device, wherein the rotary thermal cracking and ash combustion smelting furnace body comprises an indirect thermal cracking barrel body with a spiral pushing device in the middle and a spiral inverse pushing ash combustion smelting heating furnace at the outer part of the barrel body; the rotary kiln sealing device comprises a rotary barrel body, a feeding end material collection hood, a discharge end material collection hood, a water seal filling sealing ring, a nitrogen emergency sealing air chamber and scale sealing pieces; the rotary indirect thermal cracking barrel body is lined with a heat-resistant steel barrel made from a silicon carbide material; a rotary screw conveyer is arranged in the heat-resistant steel barrel; and a high temperature resistant ceramic screw conveyer blade is fixed to the outer part of the barrel body. According to the efficient and energy-saving indirect thermal cracking and ash combustion smelting furnace, a cracking furnace, a secondary combustion chamber and a smelting furnace are integrated in one furnace body, noncondensable gas, condensed oil and carbon residues generated after cracking can be utilized as fuel makeup, heat consumption is greatly reduced, and remaining ash is smelted till ash reaches the safe landfill standard.

Owner:无锡爱普特设备科技有限公司

Oven and heating unit of oven

InactiveUS20070131670A1Reduce cooking timeAvoid insufficient heatingMilk preparationStoves/ranges foundationsEngineeringProcess engineering

Owner:LG ELECTRONICS INC

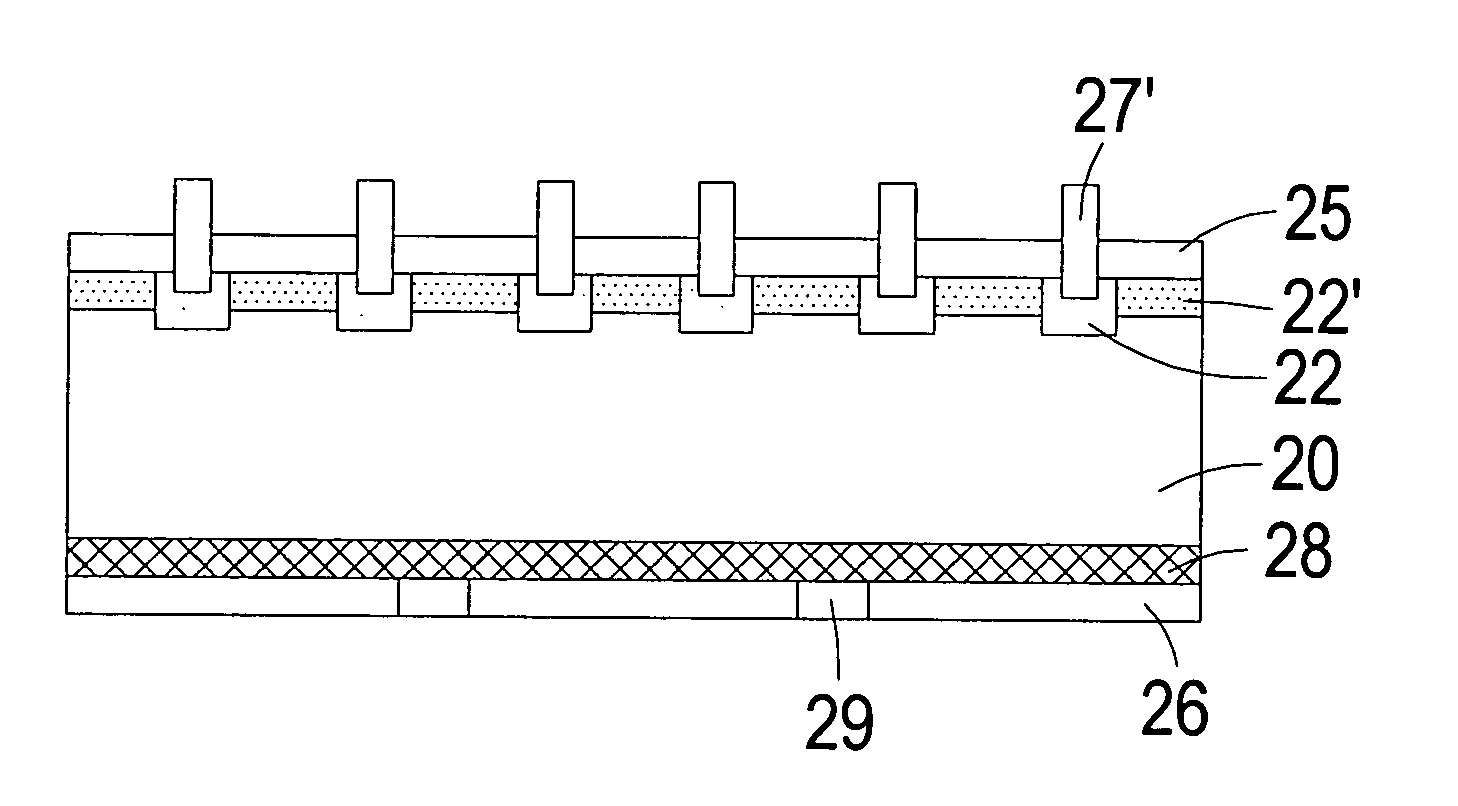

Process of manufacturing solar cell

InactiveUS7888160B2Avoid damageReduce calorie consumptionFinal product manufactureSemiconductor/solid-state device manufacturingAmorphous siliconSolar cell

A process of manufacturing a solar cell is disclosed. The process comprises steps of (a) providing a semiconductor substrate, (b) forming a dielectric layer with amorphous silicon structure on the semiconductor substrate, (c) partially removing the dielectric layer with amorphous silicon structure to expose parts of the semiconductor substrate, (d) simultaneously forming a heavily doped region on a surface of the exposed semiconductor substrate and a lightly doped region on a surface of the unexposed semiconductor substrate using the dielectric layer with amorphous silicon structure as a translucent barrier layer, (e) removing the dielectric layer with amorphous silicon structure, (f) forming an anti-reflection coating on the semiconductor substrate, and (g) forming a first electrode on the anti-reflection coating and coupled with the heavily doped region.

Owner:MOSEL VITELIC INC

Low-calcium silicate cement and preparation and hardening methods thereof

ActiveUS20180111875A1Deteriorate cement propertyLow-content calcium oxideClinker productionGrain treatmentsSilicon dioxideLow calcium

A low-calcium silicate cement, comprising: based on the total mass of oxides as 1, 50-60% of calcium oxide, 30-45% of silica, 2-6% of alumina, and 1-4% of iron oxide. A preparation method of the low-calcium silicate cement comprises: subjecting raw materials to crushing, joint grinding and uniform mixing to obtain a low-calcium silicate cement raw meal; calcining the above low-calcium silicate cement raw meal at 1050-1300° C. for 30-90 min, and cooling to obtain low-calcium silicate cement clinker; and levigating the above low-calcium silicate cement clinker till a specific surface area is 400-500 m2 / Kg, thereby obtaining a low-calcium silicate cement.

Owner:YANCHENG INST OF TECH

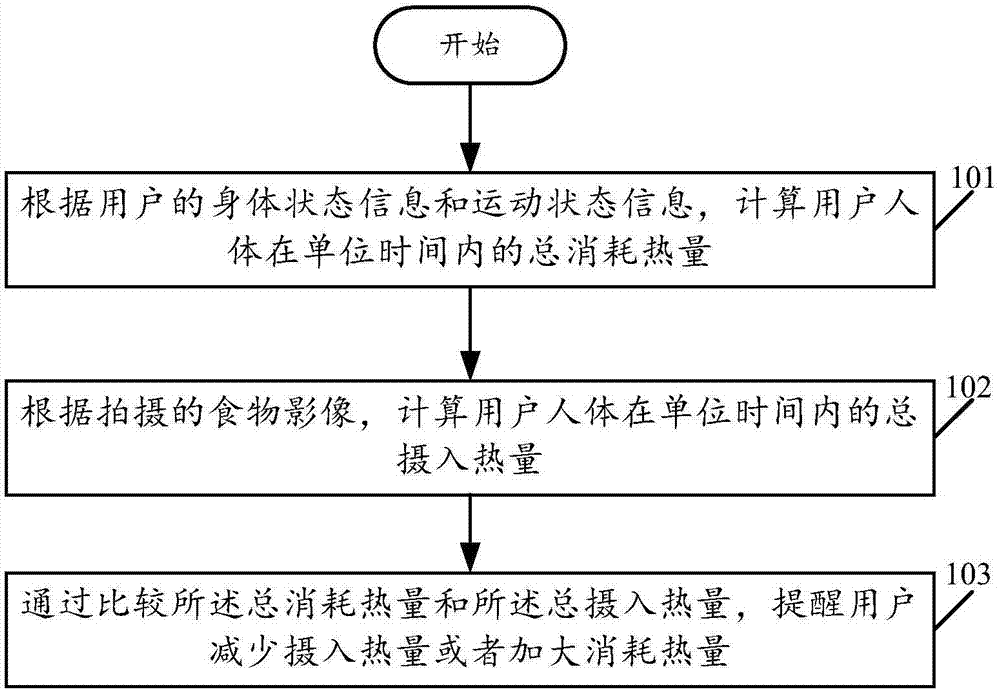

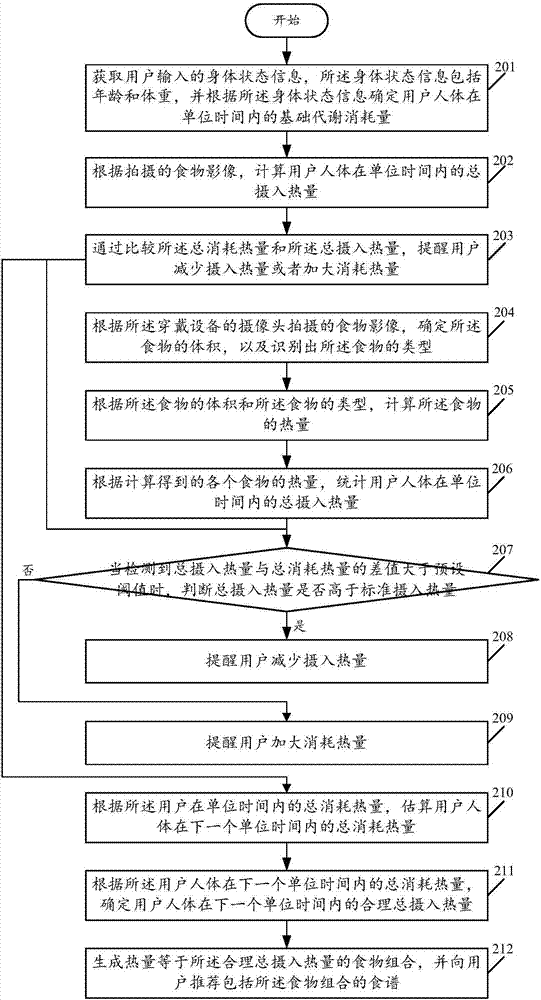

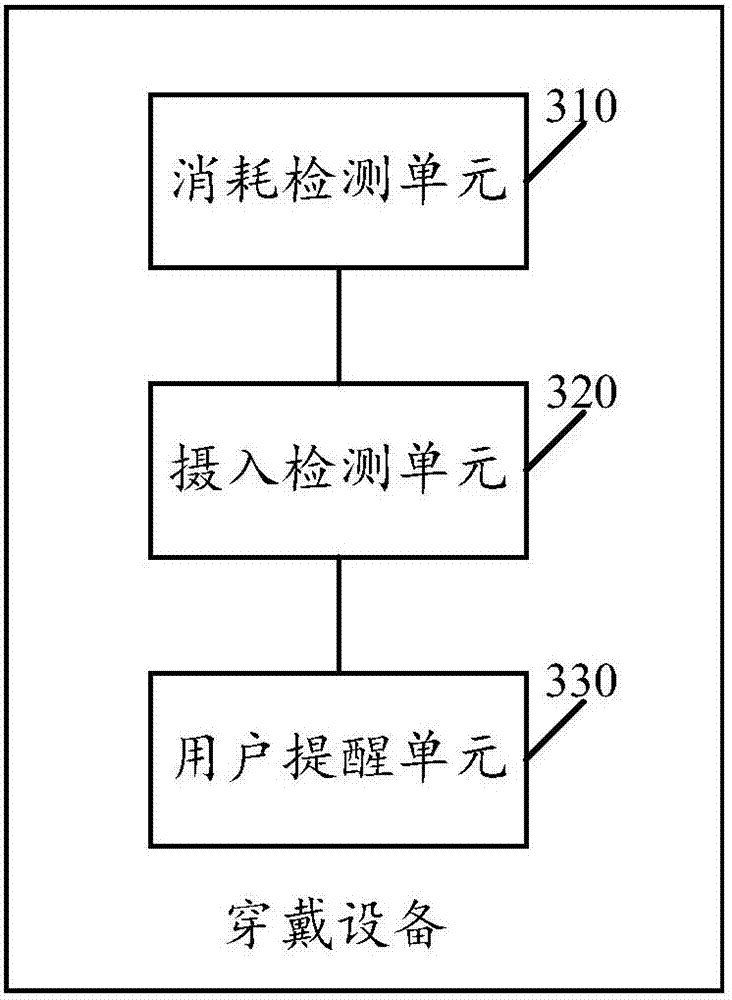

Wearing device and reminding method for wearing device

InactiveCN107145722AHelp to lose weightHelps shape bodySpecial data processing applicationsExercise stateComputer science

The embodiment of the invention relates to the technical field of a wearing device and discloses the wearing device and a reminding method for the wearing device. The method comprises the following steps: calculating the total heat consumption of user body within unit time according to the physical state information and motion state information of the user; calculating the total heat intake of the user body within unit time according to a shot food image; reminding the user of reducing the heat intake or increasing the heat consumption by comparing the total heat consumption with the total heat intake. According to the embodiment of the invention, a regulating prompt is sent to the user in the manner of comparing the total heat consumption of the body with the total heat intake, slimming, body shaping and health keeping of the user are benefited and the method has the advantages of convenience and accuracy.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

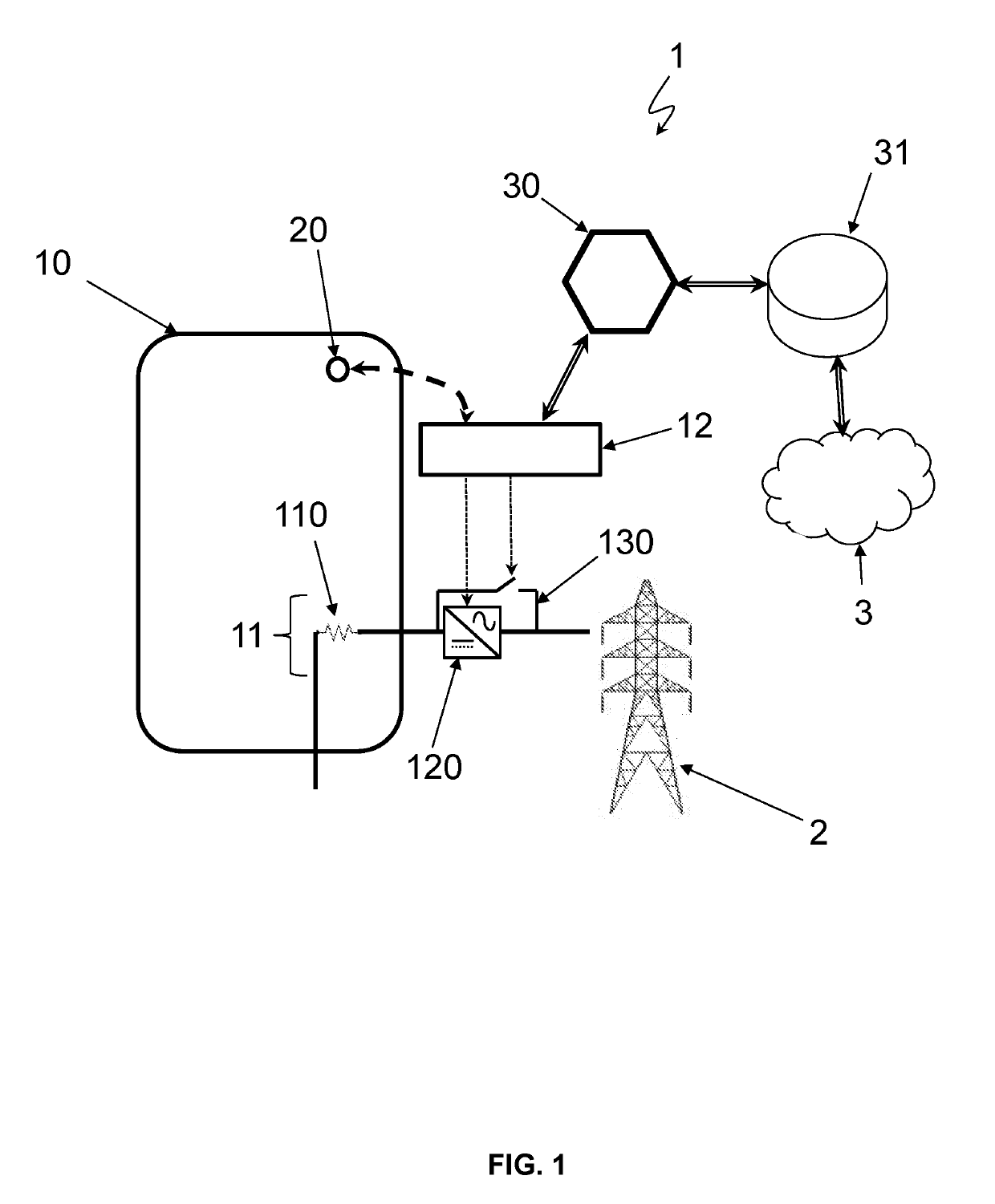

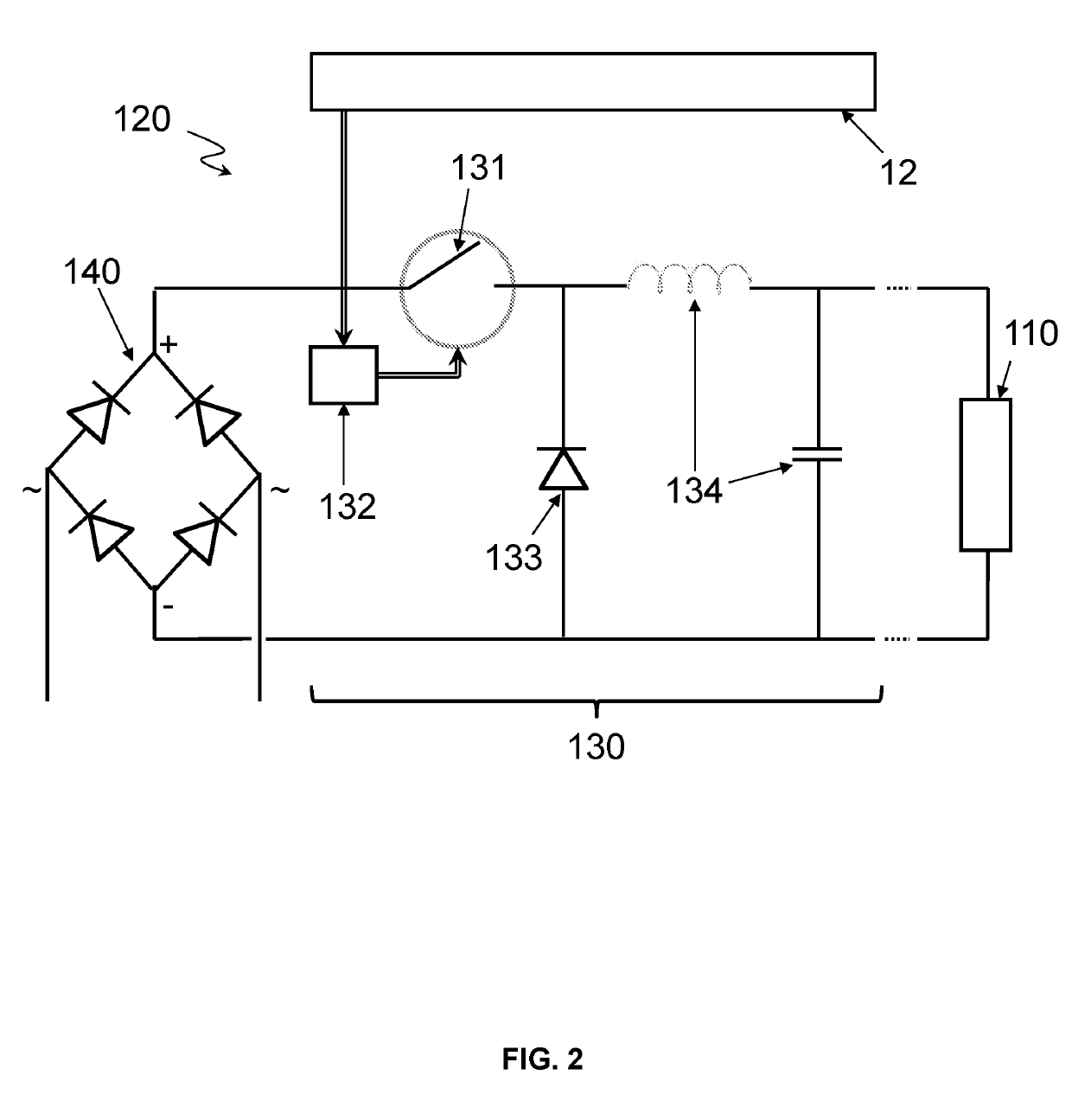

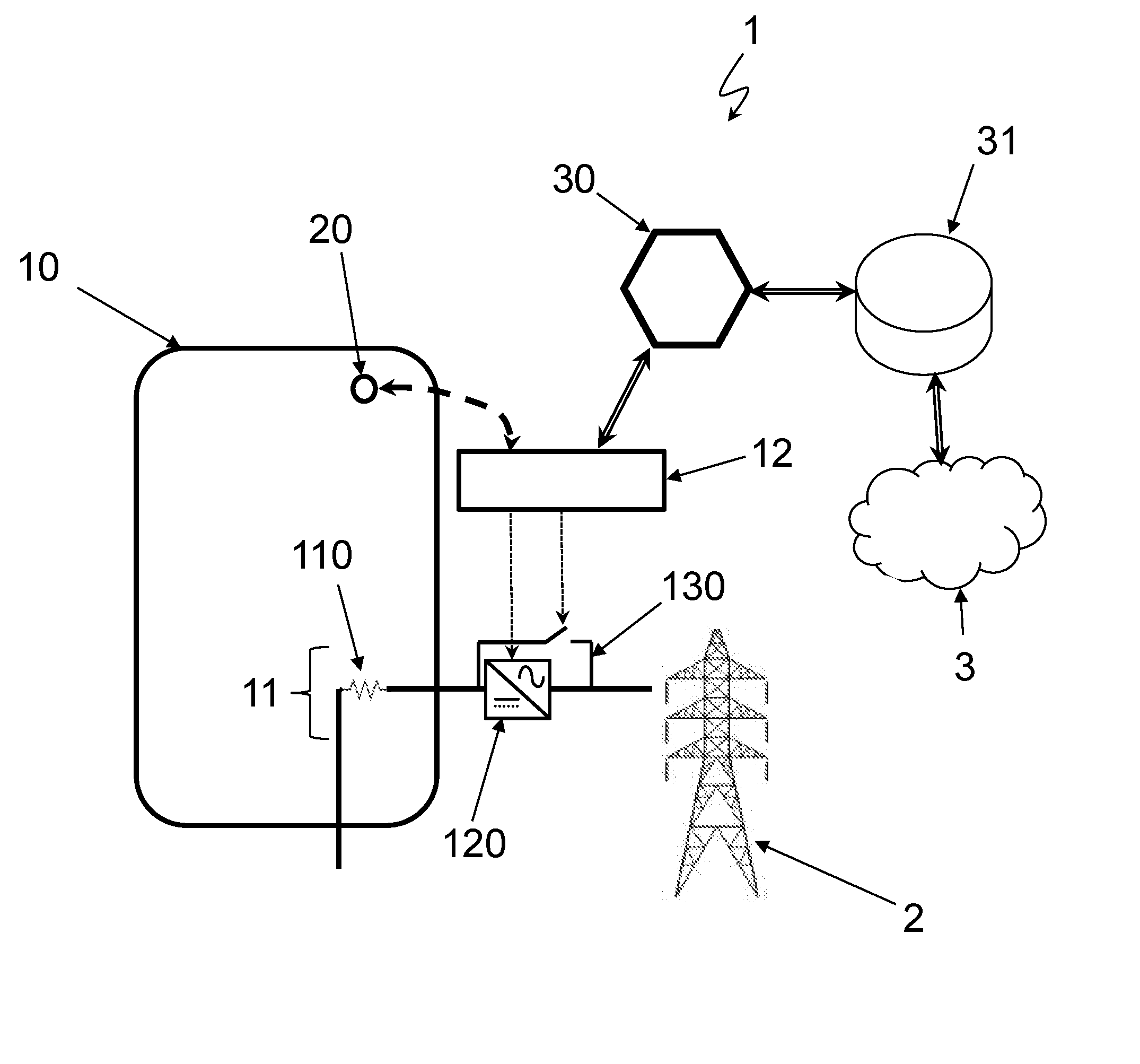

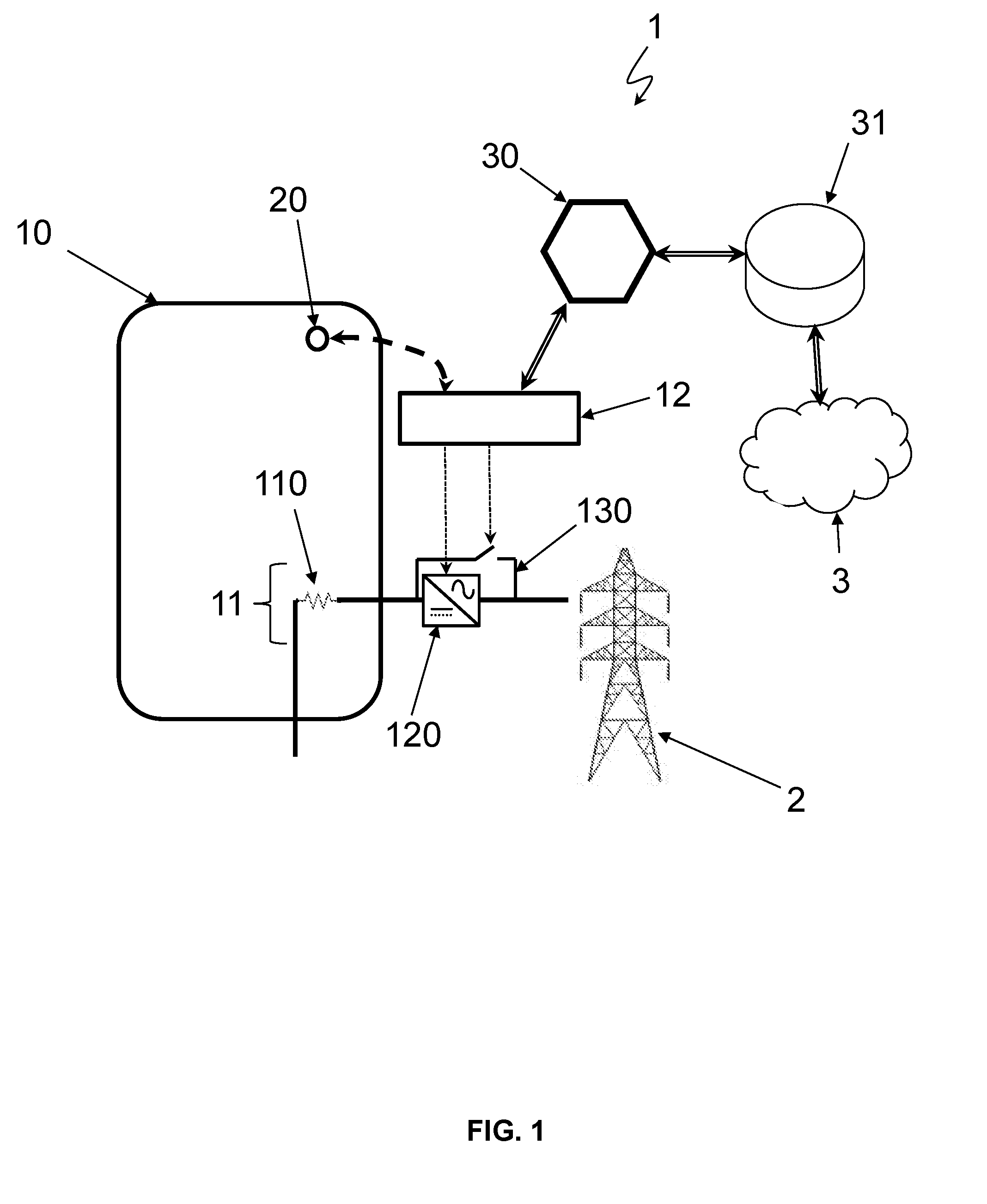

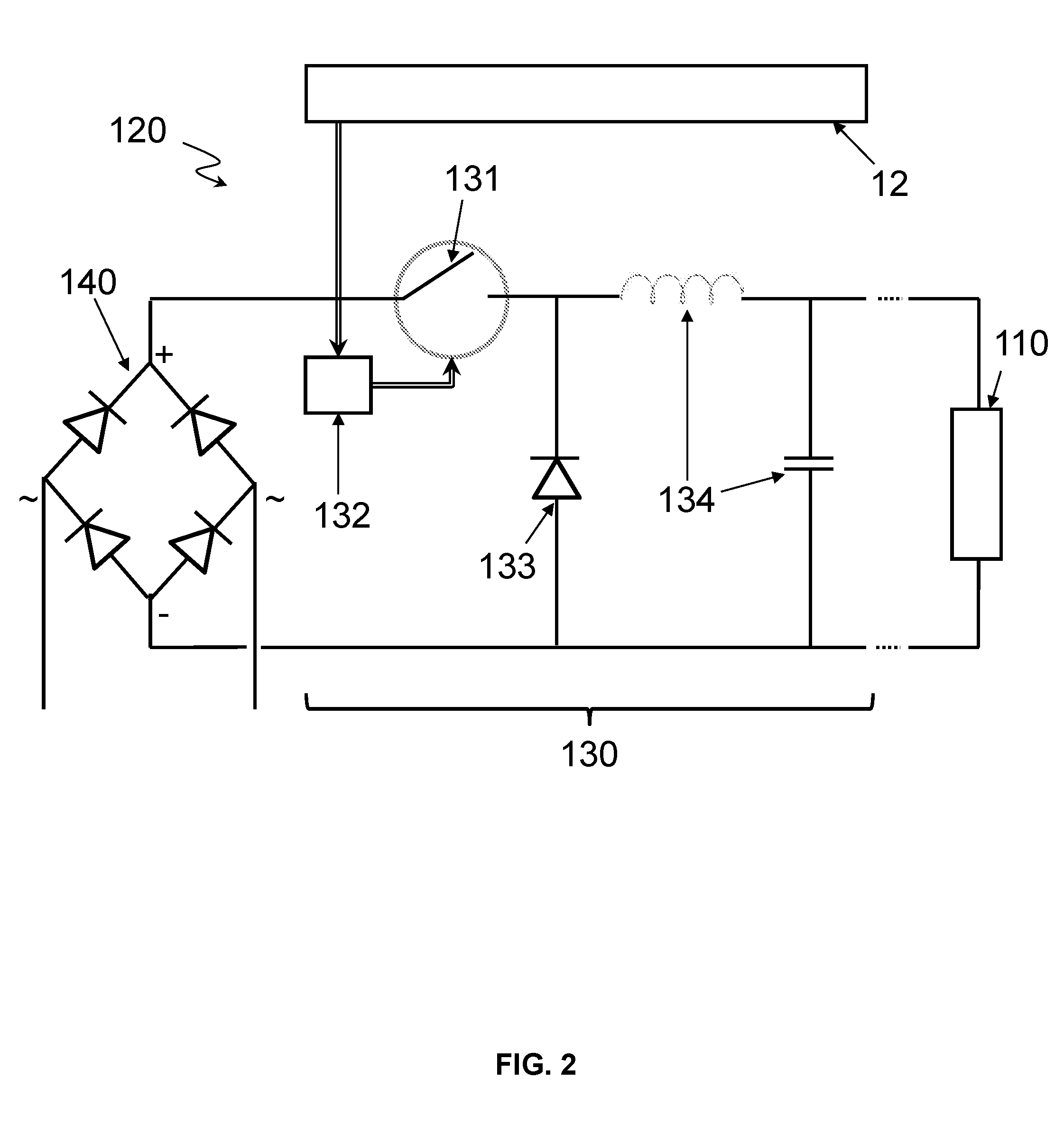

Electric water-heater with adjustable power

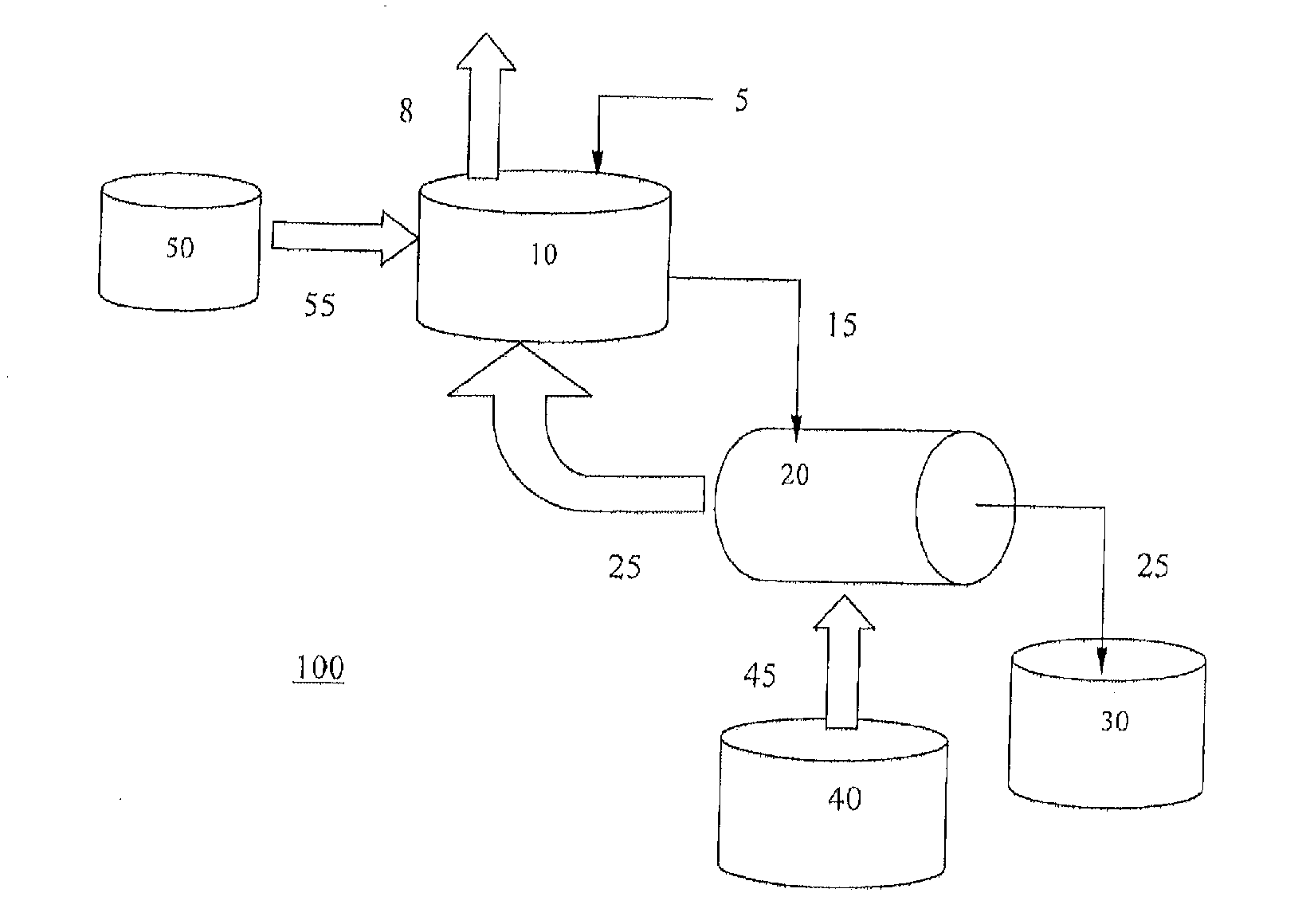

ActiveUS10334664B2Reduce calorie consumptionWeaken energyPower network operation systems integrationCooking vesselsPower gridEngineering

The invention relates to a system (1) comprising:a heating device (11) comprising at least one heating means (110) supplied by an AC power grid (2);a control module (12) for controlling said heating device (11),the system being characterized in that the heating means (110) is supplied via a switching converter (120) rectifying the alternating current of the grid (2) into direct current, the switching converter (120) being controlled by the control module (12) in accordance at least with descriptive data of a state of said power grid (2), so as to adjust the power of the heating means (110).

Owner:ELECTRICITE DE FRANCE

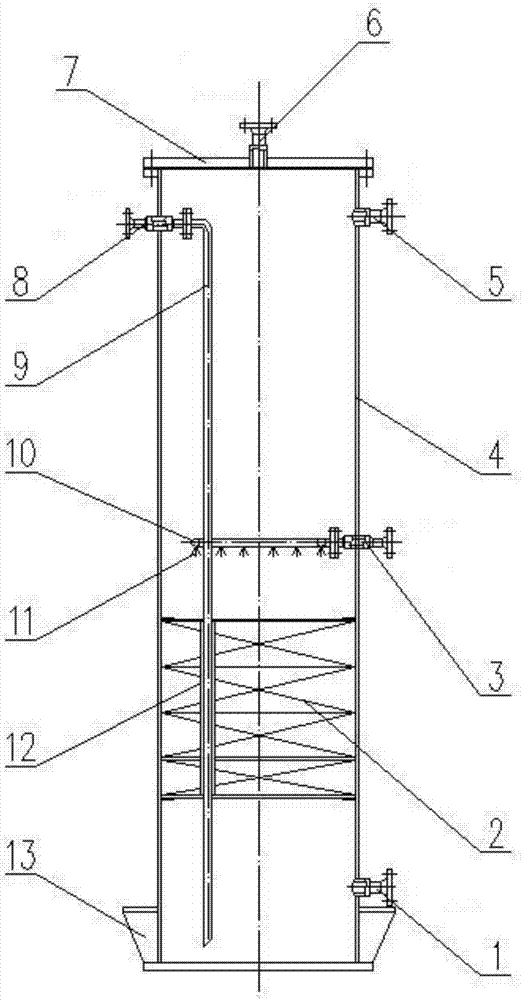

System for calcining active lime with a precalcining furnace and method using the same

ActiveUS20130224103A1Increase ratingsHigh temperatureOxide/hydroxide preparationRotary drum furnacesFlueRotary kiln

The invention provides a system for calcining active lime, including a precalcining furnace for receiving limestone materials to be calcined and precalcining the limestone materials, and a rotary kiln for receiving the materials containing precalcined product from the precalcining furnace, outputting the formed active lime, and at the same time supplying a first flue gas to the precalcining furnace. The calcining system further includes a precalcining furnace combustion device, which generates a second flue gas and supplies it to the precalcining furnace, such that the limestone materials are precalcined in the precalcining furnace under the action of the first flue gas and the second flue gas. In this way, the precalcining rate of the limestone materials in the precalcining furnace is significantly improved. Since the heat exchange in the precalcining furnace is mainly in the form of convective heat exchange having a high heat efficiency, the heat exchange efficiency of the whole system is improved, and thus the heat consumption of the system is reduced.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

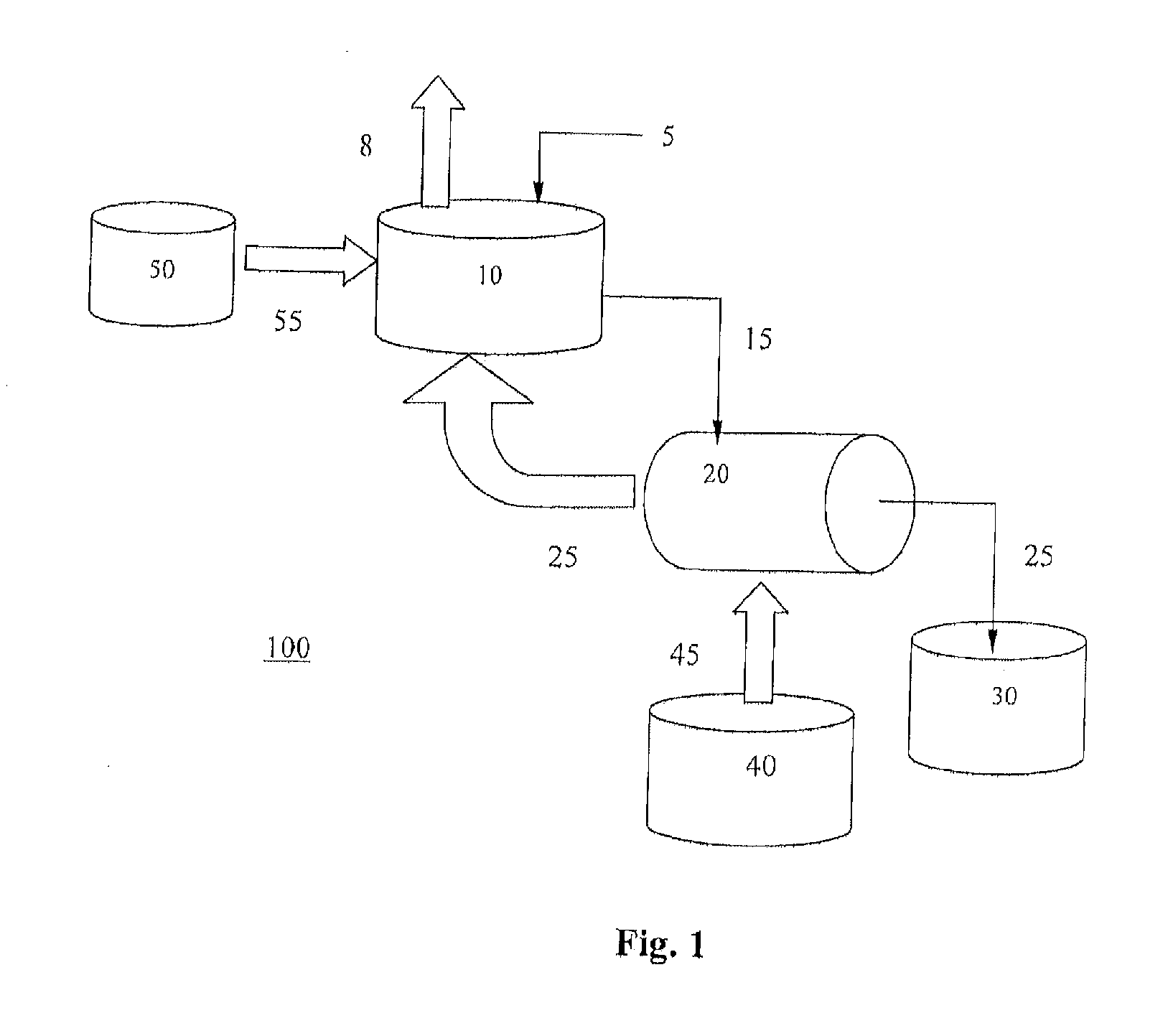

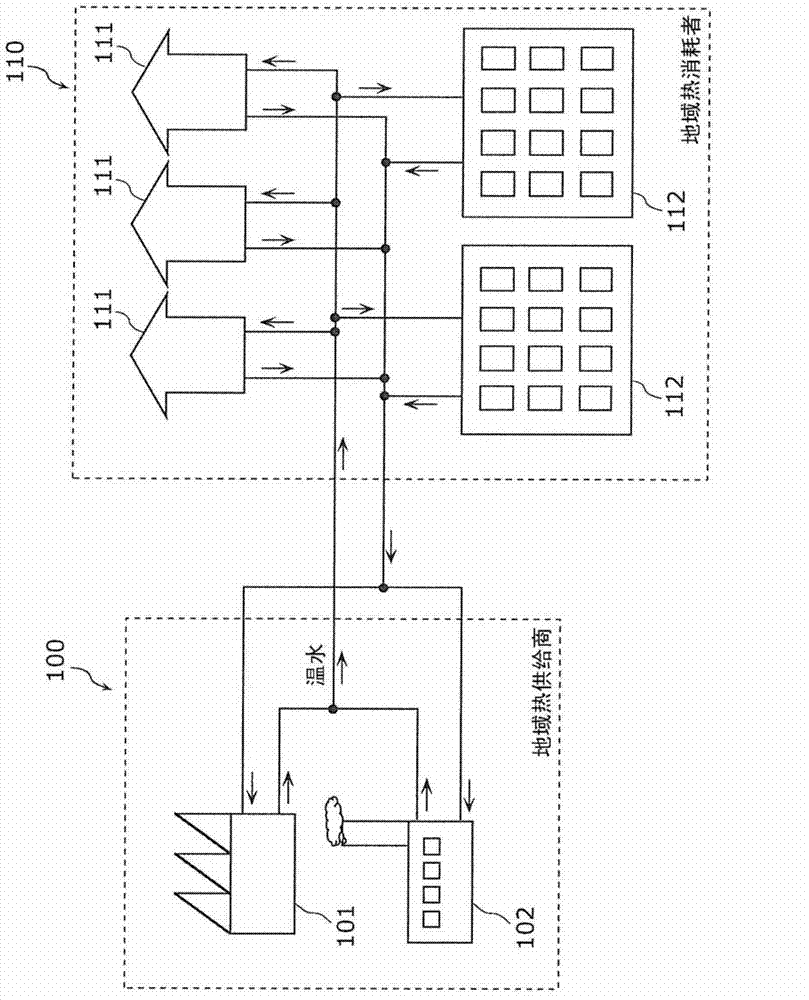

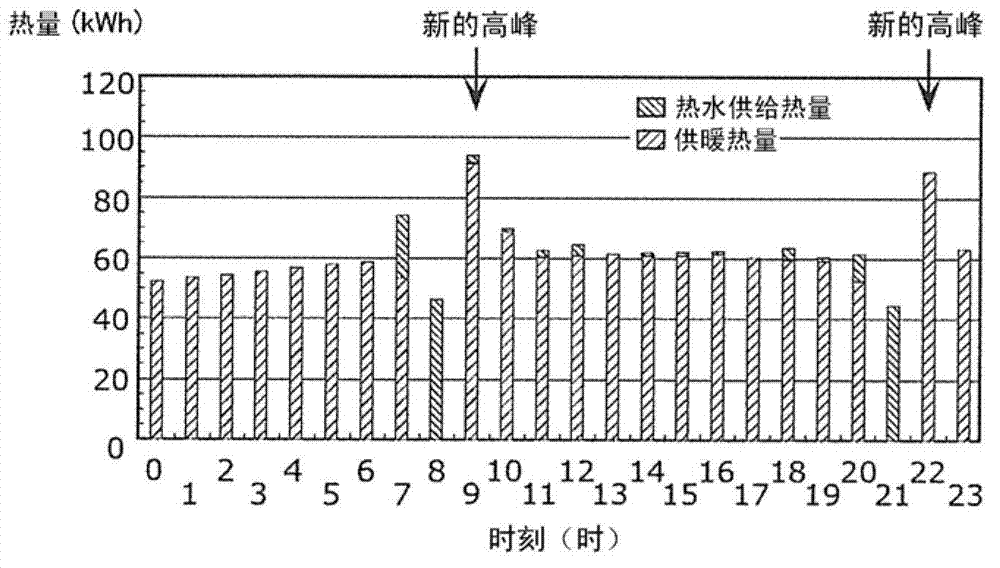

Heating system and method for controlling heating system

InactiveCN103180670AImprove comfortGuaranteed comfortDistrict heating systemLighting and heating apparatusRoom temperatureEngineering

A method for controlling a heating system comprises: an acquisition step (S101) for acquiring, from a heat supply source, a heat radiation restriction instruction requesting restriction of the heat radiated from a plurality of heating devices; a heat radiation stopping step (S102) for stopping the radiation of heat from the plurality of heating devices in accordance with the heat radiation restriction instruction acquired at the acquisition step; a detection step (S103) for detecting the respective room temperatures in a plurality of rooms; and a heat radiation restarting step (S104) for discretely restarting the radiation of heat from the heating devices installed in each room in accordance with the room temperatures detected at the detection step.

Owner:PANASONIC CORP

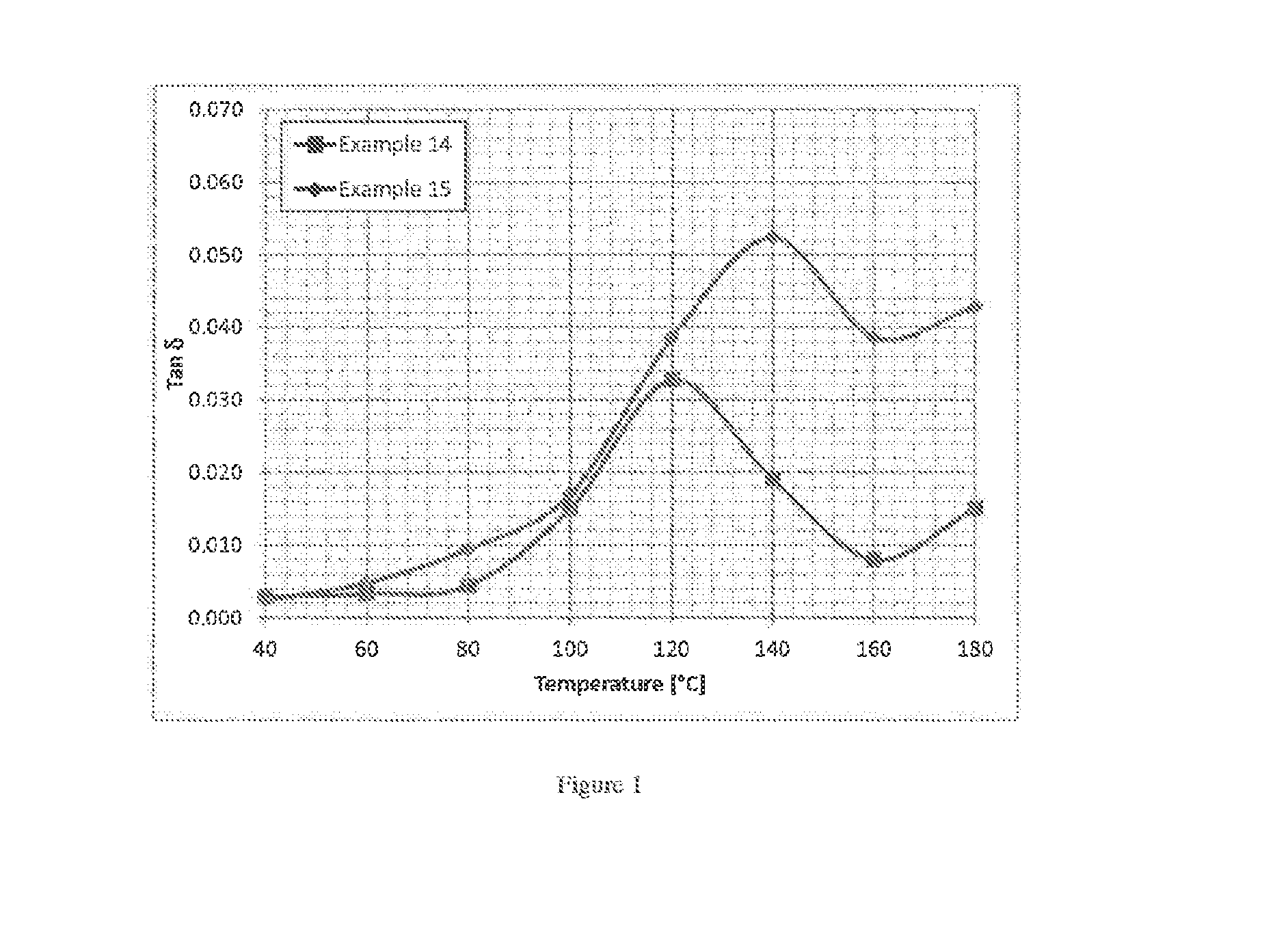

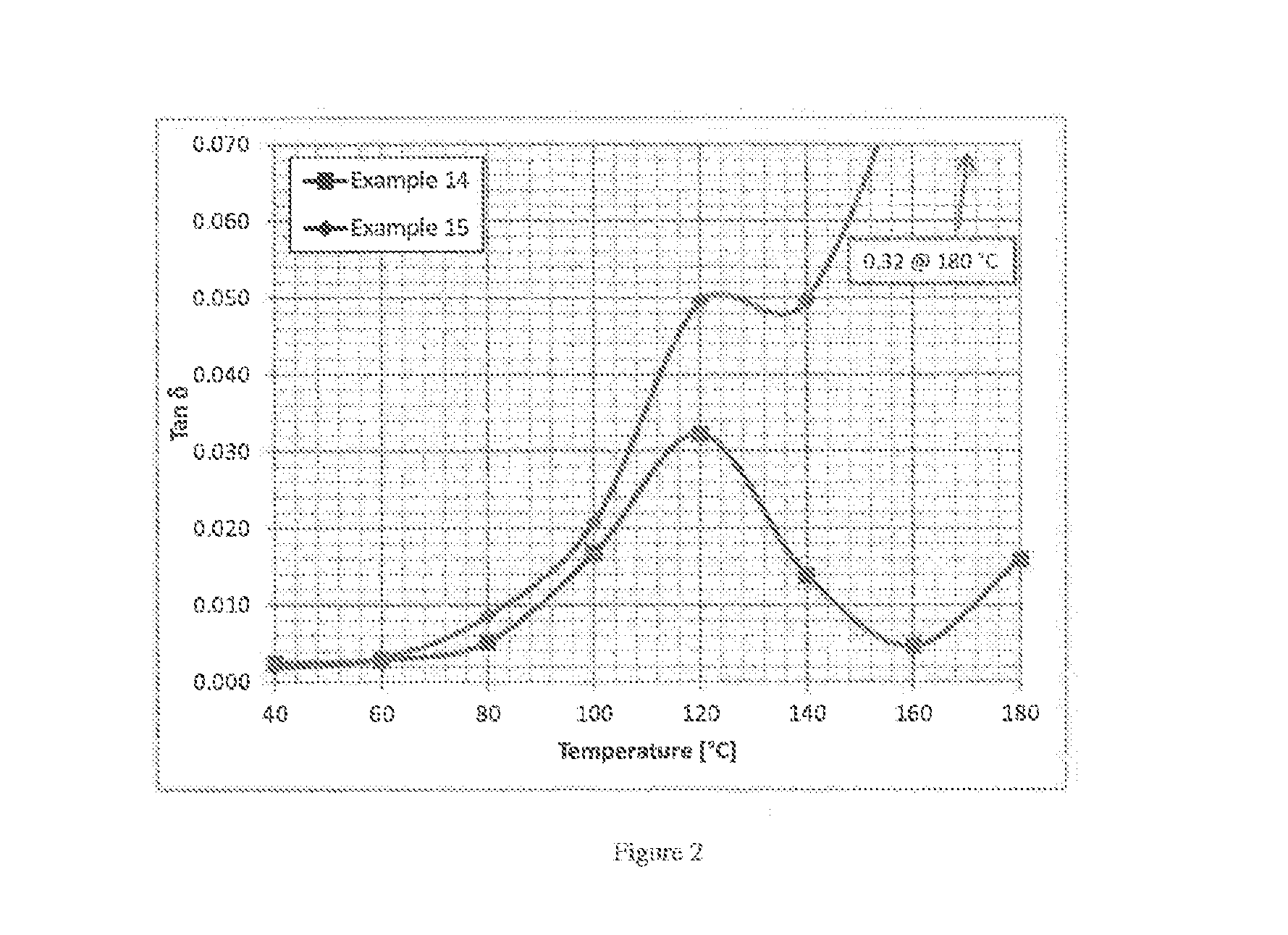

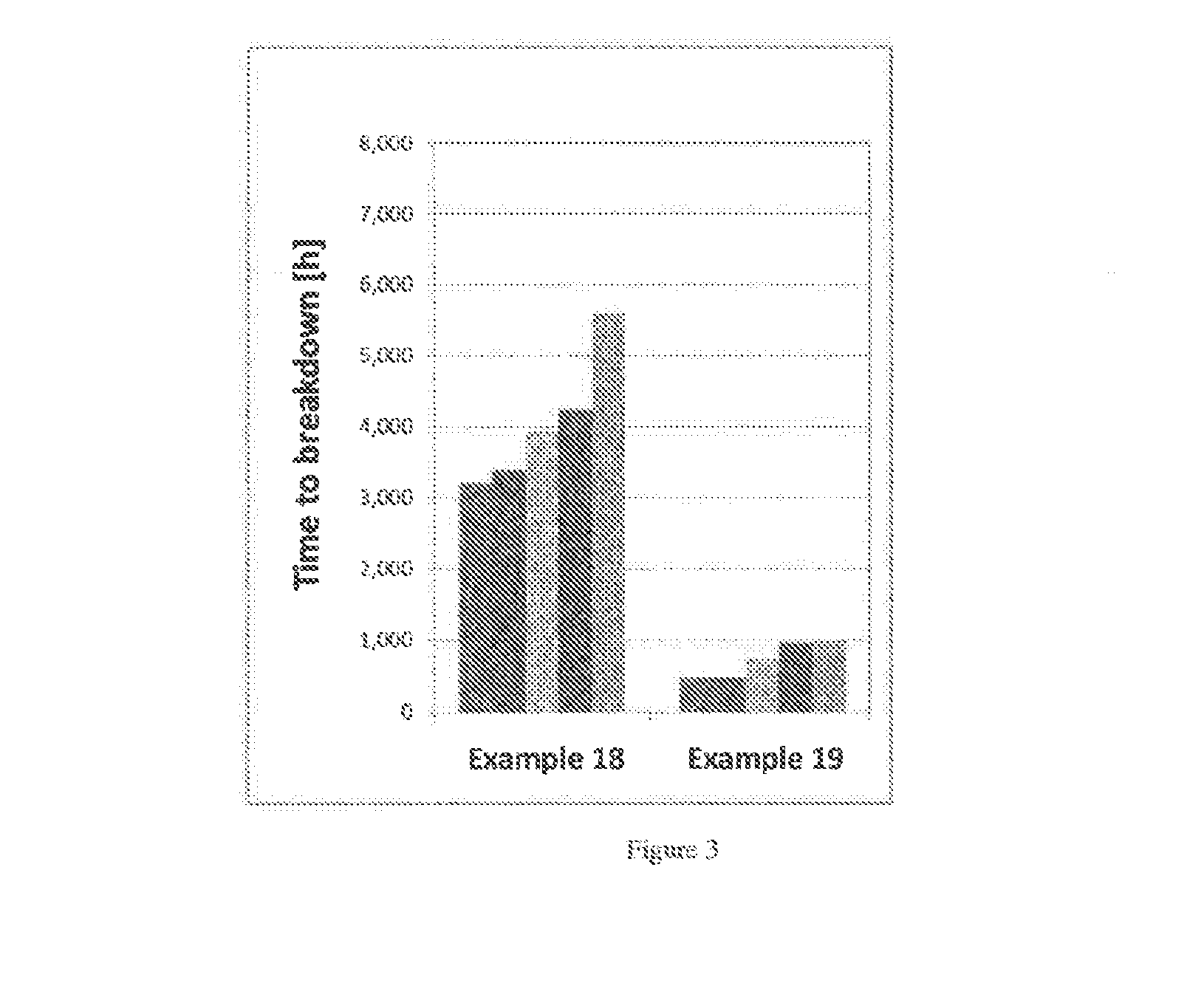

Composite high voltage insultation materials and methods for preparing the same

InactiveUS20160247596A1Excellent propertyLong storage periodWindings insulation materialWindings insulation shape/form/constructionEpoxyCellulose

The present invention relates to an anhydride-free curable epoxy resin composition for use as high voltage (HV) insulation, to an anhydride-free curable epoxy resin mica composite or an anhydride-free curable epoxy resin cellulose composite comprising the same, to an insulating material obtained by curing the anhydride-free curable epoxy resin composition, the anhydride-free curable epoxy resin mica composite or the anhydride-free curable epoxy resin cellulose composite as well as to a process for producing the same.

Owner:ABB (SCHWEIZ) AG

Double-sided sleeping pad capable of promoting growth of child

The invention relates to a double-sided sleeping pad capable of promoting growth of a child, which comprises a pad case, a pad core and a sensing device. The double-sided sleeping pad can be used by two sides according to season and temperature. When sleeping on the pad, a child consumes less heat, sleeps soundly and stably, seldom cries and grows quickly. When the pad is used, the temperature, humidity and bed wetting of the child can be monitored at any time, and remote control and near control alarms and voice and music prompts can be given through an external interface.

Owner:王福起

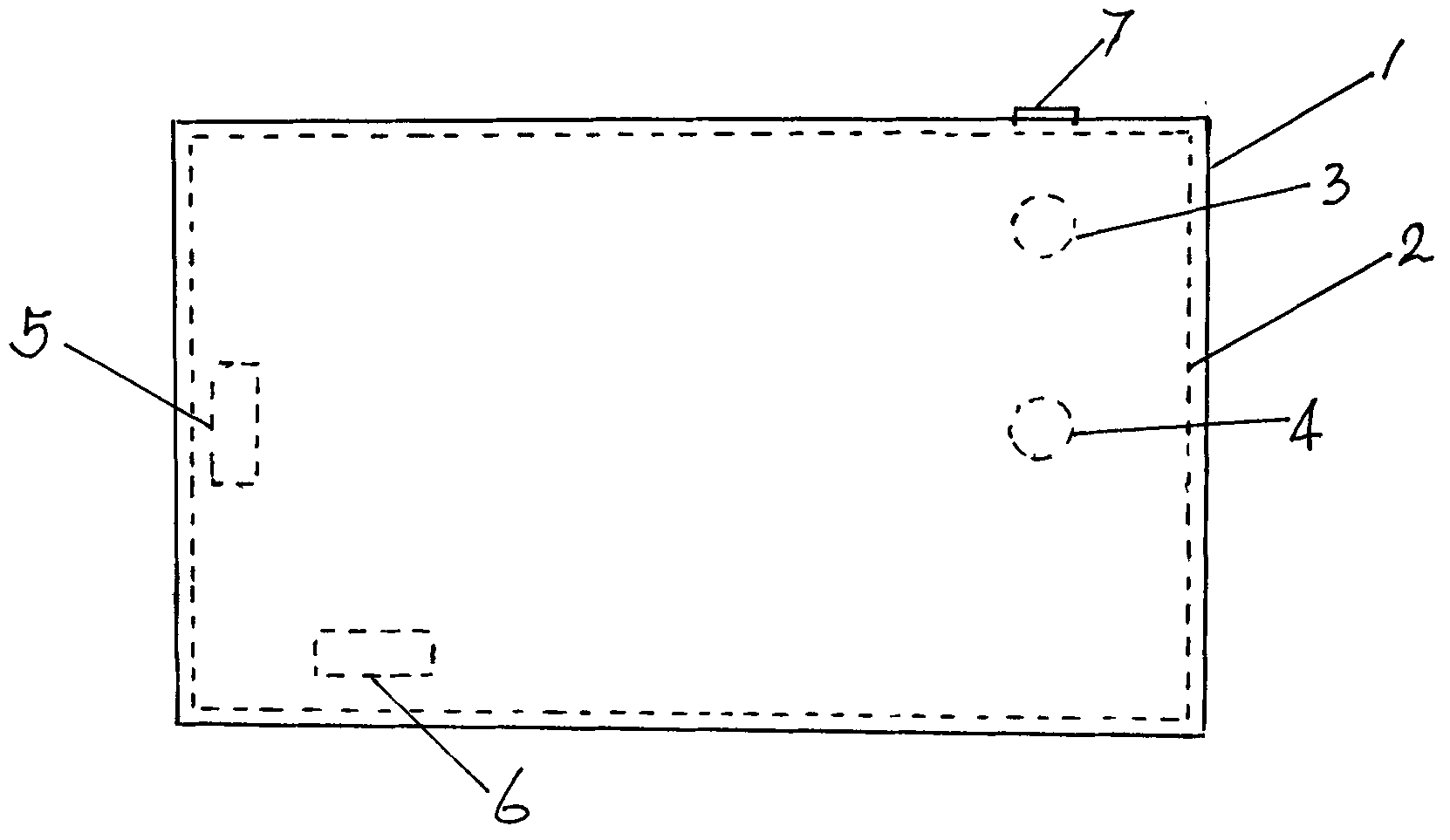

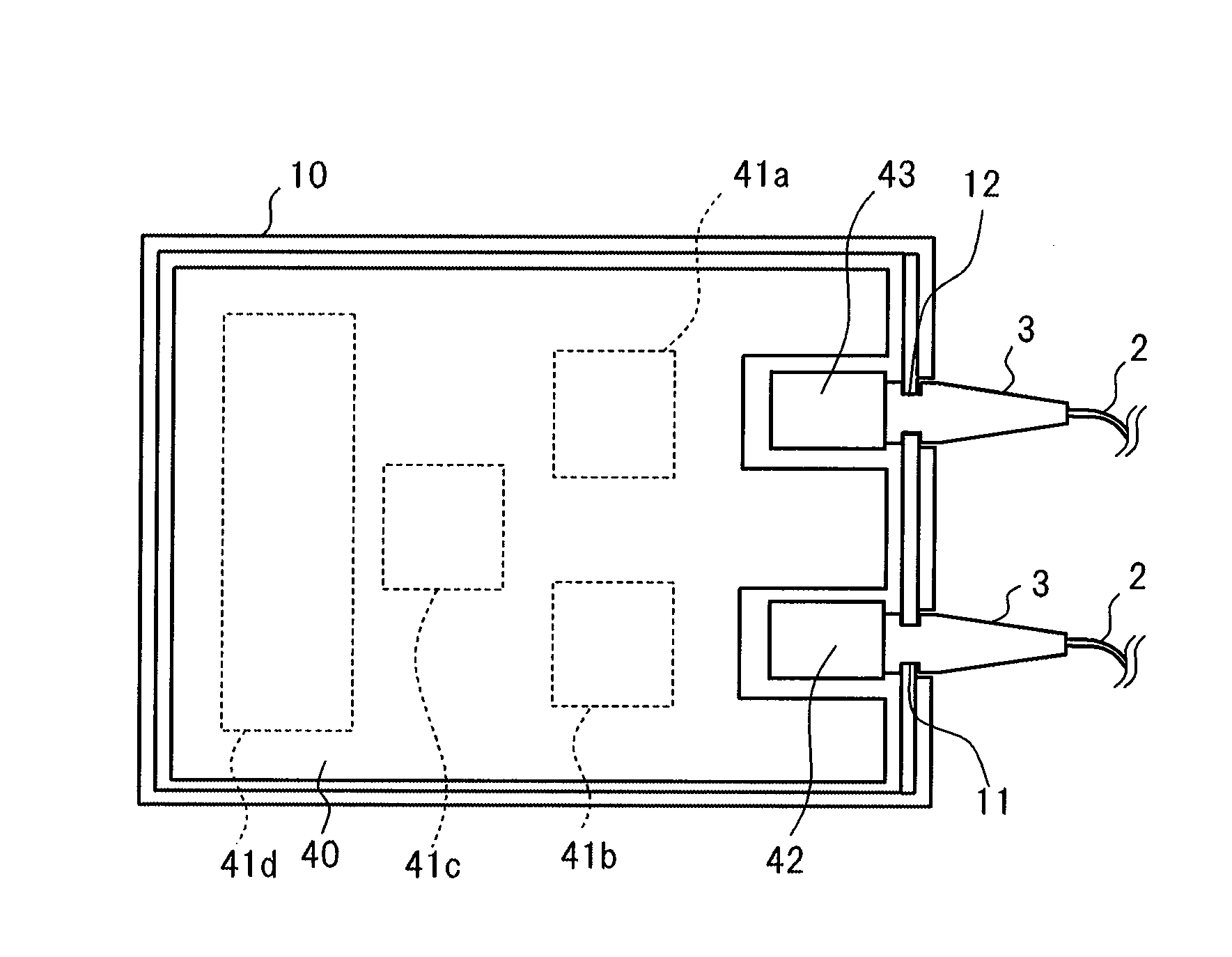

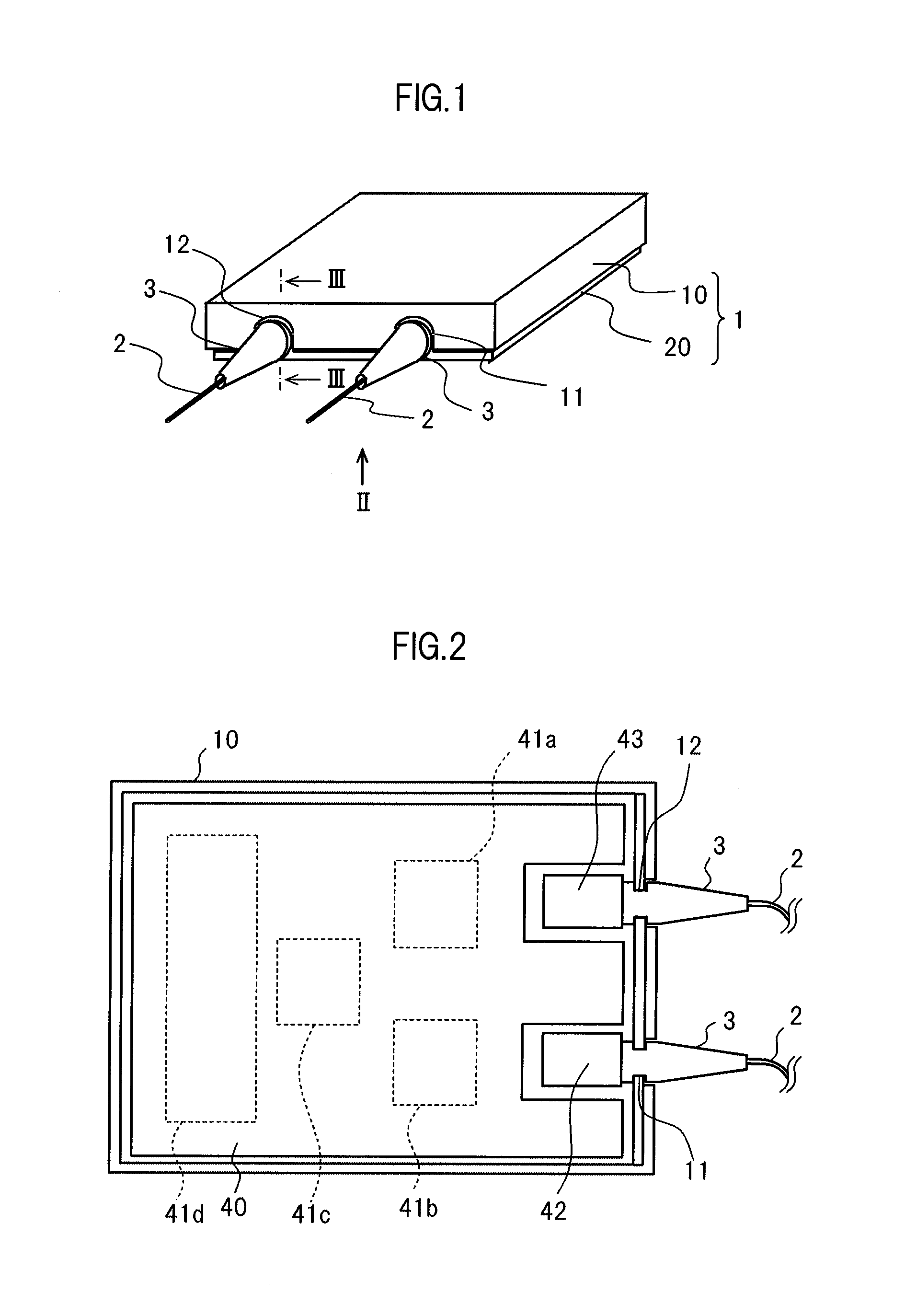

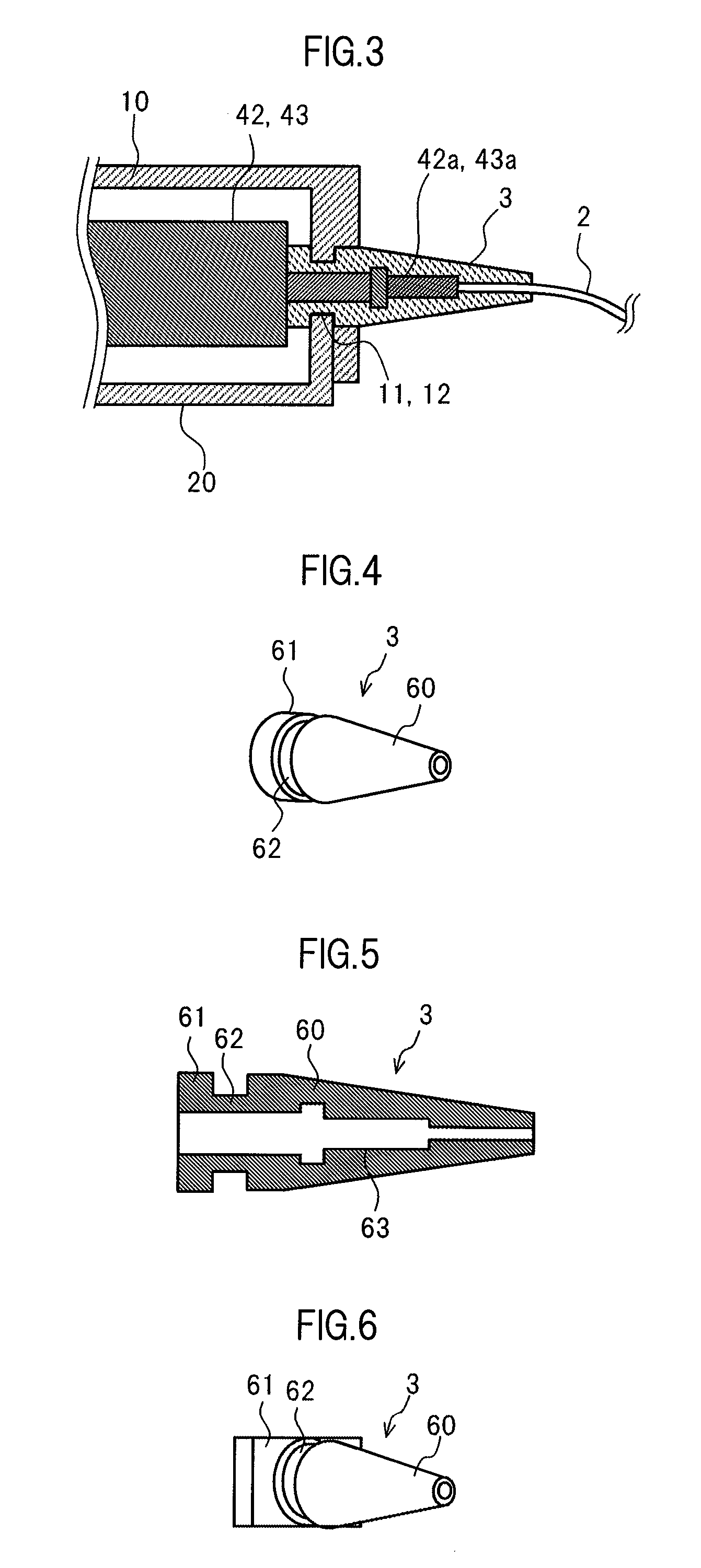

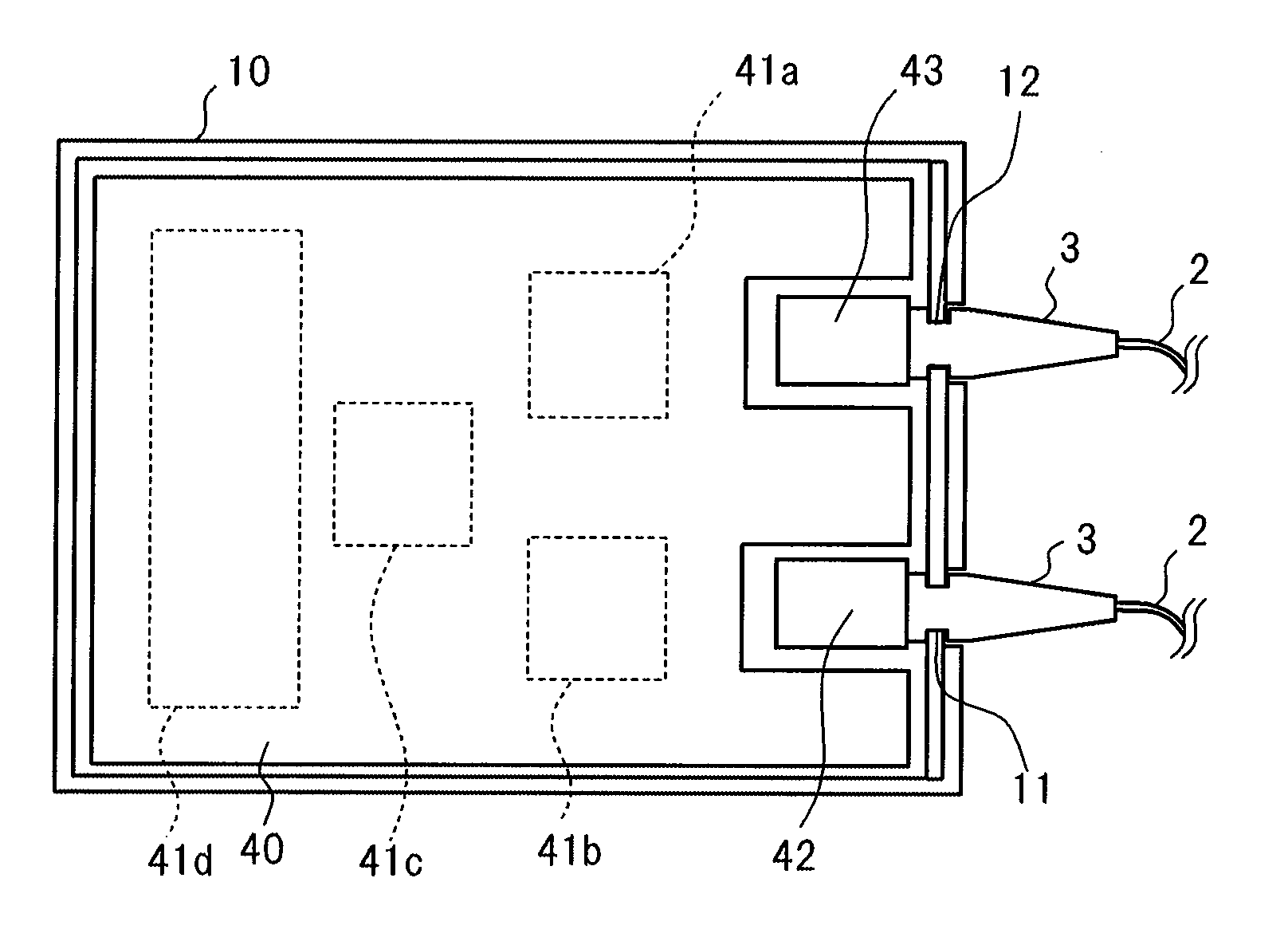

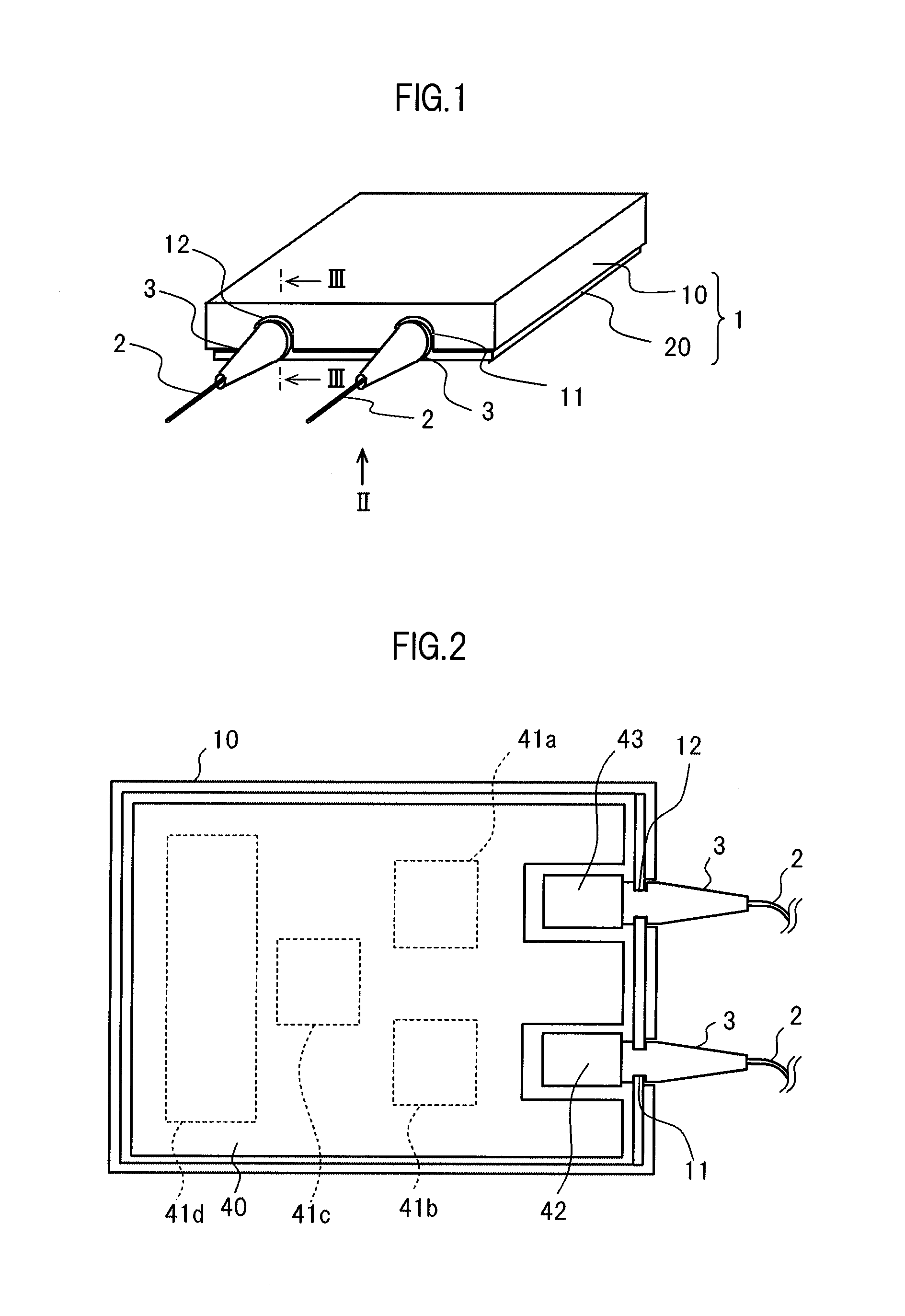

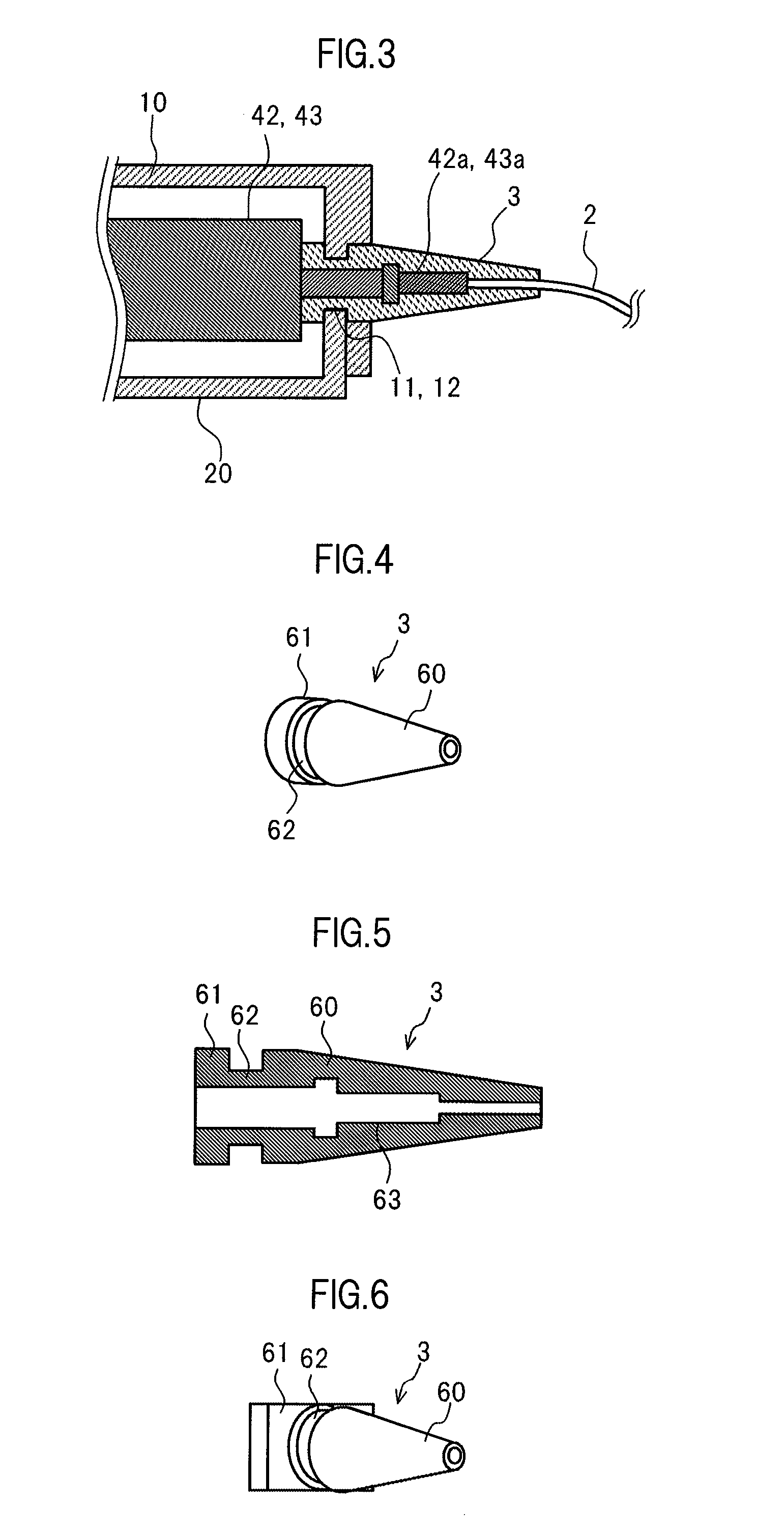

Optical transceiver and projection covering member

ActiveUS8313251B2EMI noise suppressionReduce calorie consumptionCoupling light guidesTransceiverOptical coupling

An optical transceiver has a projection covering member that can suppress EMI noise radiated from a pig-tail part. An elastic covering member covers a projection which includes an optical coupler of an optical sub assembly. The covering member is made of a conductive elastic material having a predetermined resistivity. At least a part of an outer circumference surface of the elastic covering member comes into intimate contact with an outer periphery of a conductive opening part of a case for the optical transceiver while an inner circumference surface of the elastic covering member comes into intimate contact with the projection.

Owner:LUMENTUM JAPAN INC

Optical transceiver and projection covering member

ActiveUS20100074574A1Total current dropEMI noise suppressionCoupling light guidesOptical waveguide light guideTransceiverOptical coupler

Provided are an optical transceiver and a projection covering member that can suppress EMI noise radiated from a pig-tail part. An elastic covering member for covering a projection which includes an optical coupler of an optical sub assembly is made of a conductive elastic material having predetermined resistivity. At least a part of an outer circumference surface of the elastic covering member comes into intimate contact with an outer periphery of a conductive opening part of a case while an inner circumference surface of the elastic covering member contacts with the projection.

Owner:LUMENTUM JAPAN INC

Coalescing crude benzene oil-water separator and operating method thereof

PendingCN107281783AReduce calorie consumptionReduce contentHydrocarbonsAdsorption purification/separationBenzeneHeat losses

The invention relates to a coalescing crude benzene oil-water separator and an operating method thereof; the coalescing crude benzene oil-water separator comprises a barrel, a coalescing device mounted in the barrel, a circular liquid distributor pipe and a drainage guide pipe; the middle of the barrel is provided with a material inlet that is connected with the circular liquid distributor pipe; the coalescing device is arranged below the circular liquid distributor pipe; the upper portion of the barrel is provided with a crude benzene outlet and a separated water outlet, the separated water outlet is connected to the upper end of the drainage guide pipe, and the lower end of the drainage guide pipe penetrates the coalescing device and extends into the bottom space of the barre. The coalescing crude benzene oil-water separator and the operating method thereof have the advantages that droplets in crude benzene from a benzene removal tower can be adsorbed to the surface of the coalescing device, large drops formed are separated from the coalescing device and are isolated from the crude benzene by gravity, the water content in crude benzene can be greatly decreased, heat loss of the benzene removal tower is reduced, product quality and production efficiency are improved, and labor intensity is decreased.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

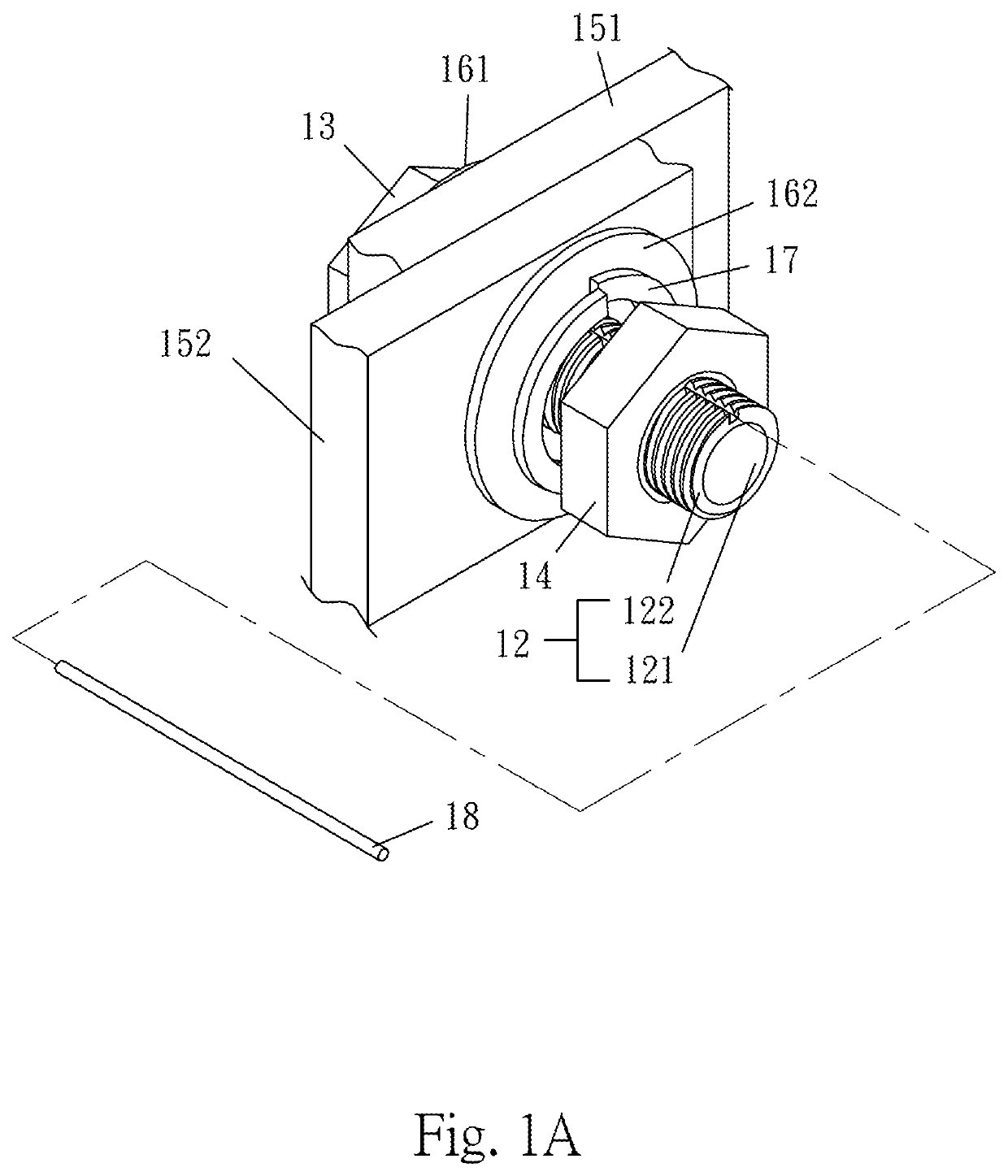

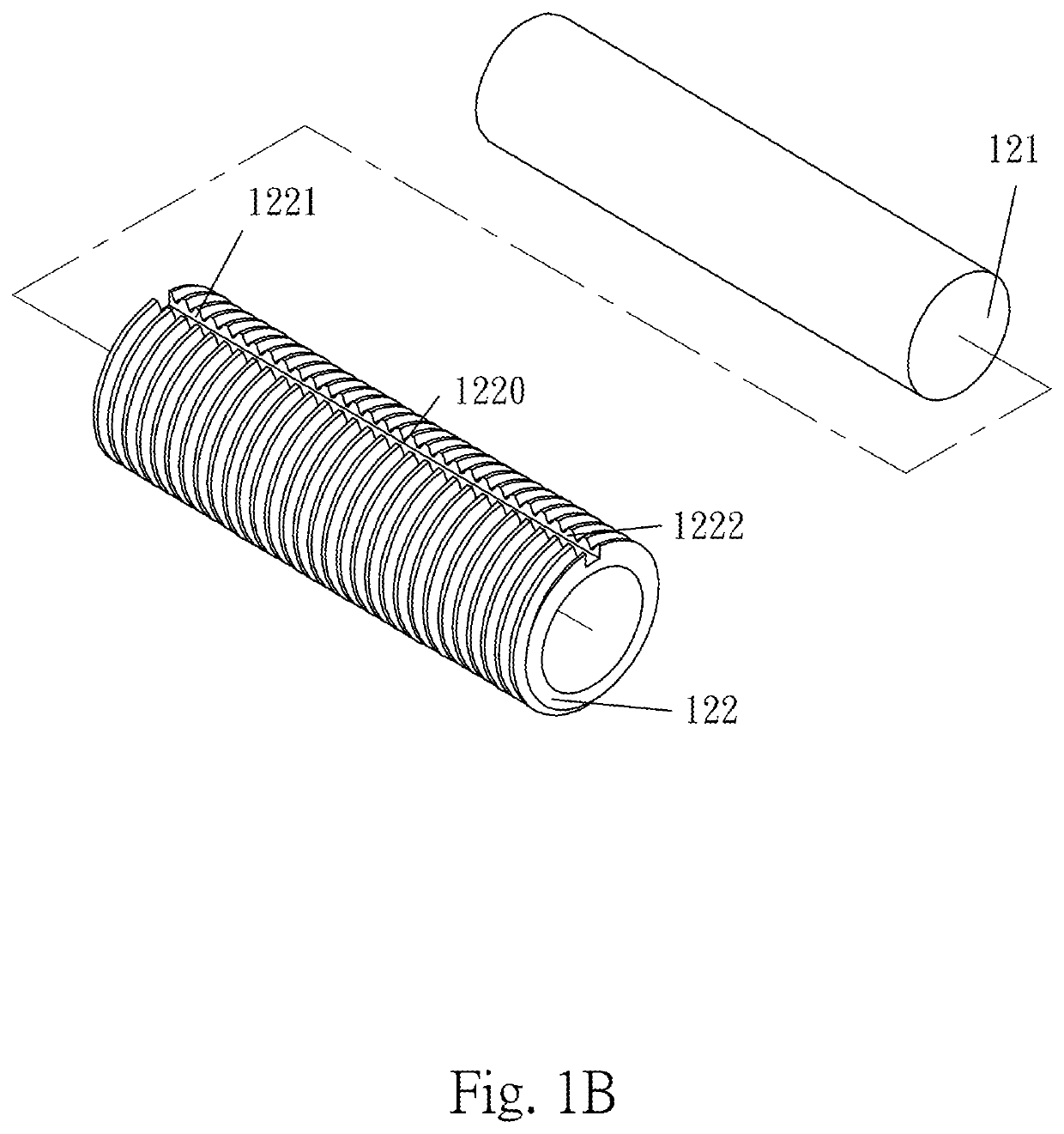

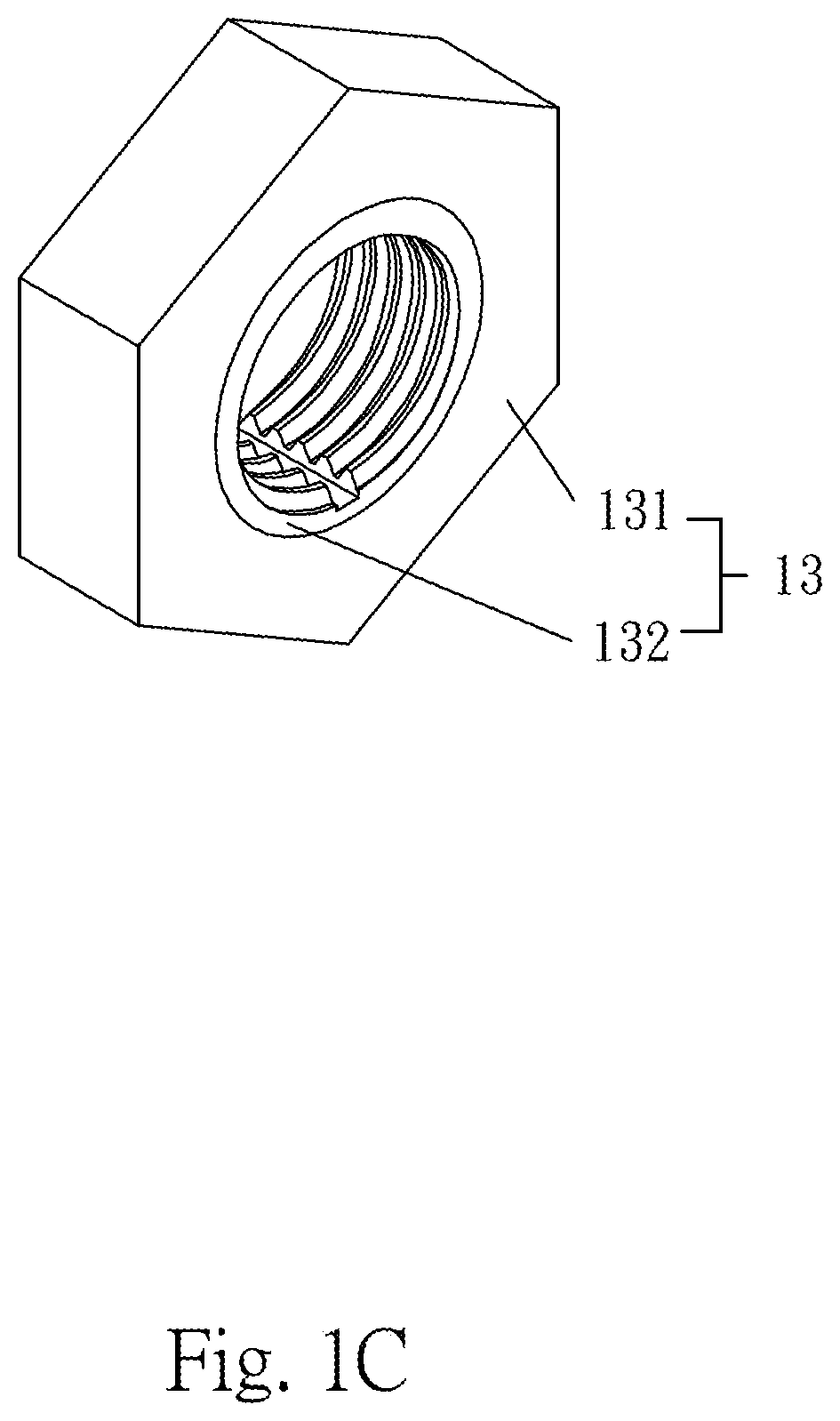

Eco-friendly fastener structure with lockable stainless steel screw pair

ActiveUS20210222725A1Correct tightening forceNever looseningWashersNutsAgricultural engineeringStructural engineering

The two lockable stainless and lossless screw pairs at two ends of the bolt are provided both to avoid screw pairs stained or destroyed by strain force from loading and to decrease the cost because of energy consumption in traditional process of bolt or its cost from environmental pollution.

Owner:YANG CHIEN FANG

Tunnel kiln for firing ceramic items

InactiveCN101479552AReasonable temperature modeReduce calorie consumptionFurnace typesWaste heat treatmentQuality characteristicsTunnel kiln

Owner:阿尔乔姆·茹里耶维奇·柴卡

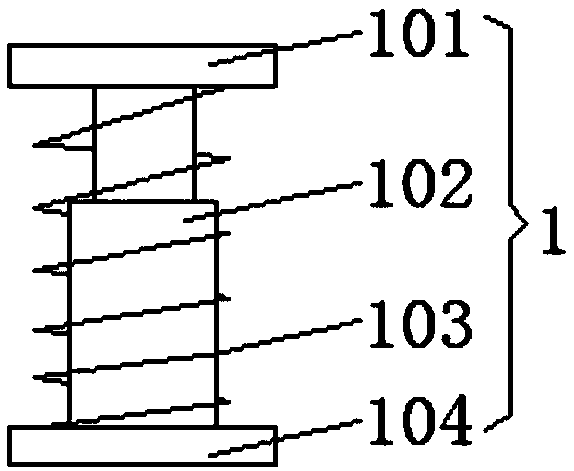

Novel printing platform

ActiveCN105773972AReduce calorie consumptionUniform heat distributionAdditive manufacturing apparatusHeat distributionEngineering

The embodiment of the invention discloses a novel printing platform. A main platform mounting plate, main platform connecting plates and main platform fixing plate bolts of the novel printing platform are connected to form a novel printing platform framework. A supporting bar is transversely mounted on the main platform connecting plates through bolts, and meanwhile the upper portion of the supporting bar is connected with a forming plate so that the forming plate can be fixed. Heating tubes are used for heating. The heating tubes are mounted on the supporting bar and are fixed by porcelain pads and stainless steel gaskets. Connecting wires of the heating tubes stretch out through holes in the main platform mounting plate. A model printing platform surface is composed of a conveyor belt and the forming plate. A driving shaft and a driven shaft are mounted on the main platform mounting plate and are connected with the conveyor belt. The driving shaft drives the conveyor belt and the driven shaft to move. The novel printing platform has the following beneficial effects that the forming plate is matched with the conveyor belt and the heating tubes for heating, so that heat consumption is small, and heat distribution is uniform.

Owner:HUBEI JIAXIN DONGYI CNC TECH

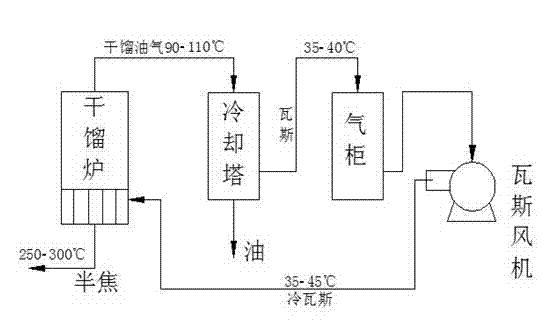

Process and device for recovering carbocoal heat discharged from carbonization furnace

ActiveCN102863974AImprove thermal energy utilization efficiencyReduce calorie consumptionCoke ovensMetallurgyCarbonization

The invention relates to a device arranged in a carbonization furnace for recovering carbocoal heat discharged from the carbonization furnace. The device is characterized in that a cold gas jetting device consisting of lattice walls, cold gas passages and cold gas jetting holes is arranged at the bottom of the carbonization furnace. Cold gas at the temperature of 35-45 DEG C is jetted, so that the temperature of the carbocoal heat discharged from the carbonization furnace is reduced from 500-550 DEG C to 250-300 DEG C recovered heat is used for complementing heat required for carbonization, and heat consumption of the carbonization furnace is reduced.

Owner:辽宁成大能源科技有限公司

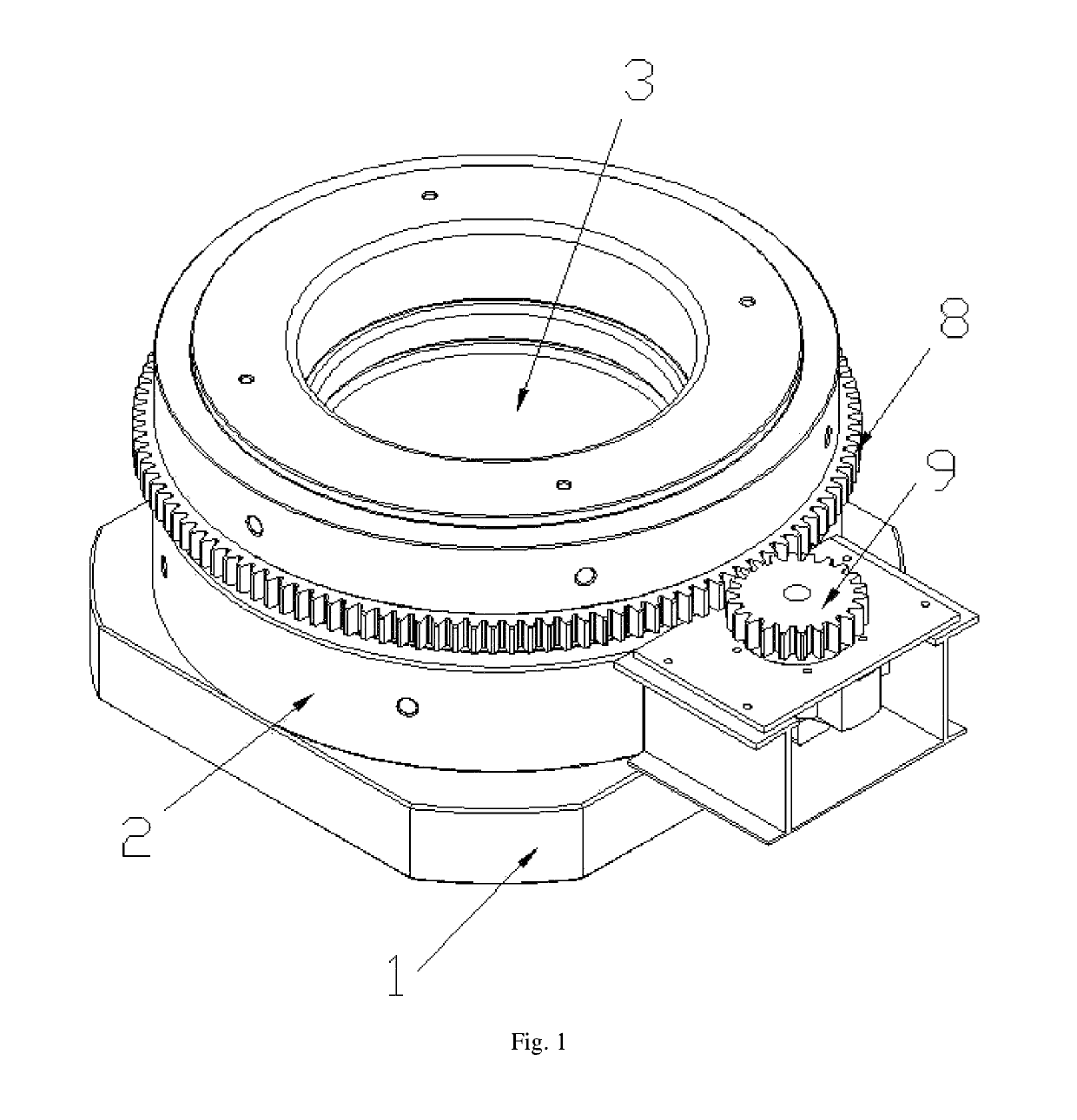

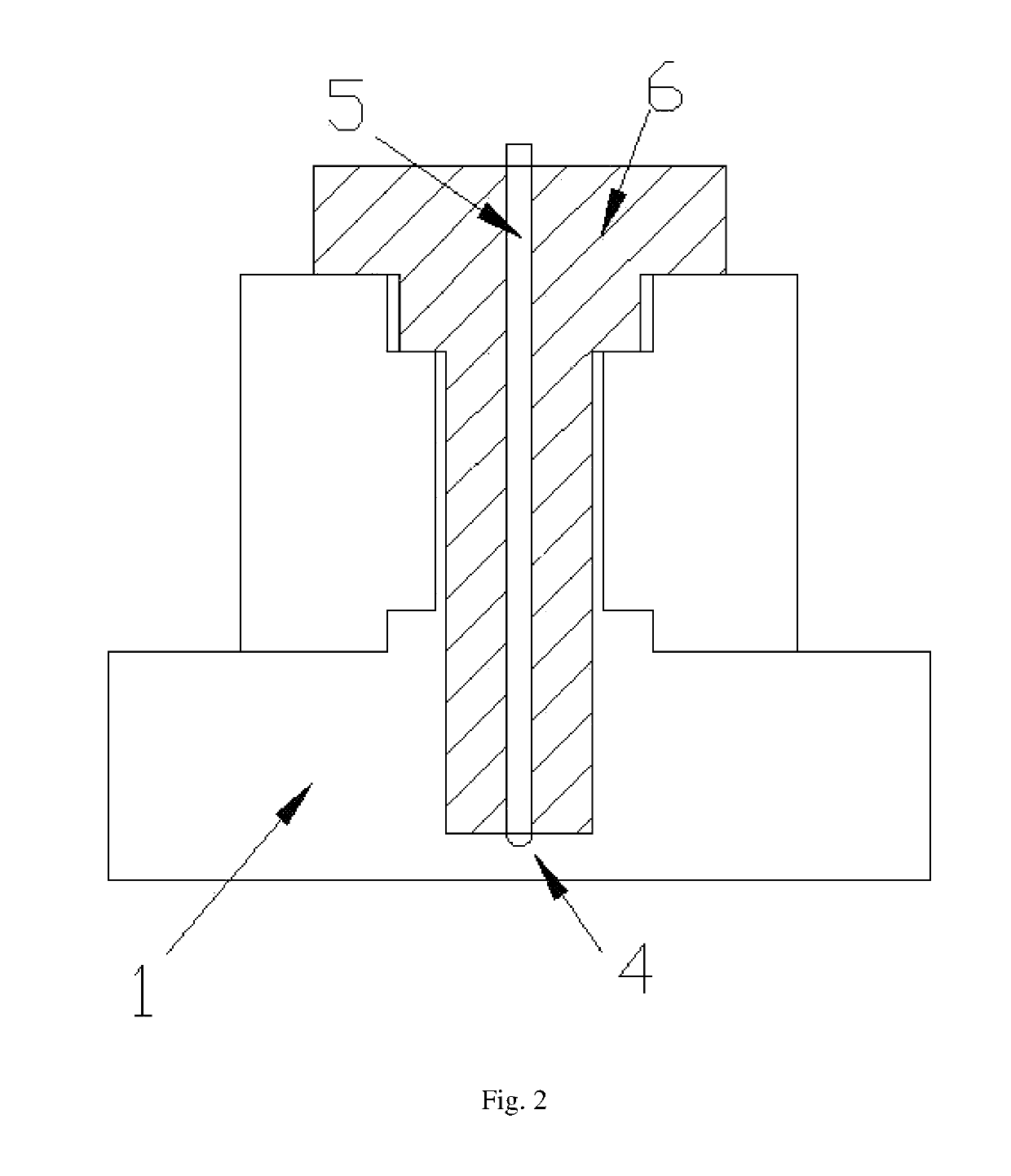

Hollow forging process for main shaft of large wind turbine generator

A hollow forging process for main shaft of large wind turbine generator, wherein, comprising the following steps as: the first step of cutting off the dead head and the bottom of an ingot; the second step of upsetting and punching a hole; the third step of drawing-out; and the fourth step of local upsetting, drawing-out and shaping-up. In the fourth step, the forged piece is shaped up by local upsetting and drawing-out through a turnplate. The hollow forging process for main shaft created by the invention can save the costs for enterprise to purchase large equipment and makes it possible to forge the main shaft of large wind turbine generator with a free forging oil press with a smaller size.

Owner:JIANGYIN ZENKUNG FORGING CO LTD

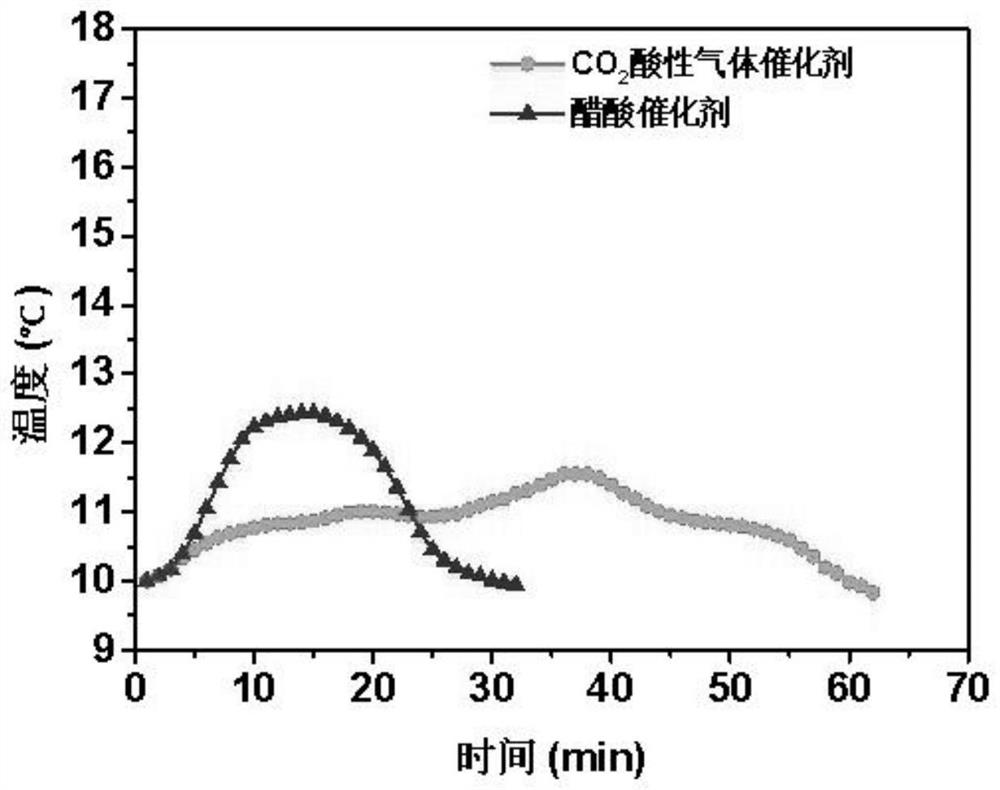

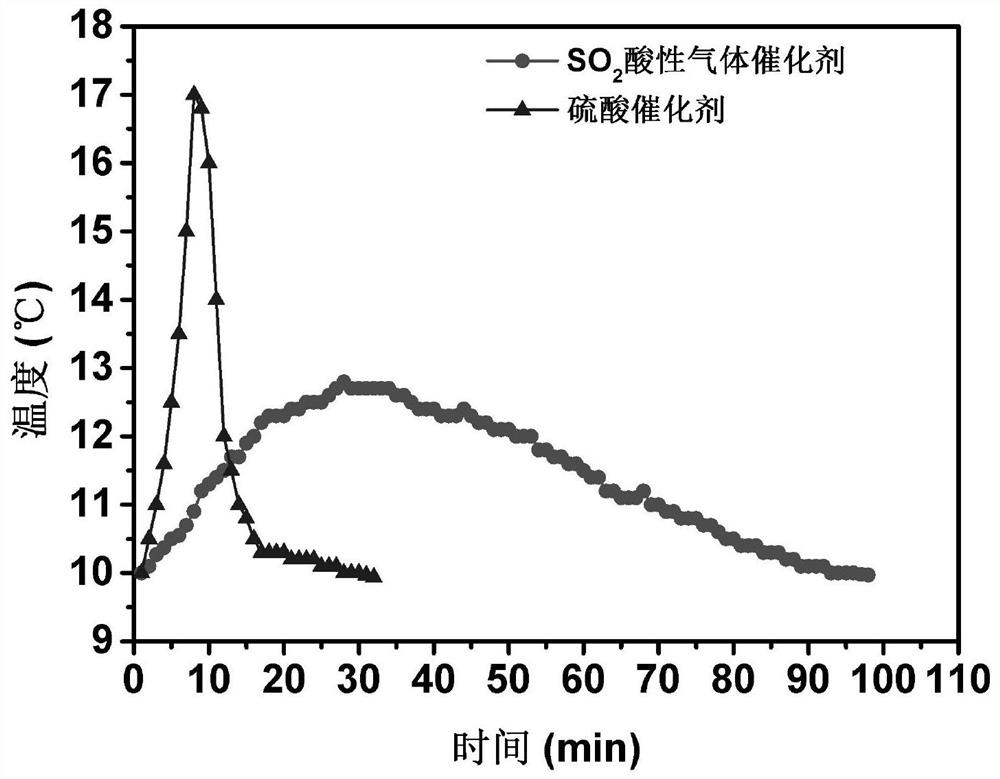

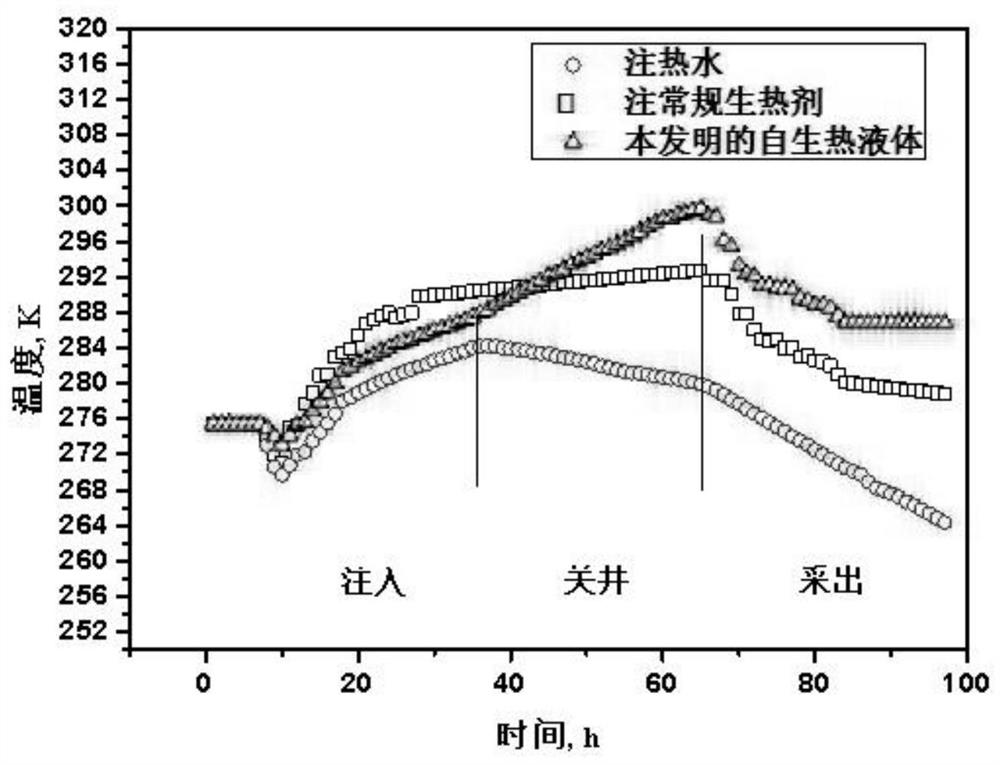

Chemical heat generating agent for natural gas hydrate exploitation and application of chemical heat generating agent

ActiveCN113216910AReduce calorie consumptionRegulated release rateInsulationFluid removalAqueous solutionEnvironmental geology

The invention discloses a chemical heat generating agent for natural gas hydrate exploitation and application of the chemical heat generating agent. The chemical heat generating agent comprises a main agent I, a main agent II and an auxiliary agent, wherein the main agent I is prepared from the following components in percentage by mass volume of 10 to 32 percent of NaNO2, 1 to 7.5 percent of foaming agent, 2 to 7.5 percent of foam stabilizer and the balance of water; the foaming agent is cationic Gemini quaternary ammonium salt; the foam stabilizer is nanoparticles; the auxiliary agent is acidic gas, and the acidic gas is selected from CO2 and / or SO2; the volume ratio of the main agent I to the auxiliary agent is 1: (4-40), and the main agent I and the auxiliary agent are mixed according to the volume ratio to obtain the foam liquid; and the main agent II is an NH4Cl aqueous solution. The chemical heat generating agent system disclosed by the invention can release a large amount of heat, can regulate and control the release speed of the heat, and meets the requirements of reservoir deep energy transportation in natural gas hydrate exploitation.

Owner:LIAOCHENG UNIV

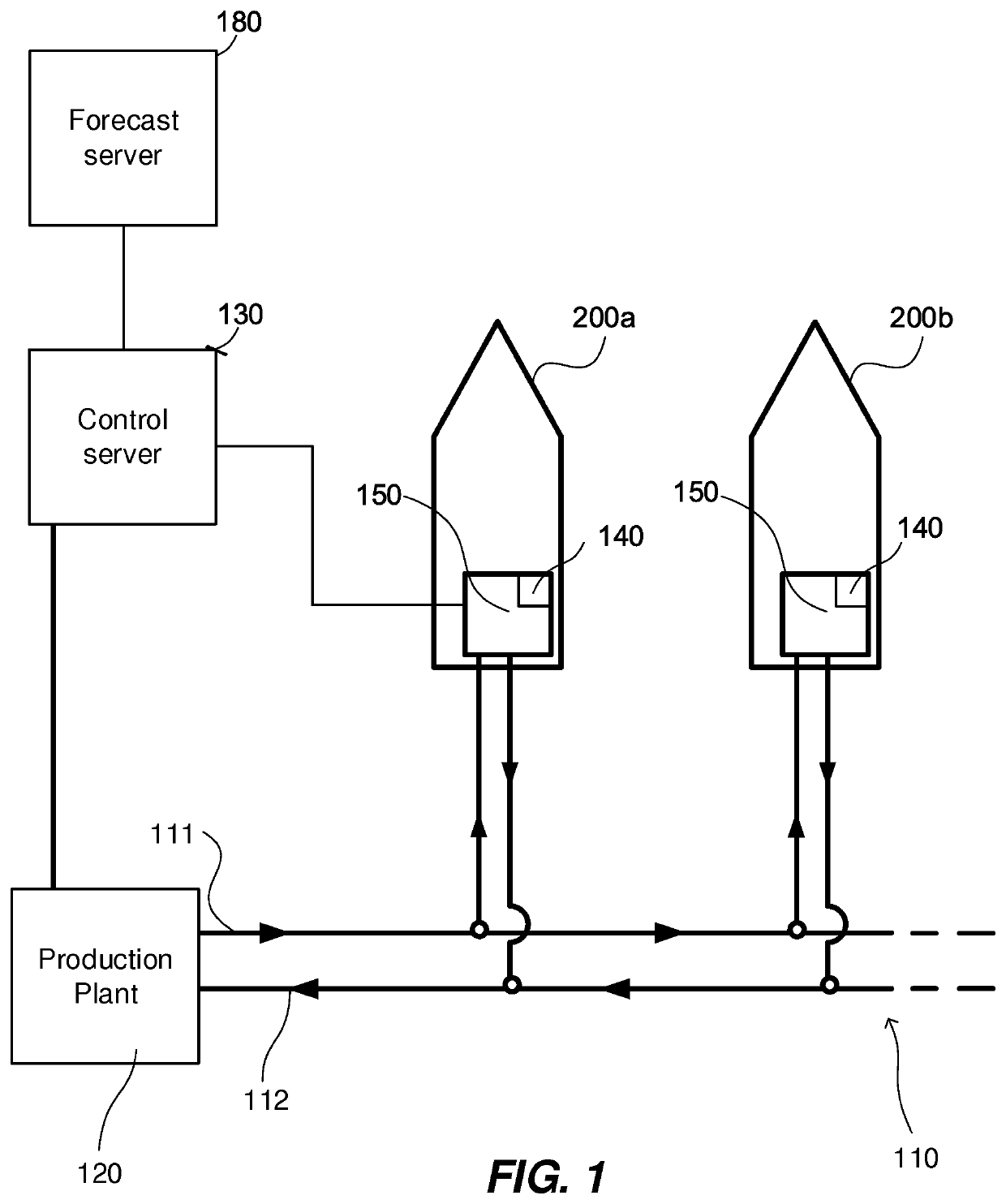

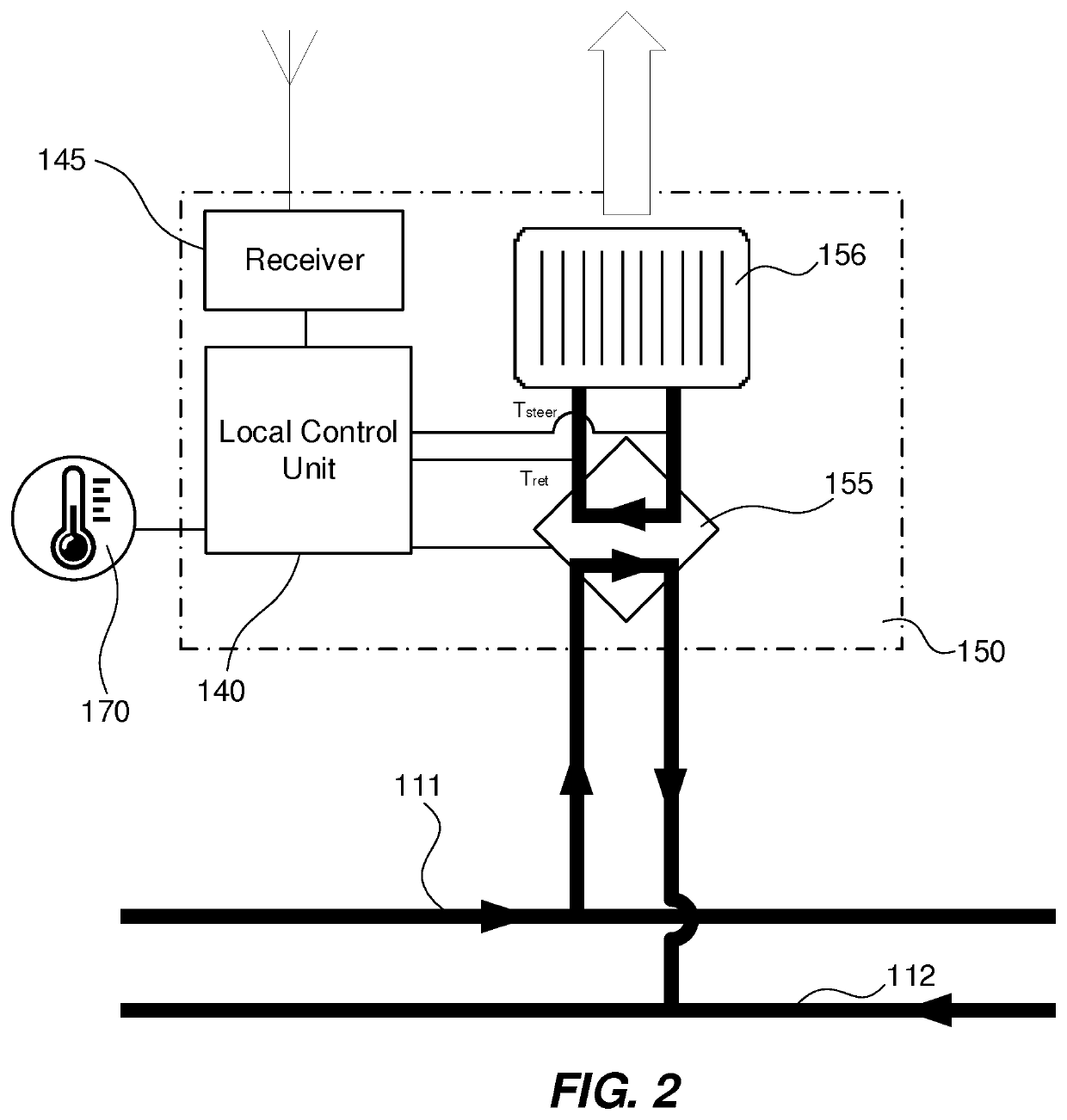

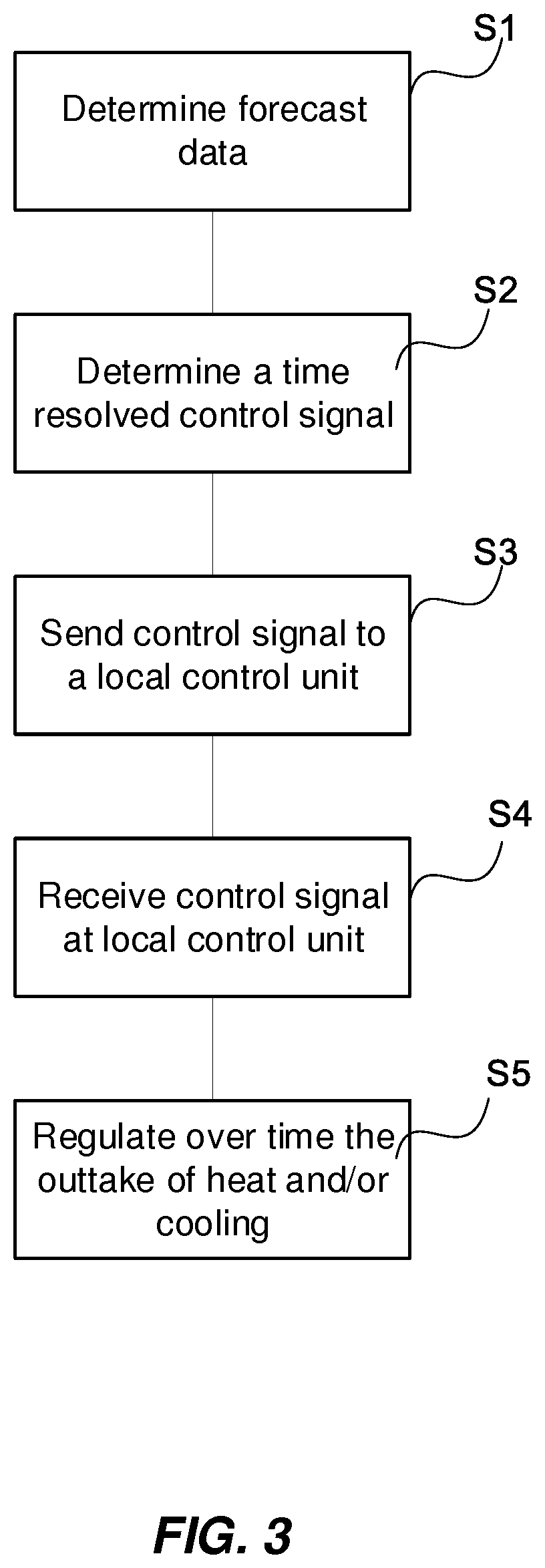

Thermal energy distribution system and control method thereof

PendingUS20210341167A1Uniform outtakeReduce temperatureDistrict heating systemHeating fuelProcess engineeringElectricity distribution systems

The disclosure relates to a method for controlling a thermal energy distribution system, the method comprising:—determining forecast data pertaining to expected overall outtake of heat and / or cooling over time from a distribution grid by local distribution systems connected to the distribution grid, and to expected production capacity of heat and / or cooling in one or more production plants,—determining, at a control server, a time resolved control signal, the control signal being based on forecast data and being associated with at least one local control unit,—sending the control signal from the control server to the associated local control unit,—receiving the control signal at the associated local control unit,—regulating over time, in response to the control signal, the outtake of heat and / or cooling of the local distribution system from the distribution grid. The thermal energy distribution system is also claimed

Owner:E ON SVERIGE

Double-layer ceramic tile for thermal insulation of building

InactiveCN108678317AImprove insulation effectReduce calorie consumptionCovering/liningsFlooringThermal insulationCeramic tiles

The invention discloses a double-layer ceramic tile for thermal insulation of a building in the technical filed of buildings. The double-layer ceramic tile comprises a support device, wherein the topand the bottom of the support device are connected with an upper ceramic tile and a lower ceramic tile respectively; mounting blocks are arranged on the outer walls of the right sides of the upper ceramic tile and the lower ceramic tile; mounting grooves matched with the mounting blocks are formed in the outer walls of the left sides of the upper ceramic tile and the lower ceramic tile; clamp blocks are uniformly arranged at front and rear ends of the right side of each of the upper ceramic tile and the lower ceramic tile; clamp grooves matched with the clamp blocks are uniformly formed in front and rear ends of the left side of each of the upper ceramic tile and the lower ceramic tile; waterproof layers are arranged at the bottom of the upper ceramic tile and the top of the lower ceramictile; three thermal insulation plates are arranged between the two waterproof layers from top to bottom sequentially. The mounting grooves are connected with the mounting blocks, so that a gap in thedouble-layer ceramic tile is reduced; insulation side plates are Z-shaped, accordingly, two adjacent ceramic tiles can be fit and connected perfectly, the interval between the ceramic tiles is reduced, mutual effect of the adjacent ceramic tiles is prevented, and indoor thermal insulation efficiency is improved.

Owner:周圣兰

Electric water-heater with adjustable power

ActiveUS20170027023A1Reduce calorie consumptionWeaken energyPower network operation systems integrationTemperatue controlPower gridAlternating current

The invention relates to a system (1) comprising:a heating device (11) comprising at least one heating means (110) supplied by an AC power grid (2);a control module (12) for controlling said heating device (11),the system being characterised in that the heating means (110) is supplied via a switching converter (120) rectifying the alternating current of the grid (2) into direct current, the switching converter (120) being controlled by the control module (12) in accordance at least with descriptive data of a state of said power grid (2), so as to adjust the power of the heating means (110).

Owner:ELECTRICITE DE FRANCE

Automobile part automatic annealing device

ActiveCN108285956ASave electricitySimple automatic loading and unloadingFurnace typesHeat treatment furnacesDrive wheelEngineering

Owner:宁波鑫神泽汽车零部件有限公司

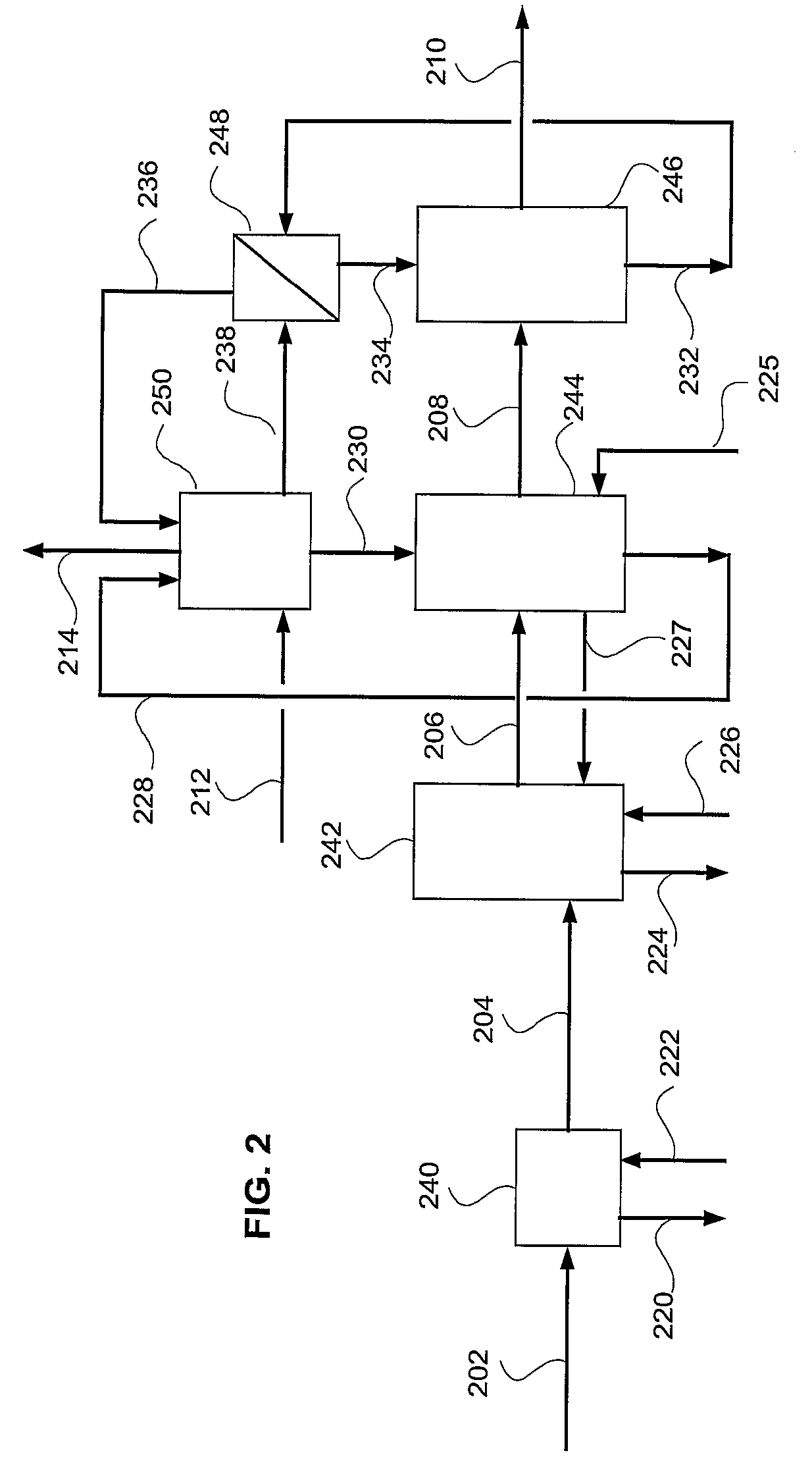

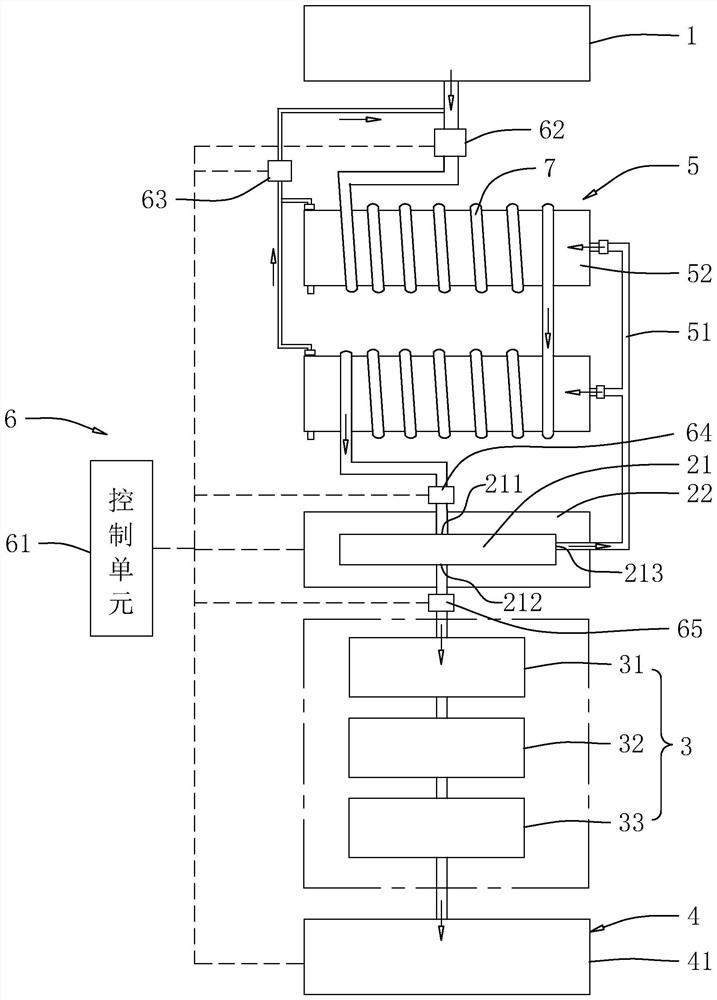

Membrane tube test platform for hydrogen purification and testing method thereof

InactiveCN113101813AReduce wasteReduce calorie consumptionSemi-permeable membranesHydrogen separation by diffusionPhysicsChemistry

The invention relates to a membrane tube testing platform for hydrogen purification and a testing method thereof.The membrane tube testing platform for hydrogen purification comprises a hydrogen production device, a membrane tube purification system, a filtering system and a detection system which are sequentially connected through a pipeline, and further comprises a tail gas backflow system and a monitoring system; and the hydrogen production device generates hydrogen-rich gas and conveys the hydrogen-rich gas to the membrane tube purification system, the membrane tube purification system separates hydrogen and conveys the hydrogen to the filtering system, tail gas separated by the membrane tube purification system is conveyed to the tail gas backflow system, and the filtering system filters the hydrogen and conveys the hydrogen to the detection system. Hydrogen in the tail gas is separated by the tail gas backflow system and is conveyed to an upstream pipeline of the membrane tube purification system; and the monitoring system includes a control unit, a first gas flow meter, and a sensor assembly. According to the invention, the membrane tube in the hydrogen purification technology can be conveniently tested.

Owner:嘉寓氢能源科技(辽宁)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com