Coalescing crude benzene oil-water separator and operating method thereof

An oil-water separator and coalescer technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of increasing production costs, large floor space, and increased water content in crude benzene, and improve product quality. and production efficiency, reduce heat consumption, reduce the effect of water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

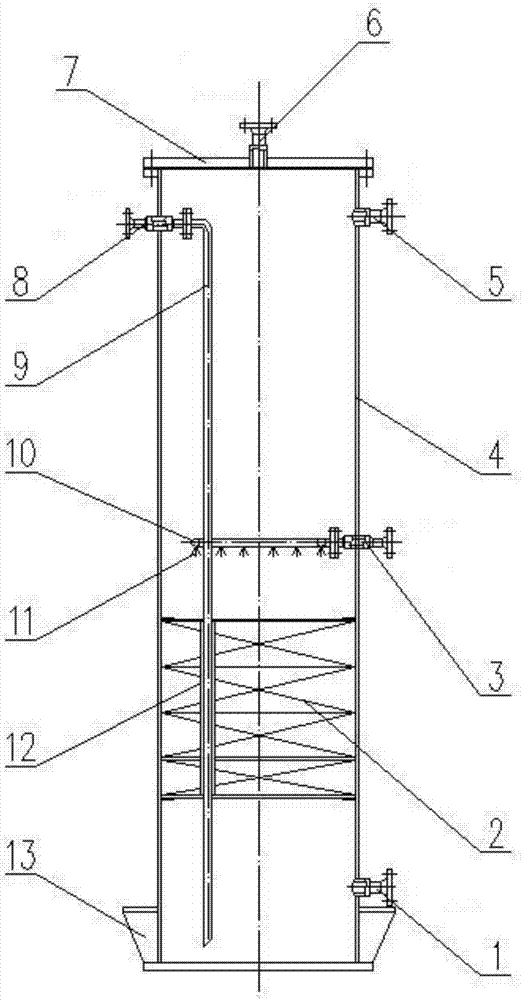

[0019] Such as figure 1 As shown, a coalescing crude benzene oil-water separator of the present invention includes a cylinder 4 and a coalescer 2 installed in the cylinder 4, an annular liquid distribution pipe 10 and a drain conduit 9; the middle part of the cylinder 4 The raw material inlet 3 is set, and the raw material inlet 3 is connected with the annular liquid branch pipe 10; the coalescer 2 is arranged under the annular liquid distribution pipe 10; the upper part of the cylinder 4 is provided with a crude benzene outlet 5 and a separated water outlet 8, and the separated water outlet 8 is connected to the drain pipe 9, the lower end of the drain conduit 9 passes through the coalescer 2 and stretches into the bottom space of the cylinder 4.

[0020] A sleeve 12 is arranged in the coalescer 2 , and the drainage conduit 9 passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com