Chemical heat generating agent for natural gas hydrate exploitation and application of chemical heat generating agent

A kind of hydrate and chemical generation technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of slowing down the heat generation rate and uncontrollable heat of chemical heat generating agents, so as to reduce the consumption of heat Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

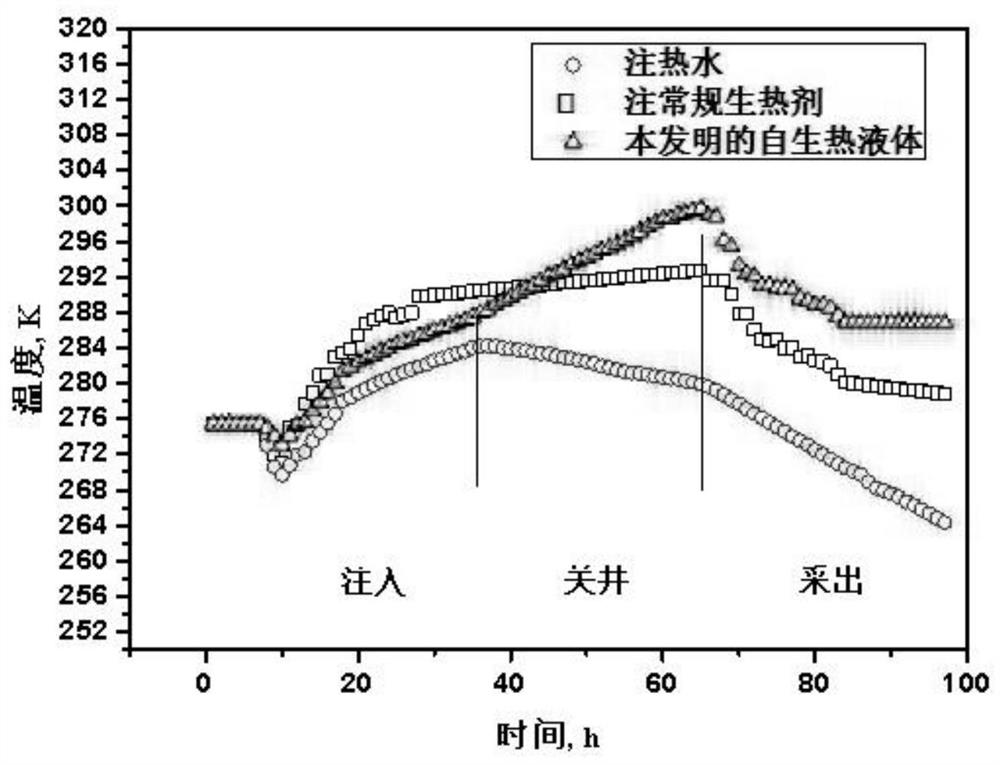

Problems solved by technology

Method used

Image

Examples

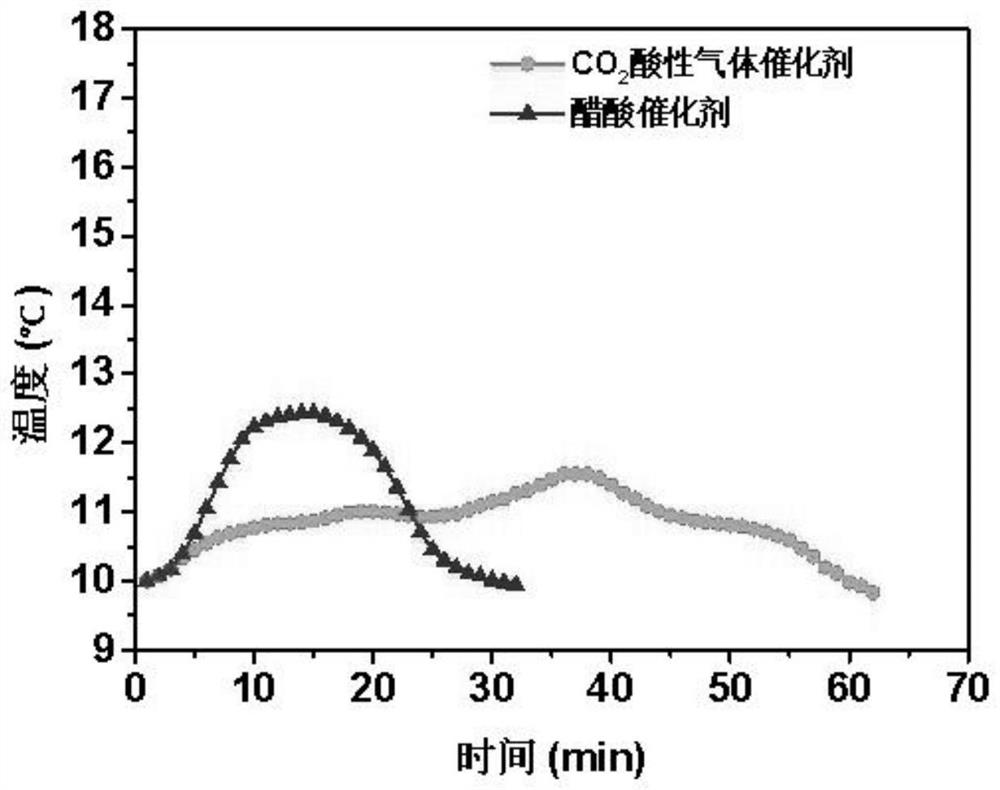

Embodiment 1

[0024] A chemical heat generating agent for natural gas hydrate exploitation, the main agent I of the heat generating agent includes the following components in mass volume percentage (W / V, g / mL): 1% foaming agent, 2% foam stabilizer agent, 10% sodium nitrite, and the balance is water; wherein, the foaming agent is selected from diquaternary ammonium adipate, and the foam stabilizer is selected from nano-silica particles. The auxiliary agent of the heat generating agent is CO 2 , main agent I and CO 2 The volume ratio is 1:4, and the main agent I and the auxiliary agent are mixed according to the volume ratio to obtain the foam liquid. The main agent II of the heat generating agent is NH 4 Cl aqueous solution, NH 4 The molar concentration of Cl aqueous solution is equal to the molar concentration of sodium nitrite in the foam liquid.

[0025] The preparation of the main ingredient I is as follows: add part of the water to the reaction vessel I, heat to 60°C, and then add 1...

Embodiment 2

[0031] A chemical heat generating agent for natural gas hydrate exploitation, the main agent I of the heat generating agent includes the following components in mass volume percentage (W / V, g / mL): 7.5% foaming agent, 7.5% foam stabilizer agent, 32% sodium nitrite, and the balance is water; wherein, the foaming agent is selected from diquaternary ammonium adipate, and the foam stabilizer is selected from nano silicon dioxide particles. The auxiliary agent of the heat generating agent is CO 2 , main agent I and CO 2 The volume ratio is 1:40, and the main agent I and the auxiliary agent are mixed according to the volume ratio to obtain the foam liquid. The main agent II of the heat generating agent is NH 4 Cl aqueous solution, NH 4The molar concentration of Cl aqueous solution is equal to the molar concentration of sodium nitrite in the foam liquid.

[0032] The preparation of the main ingredient I is as follows: add part of the water to the reaction vessel I, heat it to 60°C...

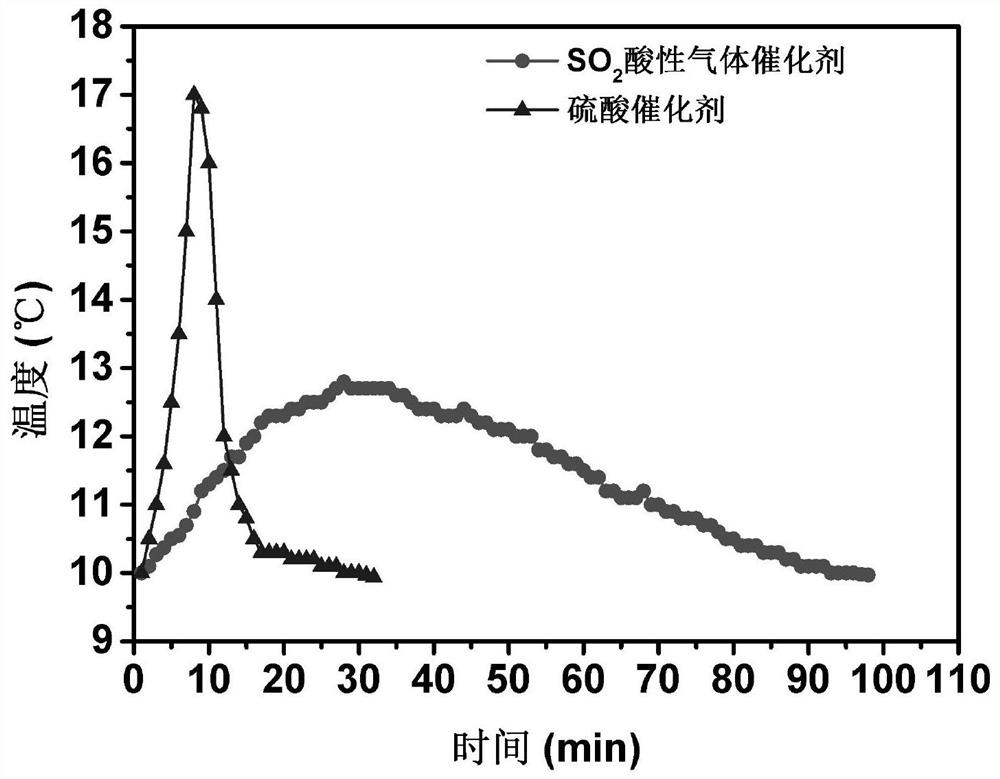

Embodiment 3

[0038] A chemical heat generating agent for natural gas hydrate exploitation, the main agent I of the heat generating agent includes the following components in mass volume percentage (W / V, g / mL): 1% foaming agent, 2% foam stabilizer agent, 10% sodium nitrite, and the balance is water; wherein, the foaming agent is selected from diquaternary ammonium adipate, and the foam stabilizer is selected from nano-silica particles. The auxiliary agent of the heat generating agent is SO 2 , main agent I and SO 2 The volume ratio is 1:10, and the main agent I and the auxiliary agent are mixed according to the volume ratio to obtain the foam liquid. The main agent II of the heat generating agent is NH 4 Cl aqueous solution, NH 4 The molar concentration of Cl aqueous solution is equal to the molar concentration of sodium nitrite in the foam liquid.

[0039] The preparation of the main ingredient I is as follows: add part of the water to the reaction vessel I, heat to 60°C, and then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com