Mixed working medium low-temperature refrigerating cycle system driving ejector through waste heat

A technology of mixing working fluid and ejector, which is used in machines using waste heat, machines using refrigerant evaporation, refrigerators, etc., can solve the problems of many components and complicated processes, and achieve the effect of reducing irreversible losses and system energy saving. Significantly reduce calorie consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

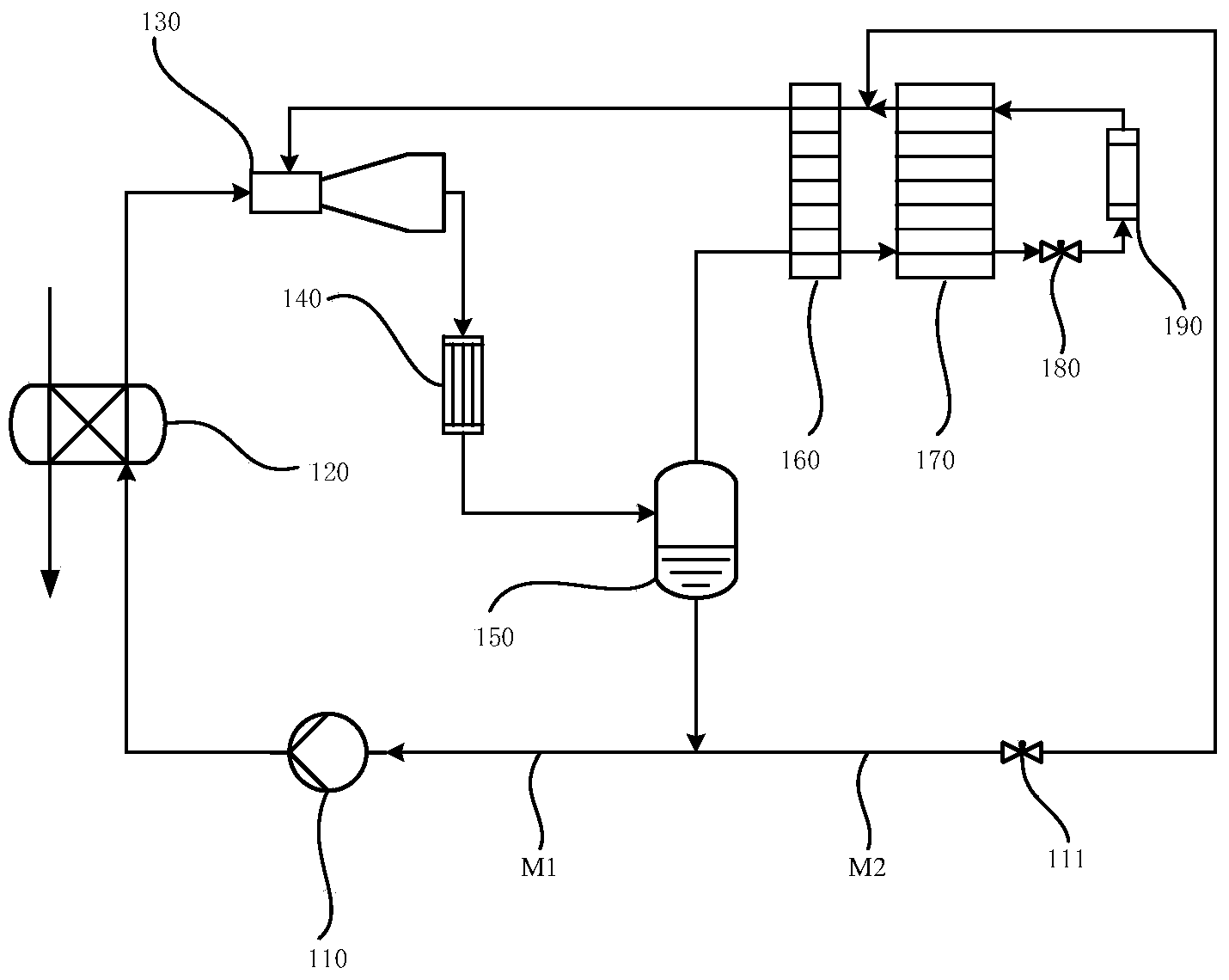

[0034] figure 1 It is an embodiment of the first technical scheme of the mixed working medium low-temperature refrigeration cycle system utilizing waste heat to drive the ejector of the present invention; figure 1 As shown, the mixed working medium low-temperature refrigeration cycle system using waste heat to drive the ejector in this embodiment includes a drive pump 110, a steam generator 120, an ejector 130, a condenser 140, a gas-liquid separator 150, a first regenerative heat exchanger 160, second regenerative heat exchanger 170, first throttle valve 180 and evaporator 190; the steam steam generator is driven by industrial waste heat, and the mixed working fluid is heated therein;

[0035]The outlet of the driving pump 110 is connected to the inlet of the steam generator 120, the outlet of the steam generator 120 is connected to the high-pressure inlet of the ejector 130, the outlet of the ejector 130 is connected to the inlet of the condenser 140, and the outlet of the e...

Embodiment 2

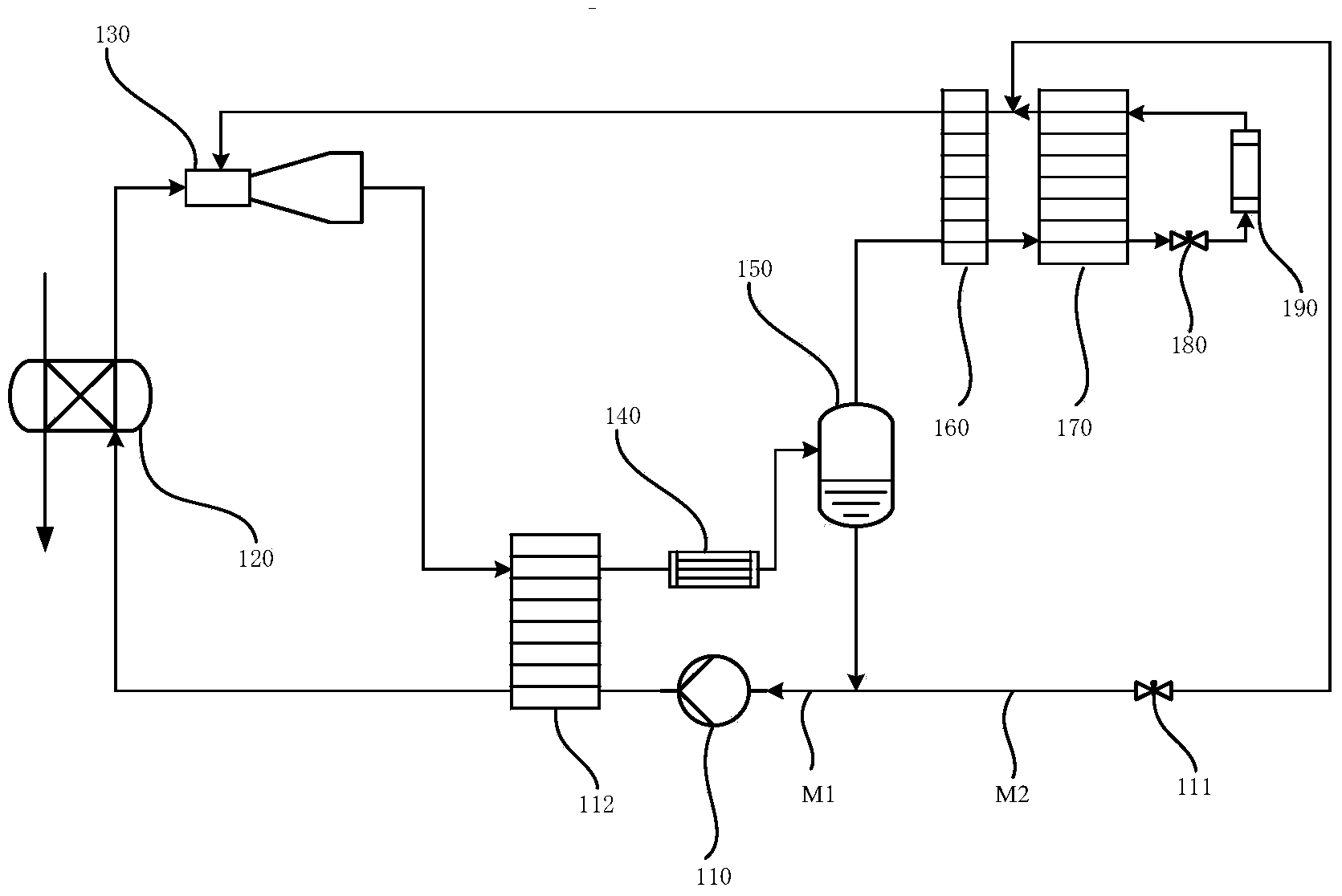

[0039] figure 2 It is another embodiment of the first technical solution of the present invention; the difference between this embodiment and Embodiment 1 is that it also includes a third recuperation heat exchanger 112, and the high-pressure inlet of the third recuperation heat exchanger 112 It is connected with the outlet of the driving pump 110, the high pressure outlet of the third recuperator 112 is connected with the inlet of the steam generator 120; the low pressure inlet of the third recuperator 112 is connected with the ejector 130 The outlet is connected, and the low-pressure outlet of the third heat recovery heat exchanger 112 is connected with the inlet of the condenser 140 .

[0040] The rest of this embodiment is the same as that of Embodiment 1; compared with Embodiment 1, this embodiment 2 adds a third regenerative heat exchanger 112, and utilizes the heat of the ejector 130 outlet working fluid to heat the outlet of the booster drive pump 110 fluid, improvin...

Embodiment 3

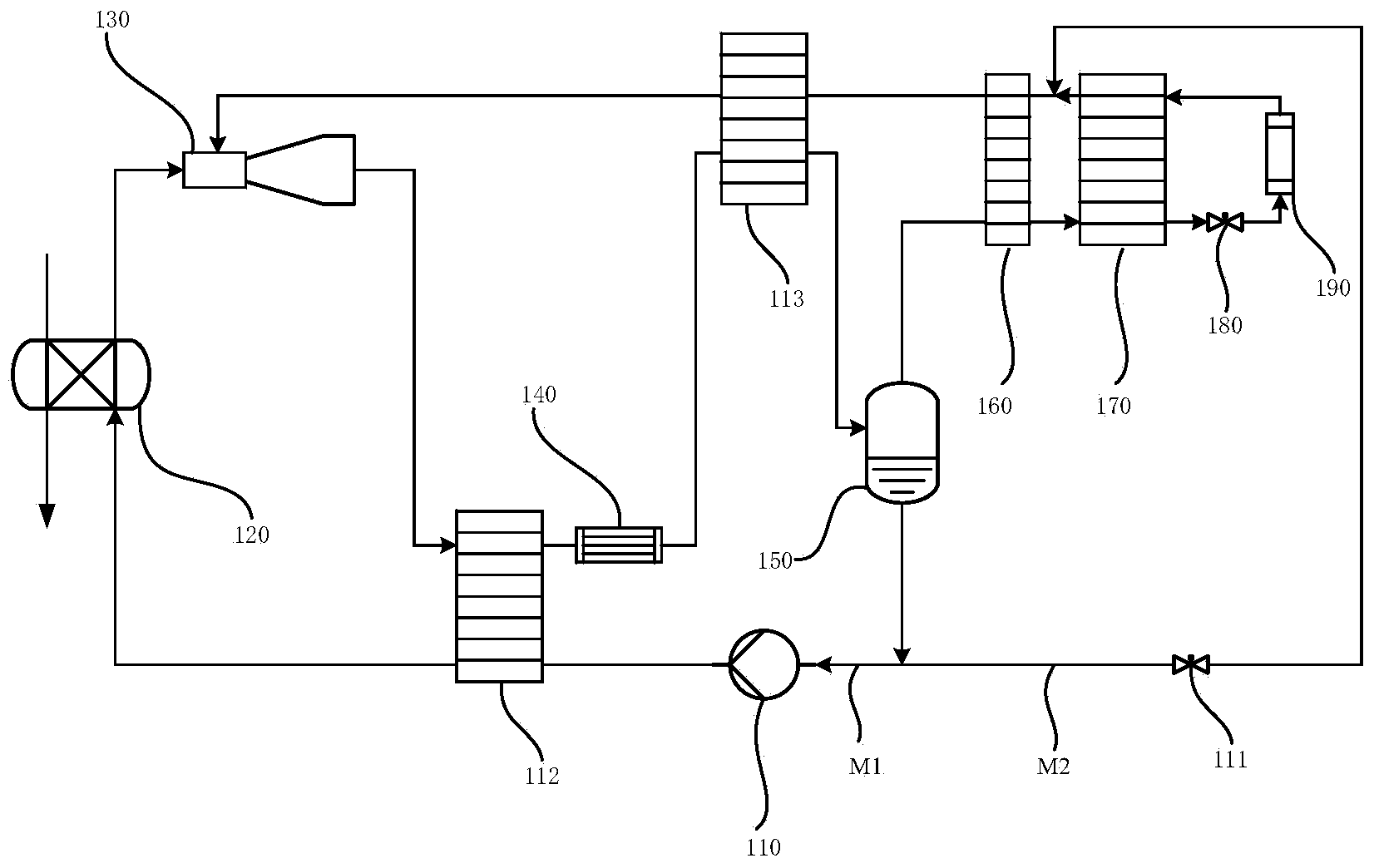

[0042] image 3 It is another embodiment of the first technical solution of the present invention; this embodiment 3 adds a fourth regenerative heat exchanger 113 on the basis of embodiment 2, and the high-pressure inlet of the fourth regenerative heat exchanger 113 is connected to the The outlet of the condenser 140 is connected, the high-pressure outlet of the fourth recuperator 113 is connected to the gas inlet of the gas-liquid separator 150; the low-pressure inlet of the fourth recuperator 113 is connected to the first The low pressure outlet of the regenerative heat exchanger 160 is connected, and the low pressure outlet of the fourth regenerative heat exchanger 113 is connected with the low pressure inlet of the ejector 130 .

[0043] The rest of this embodiment is the same as that of Embodiment 2; compared with Embodiment 2, this Embodiment 3 adds a fourth regenerative heat exchanger 113, and utilizes the working fluid at the low-pressure outlet of the first regenerato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com