Indirect thermal cracking and ash combustion smelting furnace and treatment method thereof

A thermal cracking and melting furnace technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of deformation of the wall of the analysis chamber, non-corrosion and non-condensing gas, incomplete combustion, etc., to reduce operating costs, The effect of reducing environmental pollution and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

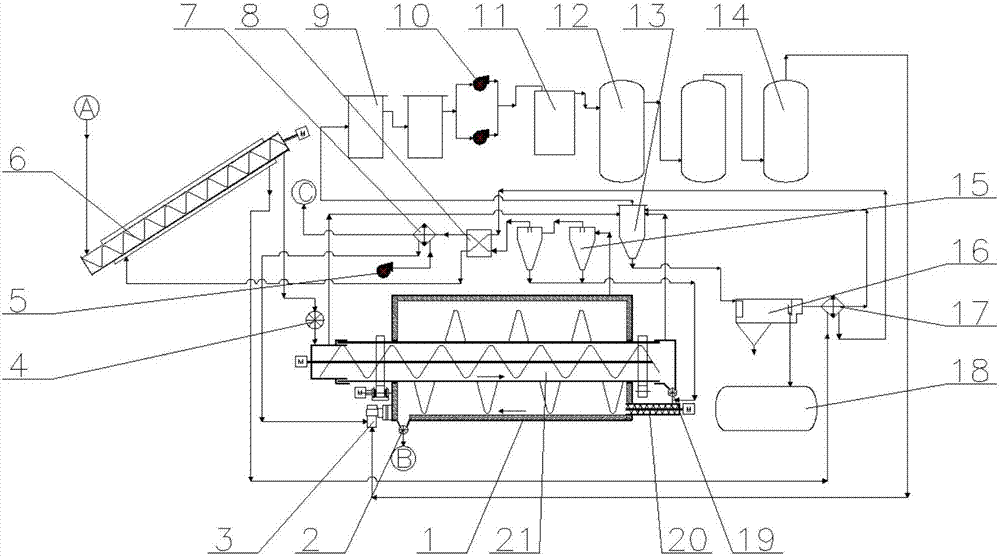

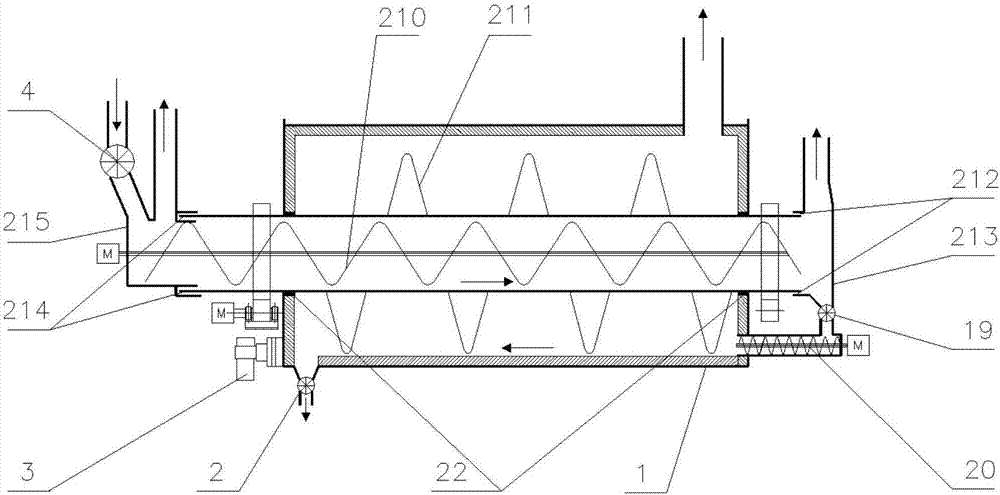

[0037] Such as Figure 1 to Figure 2 As shown, the present invention provides a high-efficiency, energy-saving and widely used indirect thermal cracking and ash combustion melting furnace, including a preheating feed system, a material heating system, a non-condensable gas treatment system and a condensation system.

[0038] The preheating feeding system includes a screw feeding device 6 with a heat exchange jacket and a waste heat boiler 8. The feeding end of the screw feeding device 6 is connected to the feeding port, and the material is physically crushed into a particle size smaller than 40mm granular post by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com