Process and device for recovering carbocoal heat discharged from carbonization furnace

A dry distillation furnace and semi-coke technology, which is applied in the coking oven and petroleum industry, etc., can solve the problem that the heat of semi-coke cannot be directly recovered, and achieve the effects of reducing heat consumption, high heat energy utilization efficiency, and reducing heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

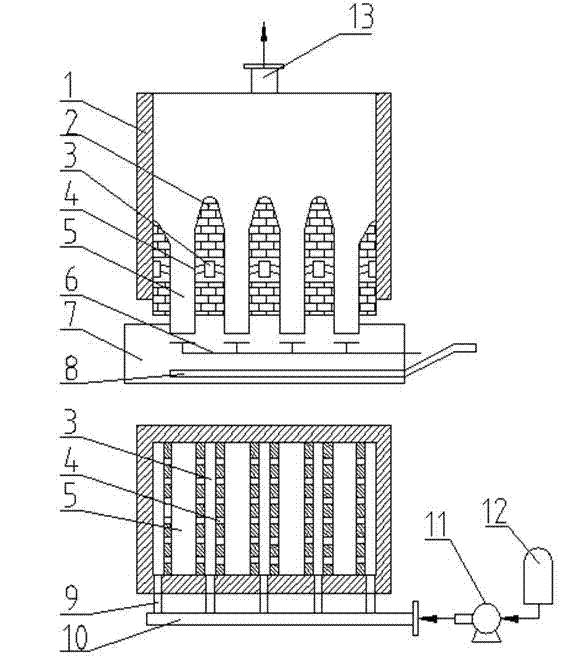

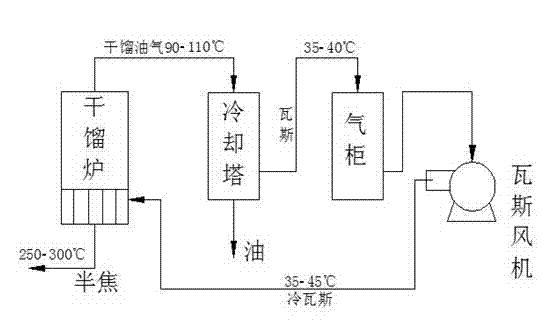

[0010] attached figure 1 Provided is the structure and connection diagram of the cold gas injection device of the present invention. It is characterized in that a plurality of upright hollow flower walls 2 are arranged at the lower part of the retort furnace, coke discharge channels 5 are formed between the two flower walls, the hollow part of the flower walls 2 is a cold gas channel 3, and two sides of the flower walls 2 are opened The cold gas injection hole 4; the outside of the cold gas channel 3 is connected in sequence with the cold gas inlet pipe 9, the cold gas connecting pipe 10, the gas blower 11, and the gas cabinet 12, and the dry distillation oil and gas discharge pipe 13 is arranged on the upper part of the dry distillation furnace.

[0011] When the carbonization furnace is in operation, the cold gas that has been cooled to 35°C to 45°C in the gas cabinet 12 is sent into the cold gas channel 3 through the gas fan 11 through the cold gas connection pipe 10 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com