Electric oven and control method thereof

An electric oven and control board technology, which is applied in non-electric variable control, temperature control, temperature control by electric means, etc., can solve the problems of hot air rising, sacrificing baking space, and low heat energy utilization of the upper heating tube, and achieves high The effect of heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

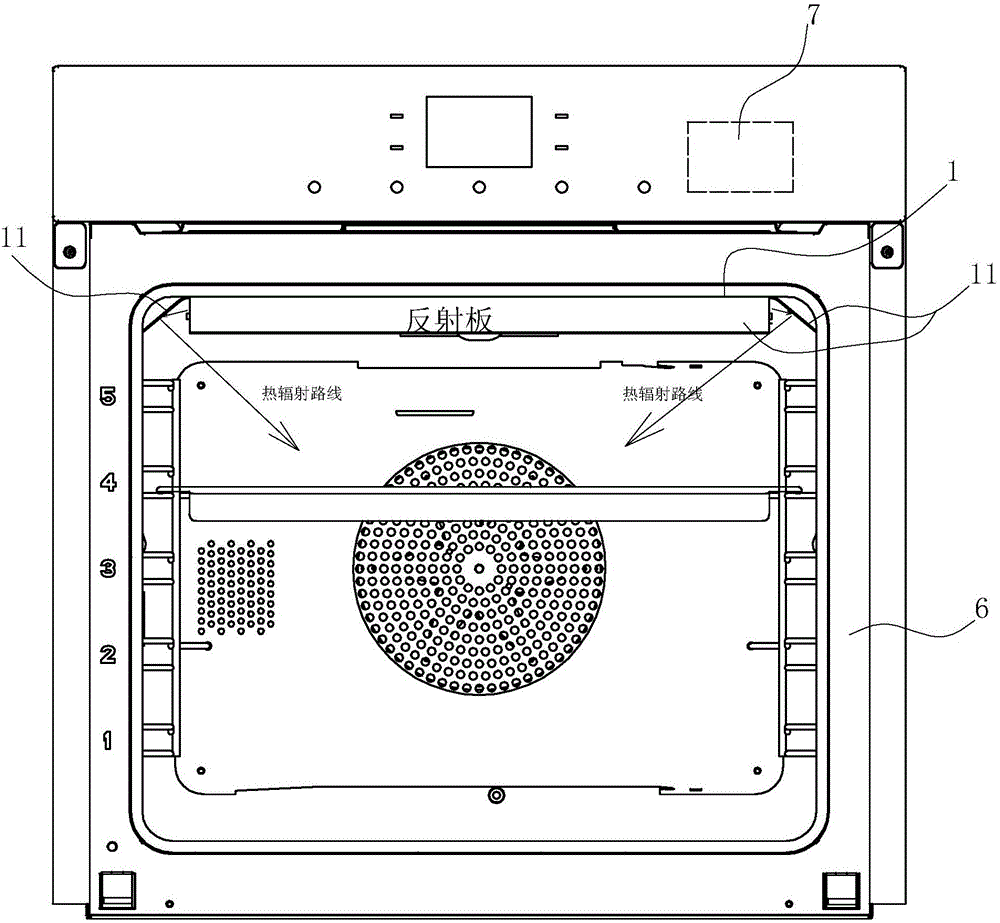

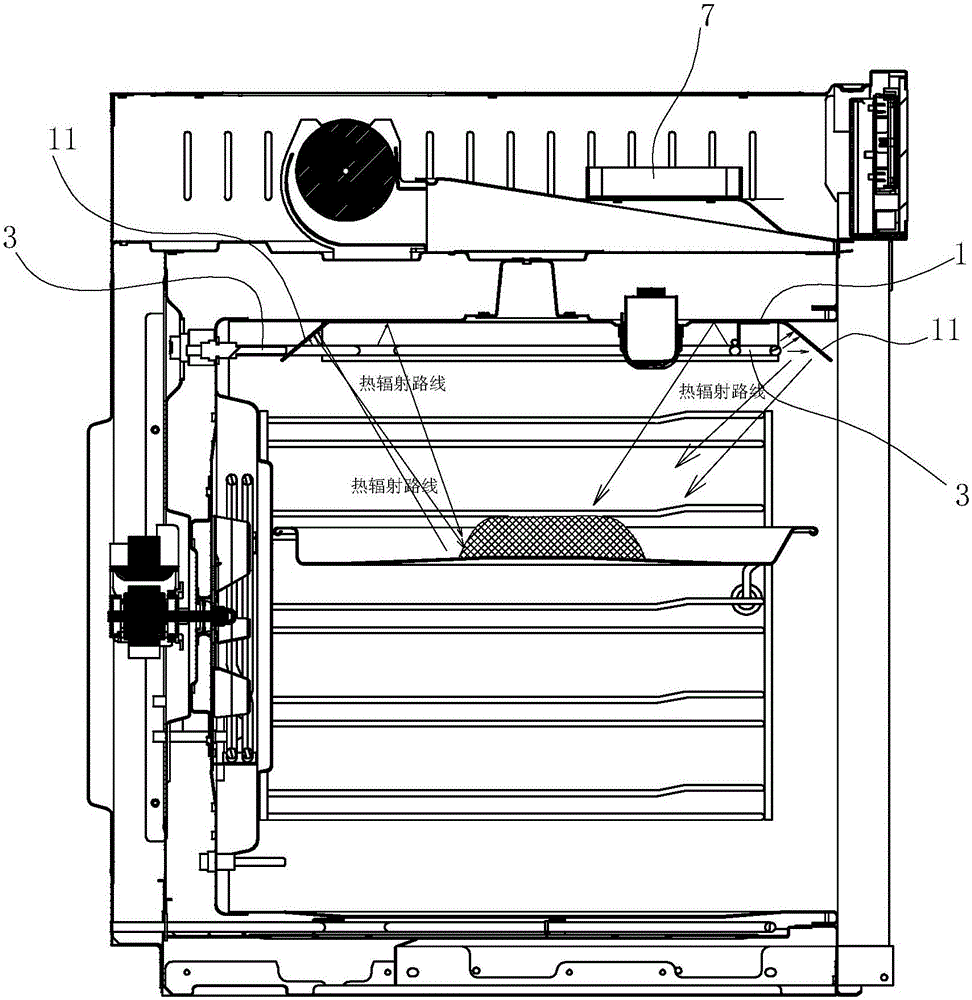

[0015] Such as figure 1 The electric oven shown includes an inner container 6 with a cooking cavity, an upper electric heating tube 2 arranged on the top of the inner container, a control panel 7 connected to the upper electric heating tube that can control the work of the upper electric heating tube, and an upper electric heating tube A reflector 1 that can reflect the heat radiation generated by the electric heating tube back to the interior of the inner tank is installed inside the inner tank above, and the size of the reflector can cover the entire upper electric heating tube.

[0016] In this embodiment, the lower side of the reflecting plate 1 is electroplated with an oxidation catalyst coating, and the surrounding of the reflecting plate 1 is provided with a folded edge 11 inclined downwards, and the angle between the folded edge and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com