Waste gas purification equipment for waste incineration power generation

A technology for waste gas purification and waste incineration, applied in incinerators, lighting and heating equipment, combustion methods, etc., can solve problems such as environmental pollution and heat energy waste, and achieve improved convenience, centralized processing, practicality and operation convenience. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

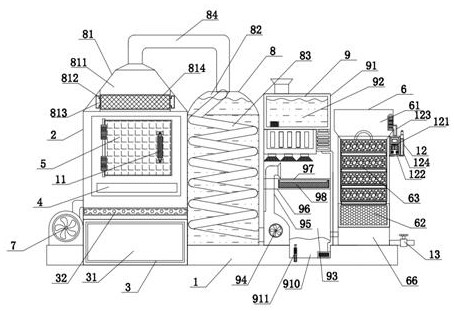

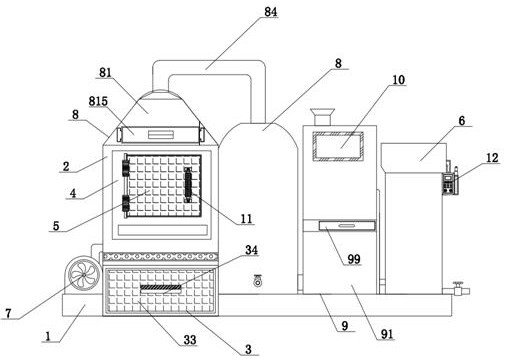

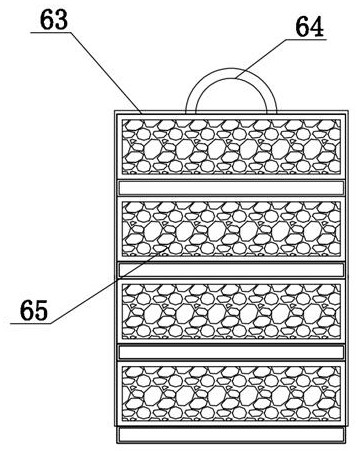

[0035] see Figure 1-5 , a kind of exhaust gas purification equipment for waste incineration power generation, comprising a base 1, an incinerator 2 is fixedly installed on the left side of the top of the base 1, and a waste collection assembly 3 is arranged at the inner bottom of the incinerator 2, and the incinerator 2 There is an incineration power generation equipment body 4 on the top of the inner waste collection assembly 3, and a heat-insulating ceramic door 5 is hinged on the front of the incinerator 2 corresponding to the position of the incineration power generation equipment body 4, and a bridge is fixedly installed on the right side of the front of the heat-insulation ceramic door 5. Type handrail 11, the lower end of the left side of the incinerator 2 on the top of the base 1 is fixedly installed with a blower 7, the output end of the blower 7 is connected with the body 4 of the incineration power generation equipment, and the middle of the top of the base 1 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com