Patents

Literature

84results about How to "To achieve hierarchical utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

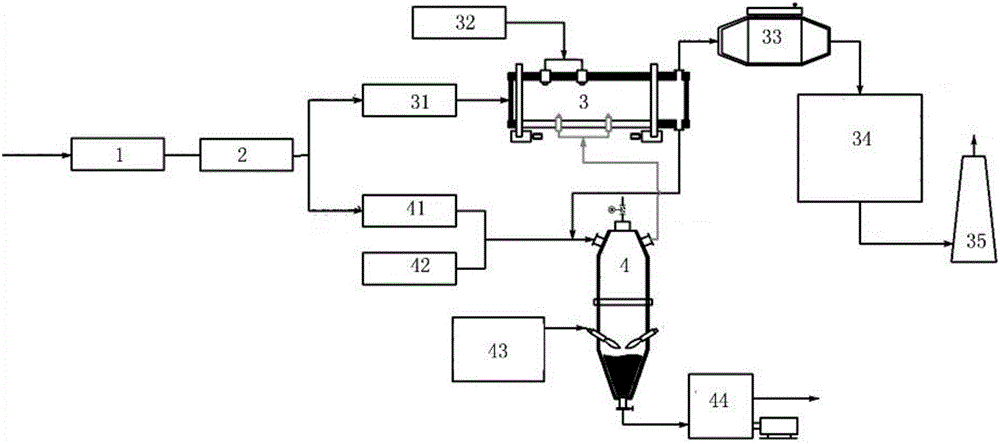

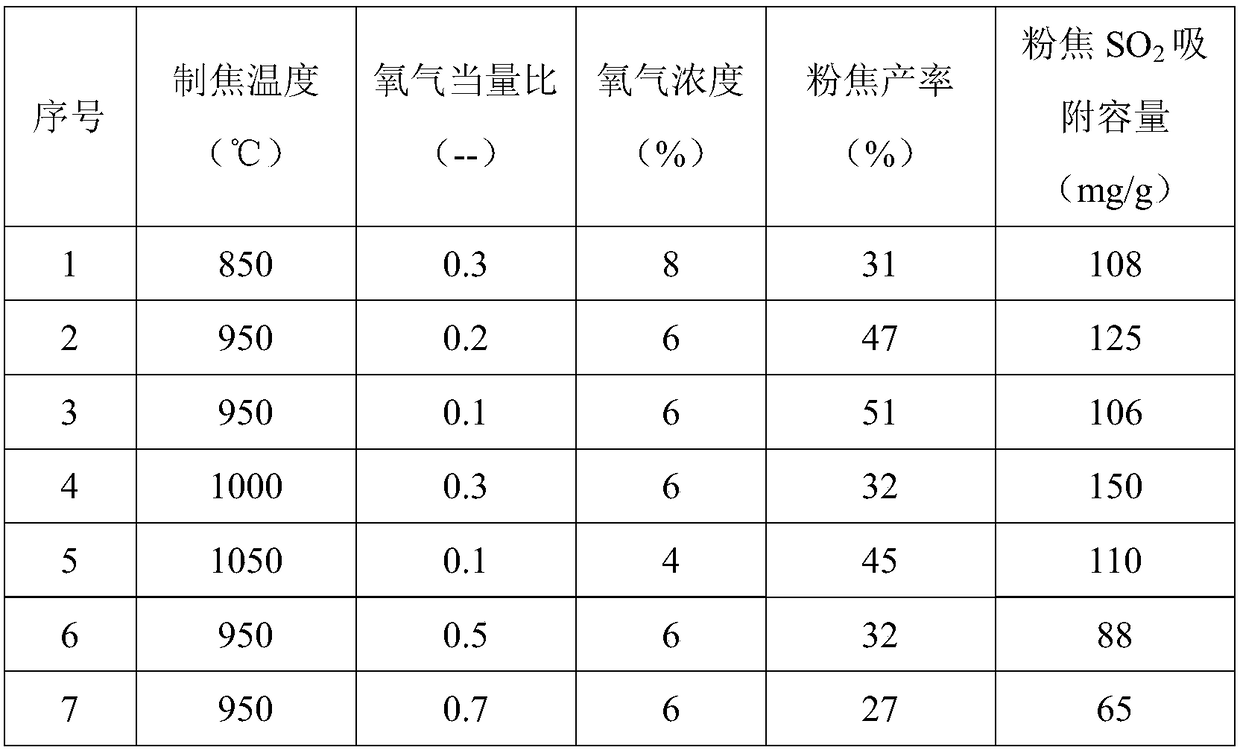

Biomass gasification hydrogen-producing system and method

InactiveCN101774542AReduce utilizationTo achieve hierarchical utilizationHydrogen productionGas solidHeat carrier

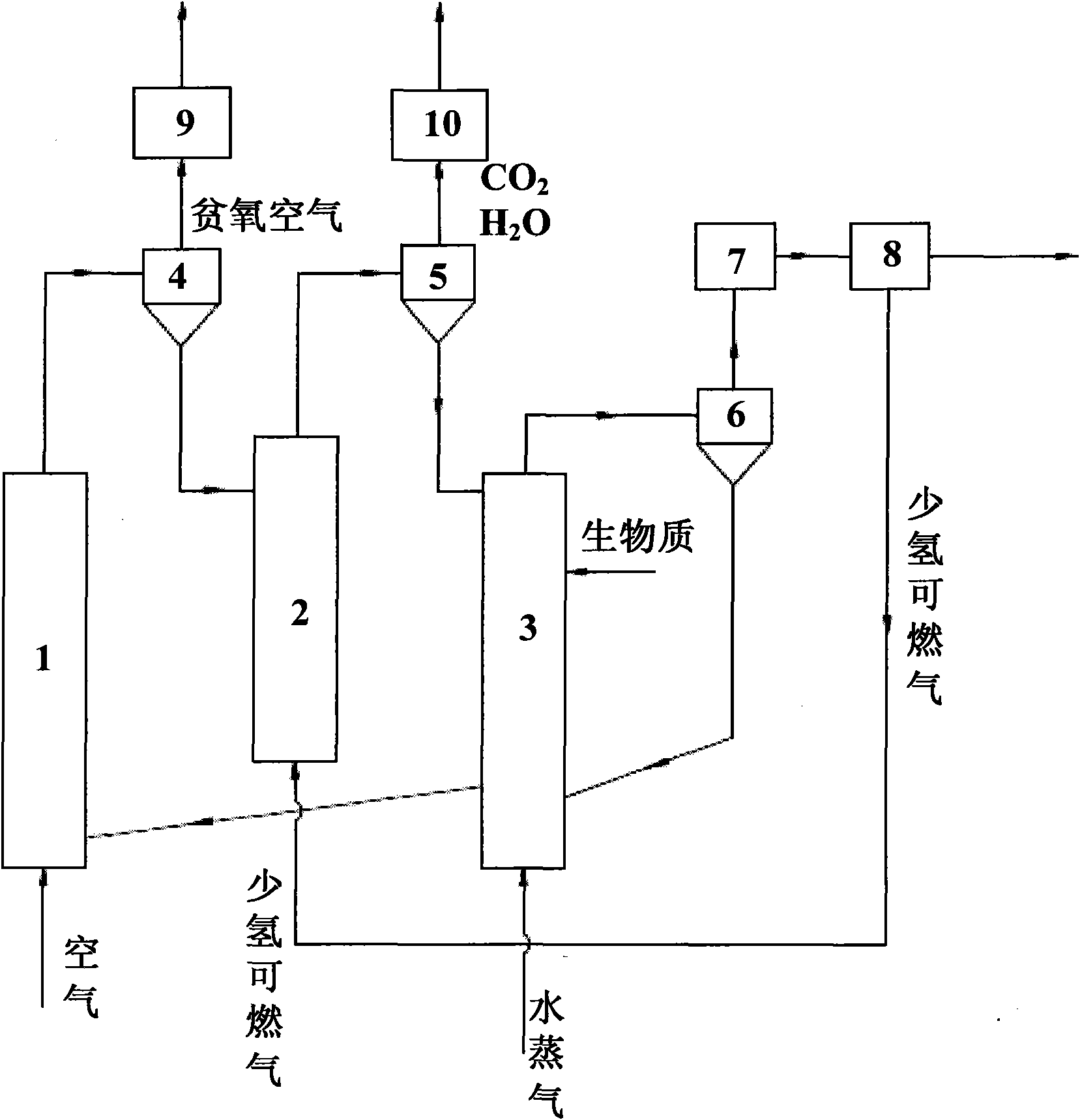

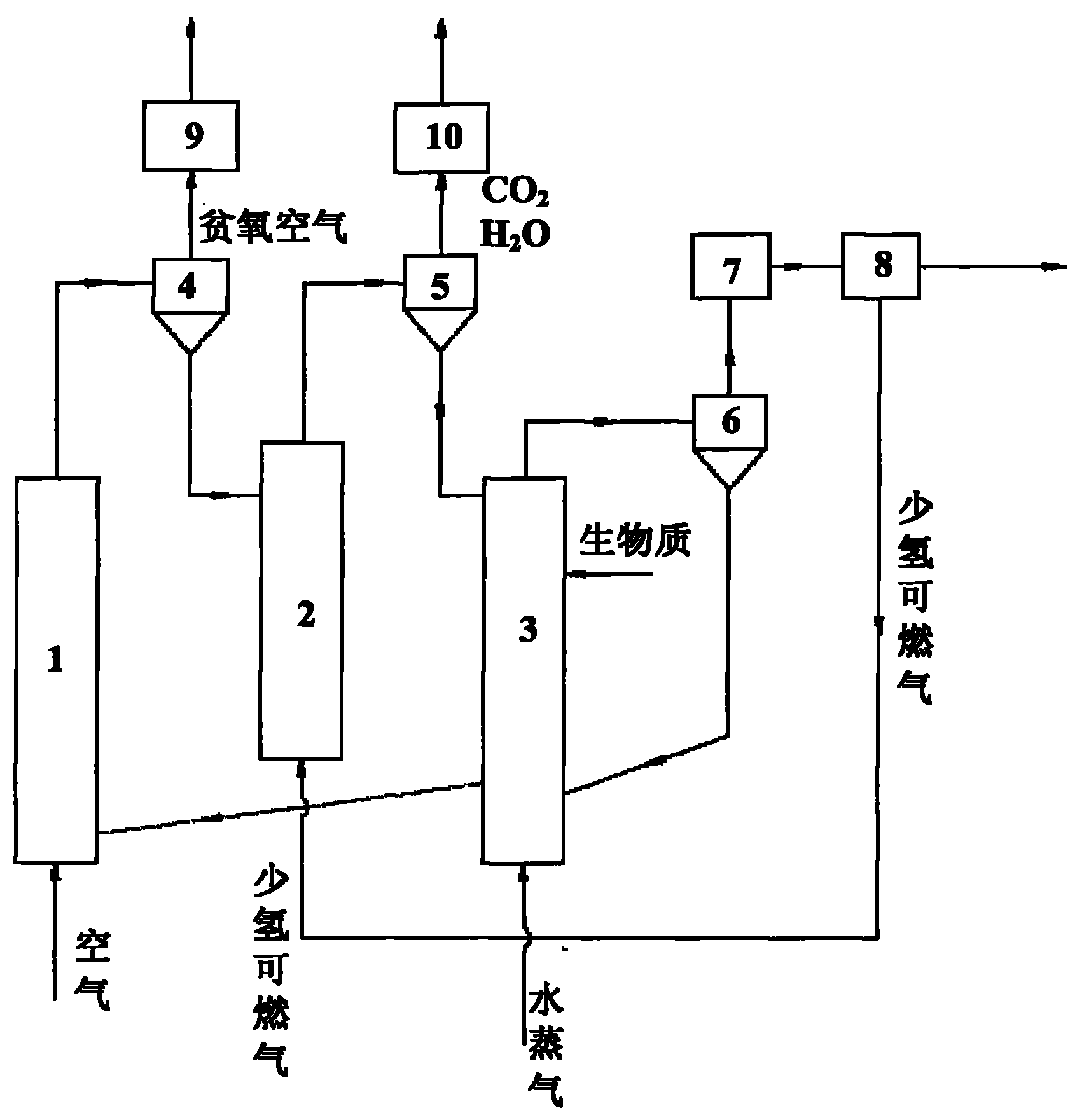

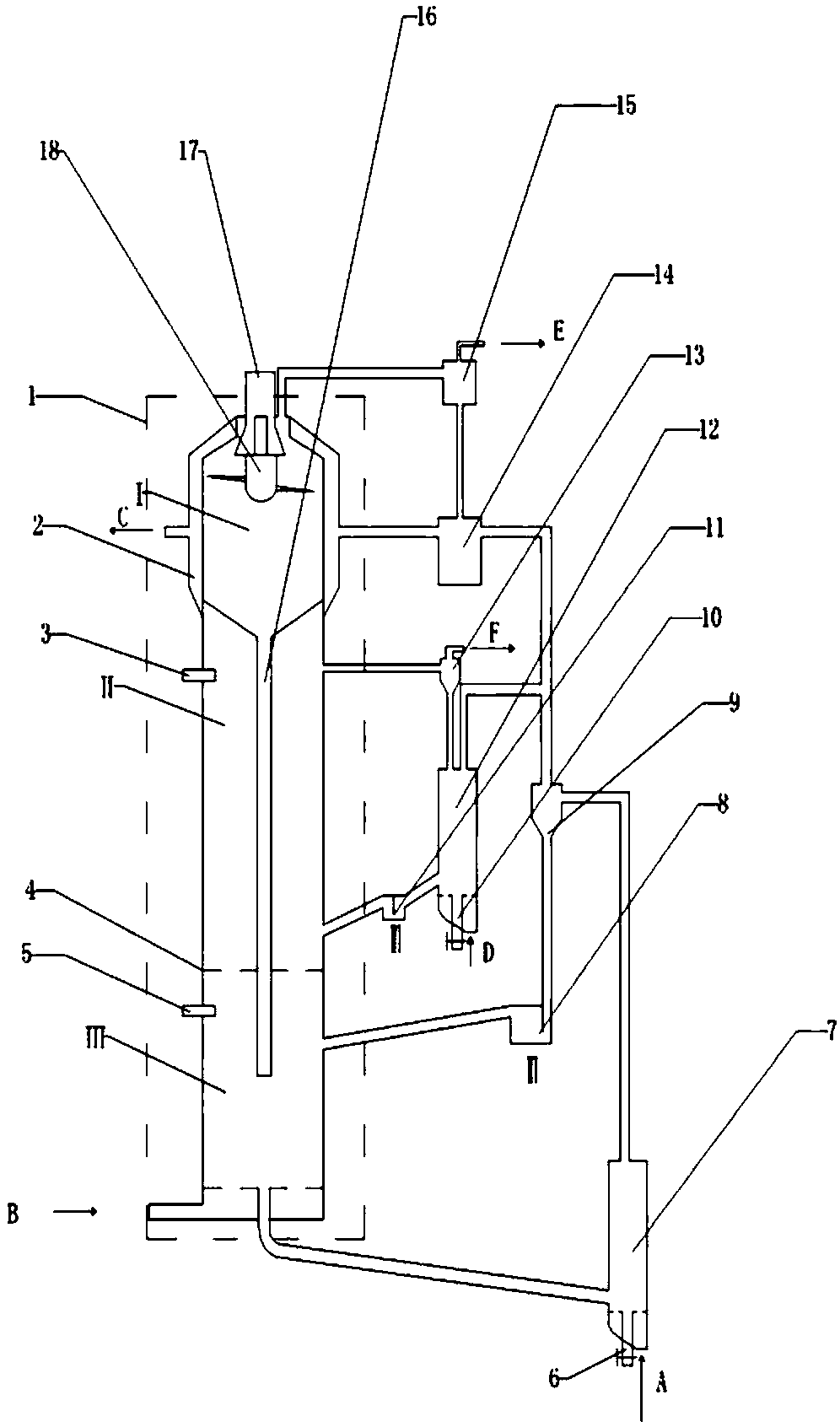

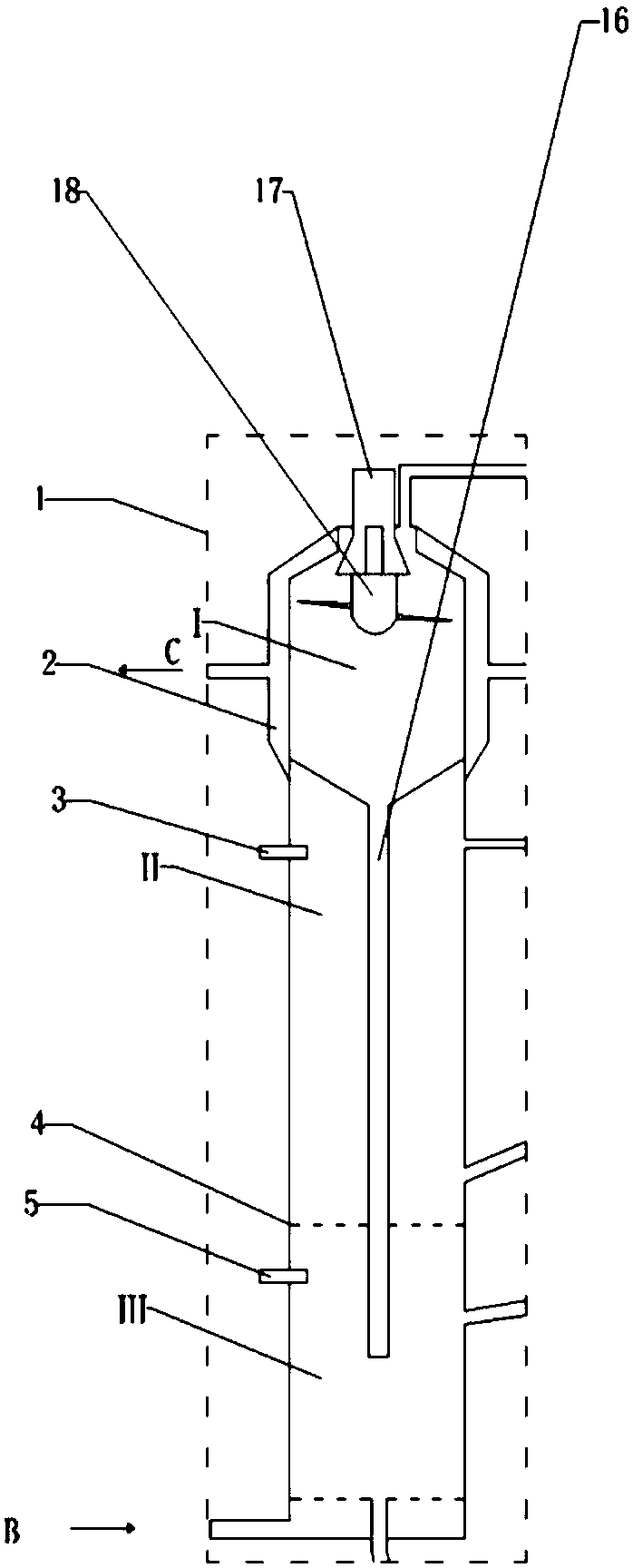

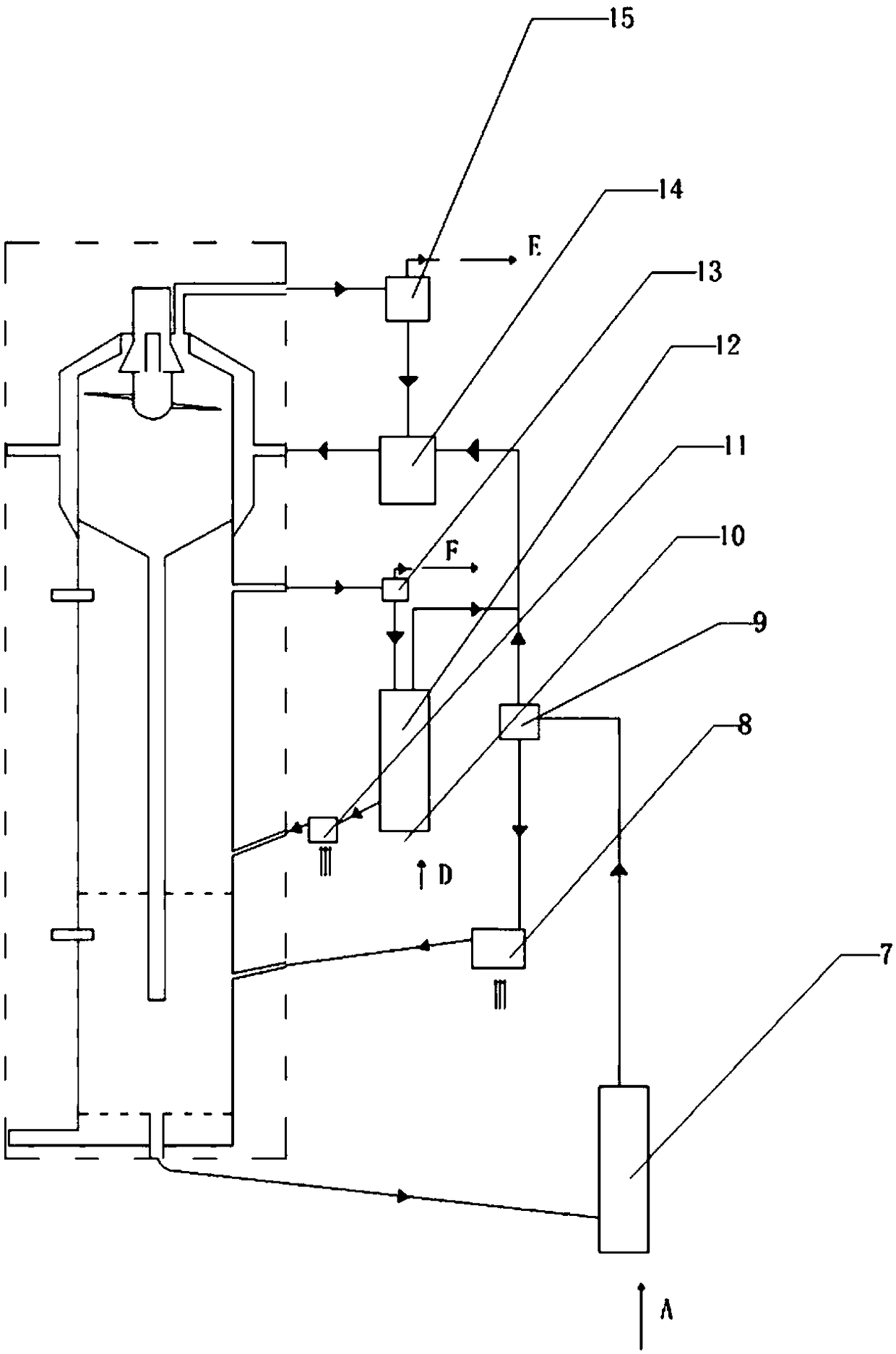

The invention discloses a biomass gasification hydrogen-producing system and a method, which belongs to the technical field of hydrogen production. Biomass gasification hydrogen production and chemical-looping combustion are combined to realize low-cost separation of carbon dioxide; and the fractional utilization of matter and energy is realized via the circulation among three beds with metal oxide as a heat carrier and an oxygen carrier. The system mainly comprises an air reactor, a fuel reactor, a moving bed gasifier, a gas-solid separation device, a gas purification device, a hydrogen separation device and a follow-up hydrogen-producing device. The system not only can realize hydrogen production, but also can realize hydrogen production with near zero emission of CO2, thereby realizing efficient cleaning and utilization of biomass.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

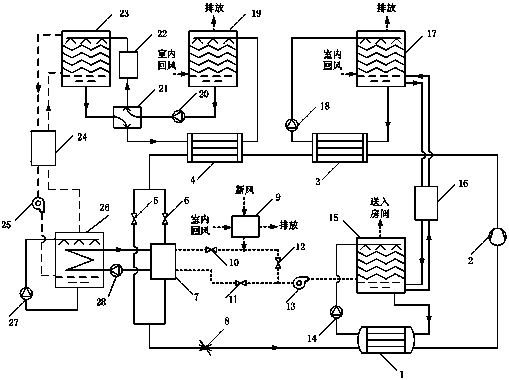

Solar energy and electric energy combined heat pump system and cooling and heating method

InactiveCN101963412ATo achieve hierarchical utilizationContinuously workingHeating and refrigeration combinationsThermal energyIntermediate heat exchanger

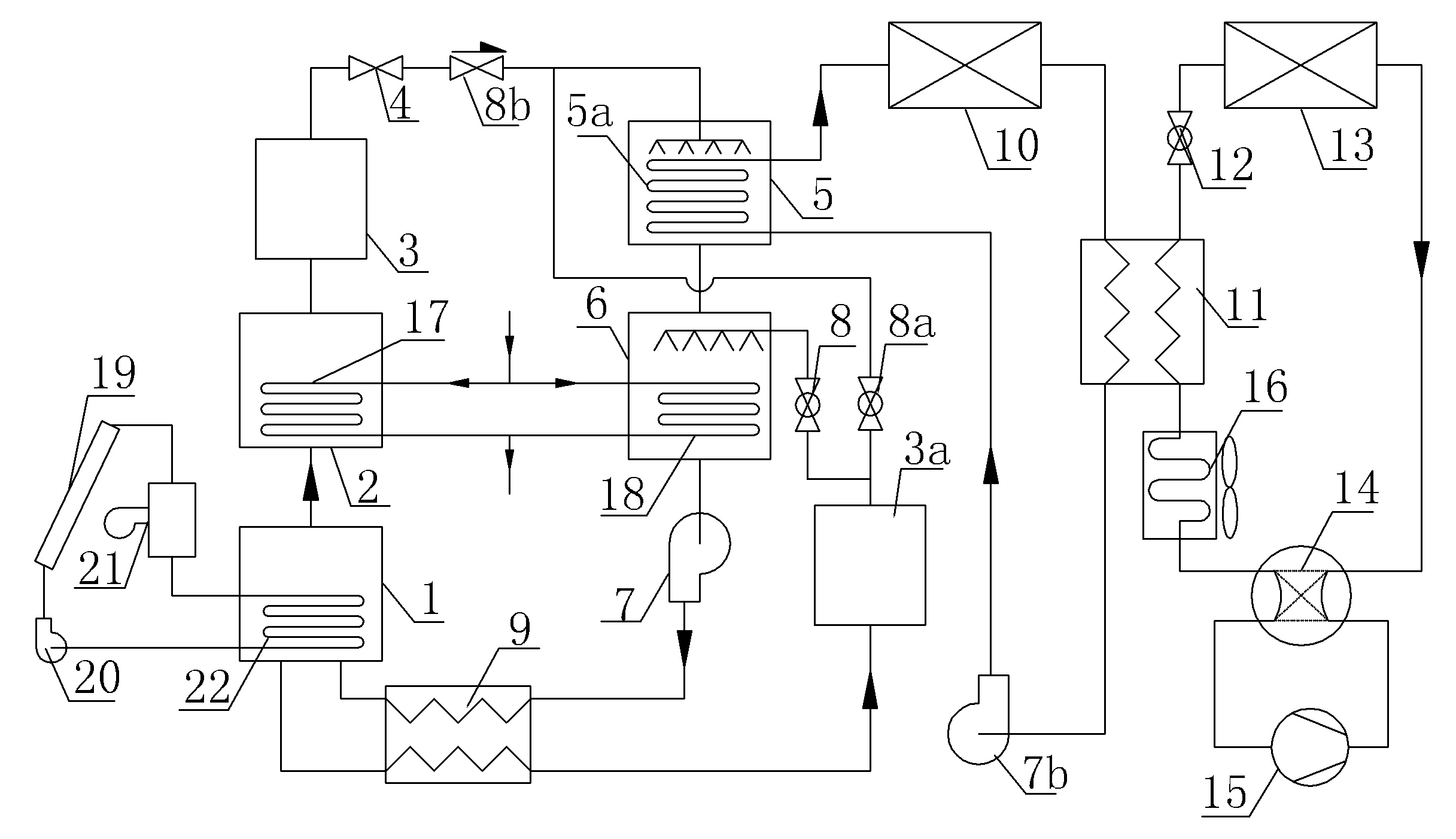

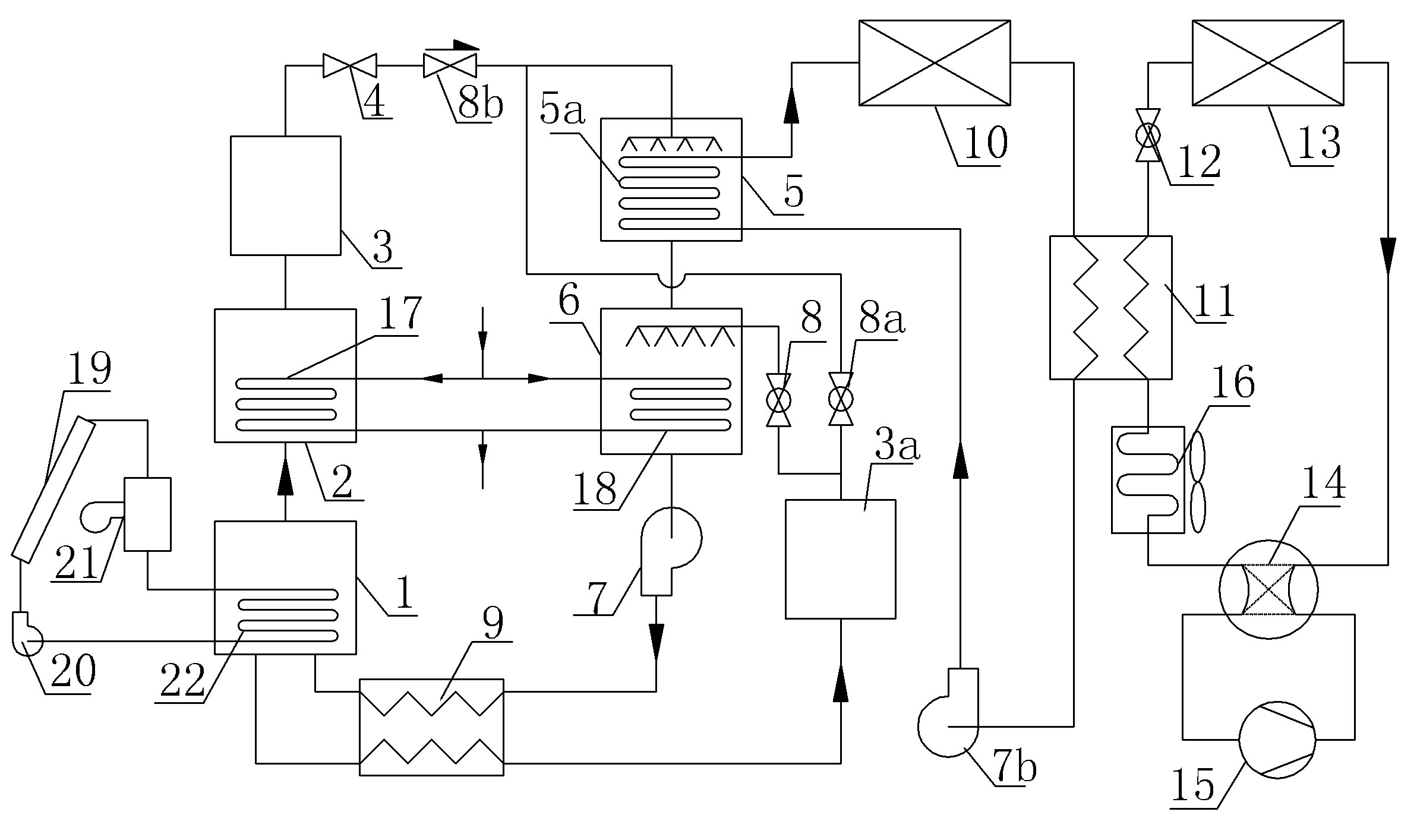

The invention discloses a solar energy and electric energy combined heat pump system and a cooling and heating method. The heat pump system comprises a solar energy absorption heat pump unit, an intermediate work medium circulating device and a compression heat pump unit, wherein a solar drive absorption heat pump drives the absorption heat pump unit to prepare a lower-temperature intermediate work medium or higher-temperature intermediate work medium; the intermediate work medium bears partial / all cold energy / heat energy required by a user through first heat mass exchange equipment, and enters an intermediate heat exchanger of the compression heat pump unit for heat exchange; and the cold energy / heat energy contained in the intermediate work medium is recycled once again through the heat pump unit so as to save the electric consumption of the compressor of the compression heat pump unit. The system realizes high-efficiency utilization of a low-level renewable energy source solar energy, and has the advantages of stable and reliable operation, efficient energy utilization, good energy-saving effect and wild application prospect.

Owner:HENAN UNIV OF SCI & TECH

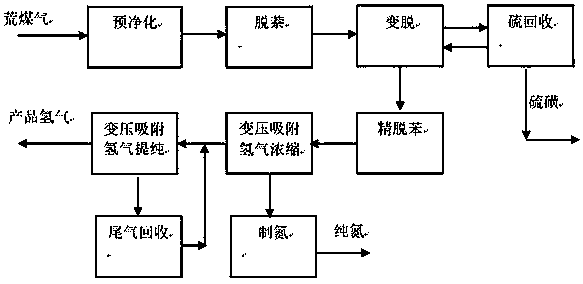

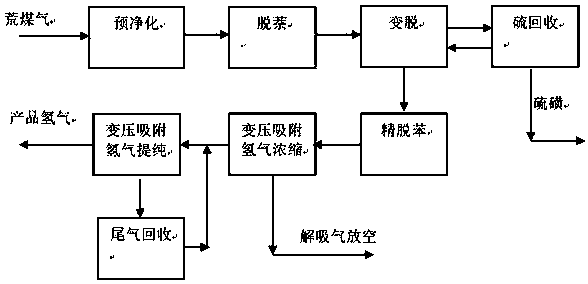

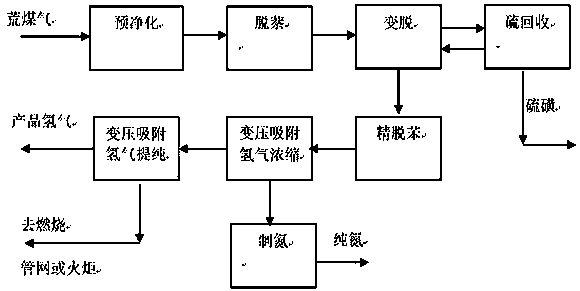

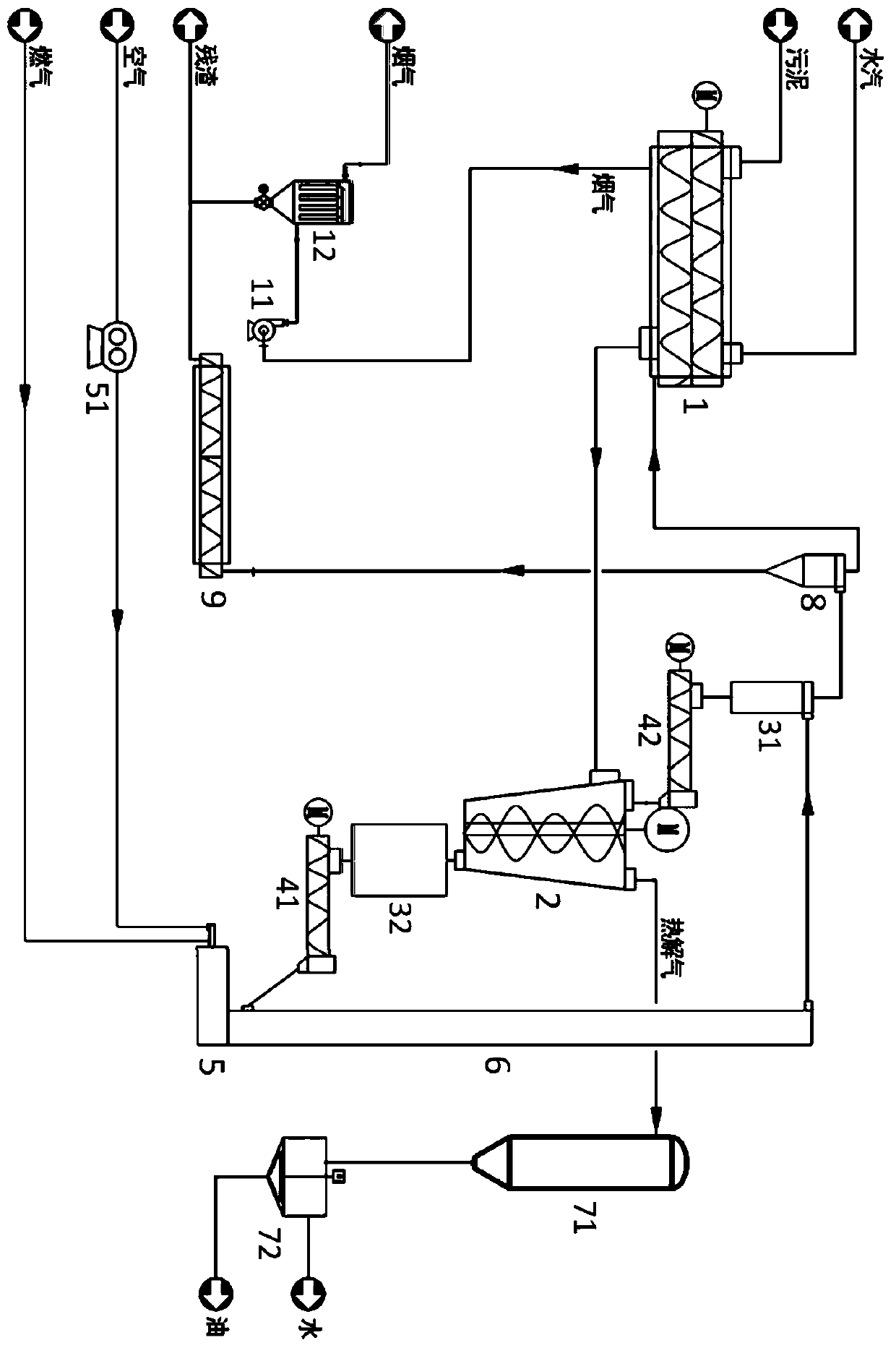

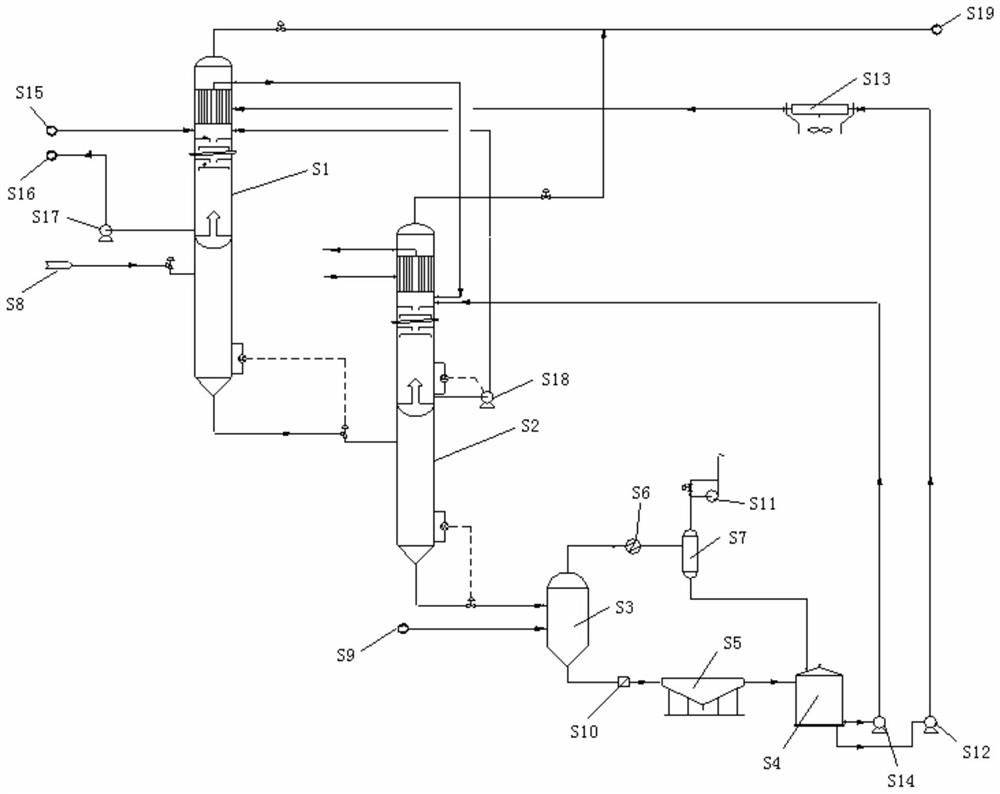

Low-energy-consumption high-yield method for preparing hydrogen from raw gas

InactiveCN107758615AReduce consumptionEmission reductionNitrogen purification/separationHydrogen separation using solid contactSulfurNitrogen

The invention discloses a low-energy-consumption high-yield method for preparing hydrogen from raw gas. The method comprises the following procedures: pre-cleaning; naphthalene removal; transformationand desulfurization; sulfur recovery; refined debenzolization; pressure swing adsorption for hydrogen production; recovery of tail gas; nitrogen production; etc. After pretreatment and naphthalene removal, raw gas is allowed to enter the procedure of transformation and desulfurization so as to obtain more hydrogen and increase the yield of hydrogen, and then desulfurization is carried out in a desulfurization tower; then pure hydrogen is prepared through the procedure of refined debenzolization and the procedure of pressure swing adsorption for hydrogen production; through the procedures of tail gas recovery and nitrogen production, effective hydrogen in desorbed gas is recovered, and hydrogen yield is further increased; and pure nitrogen with a purity of 99% or more is further prepared through a nitrogen production unit. The method provided by the invention substantially reduces the energy consumption of an apparatus for hydrogen production from raw gas, increases hydrogen yield, recovers almost all the effective hydrogen component in the desorbed gas, realizes recovery and graded utilization of each component in the raw gas while guaranteeing low energy consumption and high yield, and by-produces sulfur, pure nitrogen and the other products while preparing pure hydrogen.

Owner:SICHUAN TECHAIRS

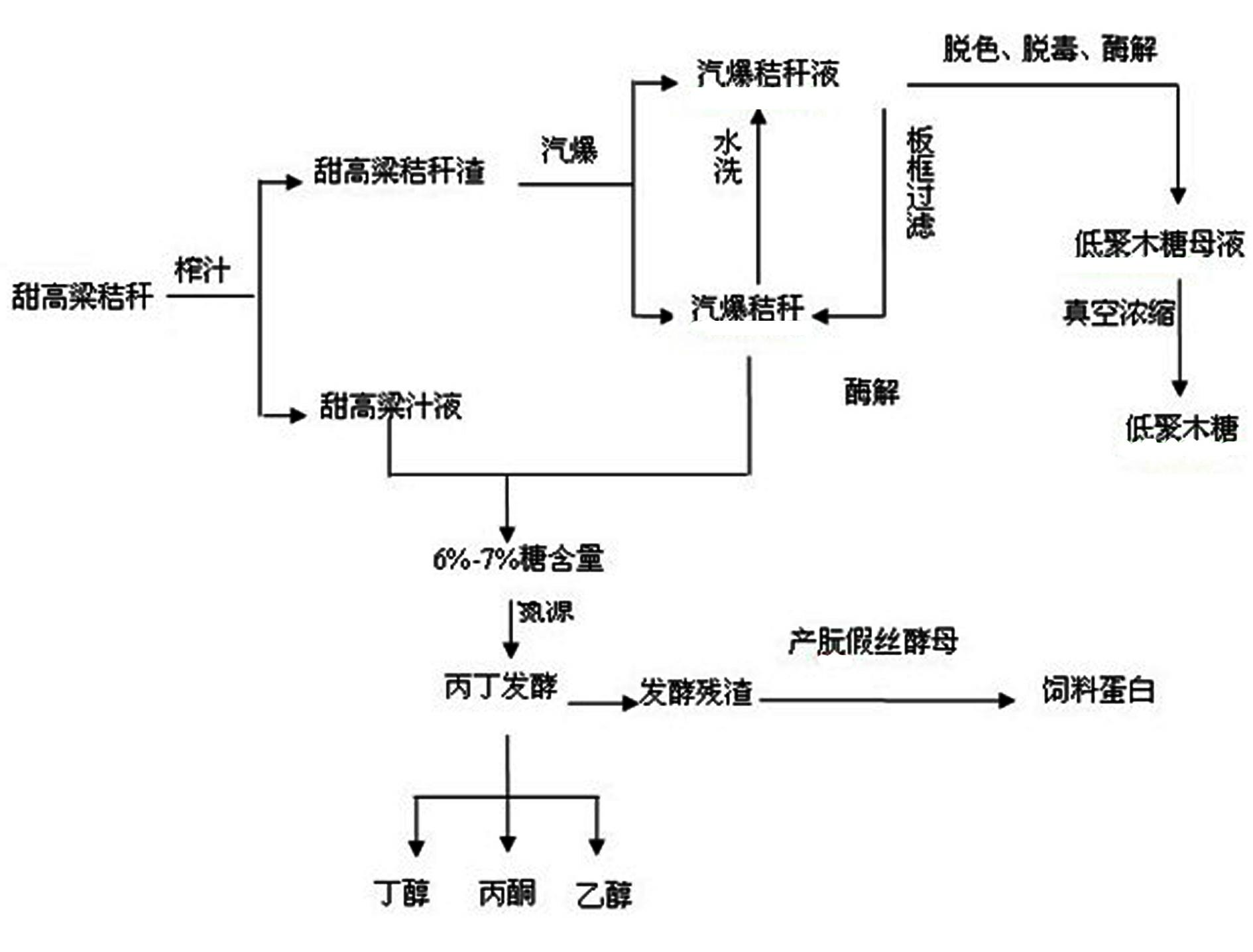

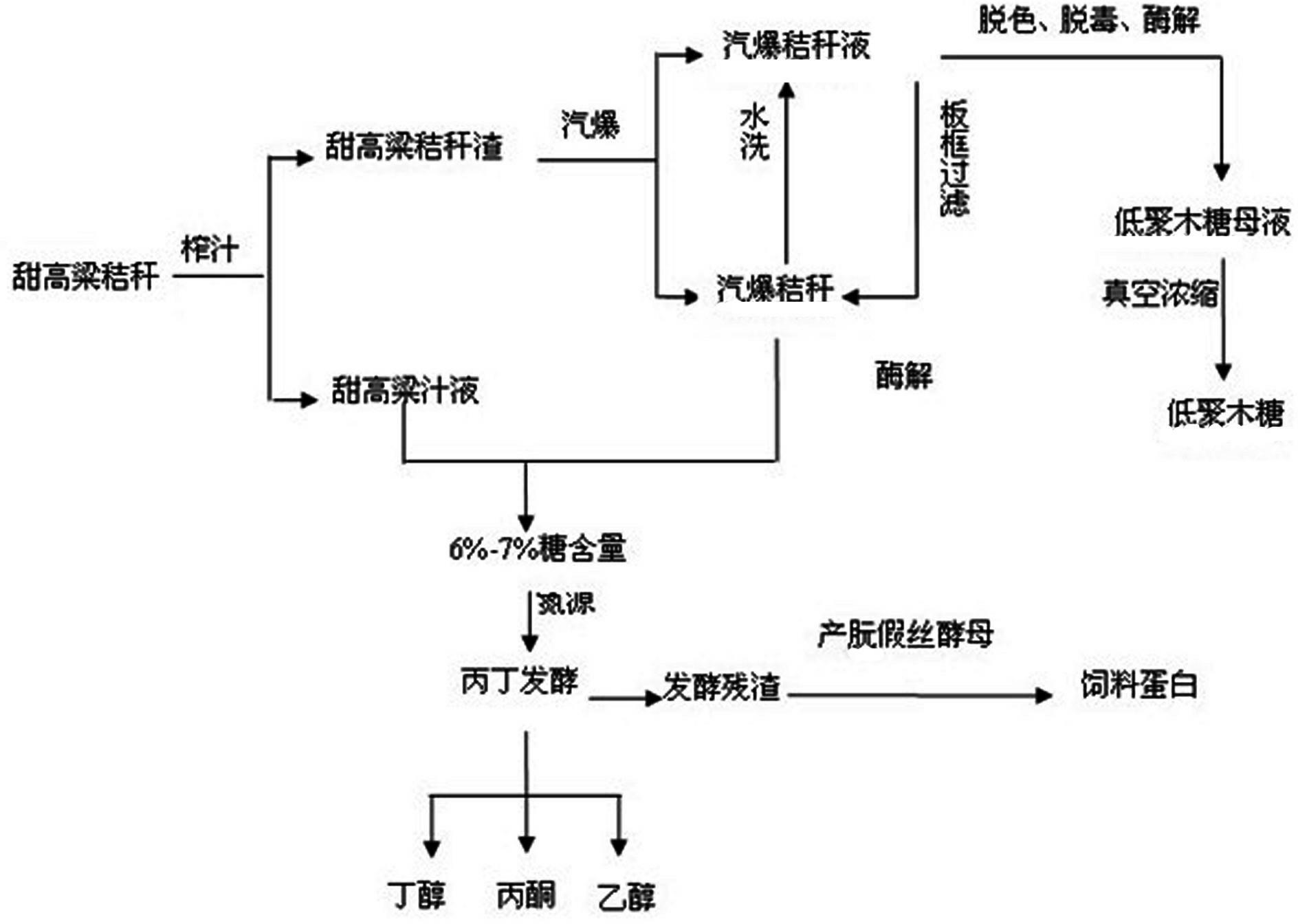

Comprehensive utilization method of sweet sorghum straw and juice thereof

ActiveCN102321679AImprove use valueTo achieve hierarchical utilizationBiofuelsMicroorganism based processesSweet sorghumDrug biotransformation

The invention discloses a comprehensive utilization method of sweet sorghum straw and juice thereof, which comprises the following steps: juicing sweet sorghum straw, separating the juice from straw residues, performing steam explosion of the sweet sorghum straw residues to obtain steam exploded straw and a steam exploded straw eluate; performing enzymatic hydrolysis of the steam exploded straw, mixing with the sweet sorghum juice, controlling the sugar content to be 6%-7%, adding a nitrogen source, performing acetone butanol fermentation to produce acetone, butanol and ethanol; inoculating bacteria into the fermentation residues to produce feed protein; performing decoloration, detoxification, and enzymatic hydrolysis of the steam exploded straw eluate to extract xylo-oligosaccharides. The invention realizes graded utilization of saccharides, cellulose and hemicellulose in sweet sorghum, can produce xylo-oligosaccharides, and can produce fermentation products such as acetone, butanol, ethanol, feed protein and the like through biotransformation. The invention realizes the comprehensive utilization of sweet sorghum straw resources, has no waste material or pollutant discharge during the production, realizes cleaner production, and has good social benefit and economic benefit.

Owner:江苏联海生物科技有限公司

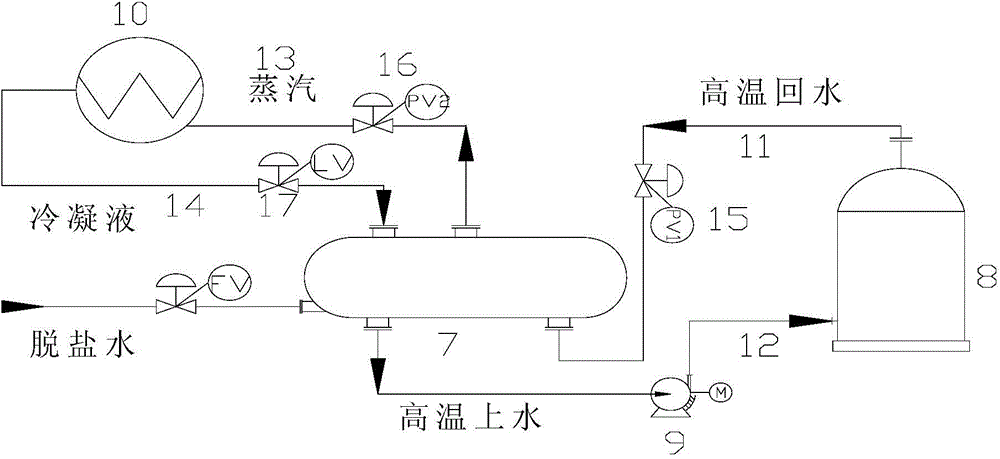

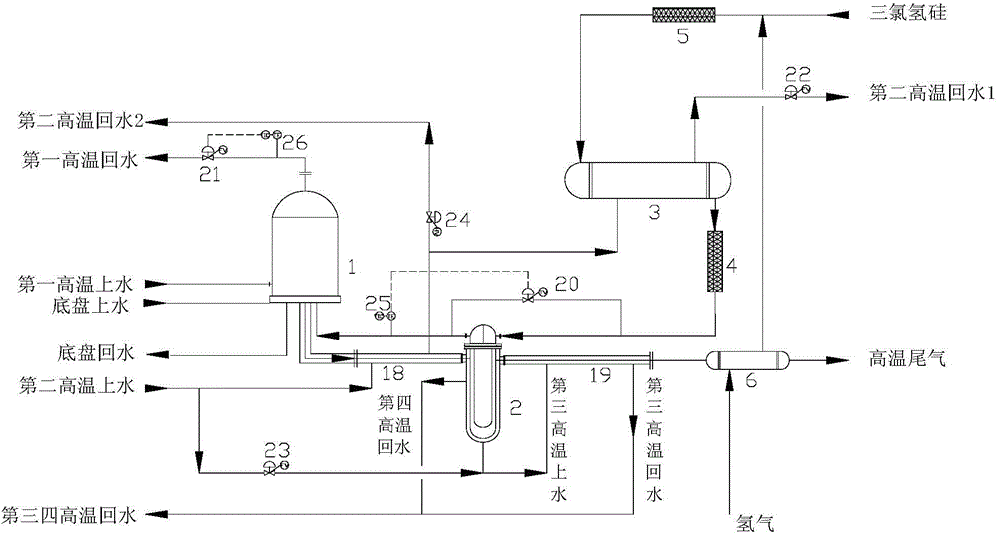

Heat energy utilization method and heat energy utilization system in polycrystalline silicon production

ActiveCN104787766AImprove feed processFeed process optimizationSiliconChemical industryMetallurgyHeat energy

The present invention discloses a heat energy utilization method and a heat energy utilization system during polycrystalline silicon production. According to the method, high temperature backwater from a reduction furnace system in polycrystalline silicon production is conveyed into a flash evaporation system and is subjected to flash evaporation in the flash evaporation system, wherein the temperature of the high temperature backwater entering the flash evaporation system is 145-160 DEG C, and the pressure is 0.5-0.6 MPa; the low pressure steam with the pressure of 0.175-0.25 MPa is flash-evaporated from the flash evaporation system, and the remaining high temperature water with the temperature of 128-133 DEG C after the flash evaporation is pressurized, then returns to the reduction furnace, and forms the high temperature feeding water of the reduction furnace system; and the flash-evaporated low pressure steam is conveyed to other equipment requiring the steam in the polycrystalline silicon production, and the condensate obtained through heat exchange with other equipment returns to the flash evaporation system. With the method of the present invention, a lot of the heat energy produced in the polycrystalline silicon production can be completely utilized so as to improve the heat energy recovery and utilization rate.

Owner:XINTE ENERGY

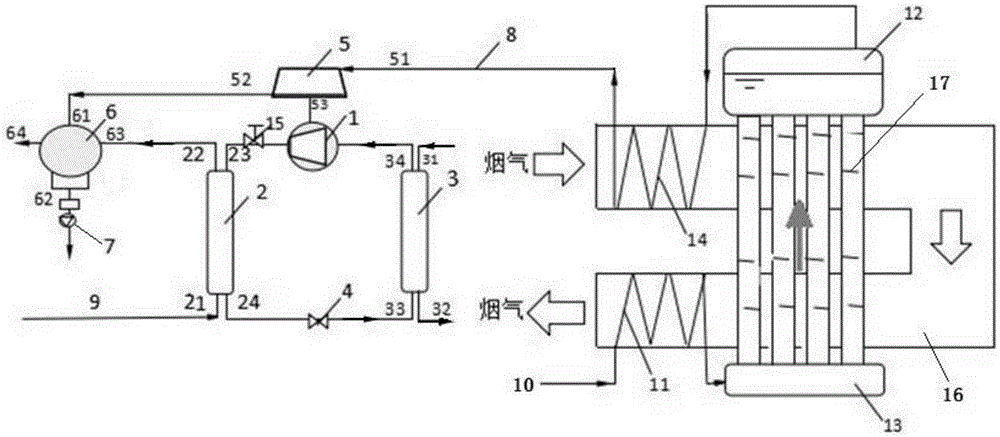

Thermal pump driving solution dehumidifying device and method based on graded utilization of condensation heat

InactiveCN104214873ATake advantage ofTo achieve the purpose of energy savingLighting and heating apparatusDispersed particle separationEvaporative coolerCondensation temperature

The invention discloses a thermal pump driving solution dehumidifying device and method based on graded utilization of condensation heat. The device comprises a conventional thermal pump driving solution dehumidifying circulation loop and a solution dehumidifying evaporation cooling circulation loop, wherein connecting components of the circulation loops comprise a secondary condenser (4) and a first cooler (7). In the device, residual condensation heat in a thermal pump driving solution dehumidifying system is used for driving a solution dehumidifying cycle to obtain dry air, and the dry air is evaporated and cooled in an indirect evaporative cooler to obtain low-temperature cooling water. The device can run in an undercooling refrigerant mode and a precooling fresh air mode. By adopting the device and the method, the aims of realizing reasonable utilization of the condensation heat in the thermal pump driving solution dehumidifying system, increasing the refrigerating capacity of the system, lowering the condensation temperature and increasing the COP (Coefficient of Performance) of the system are fulfilled.

Owner:SOUTHEAST UNIV

Recycling hazardous waste treatment system and treatment method by synergizing rotary kiln and plasma gasification

PendingCN106642159AImprove operational reliabilityEconomicalIncinerator apparatusHigh energyRotary kiln

The invention relates to a recycling hazardous waste treatment system and treatment method by synergizing a rotary kiln and plasma gasification. The system comprises a hazardous waste storage device, a hazardous waste sorting device, a rotary kiln incinerator, a plasma gasification furnace, a first crushing feeder and a second crushing feeder. The hazardous waste sorting device sorts hazardous wastes in the hazardous waste storage device, and easily handled hazardous wastes are fed into the first crushing feeder and hardly handled hazardous wastes are fed into the second crushing feeder; the first crushing feeder is connected to a feed inlet of the rotary kiln incinerator, and the second crushing feeder is connected to a feed inlet of the plasma gasification furnace. Through a reasonable design, hazardous waste harmless treatment is realized by virtue of technological advantages of the rotary kiln and the plasma gasification, so that the problem of dioxin and heavy metal pollution is avoided. Synthesized gas generated by gasification by the plasma gasification furnace supplements energy required by the rotary kiln, and meanwhile, a high energy utilization ratio of the system is achieved through recovered heat of a waste heat boiler.

Owner:XIAN AEROSPACE SOURCE POWER ENG CO LTD

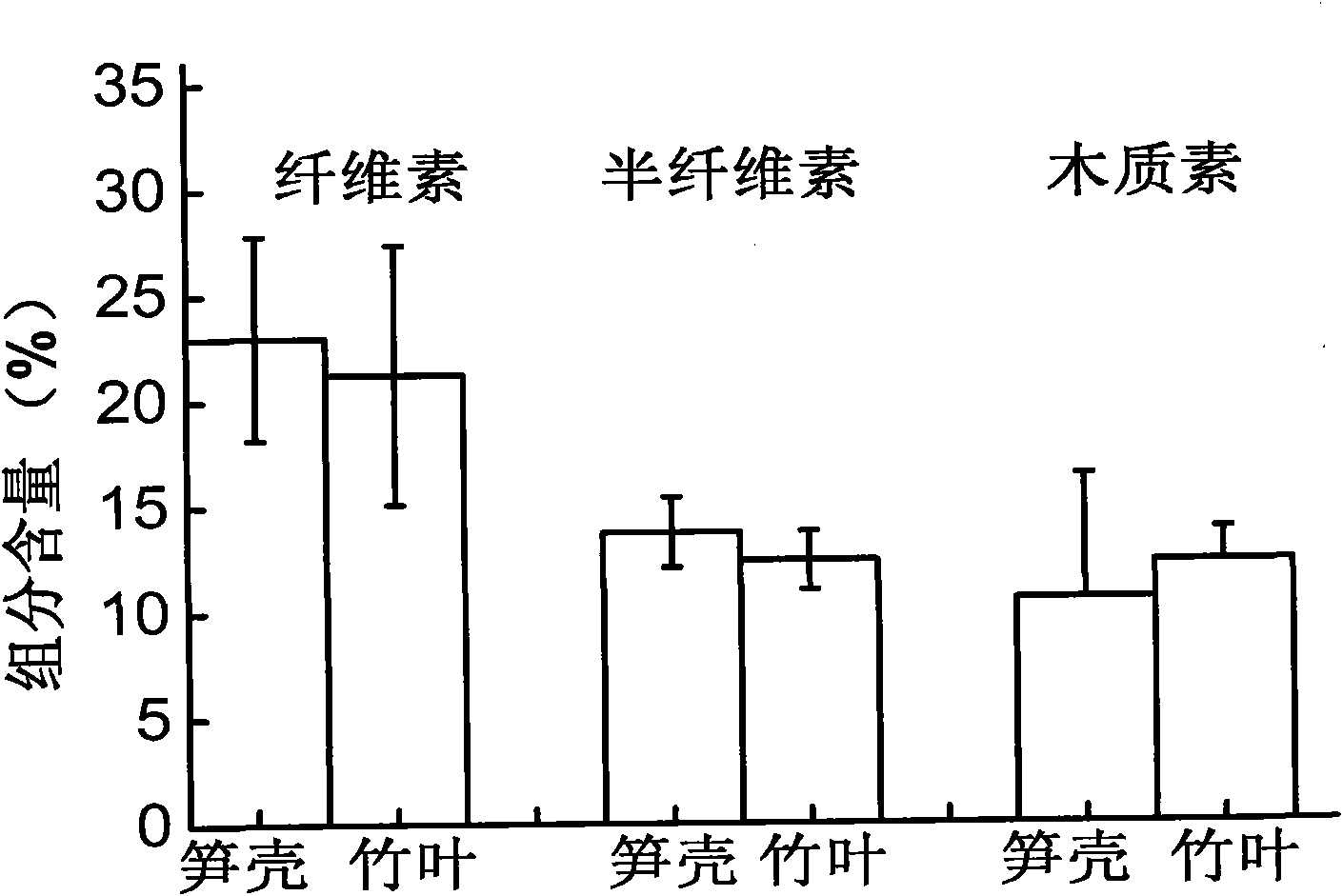

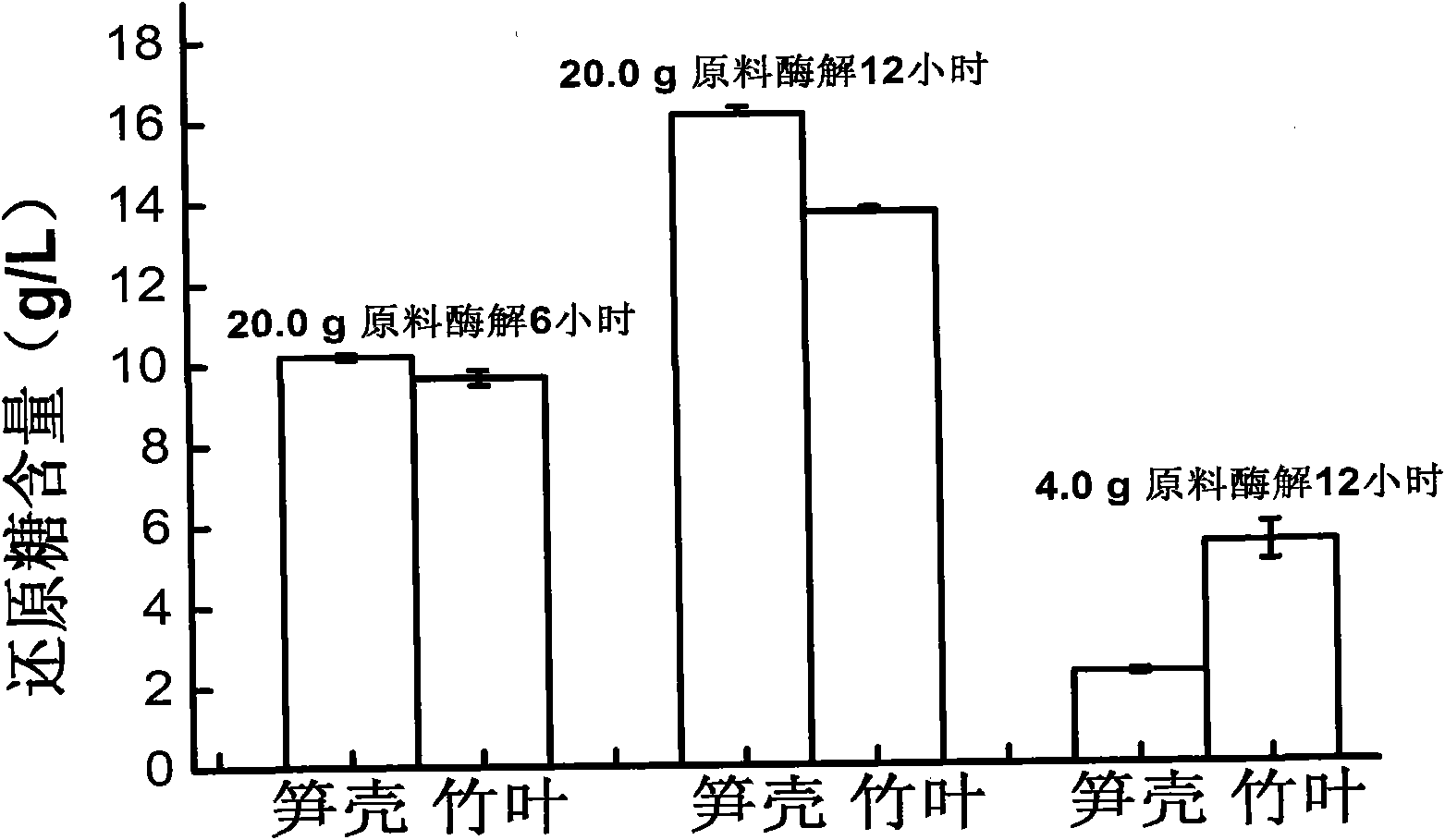

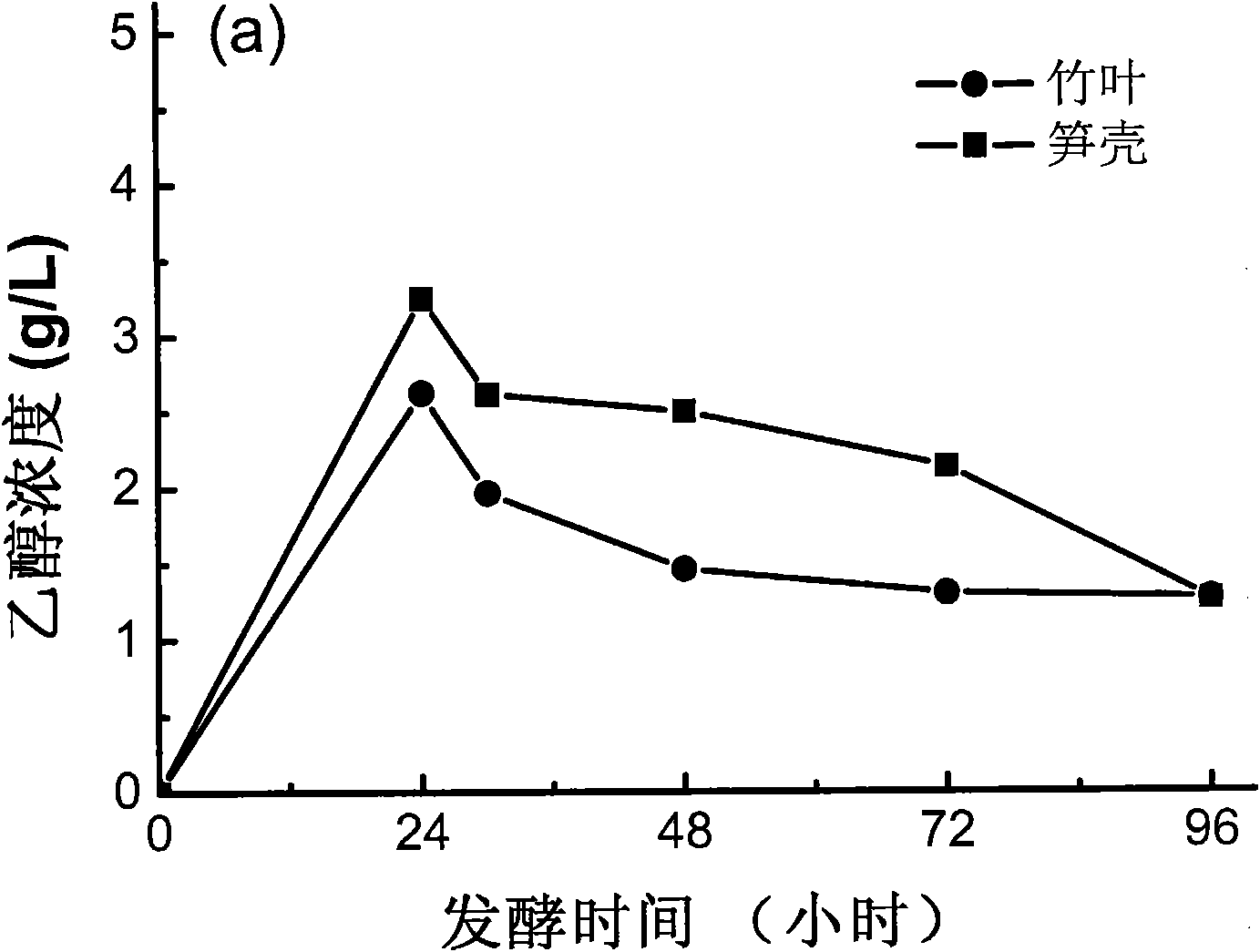

Process for producing fuel ethanol by utilizing bamboo biomass waste

InactiveCN101857885AReduce manufacturing costTo achieve hierarchical utilizationBiofuelsMicroorganism based processesProcess engineeringD-Glucose

The invention discloses a process for producing fuel ethanol by utilizing bamboo biomass waste, which comprises the following step of carrying out pretreatment on the bamboo biomass waste and preparing the fuel ethanol by hydrolysis and fermentation. The process adopts the bamboo biomass waste as the raw material, can produce a large amount of fuel ethanol with low cost, improves ethanol fermentation rate, reduces production cost of the ethanol and has simple production process and high output value. Meanwhile, the process of the invention adopts mild treatment conditions to realize the process of stage treatment of the raw material so as to realize full utilization of the raw material. Meanwhile, an adopted fermentation strain has high utilization efficiency of glucose and high ethanol yield.

Owner:BIOGAS SCI RES INST MIN OF AGRI

Treatment method of perfluoroalkyl acyl fluoride waste

ActiveCN103086865AEmission reductionMild treatment conditionsPreparation from carboxylic acid halideHalogenated hydrocarbon separation/purificationOil phaseTherapeutic effect

The invention discloses a treatment method of perfluoroalkyl acyl fluoride waste. The method comprises the following steps of: first, adding aqueous alkali to the perfluoroalkyl acyl fluoride waste, adjusting the pH value to 7-8, standing and separating to obtain a water phase and an oil phase; then, separating and purifying the water phase to obtain perfluorocarboxylate; and finally, separating and purifying the oil phase to obtain inertial fluorocarbon. The perfluoroalkyl acyl fluoride waste is treated in grades in the following steps of: adding aqueous alkali to separate the perfluoroalkyl acyl fluoride waste into the water and oil phases, and respectively separating and purifying the water and oil phases; and obtaining high purity perfluorocarboxylate after separation and purification of the water phase and obtaining high purity inertial fluorocarbon after separation and purification of the oil phase. The treatment condition is mild and the treatment effect is good.

Owner:ZHEJIANG UNIV +1

Waste heat and waste pressure type water source heat pump system applying boiler smoke waste heat

InactiveCN105605828AReduce churnImprove energy efficiencyHeat pumpsClimate change adaptationSuperheaterWater pipe

The invention provides a waste heat and waste pressure type water source heat pump system applying boiler smoke waste heat. The water source heat pump system comprises a water source heat pump system and a waste heat utilizing system of a natural circulating waste heat boiler. The waste heat utilizing system of the natural circulating waste heat boiler comprises a steam way, a water supply pipe, a coal economizer, a steam bag, a second evaporator, an overheater and a smoke pipeline. The water source heat pump system comprises a compressor, a condenser, a first evaporator, an expansion valve, a steam turbine, a steam and water heat exchanger, a condensate water pump, a circulating water return pipe and a flow control valve. By means of the waste heat and waste pressure type water source heat pump system, waste gas of the natural circulating waste heat boiler can be effectively utilized, and the energy utilization rate is increased.

Owner:JIANGSU UNIV

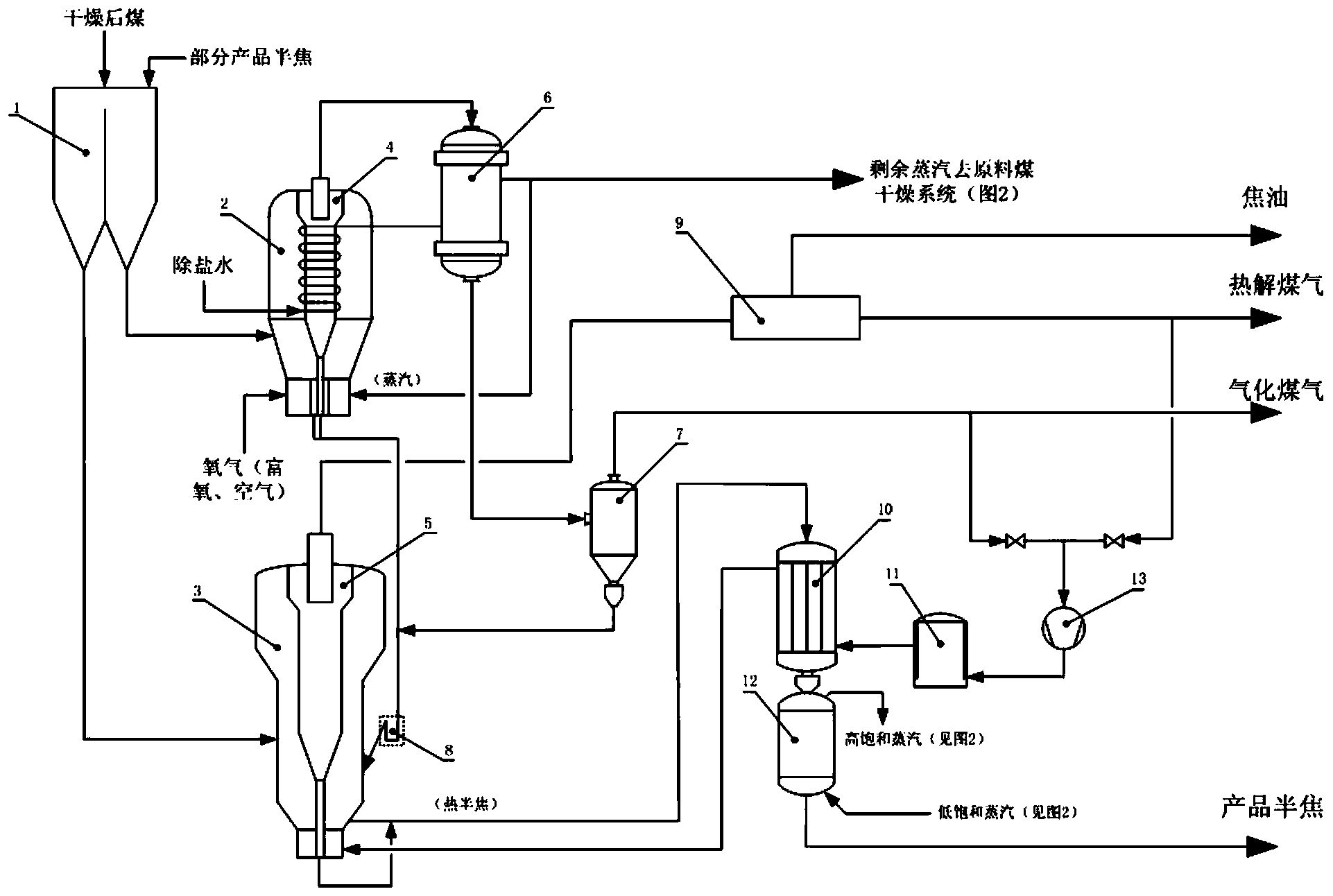

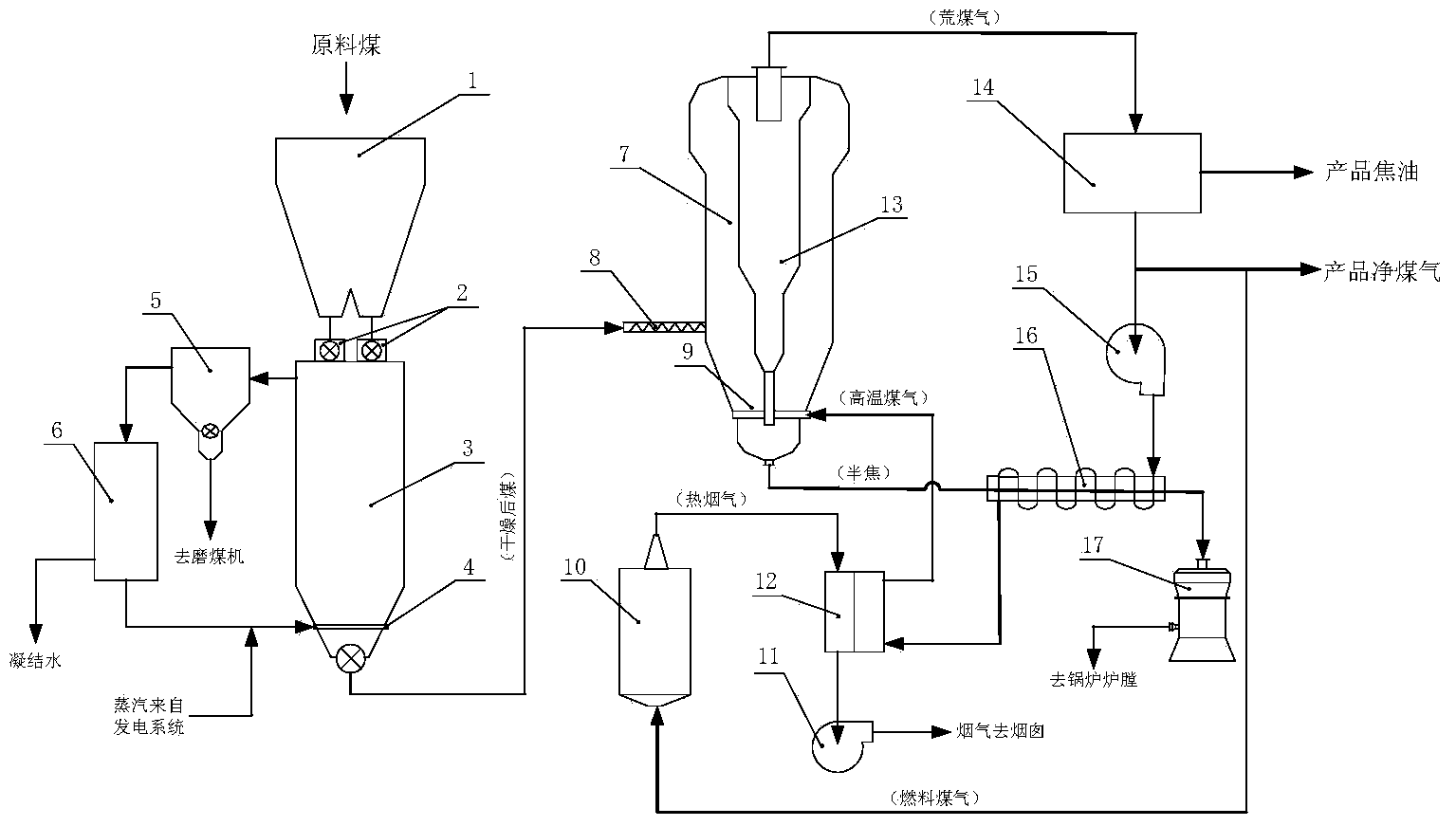

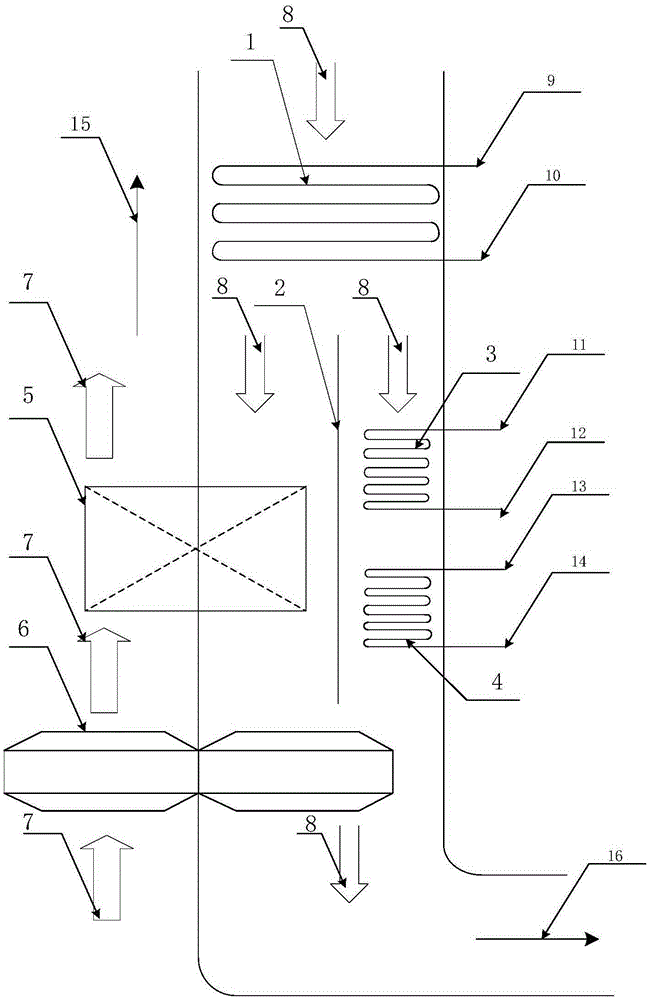

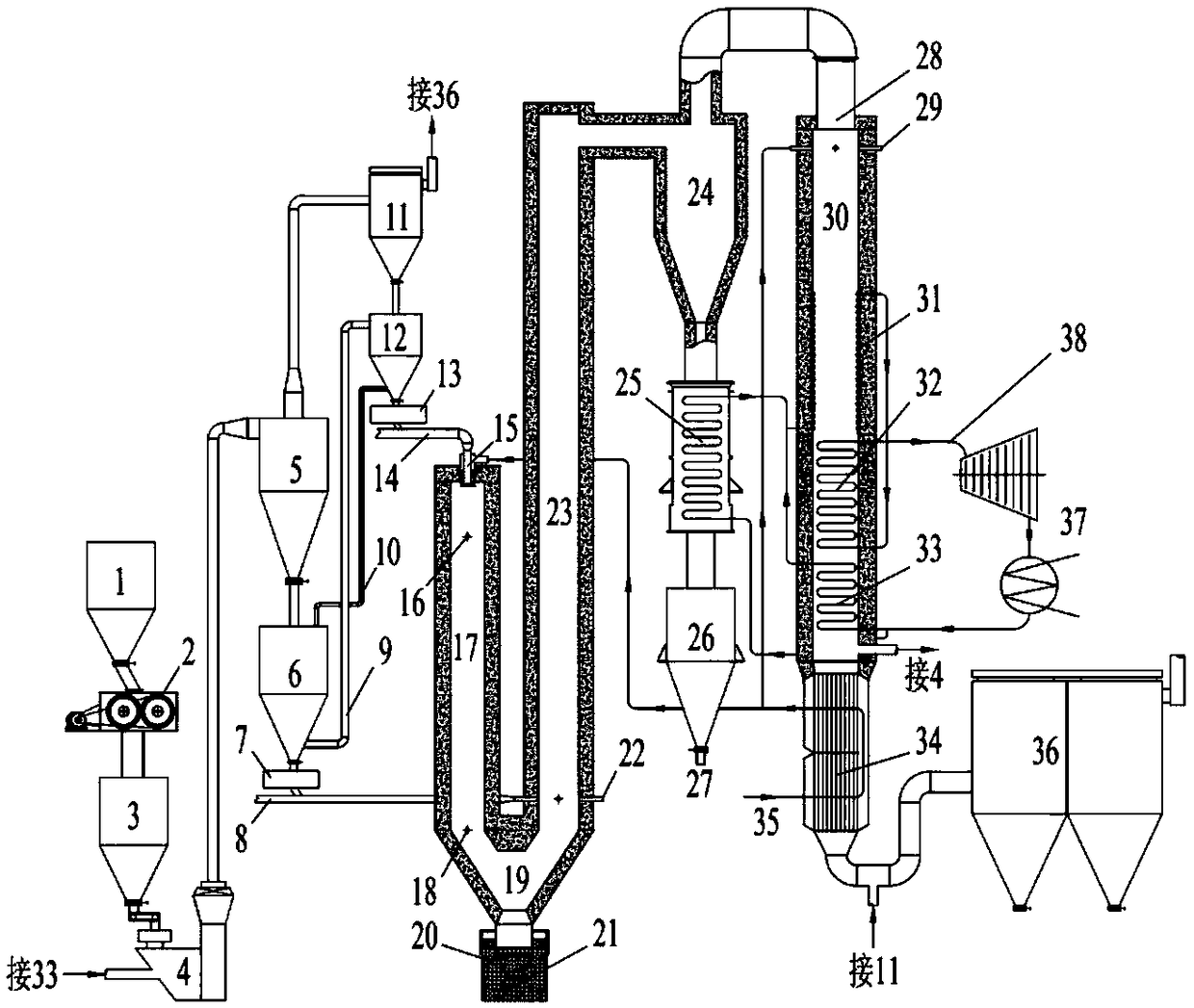

Combined coal pyrolysis gasification system

InactiveCN103965969ATo achieve hierarchical utilizationRealize cascade utilizationEnergy inputGranular/pulverulent flues gasificationFluidized bedEconomic benefits

The invention discloses a combined coal pyrolysis gasification system which comprises a raw material coal drying system, a composite coal bin, a combined gasification furnace and a combined pyrolysis furnace, wherein the combined gasification furnace is arranged at the upper part of the combined pyrolysis furnace; the combined gasification furnace operates in a fluidized bed form, and a gasification furnace built-in separator is arranged inside the combined gasification furnace; a hot gas outlet pipe of the gasification furnace built-in separator is connected with a gas inlet of a tube shell type waste heat boiler; the combined pyrolysis furnace operates in a fluidized bed form, and a pyrolysis furnace built-in separator is arranged inside the combined pyrolysis furnace; a raw gas outlet pipe of the pyrolysis furnace built-in separator is connected with a gas inlet of a pyrolysis gas purification system; a discharge port of the combined gasification furnace and a discharge port of the gasification furnace built-in separator are connected with a hot semicoke inlet of the combined pyrolysis furnace through hot semicoke return valves. The combined coal pyrolysis gasification system realizes graded utilization of coal, is favorable for saving energy and reducing emission, and can increase economic benefits of an enterprise.

Owner:BEIJING LANTIAN LIYUAN SCI & TECH

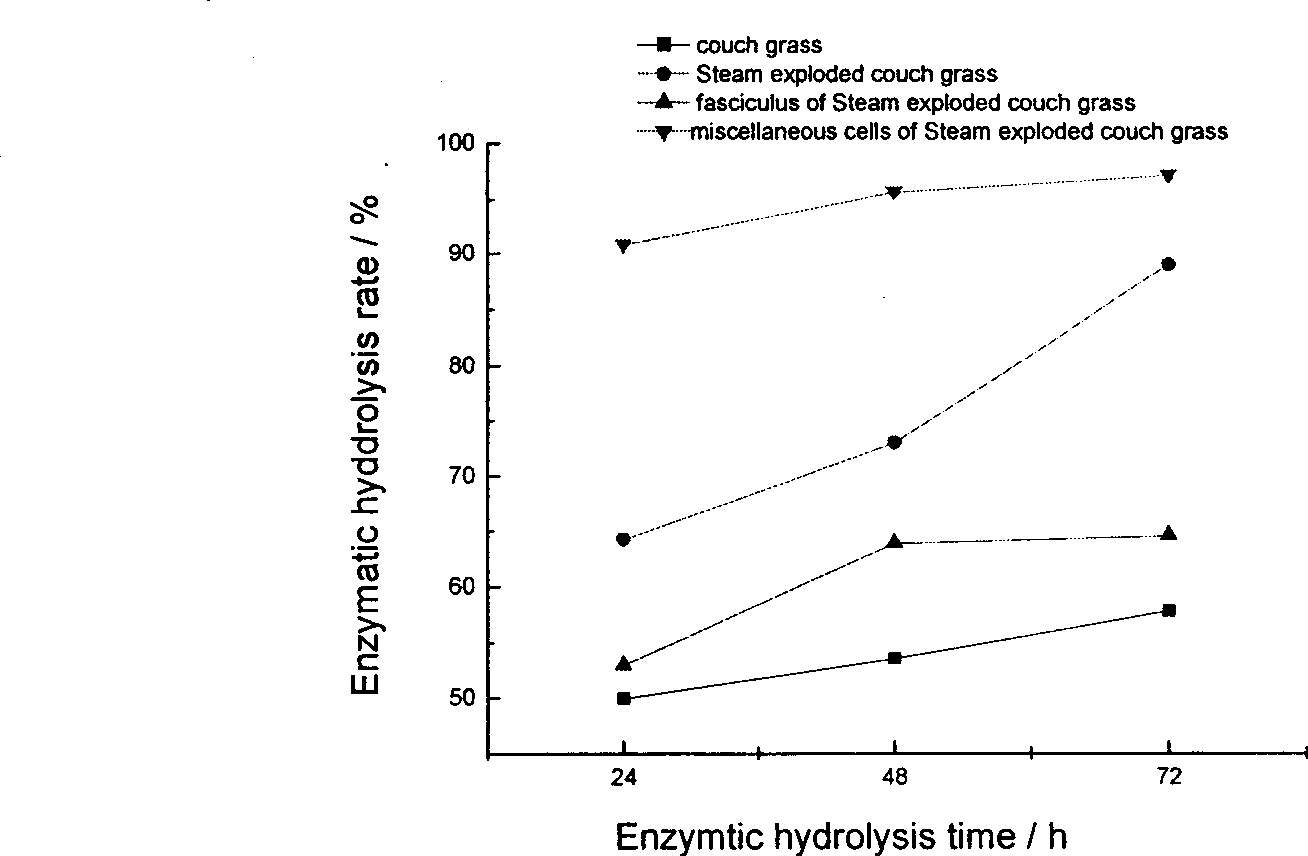

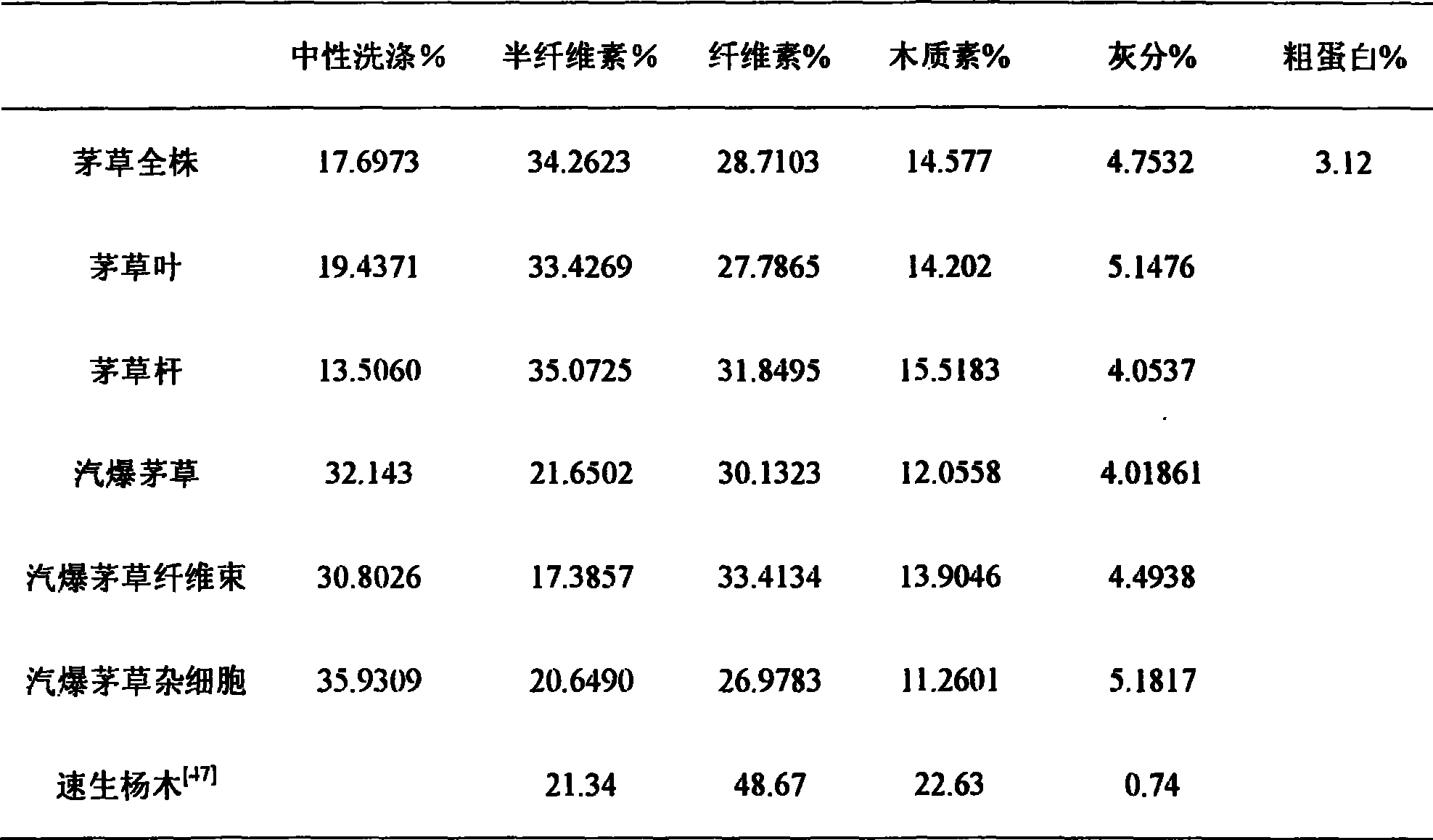

Method for co-producing paper pulp and fuel ethanol by wild grass on forest land

InactiveCN101381970ATo achieve hierarchical utilizationRealize clean high-value full utilizationWashing/displacing pulp-treating liquorsDigestersFiberOligosaccharide

The invention provides a method for co-producing paper pulp and fuel ethanol by waste grass in woodland. In the method, each link is clean and environment friendly ; the steam explosion pretreatment and a mechanical carding tissue are coupled in classification and are separated to obtain a high-quality fibre tissue, a miscellaneous cell tissue and a fine fibre tissue; a high-quality long fibre bundle tissue adopts the steam explosion pretreatment and an ethanol self-catalysis method which are coupled with each other to prepare high-grade paper pulp cleanly; a short fibre consisting of a thin-wall cell and the like ferments to produce the fuel ethanol; at the same time, xylo-oligosaccharides, lignin and nano-silica as byproducts are reclaimed and prepared, thereby realizing the fractionated separation, cleaning and high-value utilization of the waste grass resources in the woodland.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

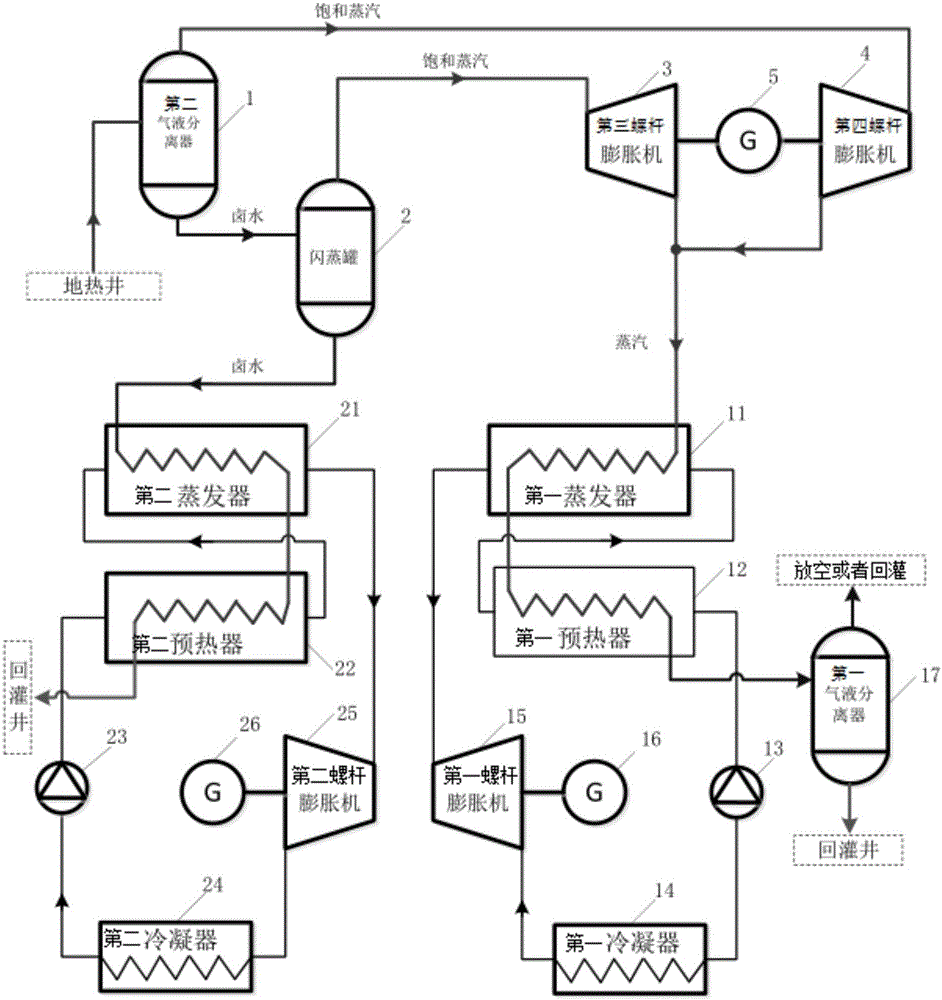

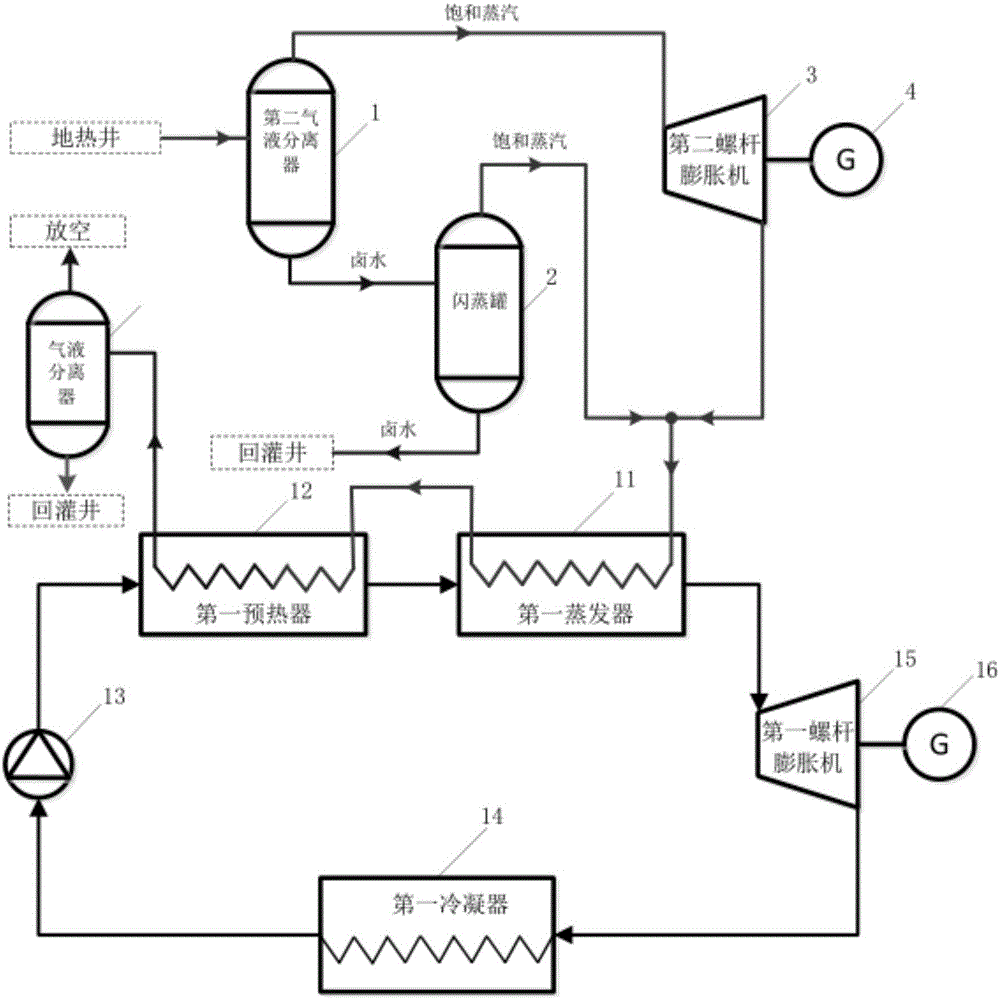

Geothermal wellhead power station system based on ORC systems and power generation method of geothermal wellhead power station system

InactiveCN105673103AImprove utilization efficiencyTo achieve hierarchical utilizationSteam engine plantsVapor–liquid separatorPower station

The invention discloses a geothermal wellhead power station system based on ORC systems and a power generation method of the geothermal wellhead power station system. The geothermal wellhead power station system comprises a second gas-liquid separator, a flash tank, a third screw expander, a fourth screw expander, a third power generator, a fourth power generator, the first ORC system and the second ORC system. The first end of the second gas-liquid separator is connected with the third screw expander. Saturated steam enters the third screw expander. An exhaust opening of the third screw expander is connected with the first ORC system and an exhaust opening of the fourth screw expander. The second end of the second gas-liquid separator is connected with the flash tank. The flash tank is connected with the fourth screw expander. High-temperature and high-pressure brine enters the flash tank. The fourth screw expander is further connected with the first ORC system. The flash tank is connected with the second ORC system. The high-temperature brine obtained after flash evaporation enters the second ORC system. By means of the geothermal wellhead power station system based on the ORC systems and the power generation method of the geothermal wellhead power station system, the geothermal utilization efficiency can be improved.

Owner:SHANGHAI KAISHAN ENERGY EQUIP +1

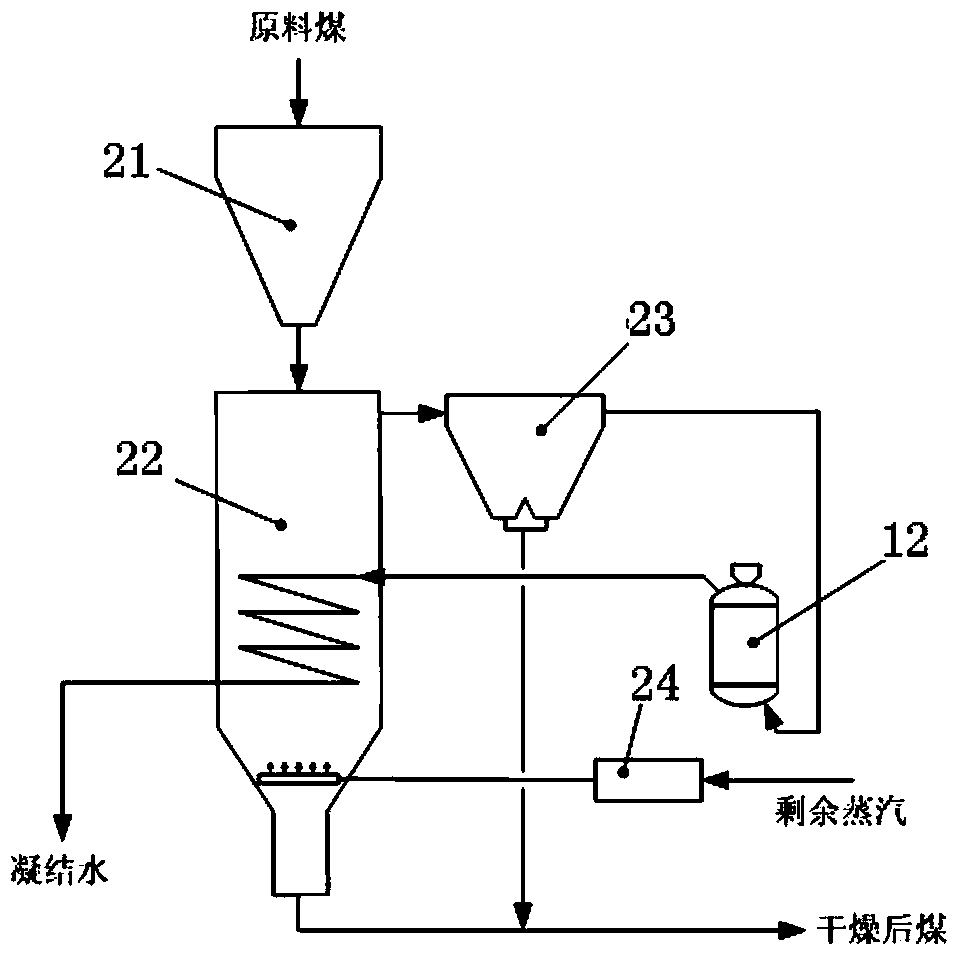

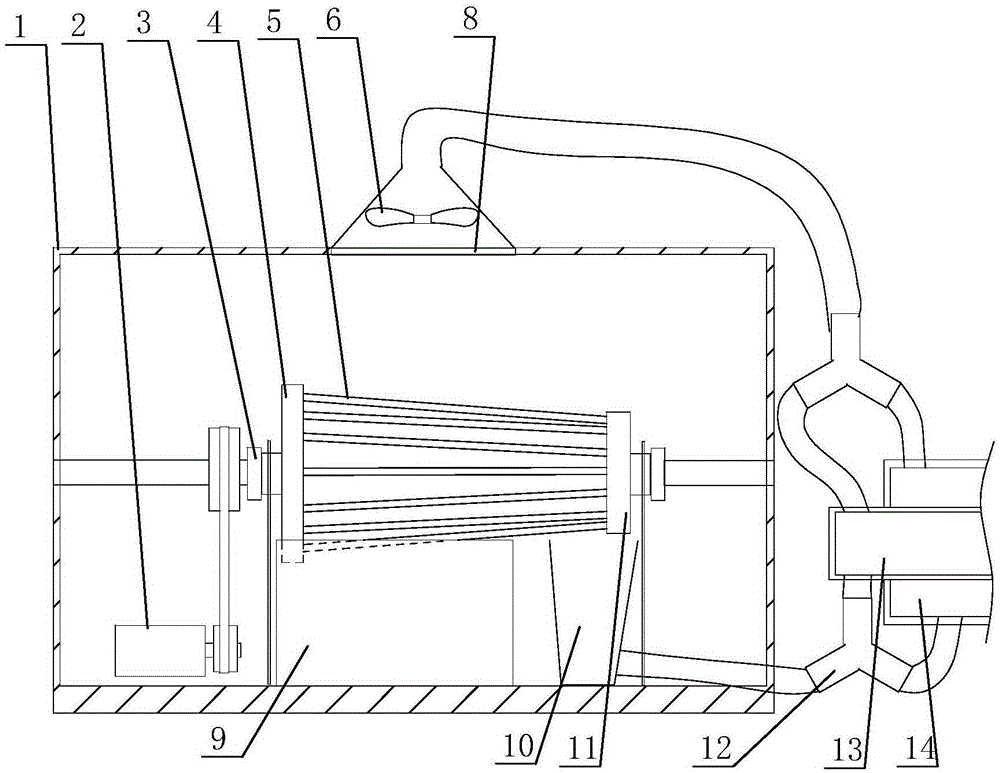

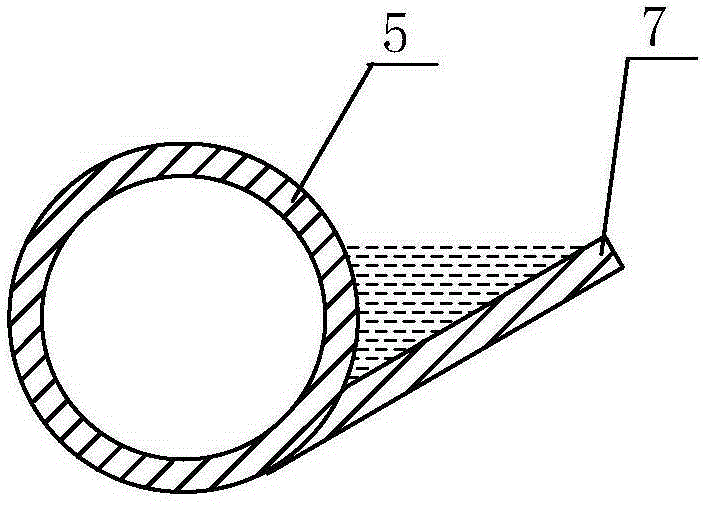

Feed coal pre-pyrolysis device for large-sized pulverized coal furnace

InactiveCN103666506ARealize polygeneration systemTo achieve hierarchical utilizationDirect heating destructive distillationSpecial form destructive distillationEngineeringCoal pyrolysis

The invention discloses a feed coal pre-pyrolysis device for a large-sized pulverized coal furnace. The device comprises a feed coal bucket, rectangular star-like unloading machines, a steam fluidized bed dryer, a screw coal feeder, a combined coal pyrolysis device, a semi-coke conveying heat exchanger and a coal mill, which are sequentially connected, wherein a fluidized steam air distribution plate is arranged at the lower part of the steam fluidized bed dryer, and a secondary steam outlet is formed in the upper part of the steam fluidized bed dryer, and is connected with a secondary steam recovery system through an electrical dust precipitator; a fluidized gas air distribution plate is arranged at the lower part of the combined coal pyrolysis device; an internal separator is arranged atthe inner middle part of the combined coal pyrolysis device, and is a multi-inlet cyclone separator; a gas outlet in the top of the internal separator is connected with the fluidized gas air distribution plate after the heat exchange of hot flue gas between a high-temperature heat pipe heat exchanger and a gas fired furnace. According to the device, a heat, electricity, oil and gas co-production system can be implemented, so that not only are the classified utilization of coal and the gradient utilization of heat energy realized to facilitate energy saving and emission reduction, but also the economic benefits of a thermoelectricity enterprise can be improved.

Owner:BEIJING LANTIAN LIYUAN SCI & TECH

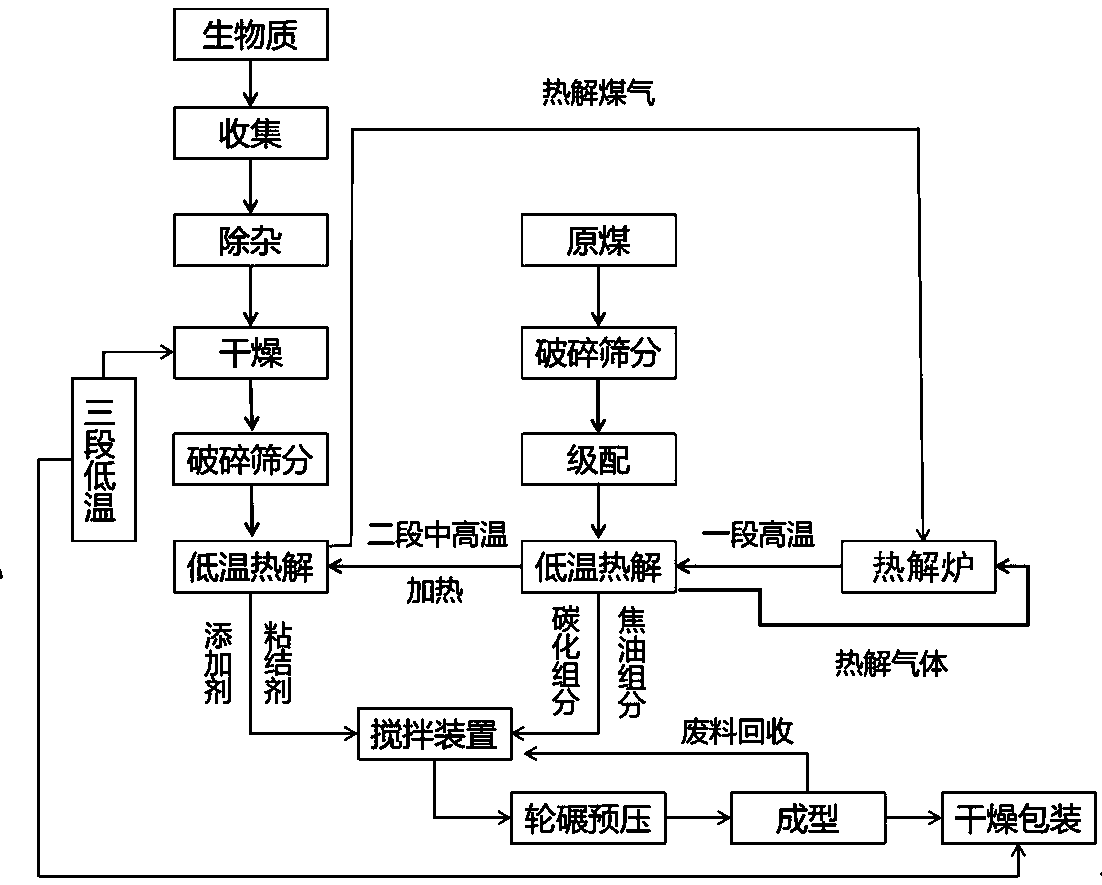

Method for making biomass waste carbonization environmental-friendly briquette coal

PendingCN109679703AHigh mechanical strengthTo achieve hierarchical utilizationBiofuelsSolid fuelsCarbonizationPollutant emissions

The invention relates to a method for making biomass waste carbonization environmental-friendly briquette coal and is applicable to the field of environment protection. The method comprises the following steps: picking and collecting biomass raw materials; carrying out sorting and decontamination on the biomass raw materials; drying the biomass raw materials; crushing and screening the biomass rawmaterials; carrying out low temperature pyrolysis on the biomass raw materials; crushing and screening crude coal; grading the crude coal; carrying out low temperature pyrolysis on the crude coal; mixing the raw materials; carrying out wheel grinding and pre-pressing; molding briquette coal; recycling waste materials; carrying out drying and packaging. The method can be applied to biomass collection and carbonization and coal molding to make environmental-friendly briquette coal on scale, the briquette coal has less impurities, heat can be utilized at multiple stages, volatile components andimmobilized carbon of the raw materials can be sufficiently utilized, environmental-friendly briquette coal which is good in combustion activity and small in pollutant emission can be made, and technical support is provided for effective utilization of biomass wastes and on-scale operation of environmental-friendly briquette coal making.

Owner:CHINA UNIV OF MINING & TECH

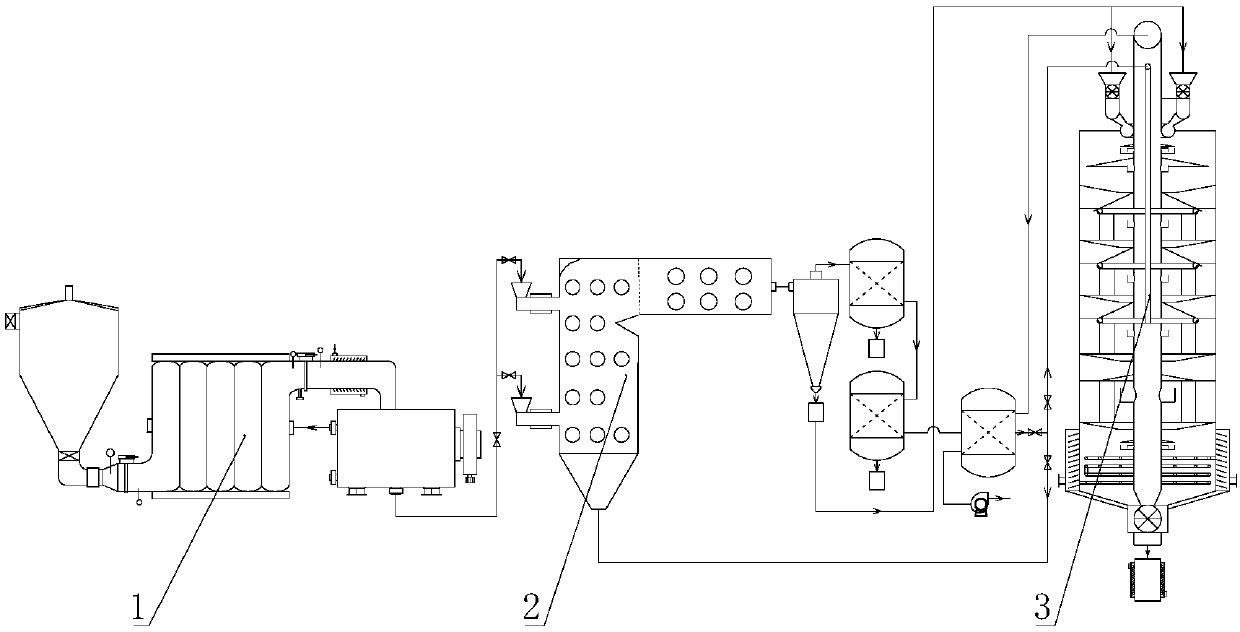

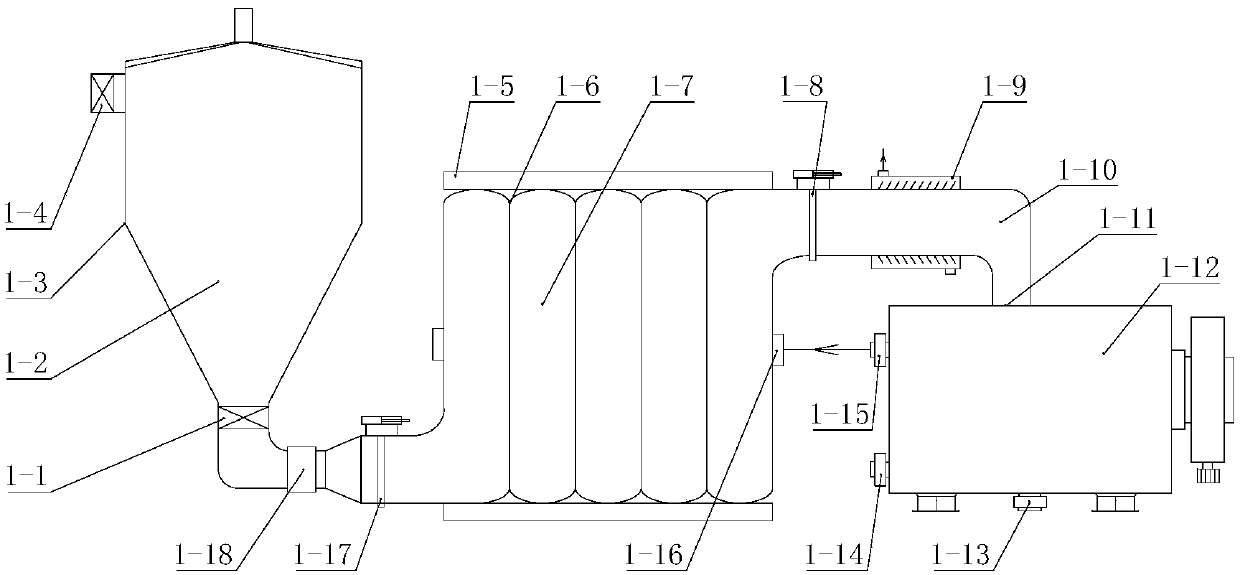

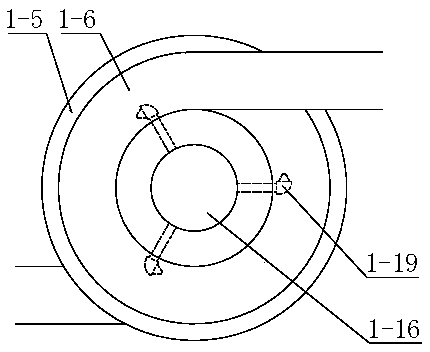

System and method for graded co-production of energy chemical and silicon carbon material through rice husks

ActiveCN109628121ATo achieve hierarchical utilizationAchieve enrichmentBiofuelsLiquid hydrocarbon mixture productionHuskCarbonization

The invention discloses a system for graded co-production of an energy chemical and silicon carbon material through rice husks. The system comprises a hydrothermal baking subsystem (1), a medium temperature pyrolysis subsystem (2) and a high temperature carbonization subsystem (3) which are connected in sequence, wherein the hydrothermal baking subsystem (1) is used for preparing a liquid productrich in furfural and hydrothermal charcoal; the medium temperature pyrolysis subsystem (2) is used for obtaining bio-oil rich in sugar and medium-temperature pyrolysis carbon; the high temperature carbonization subsystem (3) comprises a rotary feeding valve (3-1), a multi-stage high temperature electric furnace (3-2), a gas channel distribution pipeline (3-3), a product cooling device (3-8), a coke cooling tank (3-12) and a volatile condensing device (3-20), and is used for multi-stage high temperature carbonization and activation of the pyrolysis carbon to obtain the silicon carbon material with a energy storage characteristic. The invention also provides a method for the graded co-production of the energy chemical and silicon carbon material through the rice husks. The system and methodhave the advantages that the high-quality energy chemical and silicon carbon material can be simultaneously obtained, the treatment efficiency is high, the heat utilization rate is high, and the operation is convenient.

Owner:HUAZHONG UNIV OF SCI & TECH

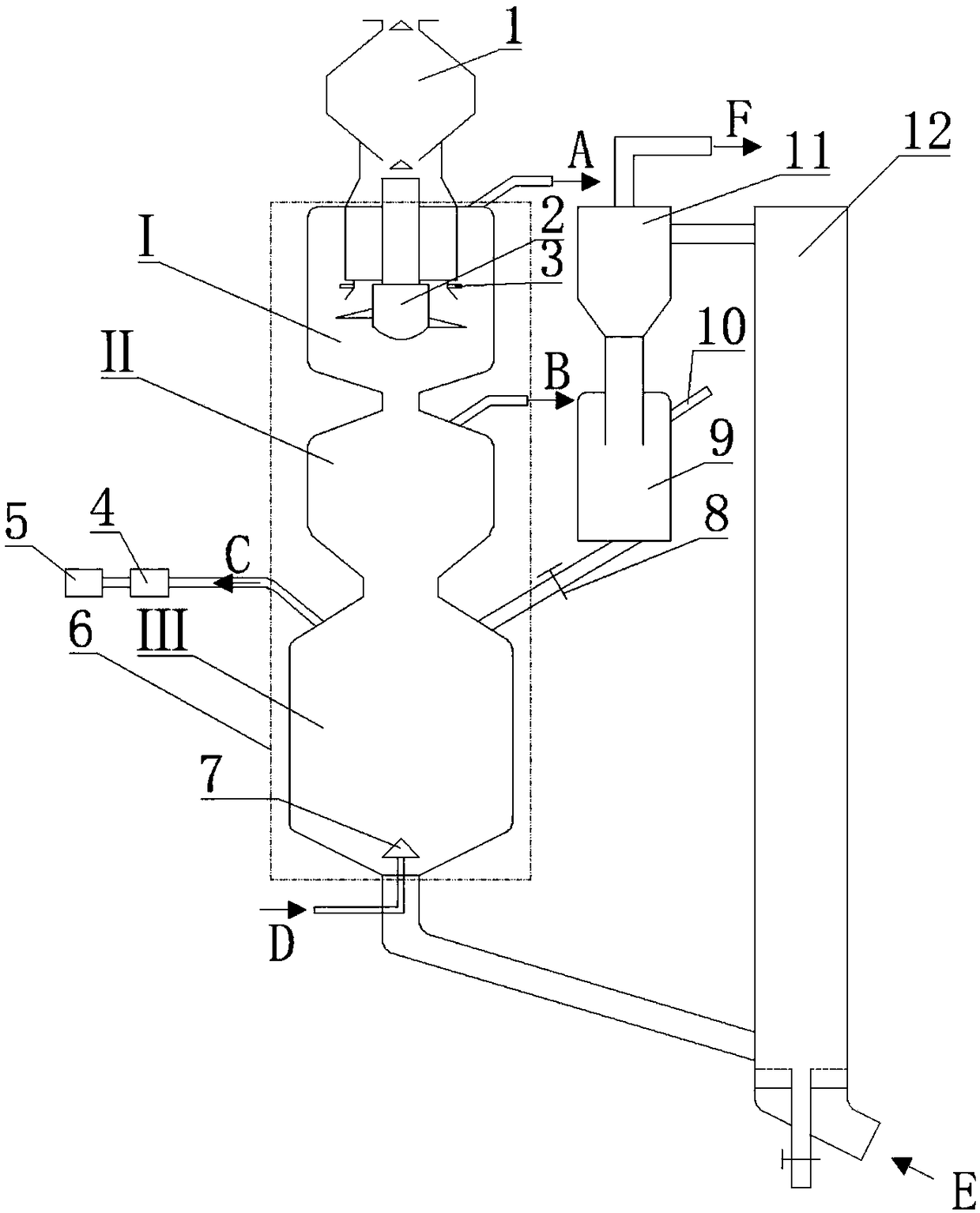

Carbon-based fuel chemical chain combustion gasification coupling device and method

PendingCN108504389ALower conversion rateExtended stayGasification processes detailsSpecial form destructive distillationGas solidCombustion

The present invention provides a carbon-based fuel chemical chain combustion gasification coupling device comprising a moving bed fuel reactor, a fast bed air reactor, a cyclone separator and an oxygen carrier storer; the moving bed fuel reactor includes a drying pyrolysis section I, a gasification section II and a combustion section III; a feeding device is arranged on one end of the drying pyrolysis section I, and the other end of the drying pyrolysis section I is connected to one end of the gasification section II, the other end of the gasification section II is in communication with one end of the combustion section III, and the combustion section III is sequentially connected to the fast bed air reactor, the cyclone separator and the oxygen carrier storer through a pipeline to form aclosed loop; tan active oxygen carrier is placed in the oxygen carrier storer; and a gasification agent distribution device is disposed at the bottom of the combustion section III. The carbon-based fuel chemical chain combustion gasification coupling device can prolong the time of gas-solid and solid-solid contact in the reactor, thereby improving the conversion rate of a carbon-based fuel, and can realize the preparation of crude gas, clean gas and the effective separation of CO2.

Owner:JIANGSU UNIV

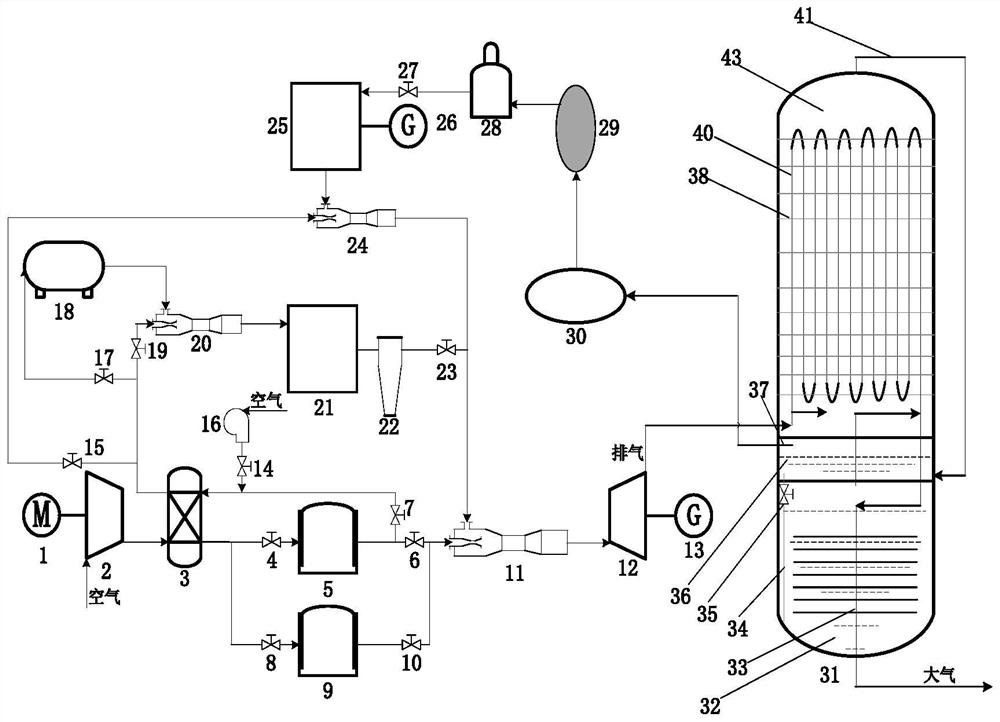

Composite compressed air energy storage system and method for coupling methanol reformer with internal combustion engine

ActiveCN114483290AMake full use of high temperature heat dissipationMake the most of heat removalHydrogenInternal combustion piston enginesMethanol waterCombustor

The composite compressed air energy storage system comprises a compressed air energy storage unit, a methanol steam reforming unit, a low-dust combustor unit and an internal combustion engine power generation unit which are mutually coupled, and low-grade compression heat, high-temperature exhaust heat of the internal combustion engine and exhaust heat of an expansion machine are fully utilized; exhaust gas of the expansion machine firstly passes through the methanol steam reaction inner pipe to provide energy for methanol reforming reaction, and then passes through the disc-shaped heat exchanger to evaporate a methanol aqueous solution to generate methanol steam, so that stepped utilization of high-temperature exhaust gas energy of the expansion machine is realized, and the energy utilization efficiency is improved; an external heat source of the reactor is avoided while high-temperature exhaust is utilized, so that the system efficiency is further improved; the mixed gas generated by the reforming reaction passes through the low-concentration methanol aqueous solution in the methanol removal chamber, methanol in the mixed gas is absorbed, heat of the mixed gas is absorbed at the same time, recycling of the methanol and the heat is achieved, and the economical efficiency of hydrogen production through methanol steam reforming is improved.

Owner:XI AN JIAOTONG UNIV

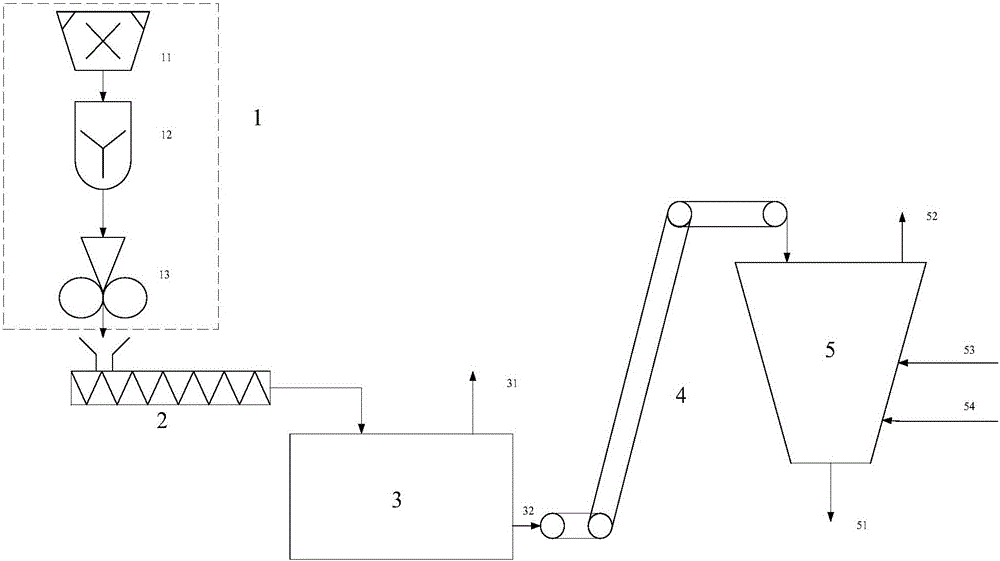

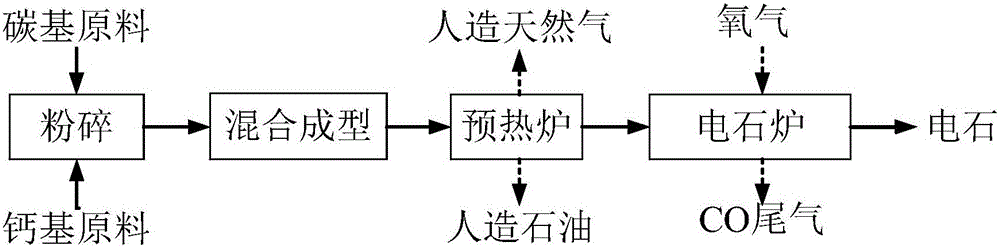

Calcium carbide preparation system and method

InactiveCN105776218AReduce consumptionImprove utilization efficiencyChemical industryCalcium carbideOxygenCalcium carbide

The invention discloses a calcium carbide preparation system and method, wherein the calcium carbide preparation system comprises a raw material pretreatment unit, a feeding device, a preheating furnace, a high-temperature conveying device and a calcium carbide furnace, wherein the raw material pretreatment unit comprises a crushing device, a mixing device and a forming device in sequential connection; the crushing device is provided with a raw material inlet; an outlet of the forming device is communicated with an inlet of the feeding device; an outlet of the feeing device is communicated with an inlet of the preheating furnace; the preheating furnace is provided with a solid material outlet and an oil gas outlet; the solid material outlet is connected with the high-temperature conveying device; an outlet of the high-temperature conveying device is communicated with a high-temperature solid material inlet of the calcium carbide furnace; the calcium carbide furnace is provided with the high-temperature solid material inlet, an oxygen inlet, a calcium carbide outlet and a furnace gas outlet; the high-temperature solid material inlet is connected with the solid material outlet; the calcium carbide product is guided out from the calcium carbide outlet; gas generated in the calcium carbide reaction process is guided out from the furnace gas outlet.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

Bypass grading coal economizer system with active exhaust gas temperature control function

InactiveCN105387446AReduce the temperatureTo achieve hierarchical utilizationFluid heatersFeed-water heatersAir preheaterTemperature control

The invention discloses a bypass grading coal economizer system with the active exhaust gas temperature control function. The system comprises a high-temperature coal economizer, a front air preheater and a bypass grading device. The high-temperature coal economizer and the front air preheater are arranged at the upper portion and the lower portion of a flue respectively. The bypass grading device is arranged between the high-temperature coal economizer and the front air preheater and comprises a control valve, a main air preheater, a bypass coal economizer high-temperature section and a bypass coal economizer low-temperature section. The flue is divided into a main flue body and a bypass flue body through the control valve, the main air preheater is located on the main flue body, and the bypass coal economizer high-temperature section and the bypass coal economizer low-temperature section are located on the bypass flue body up and down. By the adoption of the bypass grading coal economizer system, the control valve is additionally arranged to divide the flue into the main flue body and the bypass flue body, so that the separated flue is formed, exhaust gas waste heat is used grade by grade, and the exhaust gas temperature is actively controlled.

Owner:HUAZHONG UNIV OF SCI & TECH

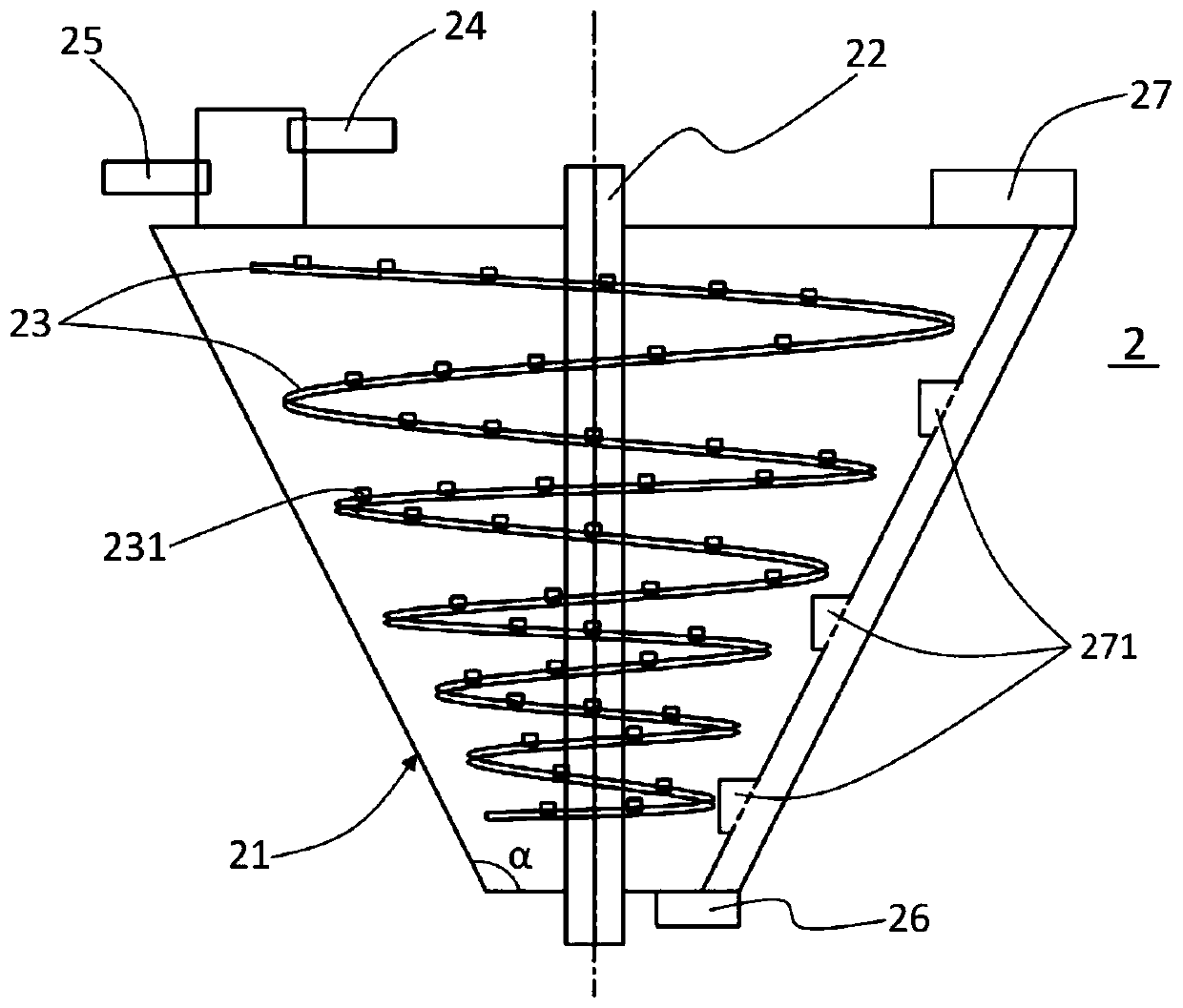

Sludge pyrolysis recycling system and pyrolysis method

ActiveCN110066083AImprove thermal efficiencyHeating evenlySludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisHeat carrierSludge

The embodiment of the invention provides a sludge pyrolysis recycling system, which adopts solid porcelain balls or quartz sand as a heat carrier to rapidly transfer heat to sludge according to the material and pyrolysis characteristics of the sludge, and comprises a specially designed spiral pyrolysis reactor capable of achieving forced mixing and rapid heat transfer of the sludge. According to the invention, the solid heat carrier and the sludge are mixed and directly heated, compared with an indirect heating mode, the heat efficiency is high and the heating is uniform; spiral blades and stirring blades which are reasonably arranged in the pyrolysis reactor can achieve full mixing and rapid heat transfer of the sludge and the heat carrier, the pyrolysis reaction speed is high, the systemtreatment capacity is strong, the coking problem caused by uneven stirring of the sludge is effectively solved, and the long-term stable operation of the system is achieved; the waste heat flue gas is recycled to pre-dry the sludge, so that the energy grading utilization is achieved, the energy consumption can be effectively reduced, and the energy utilization efficiency of the system is improved. The embodiment of the invention also provides a method for pyrolyzing the sludge by adopting the sludge pyrolysis recycling system.

Owner:嘉禾聚能(天津)科技有限公司

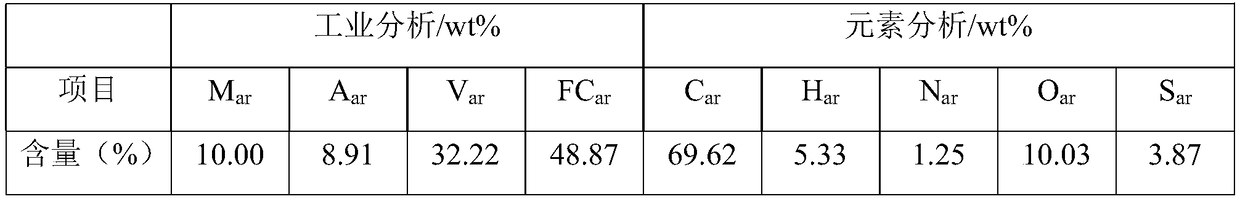

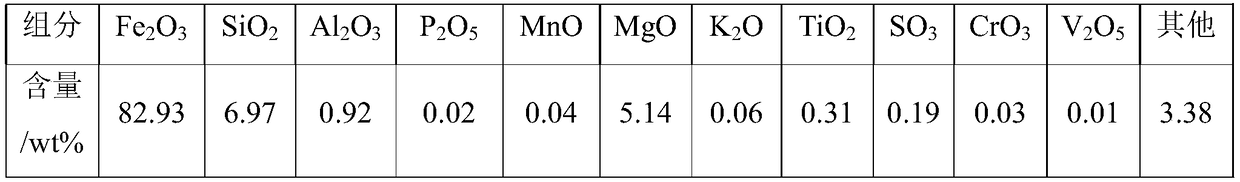

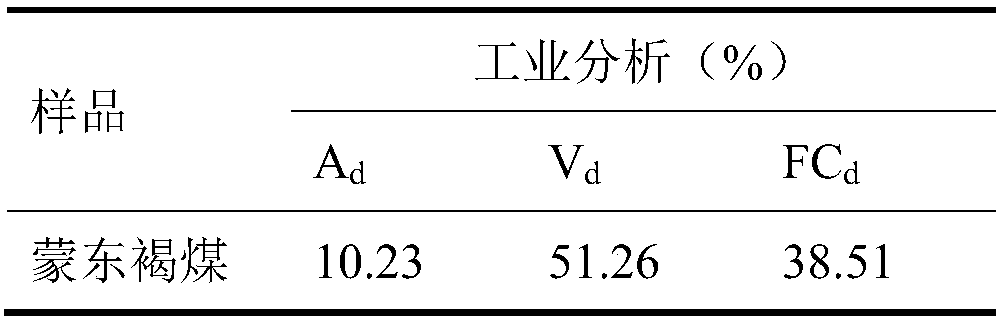

Process and system for preparing high-yield and high-activity powdery active coke from lignite

InactiveCN108910874ATo achieve hierarchical utilizationLow ash contentCarbon compoundsSpecial form destructive distillationCombustionBiochemical engineering

The invention discloses a process and system for preparing high-yield and high-activity powdery active coke from lignite. The process is characterized in that the lignite is used as raw materials; a graded and sectioned powdery coke preparation process is used, wherein the oxygen equivalent weight ratio in the smoke gas entering a coke preparation section from a combustion section is 0.1 to 0.3; the temperature of the coke preparation section is 850 to 1050 DEG C. The powdery active coke is prepared; meanwhile, the characteristics of high yield and high activity are realized.

Owner:SHANDONG UNIV

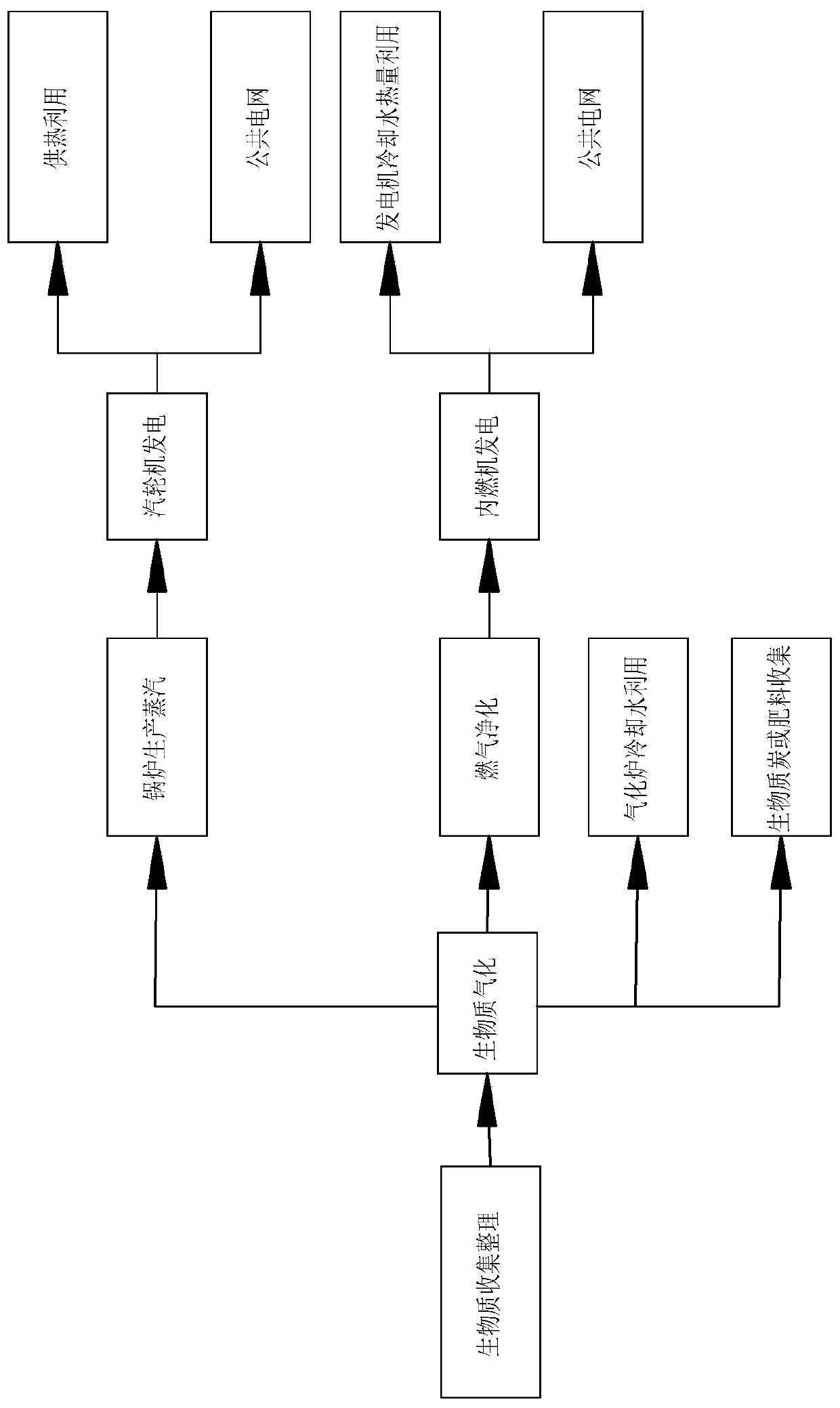

Biomass pyrolysis and gasification poly-generation system and method

PendingCN111057567ASolve a single problemSolve hierarchical utilizationInternal combustion piston enginesBiofuelsInternal combustion engineElectric generator

The invention discloses a biomass pyrolysis and gasification poly-generation system and method. The biomass pyrolysis and gasification poly-generation system comprises a biomass collection and arrangement device for classifying, arranging and pretreating biomass raw materials, a biomass gasification device for pyrolyzing and gasifying biomass raw materials, and a biomass boiler; one part of combustible gas generated by pyrolysis and gasification is directly used for combustion of the biomass boiler; generated steam is used for power generation of a steam turbine generator unit; the rest combustible gas enters a gas purification device to be purified, and after impurities are removed, the rest combustible gas is used for power generation of an internal combustion engine generator set; solidsubstances generated by pyrolysis and gasification form biomass charcoal or fertilizers; waste heat of cooling water of pyrolysis gasification is recycled through the gasification furnace cooling water utilization device, the steam turbine generator unit and the internal combustion engine generator unit generate electricity and then the electricity is fed into a public power grid, hot water generated by the steam turbine generator unit is utilized through a heat supply utilization device, and waste heat of cooling water of the internal combustion engine generator unit is recycled through a generator cooling water heat utilization device. The method can be widely applied to the field of biomass utilization.

Owner:珠海横琴博信能源建设有限公司

Geothermal well opening power station system and power generation method thereof

InactiveCN105736263AImprove utilization efficiencyTo achieve hierarchical utilizationGeothermal energy generationGeothermal systemsVapor–liquid separatorPower station

The invention discloses a geothermal well opening power station system and a power generation method thereof. The geothermal well opening power station system comprises a second gas-liquid separator, a flash evaporation tank, a second screw expander, a second electric generator and a steam ORC system; the second screw expander is connected with the second electric generator; the first end of the second gas-liquid separator is connected with the second screw expander, and the second end of the second gas-liquid separator is connected with the flash evaporation tank; saturated steam enters the second screw expander, and high-temperature and high-pressure brine enters the flash evaporation tank; steam obtained by flash evaporation is mixed in an outlet of the second screw expander and then enters the steam ORC system through a first evaporator, and the brine obtained by flash evaporation is conveyed to a recharge well through a first conveying mechanism and is injected into the underground again; and according to the geothermal well opening power station system and the power generation method thereof, the utilization efficiency of the geothermy can be improved.

Owner:SHANGHAI KAISHAN ENERGY EQUIP +1

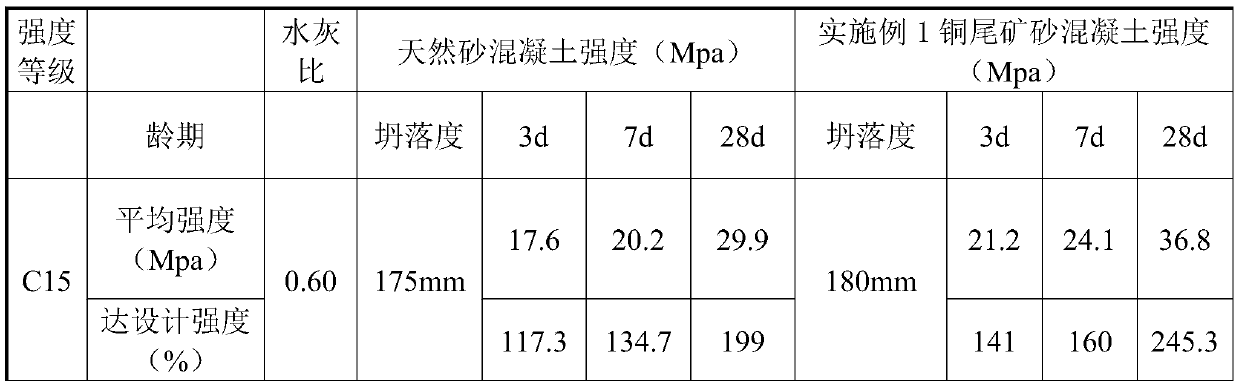

Concrete containing copper tailings and preparation method thereof

InactiveCN110498651ASolve technical problems with insufficient resourcesTo achieve hierarchical utilizationSolid waste managementRiver sandHigh strength concrete

The invention relates to a concrete containing copper tailings and a preparation method thereof, and aims to solve the technical problems of environmental pollution and wasting of resources caused bystacking of copper tailings. According to a technical scheme, the concrete containing copper tailings is composed of the following raw materials by weight percentage: 9-30% of copper tailing sand, 7-8% of water, 12-20% of cement, 0-25% of coarse sand, 40-45% of stone and 0.2-0.4% of an admixture. Specifically, the coarse sand is river sand, the stone is river gravel or waste rock, and the admixture is a water reducing agent. The beneficial effects of the invention lie in that: the invention provides a method for preparation of high-strength concrete from copper tailings, specifically copper tailing sand is employed to replace part of or all natural sand, the prepared concrete has indexes superior to natural sand concrete, good workability and fluidity, and no water segregation phenomenon,realizes graded comprehensive utilization of tailing resources, alleviates the environmental pollution brought about by tailing storage and stacking, reduces wasting of resources and environmental pollution, and has significant social and economic benefits.

Owner:中条山有色金属集团有限公司

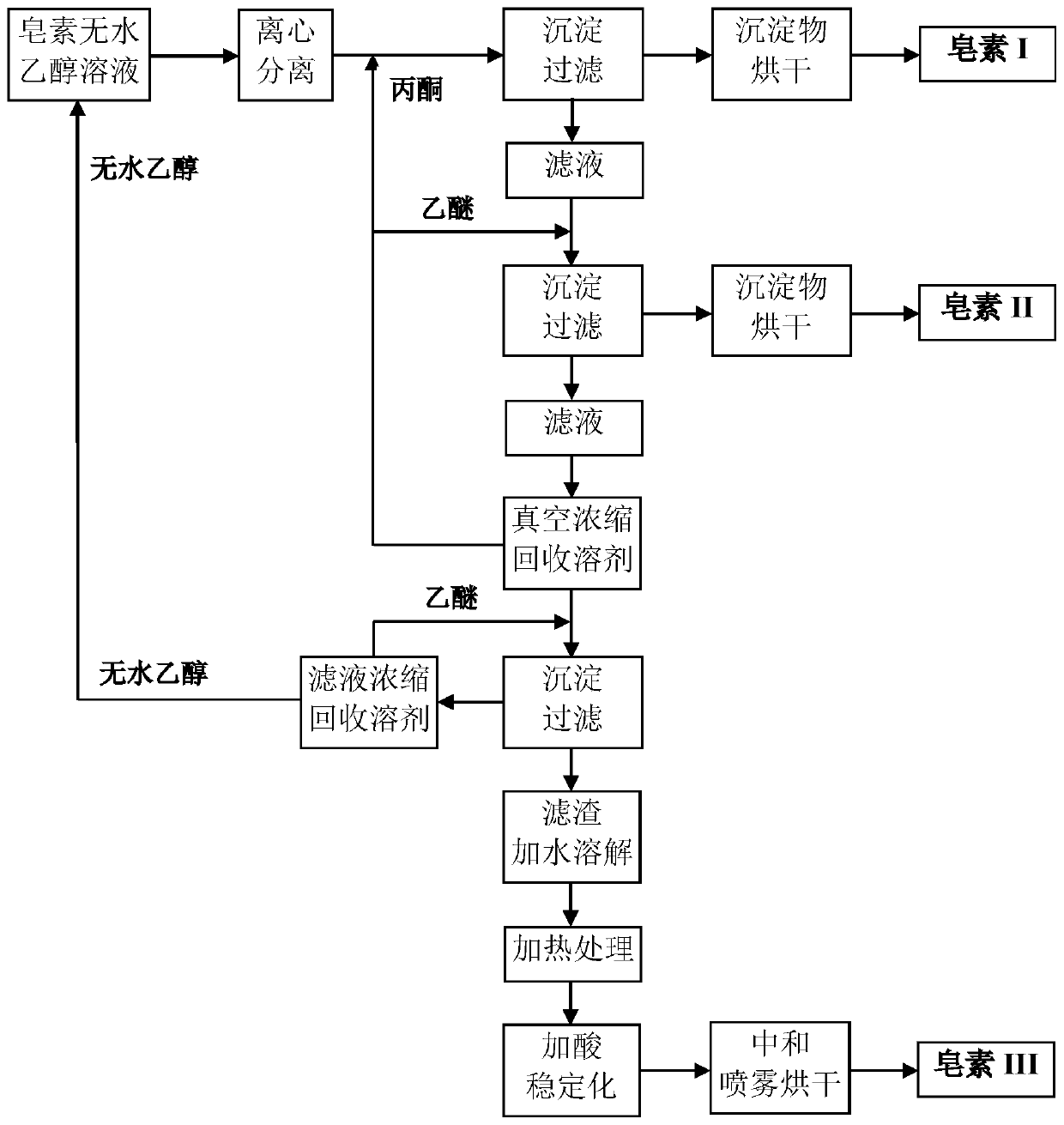

Saponin separation and stabilization method

ActiveCN111298710AReduce concentrationReduce surface tensionTransportation and packagingGlycosidesCritical micelle concentrationSaporin

The invention belongs to the technical field of high-quality utilization of plant extracts, and particularly relates to a saponin separation and stabilization method. The saponin separation and stabilization method comprises the following steps: crude saponin is used as a raw material and filtering by absolute ethyl alcohol, obtained filtrate I is subjected to acetone precipitation separation to obtain saponin I, obtained filtrate II is subjected to acetone / diethyl ether precipitation separation to obtain saponin II, obtained filtrate III is further subjected to diethyl ether precipitation separation, obtained precipitation filter residues are dissolved in water and then subjected to heat treatment and acid stabilization treatment, and thus saponin III is obtained. According to the method,after the crude saponin is filtered by absolute ethyl alcohol, acetone, acetone / diethyl ether and diethyl ether are sequentially used for fractional purification so that three saponin products with different properties can be obtained at the same time, and a basis is provided for refined and high-quality utilization of saponin; in addition, saponin obtained through diethyl ether precipitation issubjected to stabilizing treatment and the stability is remarkably improved, the critical micelle concentration and surface tension of saponin are remarkably reduced, and the quality of saponin products is improved.

Owner:BEIJING FORESTRY UNIVERSITY

Evaporative condenser

ActiveCN105180522AGood cooling effectImprove heat source qualityEvaporators/condensersSteam/vapor condensersRefrigerantEvaporative cooler

The invention relates to an evaporative condenser, and belongs to the field of heat exchangers. The evaporative condenser includes a housing, wherein a heat exchanging assembly is arranged in the housing; the heat exchanging assembly includes a large distribution disk and a small distribution disk which are both oblate cavities; straight pipes are uniformly distributed between the large distribution disk and the small distribution disk; the straight pipes are communicated with the large distribution disk and the small distribution disk; the outer side surfaces of the large distribution disk and the small distribution disk are both connected with refrigerant pipes through sealed bearings; the large distribution disk, the small distribution disk, and the straight pipes form a frustum shape; a water tank is arranged below the large distribution disk; one third of the large distribution disk and part of the straight pipes are immersed into the water tank; a groove is axially formed in a coil; a water stirring piece is axially fixed on the coil and is parallel to the tangential direction of the straight pipes; a water collection tank is arranged below the small distribution disk and is connected with a sleeve through a three-way valve; one connecting opening of the three-way valve is connected with the inner pipe of the sleeve, and another connecting opening is connected with the interlayer of the sleeve. The evaporative condenser is high and uniform in cooling speed; the heat exchanged from the cooling process can realize multi-level utilization; the structure is simple, and the cost is low.

Owner:SHANDONG AONAER REFRIGERATION TECH

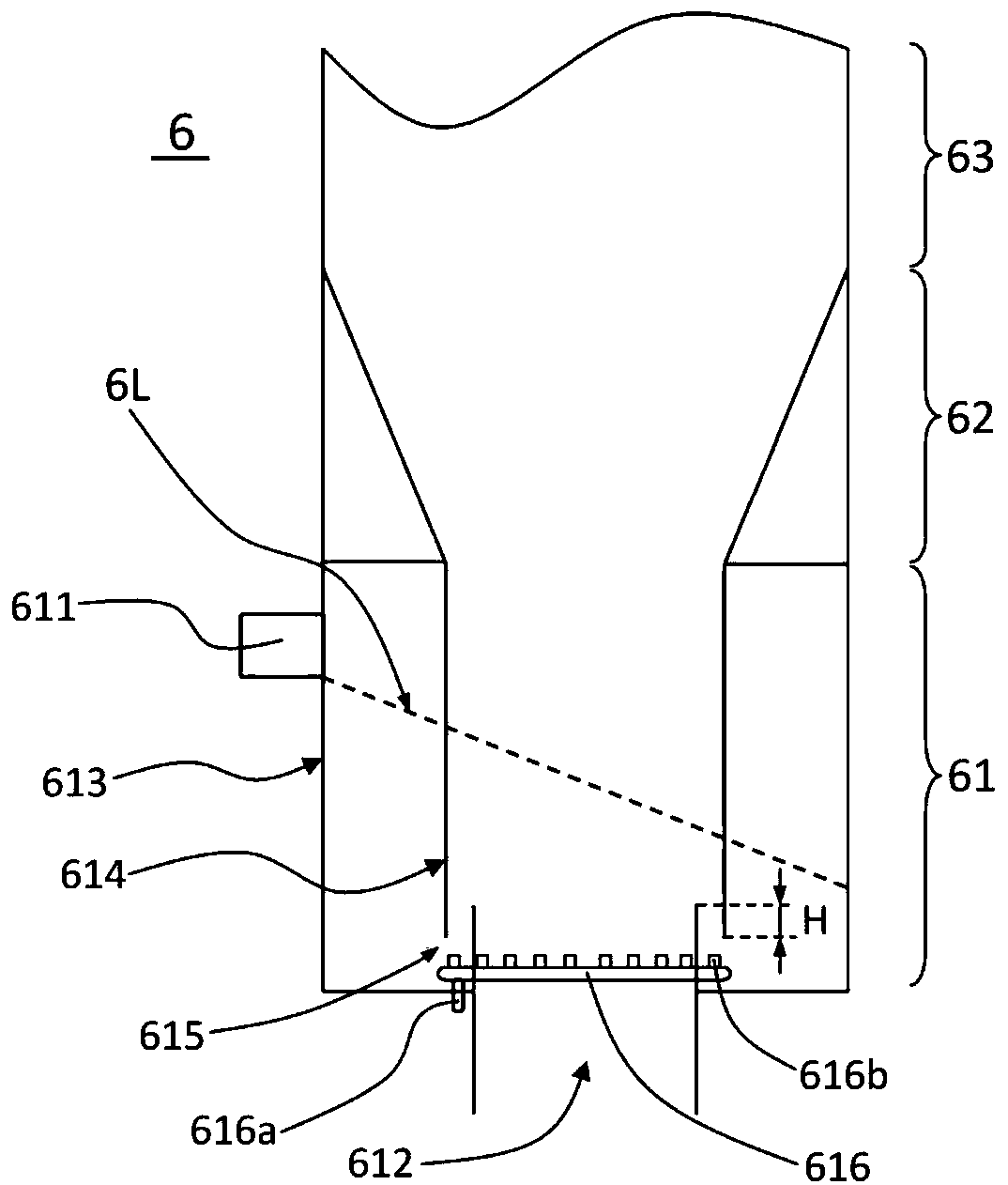

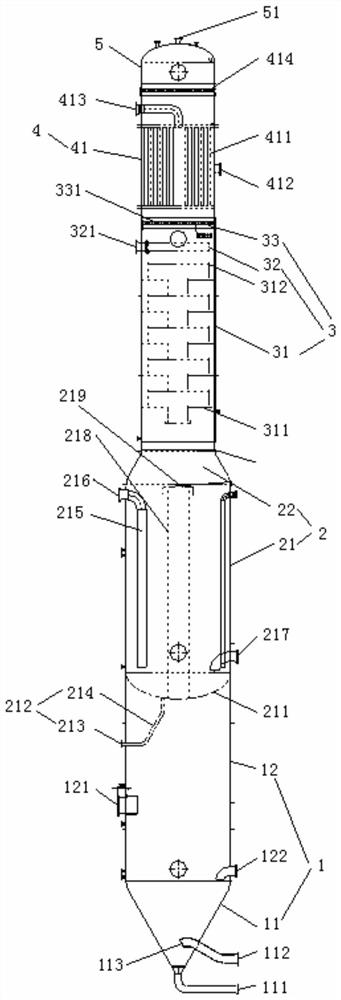

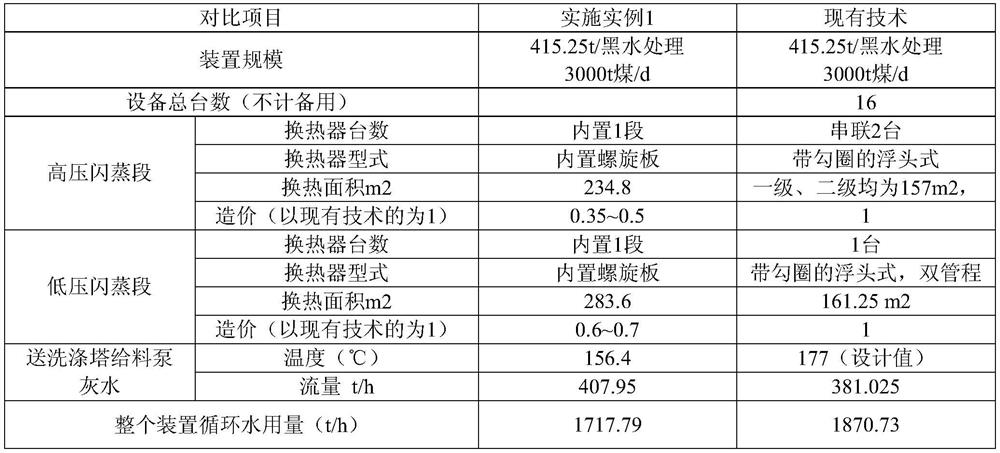

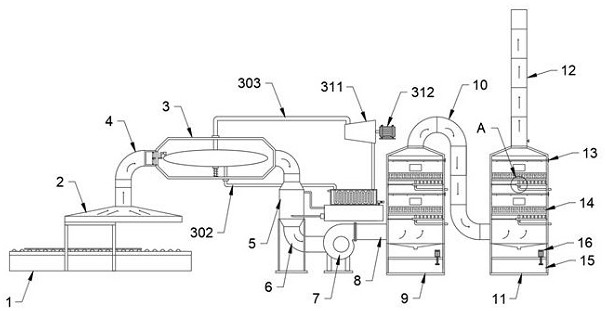

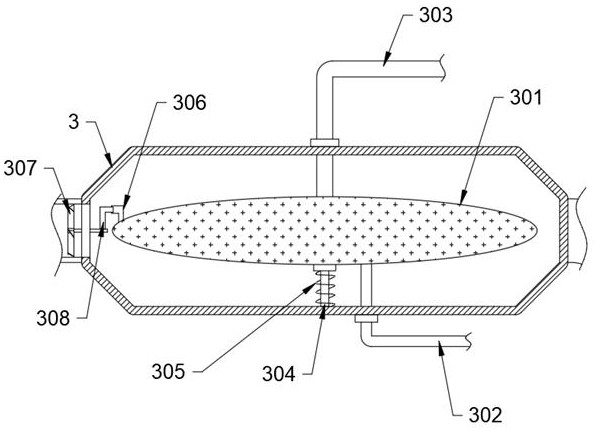

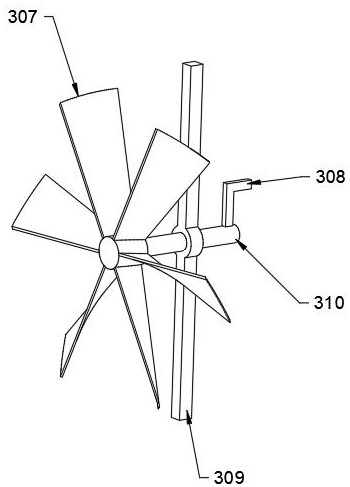

Flash evaporation stripping cooling system and black water treatment process thereof

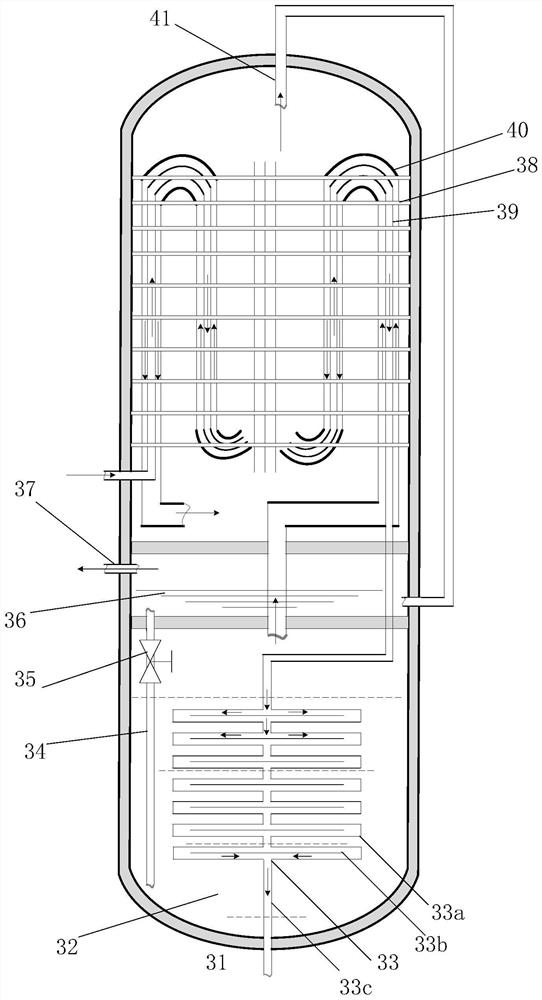

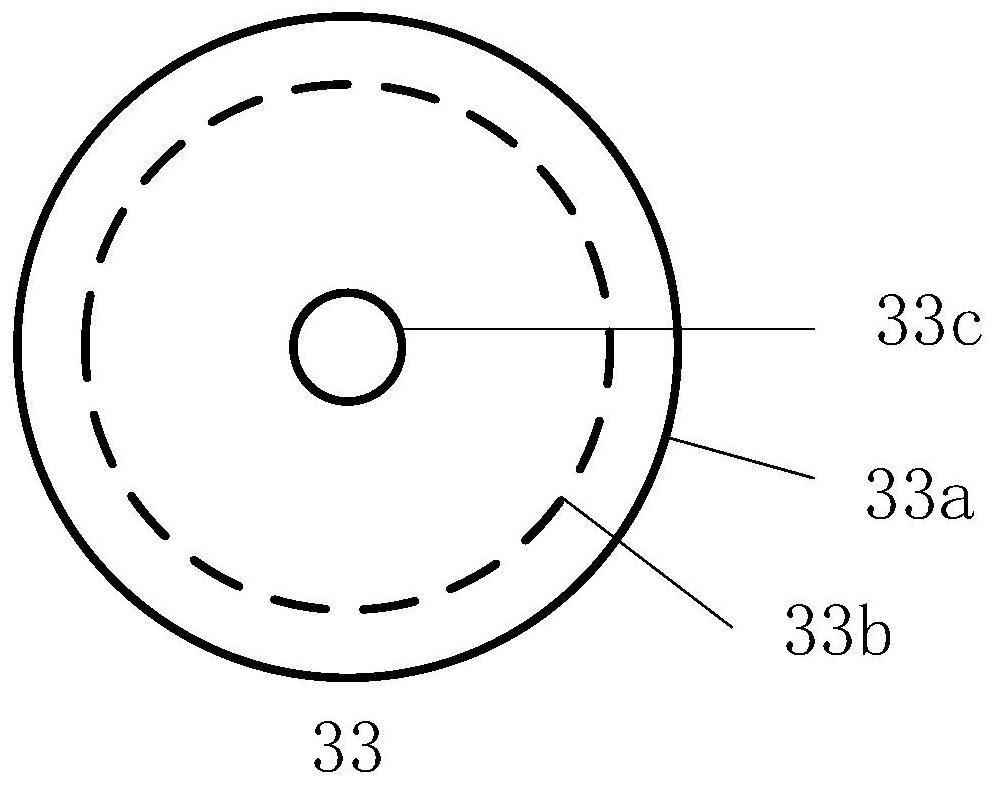

ActiveCN112107875AEasy to handleSmall footprintWater treatment parameter controlDistillation regulation/controlBlackwaterCooling tower

The invention provides a flash evaporation stripping cooling tower. The flash evaporation stripping cooling tower is sequentially provided with a flash evaporation chamber, a liquid phase staying chamber, a stripping chamber, a heat exchange chamber and a separation chamber from bottom to top, wherein the stripping chamber is sequentially provided with a tray section, a liquid phase distributor and a gas phase distributor in the steam flowing direction, a plurality of trays are arranged in the tray section, a heat exchanger section is arranged in the heat exchange chamber, and a plurality of heat exchangers are arranged in the heat exchanger section. The invention further provides a flash evaporation stripping cooling system. The invention also provides a black water treatment process. According to the flash evaporation stripping cooling system and the black water treatment process thereof, equipment integration is achieved, the process is simplified, energy consumption is reduced, theheat transfer effect is improved, low-temperature grey water is used for cooling, graded utilization of the low-temperature grey water is achieved, a large amount of circulating water is saved, and complete recycling of slag water is achieved.

Owner:上海华谊工程有限公司

Environment-friendly oil smoke treatment device capable of realizing heat energy recovery

ActiveCN113758293ATo achieve hierarchical utilizationAchieve high temperature utilizationFeed water supplyIncreasing energy efficiencyHeat energyElectric generator

The invention discloses an environment-friendly oil smoke treatment device capable of realizing heat energy recovery, and relates to the technical field of annealing furnace smoke treatment. The environment-friendly oil smoke treatment device comprises an annealing furnace, a heat exchange pipe, a cooler, a fan, a first spray tower and a second spray tower, a suction hood is arranged above the annealing furnace, a steam generation mechanism is arranged on the inner wall of the heat exchange pipe, multiple flow dividing pipes are sleeved with the inner wall of a flow dividing opening, a heat dissipation accelerating assembly is installed on the outer wall of a flow dividing sleeve, and the outer wall of the cooler is sleeved with a water cooling mechanism. Water is added into the inner wall of an ellipsoidal water tank in advance through a water return pipe, smoke can heat the water on the inner wall of the ellipsoidal water tank until the water is boiled, high-pressure steam generated during boiling is supplied into a steam turbine through a steam pipe to drive blades to rotate to drive a generator to generate electricity, the high-heat part of the smoke is recovered in advance, then the smoke enters a subsequent heat exchange device, graded utilization of heat in the smoke is achieved, high-temperature utilization of the smoke is achieved, the environmental protection property is good, and the heat collection efficiency is improved.

Owner:温州宪江防腐设备有限公司

Chemical-looping-based carbon-based fuel graded combustion and dry distillation device and method

PendingCN108488786AAvoid influenceReduce lossFluidized bed combustionApparatus for fluidised bed combustionTarContact time

The invention provides a chemical-looping-based carbon-based fuel graded combustion and dry distillation device. The device comprises a fuel reactor, a fast bed air reactor, a bubbling bed air reactorand a tar combustor. The other end of a dry distillation segment I is provided with a delivery pipe. The delivery pipe passes through a fluidized bed fuel reaction segment II and is arranged in a moving bed fuel reaction segment III. The fluidized bed fuel reaction segment II is separated from the moving bed fuel reaction segment III through an air distribution plate. The moving bed fuel reactionsegment III is sequentially connected with the fast bed air reactor, a first cyclone separator and a first return feeder through a pipe, so that a closed loop is formed. The fluidized bed fuel reaction segment II is sequentially connected with a second cyclone separator, the bubbling bed air reactor and a second return feeder through a pipe, so that a closed loop is formed. By means of the chemical-looping-based carbon-based fuel graded combustion and dry distillation device, impurities in coal can be prevented from contaminating a second oxygen carrier; the contact time of gas-solid and solid-solid in the reactors is prolonged; and the conversion rate of carbon-based fuel is increased.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com