Process for producing fuel ethanol by utilizing bamboo biomass waste

A technology of biomass waste and fuel ethanol, which is applied in the direction of biofuels, microorganism-based methods, microorganisms, etc., can solve the problems of high planting costs, large power consumption, and high processing costs, and achieve reduced production costs, reduced production costs, The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A process for producing fuel ethanol from bamboo biomass waste comprises the following steps: after pretreatment of bamboo biomass waste, fuel ethanol is obtained by hydrolysis and fermentation.

[0038] The pretreatment includes: a. Put the bamboo biomass waste at 50 ℃ H 3 PO 4 In the solution, a conventional constant temperature shaking culture shaker was used for 0.5 hours at a speed of 90 rpm, and the bamboo biomass waste was mixed with H. 3 PO 4 The solid-liquid volume ratio of the solution is 1:8; b. Add 2.5 times H 3 PO 4Pre-cooled acetone of the solution volume, stir and mix evenly, and then solid-liquid separation; c. Use 5 times H 3 PO 4 The solution volume of acetone is washed, and then solid-liquid separation is performed, and the precipitate is collected; d, the precipitate is washed with water to obtain a cellulose component.

[0039] In steps b and c, the supernatant is collected after solid-liquid separation to obtain lignin, acetic acid, acetone a...

Embodiment 2

[0048] A process for producing fuel ethanol from bamboo biomass waste comprises the following steps: after pretreatment of bamboo biomass waste, fuel ethanol is obtained by hydrolysis and fermentation.

[0049] The pretreatment includes: a. Put the bamboo biomass waste at 50 ℃ H 3 PO 4 In the solution, the conventional constant temperature shaking culture shaker was used for 1 hour at 90 rpm, and the bamboo biomass waste was mixed with H. 3 PO 4 The solid-liquid volume ratio of the solution is 1:8; b. Add 2.5 times H 3 PO 4 Pre-cooled acetone of the solution volume, stir and mix evenly, and then solid-liquid separation; c. Use 5 times H 3 PO 4 The solution volume of acetone is washed, and then solid-liquid separation is performed, and the precipitate is collected; d, the precipitate is washed with water to obtain a cellulose component.

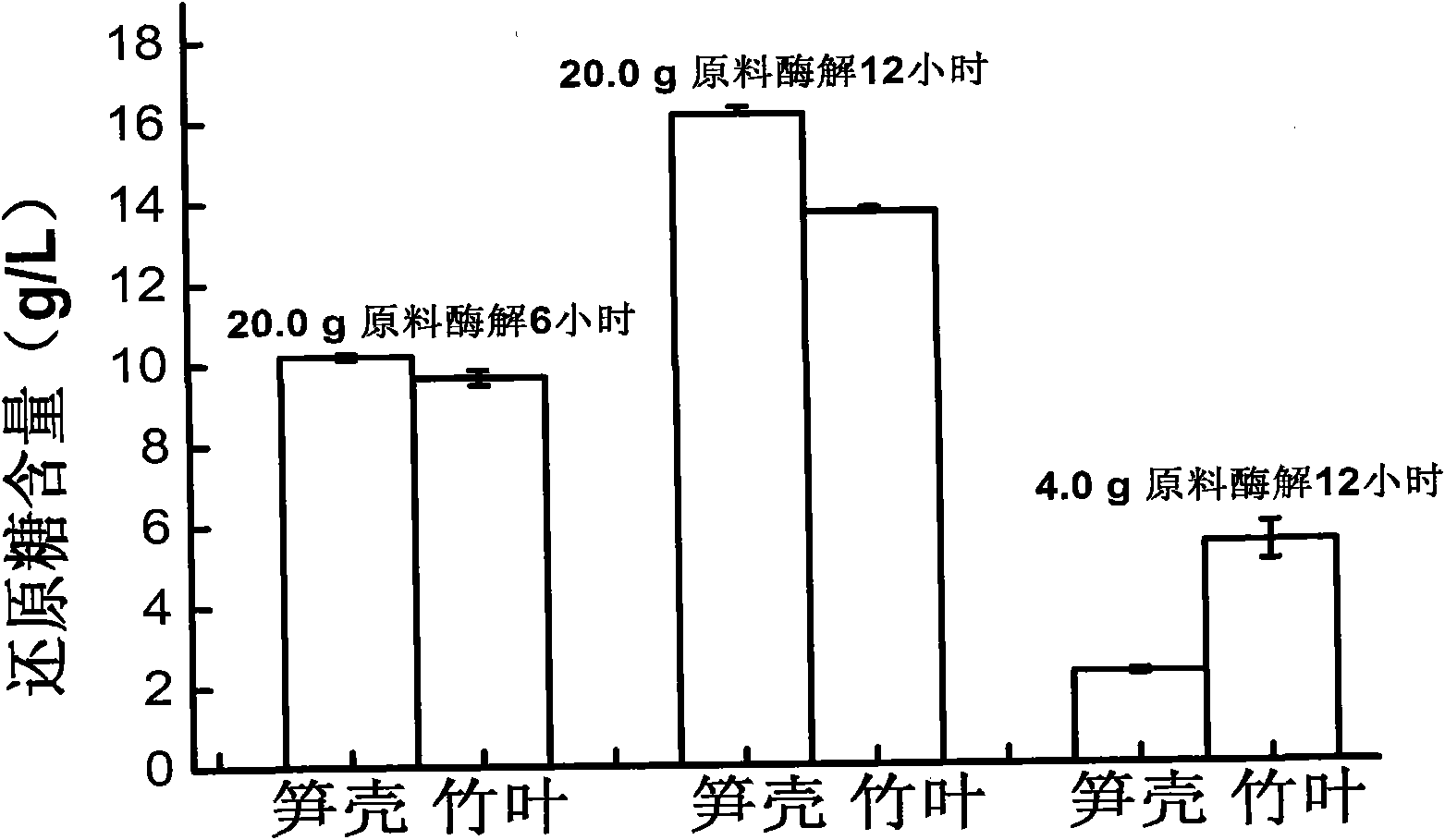

[0050] The hydrolysis is as follows: adding the pretreated cellulose component to pH 4.8, 0.1M sodium citrate buffer, then adding 2.0-4...

Embodiment 3

[0056] A process for producing fuel ethanol from bamboo biomass waste comprises the following steps: after pretreatment of bamboo biomass waste, fuel ethanol is obtained by hydrolysis and fermentation.

[0057] The pretreatment includes: a. Put the bamboo biomass waste at 50 ℃ H 3 PO 4 solution, treated at 90 rpm for 0.8 h, bamboo biomass waste was mixed with H 3 PO 4 The solid-liquid volume ratio of the solution is 1:8; b. Add 2.5 times H 3 PO 4 Pre-cooled acetone of the solution volume, stir and mix evenly, and then solid-liquid separation; c. Use 5 times H 3 PO 4 The solution volume of acetone is washed, and then solid-liquid separation is performed, and the precipitate is collected; d, the precipitate is washed with water to obtain a cellulose component.

[0058] In steps b and c, the supernatant is collected after solid-liquid separation to obtain lignin, acetic acid, acetone and H 3 PO 4 of the mixture.

[0059] In step d, the precipitate is washed with water, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com