Feed coal pre-pyrolysis device for large-sized pulverized coal furnace

A pulverized coal furnace and raw material technology, which is used in coke ovens, direct heating dry distillation, special forms of dry distillation, etc., can solve the problem of high equipment cost, complex equipment structure, and the inability of gas generators to adapt to large and medium-sized, high-parameter pulverized coal furnaces. production application and other issues to achieve the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

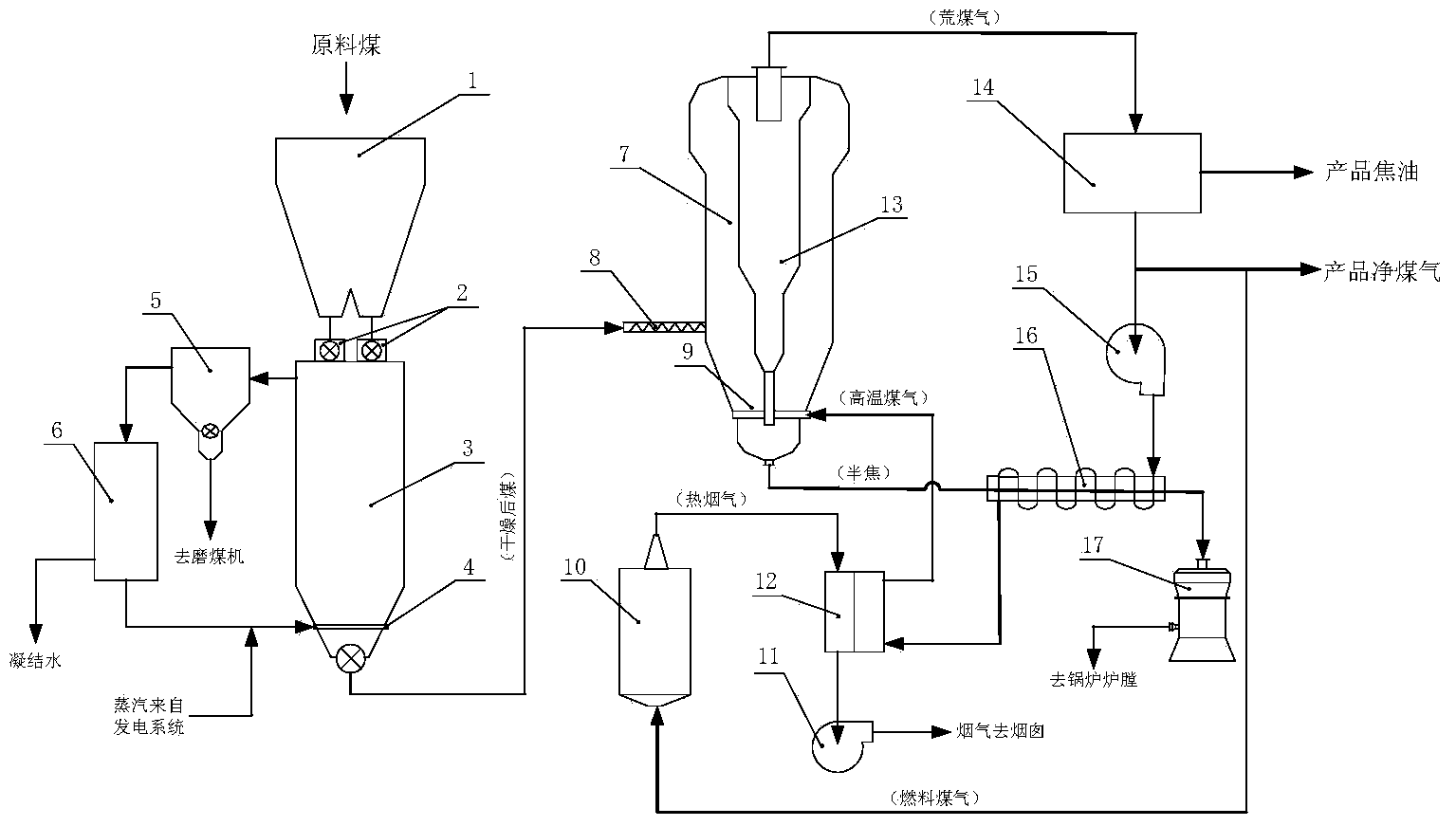

[0017] The preferred embodiment of the raw coal pre-pyrolysis device for large pulverized coal furnaces of the present invention is:

[0018] Comprising a raw coal scuttle, the feed opening at the bottom of the raw coal scuttle is connected to the feed inlet at the top of the steam fluidized bed dryer through a rectangular star unloader, and the discharge port at the bottom of the steam fluidized bed dryer The spiral coal feeder is connected to the feed port in the middle of the combined briquette pyrolysis device, and the discharge port at the bottom of the combined briquette pyrolysis device is connected to the coal mill through a semi-coke conveying heat exchanger;

[0019] The lower part of the steam fluidized bed dryer is provided with a fluidized steam air distribution plate, the fluidized steam air distribution plate is connected to the steam pipeline, and the upper part of the steam fluidized bed dryer is provided with a secondary steam outlet, The secondary steam outl...

specific Embodiment

[0032] Such as figure 1 As shown, including the raw coal hopper 1, the raw coal enters the steam fluidized bed dryer 3 through the raw material coal hopper 1 through the rectangular star unloader 2, and the steam fluidized bed dryer 3 is equipped with a fluidized steam air distribution plate 4. The fluidized steam used in the steam fluidized bed dryer 3 comes from the low-grade steam discharged from the steam turbine of the power generation system; The secondary steam from the dedusting of the device 5 enters the secondary steam recovery system 6 for recovery and reuse.

[0033] The raw coal dried by the steam fluidized bed dryer 3 is sent to the combined briquette pyrolysis device 7 through the unloading device at the bottom of the steam fluidized bed dryer 8; the dried raw coal is in the combined briquette pyrolysis device 7 The high-temperature gas sent by the fluidized gas distribution plate 9 is fluidized, heated and pyrolyzed; the raw coal gas produced by coal pyrolysis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com