Saponin separation and stabilization method

A technology for stabilizing saponin, which is applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc., can solve the problems of short shelf life of saponin-related products, difficult production quality control, and high content of saponin impurities. Achieve the effects of improving the quality of saponin products, low energy consumption for solvent recovery, and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

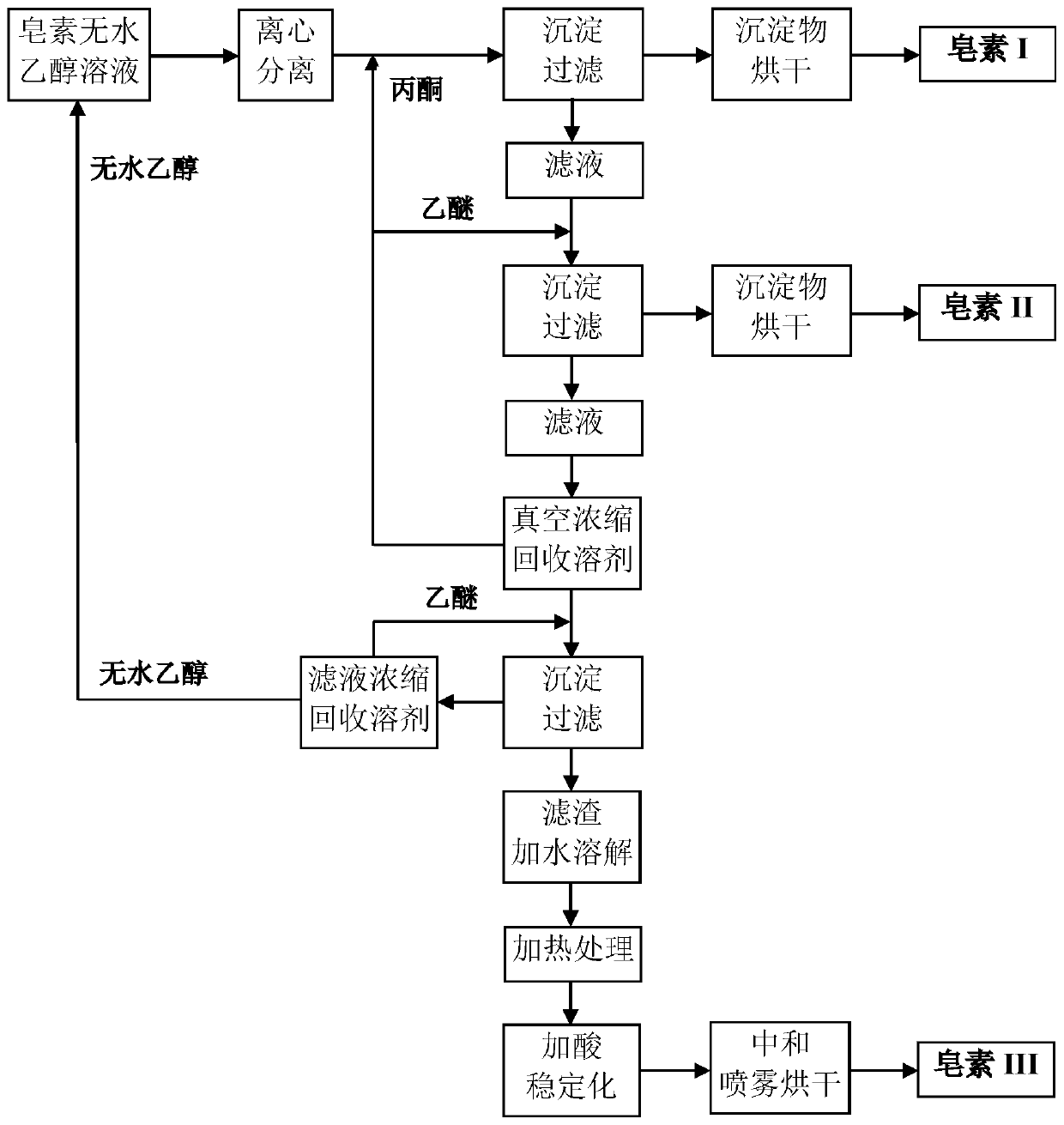

[0040] This embodiment provides a kind of saponin separation and stabilization method, such as figure 1 shown, including:

[0041] (1) Take 300g of Sapindus Sapindin crude extract, add 900g of absolute ethanol=1:3, heat to 60°C, centrifuge at 4000r / min, filter, and remove solid residue;

[0042] (2) Add 2200mL acetone to the ethanol filtrate containing saponin, let it stand for 30min, centrifuge and filter at 4000r / min for 15min, wash the precipitate with acetone, and dry to obtain saponin I;

[0043] After testing, the yield of saponin I was 9.8%, the purity was 76.5%, the surface tension was 44.3mN / m, and the critical micelle concentration was 0.3g / L;

[0044] (3) Add 2200mL ether to the filtrate obtained in step (2), let stand for 60min, centrifuge and separate at 4000r / min for 15min, wash the precipitate with acetone and ether successively, and dry to obtain saponin II;

[0045] After testing, the yield of saponin II was 17.6%, the purity was 75.8%, the surface tension w...

Embodiment 2

[0049] The present embodiment provides a saponin separation and stabilization method, comprising:

[0050] (1) Take 300g of Sapindus Sapindin crude extract, add 900g of absolute ethanol=1:3, heat to 60°C, and centrifuge at 4000r / min to remove solid residue;

[0051] (2) Add 2200mL acetone to the saponin ethanol solution, let it stand for 30min, centrifuge and filter at 4000r / min for 15min, wash the precipitate with acetone, and dry to obtain saponin I;

[0052] After testing, the yield of saponin I was 9.8%, the purity was 76.5%, the surface tension was 44.3mN / m, and the critical micelle concentration was 0.3g / L;

[0053] (3) Add 2200 mL of absolute ethanol solution to the above-mentioned filtrate, let it stand for 60 minutes, centrifuge at 4000 r / min and separate for 15 minutes, wash the precipitate with acetone and ether in sequence, and dry to obtain saponin II;

[0054] After testing, the yield of saponin II was 17.6%, the purity was 75.8%, the surface tension was 49.2mN / ...

Embodiment 3

[0058] The present embodiment provides a saponin separation and stabilization method, comprising:

[0059] (1) Take 300g of Sapindus Sapindin crude extract, add 900g of absolute ethanol=1:3, heat to 60°C, and centrifuge at 4000r / min to remove solid residue;

[0060] (2) Add 2200mL acetone to the saponin ethanol solution, let it stand for 30min, centrifuge and filter at 4000r / min for 15min, wash the precipitate with acetone, and dry to obtain saponin I;

[0061] After testing, the yield of saponin I was 9.8%, the purity was 76.5%, the surface tension was 44.3mN / m, and the critical micelle concentration was 0.3g / L;

[0062] (3) Add 2200 mL of absolute ethanol solution to the above-mentioned filtrate, let it stand for 60 minutes, centrifuge at 4000 r / min and separate for 15 minutes, wash the precipitate with acetone and ether in sequence, and dry to obtain saponin II;

[0063] After testing, the yield of saponin II was 17.6%, the purity was 75.8%, the surface tension was 49.2mN / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| critical micelle concentration (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com