Heat energy utilization method and heat energy utilization system in polycrystalline silicon production

A polysilicon and thermal energy technology, applied in the direction of silicon, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of increasing the production cost of polysilicon, not fully utilizing the thermal energy of the reduction furnace, and wasting thermal energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] This embodiment provides a method for utilizing heat energy in polysilicon production. This method is to send high-temperature return water from the reduction furnace system in polysilicon production into the flash system, and perform flash evaporation in the flash system, and then enter the flash system The temperature of the high-temperature return water is 145°C-160°C, the pressure is 0.5MPa-0.6MPa, and the low-pressure steam with a pressure of 0.175MPa-0.25MPa is flashed in the flash evaporation system, and the remaining The high-temperature water with a temperature of 128°C to 133°C is pressurized and then sent to the reduction furnace system to form high-temperature water for the reduction furnace system; the low-pressure steam from flash evaporation is sent to other equipment that needs steam in polysilicon production. The condensate obtained after exchanging heat with the other equipment is returned to the flash system.

[0078]Preferably, the temperature of the...

Embodiment 2

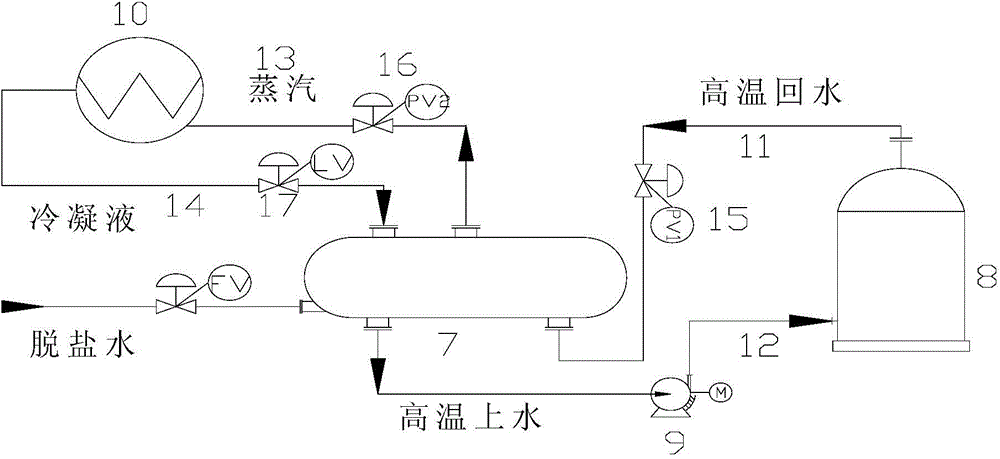

[0101] Please refer to figure 1 , figure 1 Specifically, it is a schematic diagram of a heat energy utilization method for polysilicon in this embodiment, which is mainly a comprehensive heat energy utilization method outside the reduction furnace system in the production process.

[0102] like figure 1 As shown, the thermal energy utilization method in the polysilicon production is to send the high-temperature return water from the reduction furnace system 8 in the polysilicon production to the flash system, and perform flash evaporation in the flash system, and enter the high-temperature return water in the flash system The temperature is 145℃~160℃, the pressure is 0.5MPa~0.6MPa, and the low-pressure steam with a pressure of 0.175MPa~0.25MPa is flashed out in the flash evaporation system, and the remaining temperature in the flash evaporation system is 128℃ The high-temperature water at ~133°C is pressurized and returned to the reduction furnace system 8 to form high-tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com