Method for preparing high-quality granulated carbon black from pyrolysis carbon residues

A technology of granulating carbon black and pyrolysis carbon, which is applied in the direction of fibrous fillers, etc., can solve the problems of secondary pollution, pyrolysis carbon powder is easy to fly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

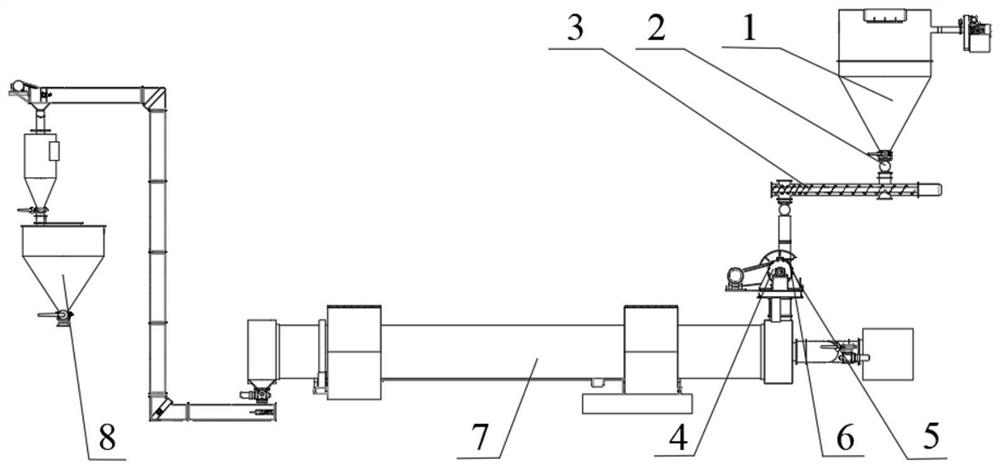

Method used

Image

Examples

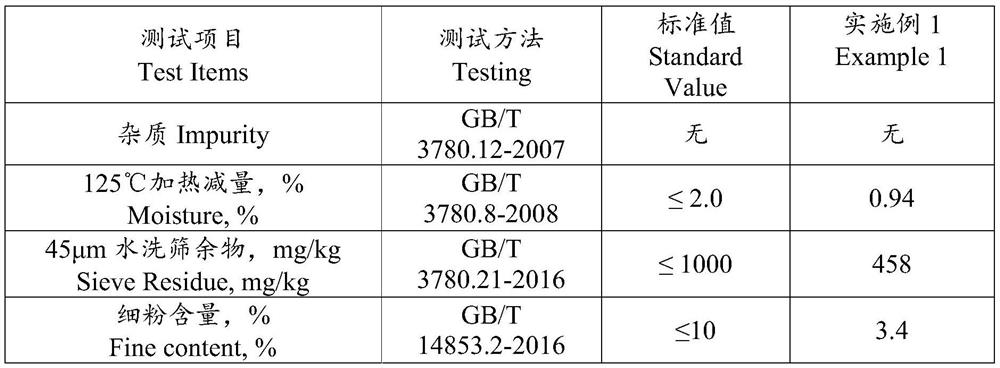

Embodiment 1

[0037] Grind the pyrolysis carbon slag, take 100g of the ground charcoal powder and test the toluene light transmittance and the 45 micron sieve residue. Grain requirements.

[0038] When the temperature of the 4th wall of the granulator rises to 120°C, start feeding. After the carbon powder is fed from the silo 1 through the star discharge valve 2, the opening of the control valve 2 is 4Hz, and enters the variable diameter feeding screw 3 (the diameter reduction ratio is 0.5), and the compacted carbon powder enters the granulation Machine 4. When there is powder carbon black in the sampling port 5, open the granulation water ball valve 6. By continuously observing the granulation of the carbon black at the sampling port 5, the opening of the granulation water ball valve 6 is reasonably adjusted. When the particle is stable at the size of small grains (about 0.5-2mm), fix the opening of the granulation water valve 6 at this moment.

[0039] The granulated carbon black ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com