Patents

Literature

62results about How to "Raise feed temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

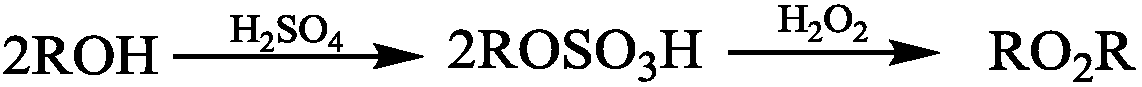

Preparation method of di-tert-butyl peroxide

ActiveCN107056670ARapid peroxidationWith operational continuityOrganic compound preparationPeroxy compound preparationDi-tert-butyl peroxideTert-butyl peroxide

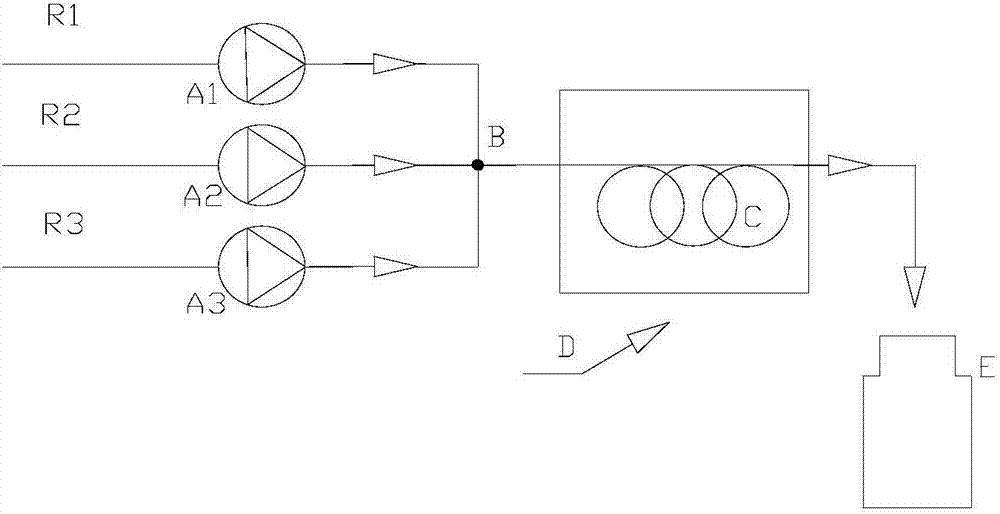

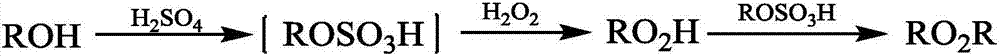

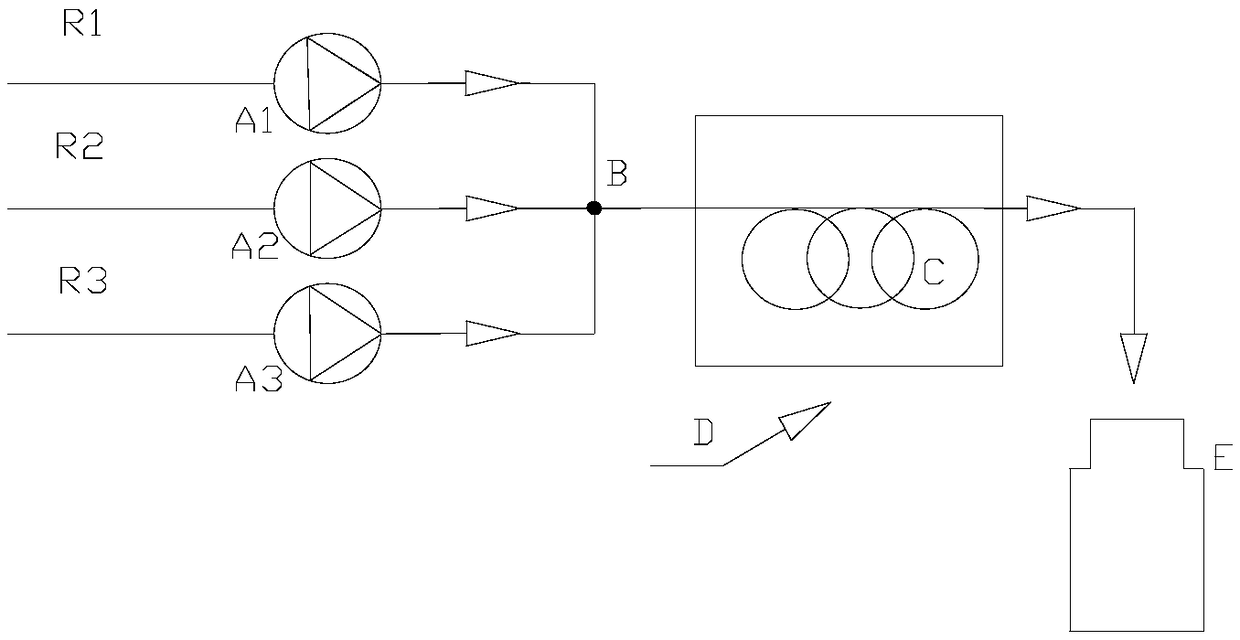

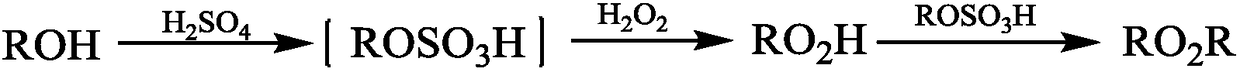

The invention discloses a preparation method of di-tert-butyl peroxide. Tert-butyl alcohol, hydrogen peroxide and a catalyst are continuously introduced into a micro-reactor, so that tert-butyl alcohol and hydrogen peroxide are subjected to a peroxidation reaction, and a material flow containing a di-tert-butyl peroxide is prepared; the material flow containing the di-tert-butyl peroxide is led out from the micro-reactor, and the di-tert-butyl peroxide is obtained through separation, washing and drying, wherein the molar ratio of tert-butyl alcohol to hydrogen peroxide is 1:2-1:2.2, and the catalyst accounts for 10-20% of the total mass of tert-butyl alcohol, hydrogen peroxide and the catalyst. The process is simple, the micro-reactor good in safety is used for continuous production, the prepared di-tert-butyl peroxide is high in reaction selectivity and good in yield, the production procedures are reduced, and the production cost is reduced.

Owner:西安万德能源化学股份有限公司

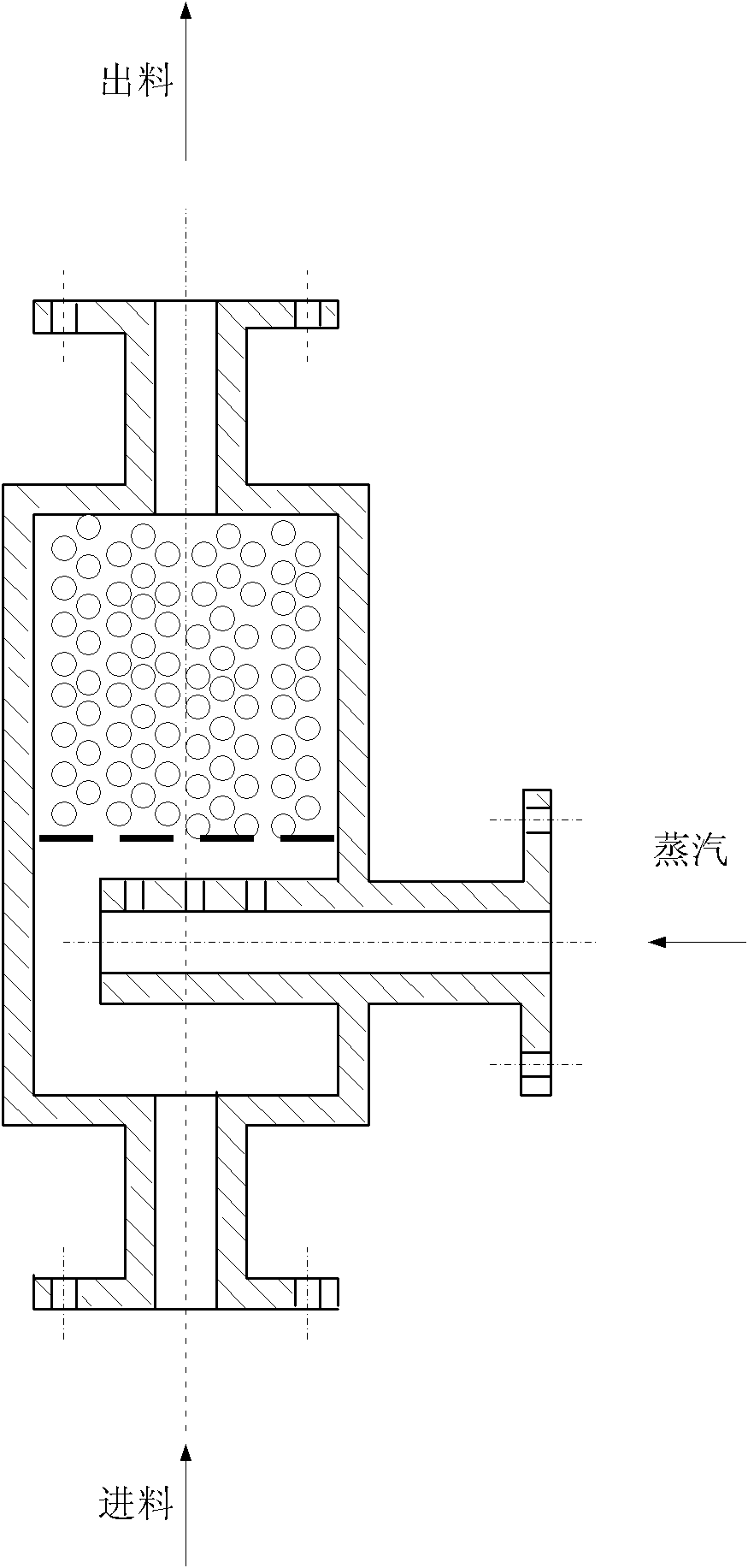

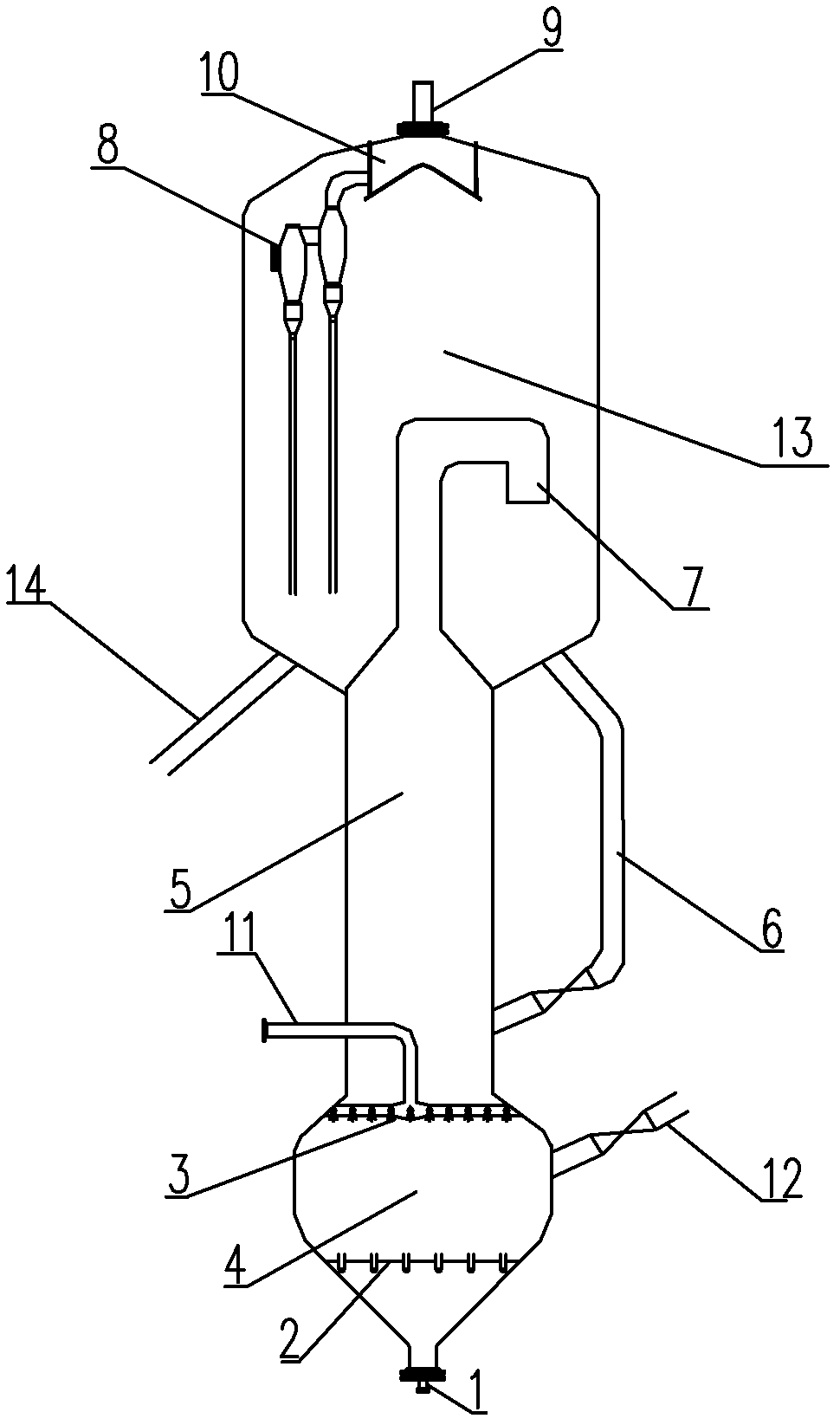

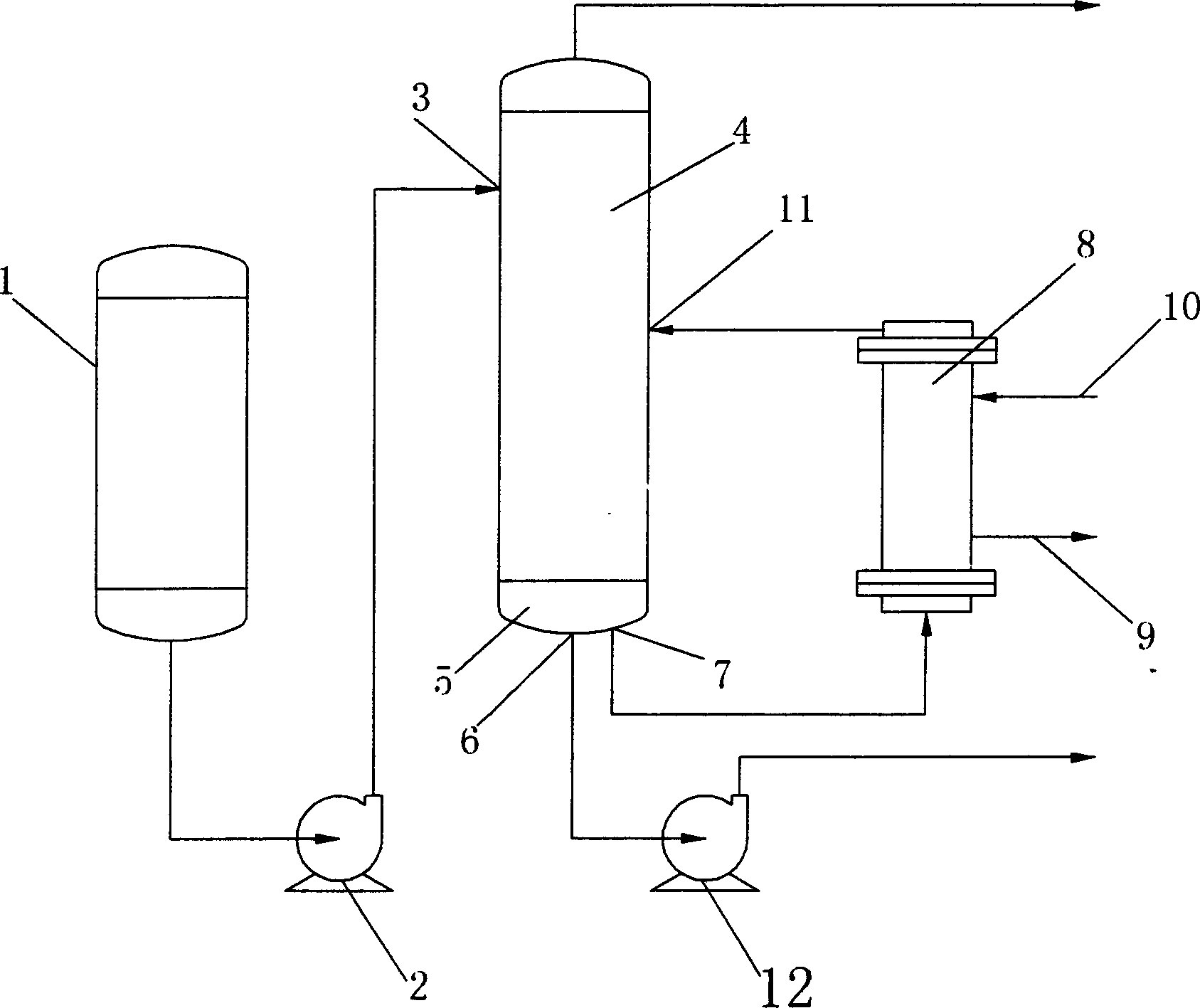

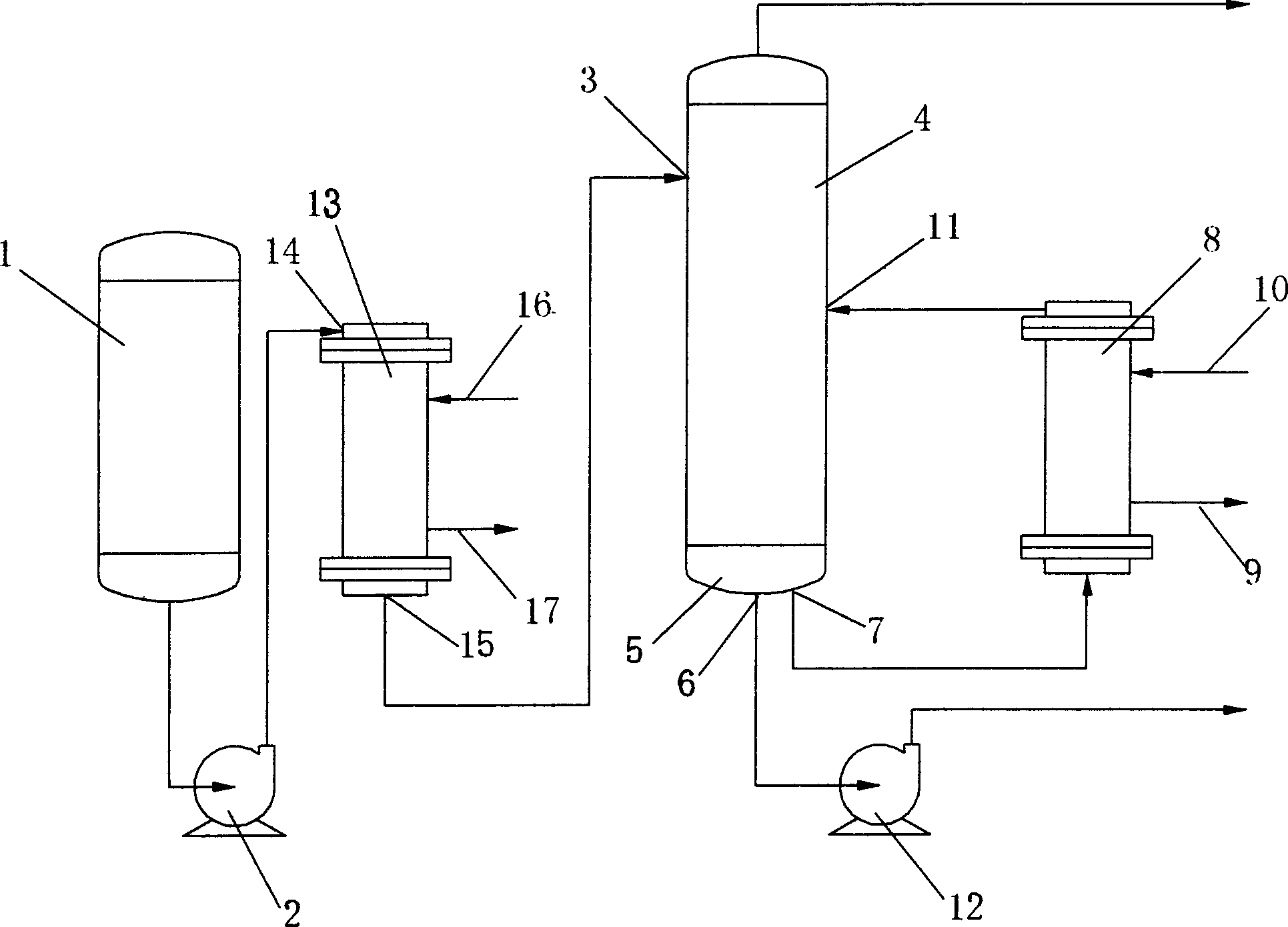

Method and device for reducing volatile matters of o-cresol-formaldehyde epoxy resin

ActiveCN102464792AUniform film formationGuaranteed removal rateMultiple-effect evaporationEpoxyVapor–liquid separator

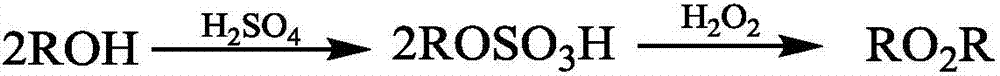

The invention discloses a method and device for reducing volatile matters of an o-cresol-formaldehyde epoxy resin. The method comprises the following step of: performing a two-stage desolventizing step, including a coarse desolventizing step and a fine desolventizing step to remove a solvent and a high-boiling residue component from an o-cresol-formaldehyde epoxy resin. The device comprises a feed pump, a first pipeline mixer, a falling film evaporator, a gas-liquid separator, a primary removal extraction pump, a second pipeline mixer, a thin-film evaporator, a packing tower and a secondary removal extraction pump which are connected in sequence, wherein a part of an o-cresol-formaldehyde epoxy resin solution output by the gas-liquid separator returns to the first pipeline mixer through areflux pump; a steam inlet / outlet is formed in the second pipeline mixer; and both the gas-liquid separator and a film evaporator are provided with a volatile matter gas-phase outlet. According to the method and the device for reducing the volatile matters of the o-cresol-formaldehyde epoxy resin, volatile matters of a product can be reduced to be below 0.05 percent, and the performance of the product applied to an electronic molding compound can be improved remarkably.

Owner:CHINA PETROCHEMICAL CORP

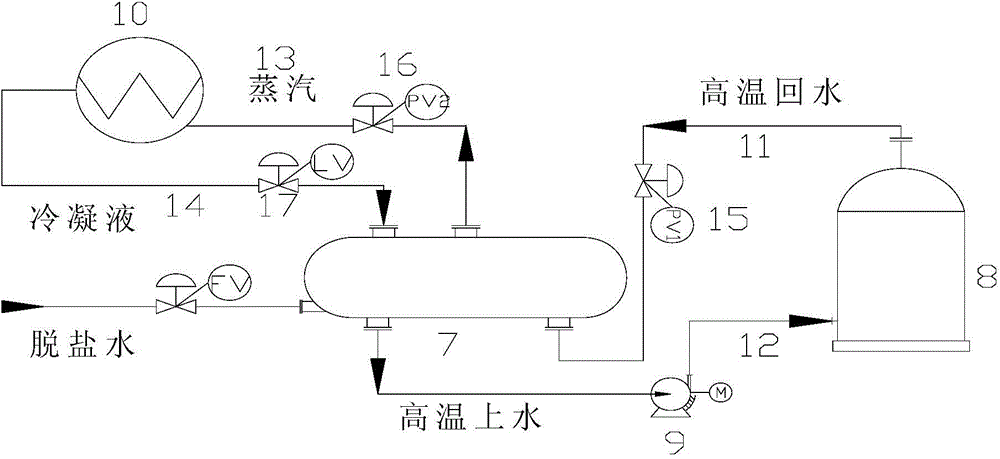

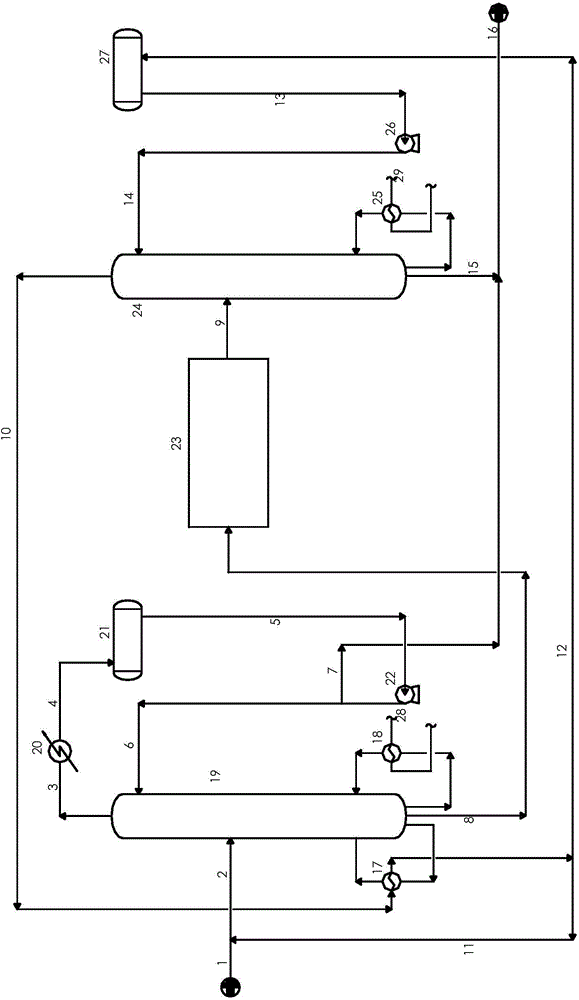

Heat energy utilization method and heat energy utilization system in polycrystalline silicon production

ActiveCN104787766AImprove feed processFeed process optimizationSiliconChemical industryMetallurgyHeat energy

The present invention discloses a heat energy utilization method and a heat energy utilization system during polycrystalline silicon production. According to the method, high temperature backwater from a reduction furnace system in polycrystalline silicon production is conveyed into a flash evaporation system and is subjected to flash evaporation in the flash evaporation system, wherein the temperature of the high temperature backwater entering the flash evaporation system is 145-160 DEG C, and the pressure is 0.5-0.6 MPa; the low pressure steam with the pressure of 0.175-0.25 MPa is flash-evaporated from the flash evaporation system, and the remaining high temperature water with the temperature of 128-133 DEG C after the flash evaporation is pressurized, then returns to the reduction furnace, and forms the high temperature feeding water of the reduction furnace system; and the flash-evaporated low pressure steam is conveyed to other equipment requiring the steam in the polycrystalline silicon production, and the condensate obtained through heat exchange with other equipment returns to the flash evaporation system. With the method of the present invention, a lot of the heat energy produced in the polycrystalline silicon production can be completely utilized so as to improve the heat energy recovery and utilization rate.

Owner:XINTE ENERGY

Oil atmospheric vacuum distillation technology

ActiveCN102746883AImprove heat transfer coefficientImprove securityTreatment with plural serial refining stagesMolten bathFractionating column

The invention relates to an oil atmospheric vacuum distillation technology. An raw material inlet of a vacuum distillation tower and / or an atmospheric tower is connected with a tube side of a dividing-wall heat exchanger, a shell side inlet of the dividing-wall heat exchanger is connected with a molten salt heating furnace, a shell side outlet of the dividing-wall heat exchanger is connected with a molten bath, and the molten salt heating furnace is connected with the molten bath. Mixed inorganic salt powder-shaped particles are added in the molten bath, high-pressure steam or electricity is let in the molten bath, the mixed inorganic salt powder-shaped particles are molten to liquid, a molten salt circulating pump is started to carry out forced liquid phase cycles on molten salt when the melting temperature reaches 180 DEG C, the molten salt is transmitted to the molten salt heating furnace for heating, the temperature of the molten salt in the outlet of the molten salt furnace and the temperature of molten salt flow at the inlet of the dividing-wall heat exchanger are controlled between 350 DEG C to 530 DEG C, the molten salt is transmitted to the dividing-wall heat exchanger to heat oil flow to 360 DEG C to 440 DEG C and returns to the melting bath, and the oil flows from the dividing-wall heat exchanger and enters the atmospheric tower or the vacuum tower. According to the technology, the probability of green coke is low, the heating temperature can be improved, and the pull-out rate of the distillation towers can be increased.

Owner:PETROCHINA CO LTD

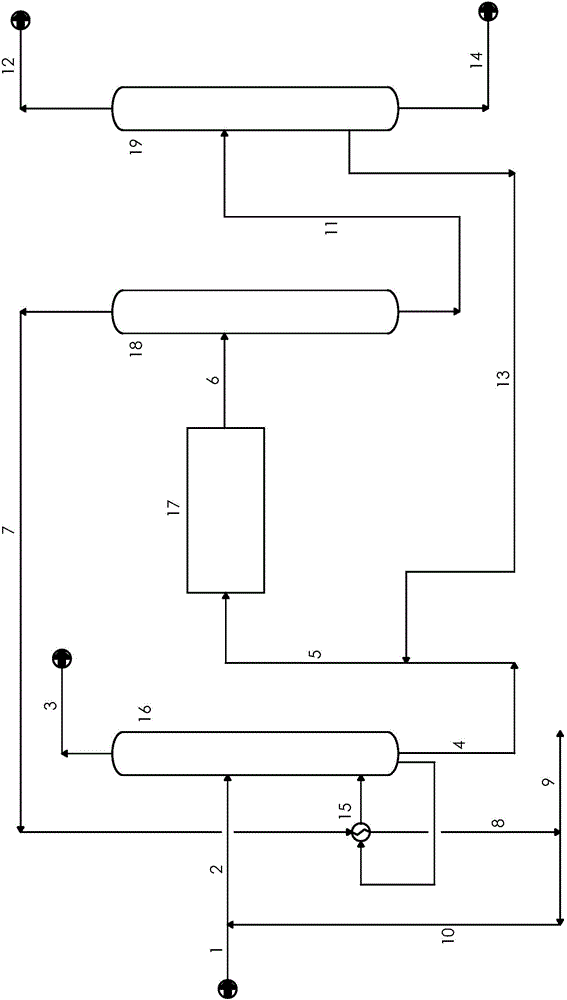

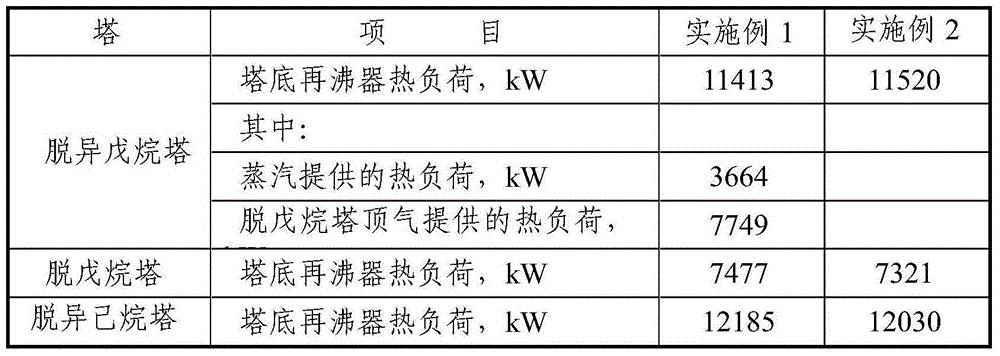

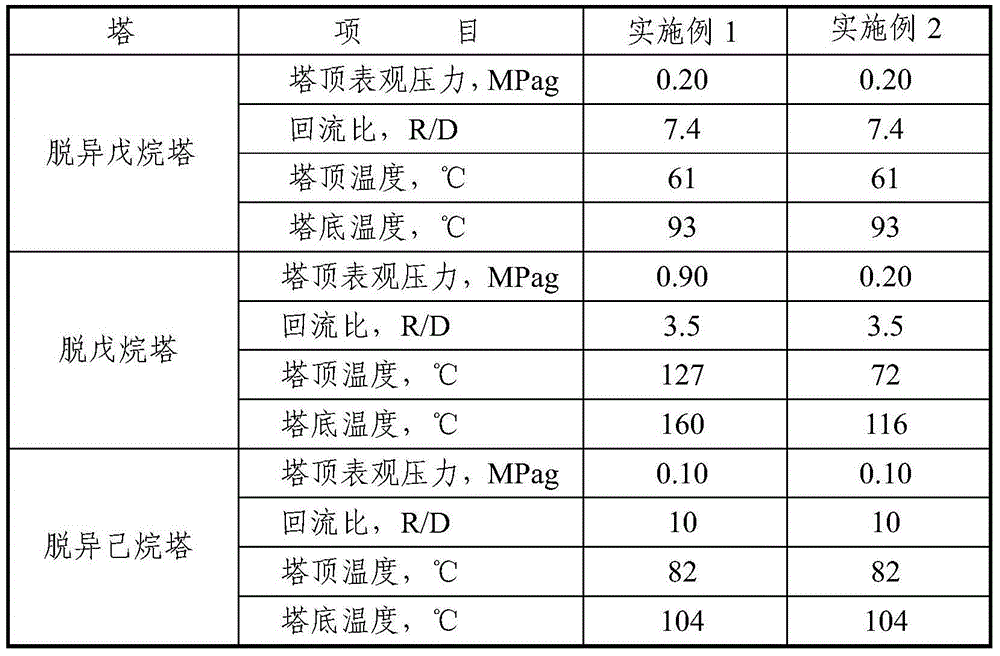

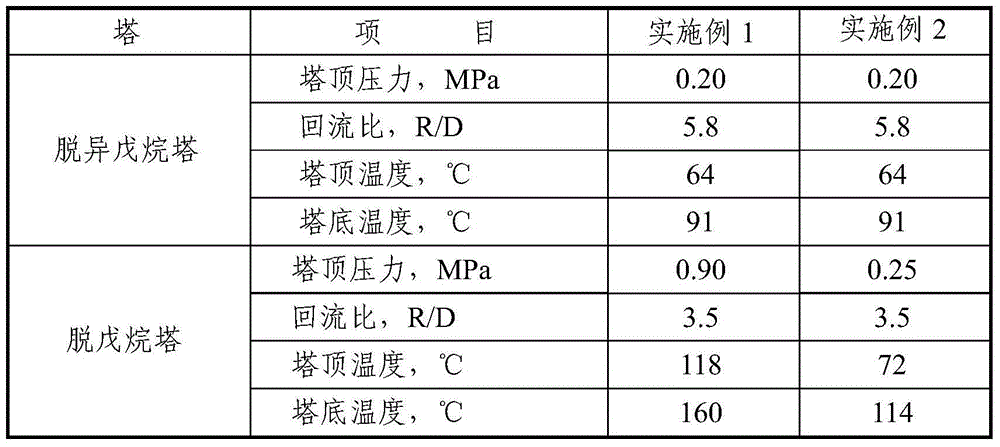

Method for isomerization of light hydrocarbon

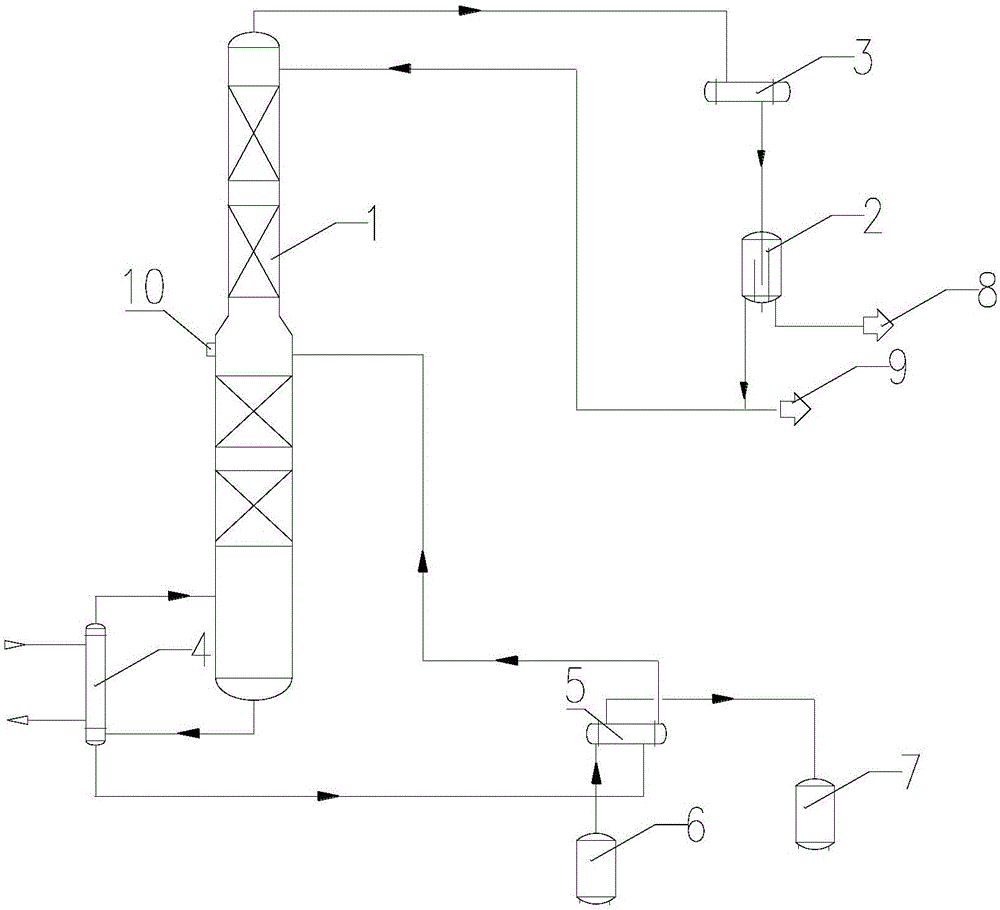

ActiveCN105820838AIncrease conversion rate per passImprove utilization efficiencyTreatment with hydrotreatment processesAlkaneIsomerization

The invention relates to a method for isomerization of light hydrocarbon. According to the method, a light hydrocarbon raw material is introduced into an isopentane removal tower, a material flow at the top of the tower is taken as an isomerization product for eduction, the reaction products are introduced into a pentane removal tower for being separated, a material flow at the top of the pentane removal tower and the light hydrocarbon raw material are mixed and introduced into the isopentane removal tower, a material flow at the bottom of the isopentane removal tower is introduced into an isohexane removal tower, the material flow at the top of the isohexane removal tower is taken as the isomerization product for eduction, methylpentane and hexane extracted from side line of the isohexane removal tower are returned to an isomerization reactor for further conversion; the pentane removal tower is operated under pressurization, and the material flow at the top of the pentane removal tower is taken as a heat source of a reboiler of the isopentane removal tower. The method can fully use heat of condensation of the material flow at the top of the pentane removal tower during a separating process of n-alkanes and iso-paraffin, and the energy consumption of an light hydrocarbon isomerization apparatus is effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

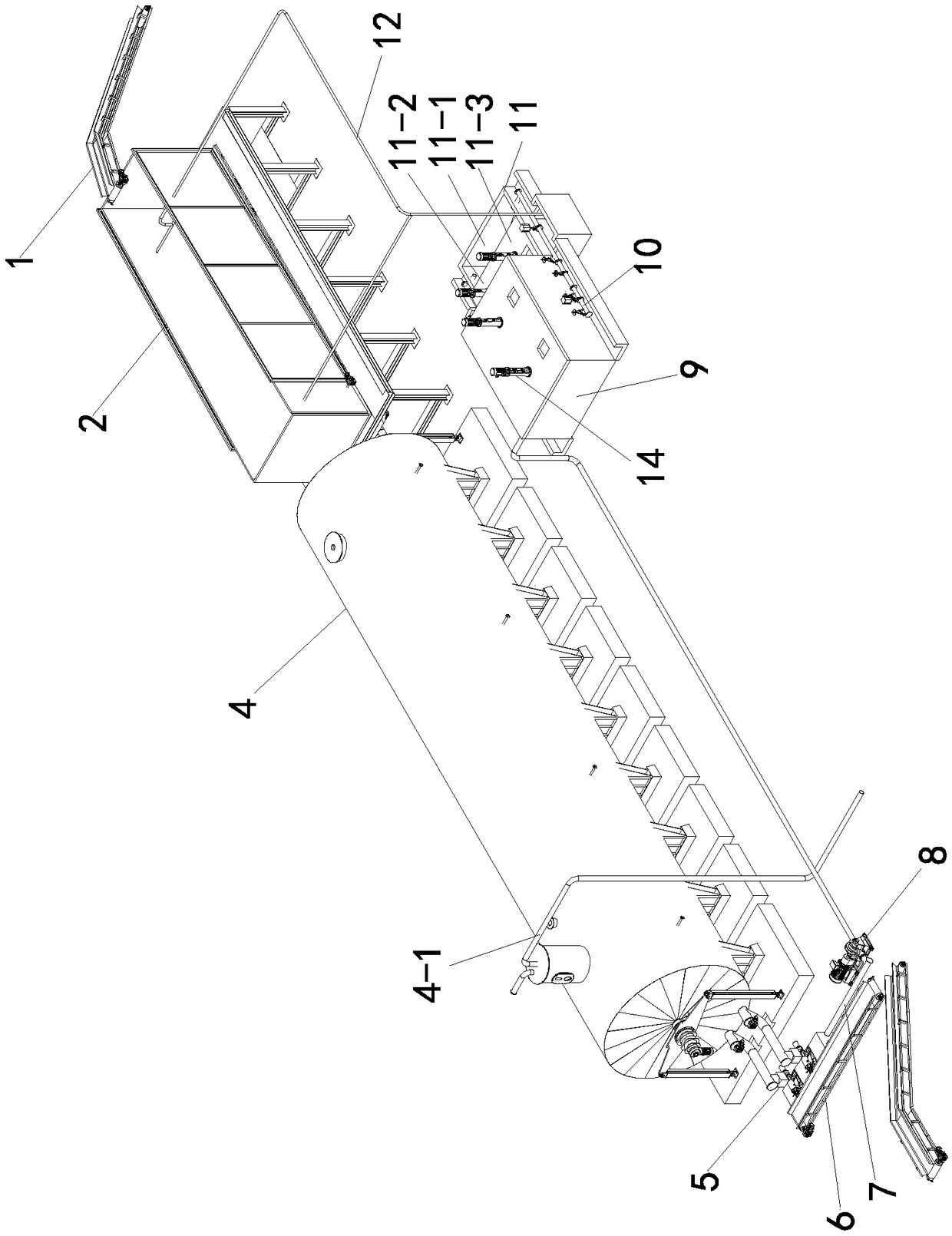

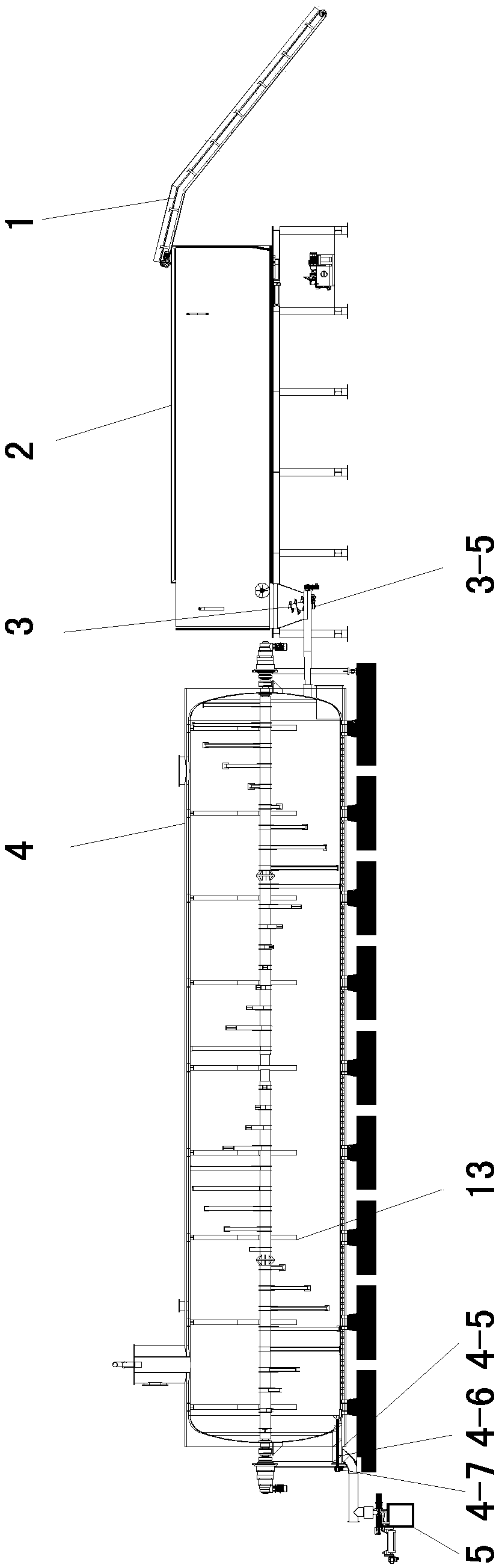

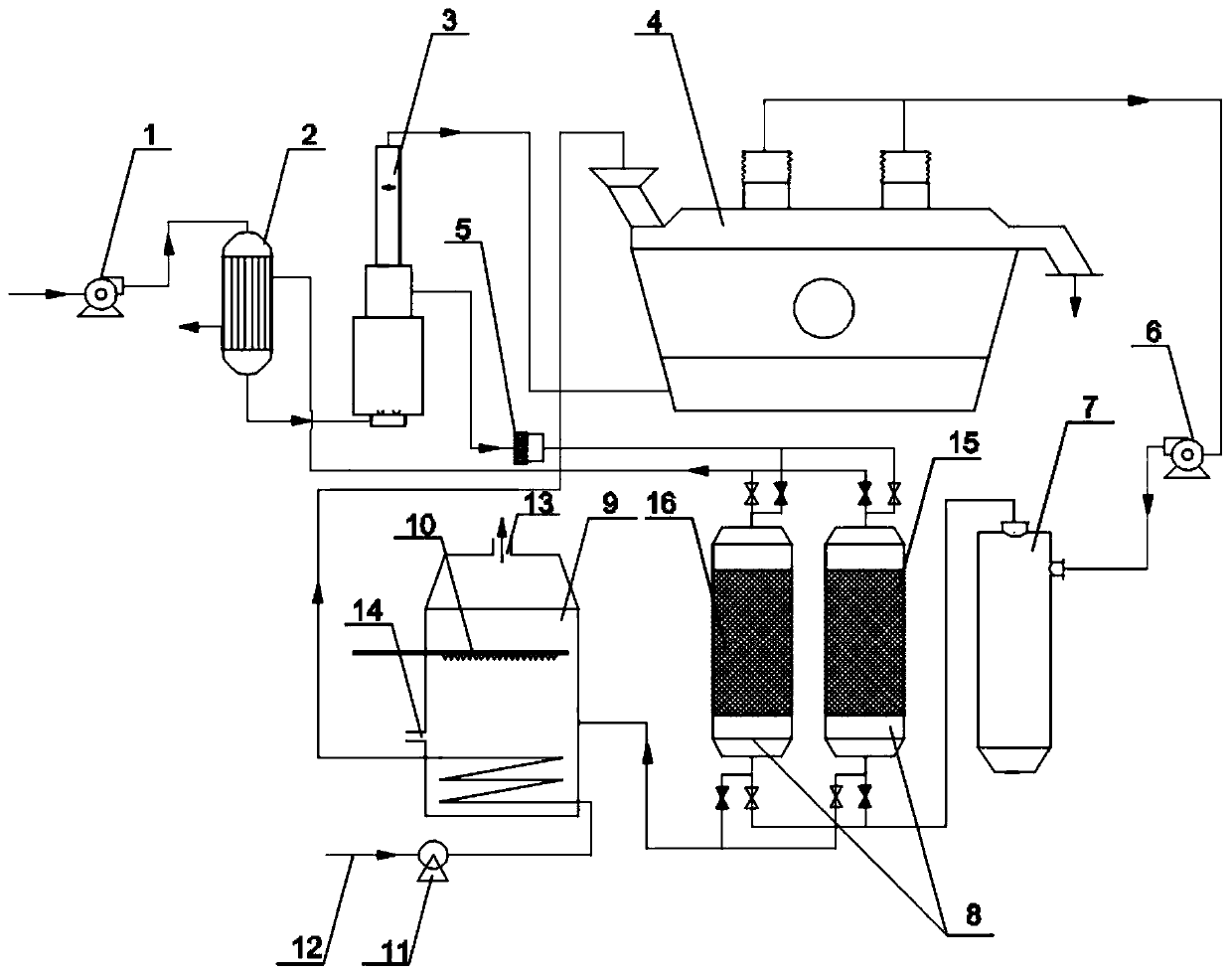

Horizontal push-flow anaerobic dry fermentation device and process for organic waste

PendingCN108660075AReduce heat consumptionIncrease gas production rateBioreactor/fermenter combinationsBiological substance pretreatmentsDry matterBiogas

The invention relates to a horizontal push-flow anaerobic dry fermentation device and process for organic waste, and belongs to the technical field of anaerobic fermentation. The concentration of drymatter in a tank can be increased to 30%-60%, heat consumption is effectively reduced, and gas production rate is increased. Water spraying pipes are arranged at a feed end and a discharge end of a pretreatment pool, a feeder is arranged at the discharge end of the pretreatment pool and communicated with feed ports of an anaerobic fermentation tank, discharge ports of the anaerobic fermentation tank are communicated with inlets of pressers, a conveyor belt II is arranged in the position of the pressers and conveys biogas residues discharged from solid outlets of the pressers outwards, a biogasslurry tank conveys biogas slurry into a cow dung tank through a conveying pipe, the cow dung tank is communicated with inlets of the water spraying pipes, and a push-flow stirring shaft is arrangedin the anaerobic fermentation tank. The concentration of the dry matter inside can be increased to 30%-60% by the anaerobic fermentation tank, heat consumption is effectively reduced, the gas production rate is increased and the yield is increased.

Owner:黑龙江乾进能源科技有限公司

Method for improving production efficiency of vacuum crystallization for titaniferous solution

ActiveCN102757100ARaise feed temperatureShorten the boil timeSolution crystallizationIron sulfatesPhysical chemistryCrystallization

The invention discloses a method for improving the production efficiency of vacuum crystallization for titaniferous solution, wherein the method comprises a titaniferous solution vacuum crystallization process and a titaniferous solution hot concentration process; the hot concentration discharging temperature is higher than the feeding titaniferous solution temperature for the titaniferous solution vacuum crystallization; heat exchange is carried out between feeding titaniferous solution for the titaniferous solution vacuum crystallization and discharging material for the titaniferous solution hot concentration; and then the feeding titaniferous solution that is processed through heat exchange is conveyed to a titaniferous solution vacuum crystallization container for crystallization. The method adopts the technical scheme that the conventional production temperatures and negative pressure conditions are utilized to perform the heat exchange between the feeding material for the titaniferous solution vacuum crystallization and the discharging material for the hot concentration, and the feeding temperature for the titaniferous solution vacuum crystallization is raised, so that the time for titaniferous solution boiling is shortened without changing the negative pressure conditions, the crystallization time of titaniferous solution in the vacuum crystallization container is shortened, and the production efficiency of vacuum crystallization for titaniferous solution can be improved further.

Owner:LOMON BILLIONS GRP CO LTD

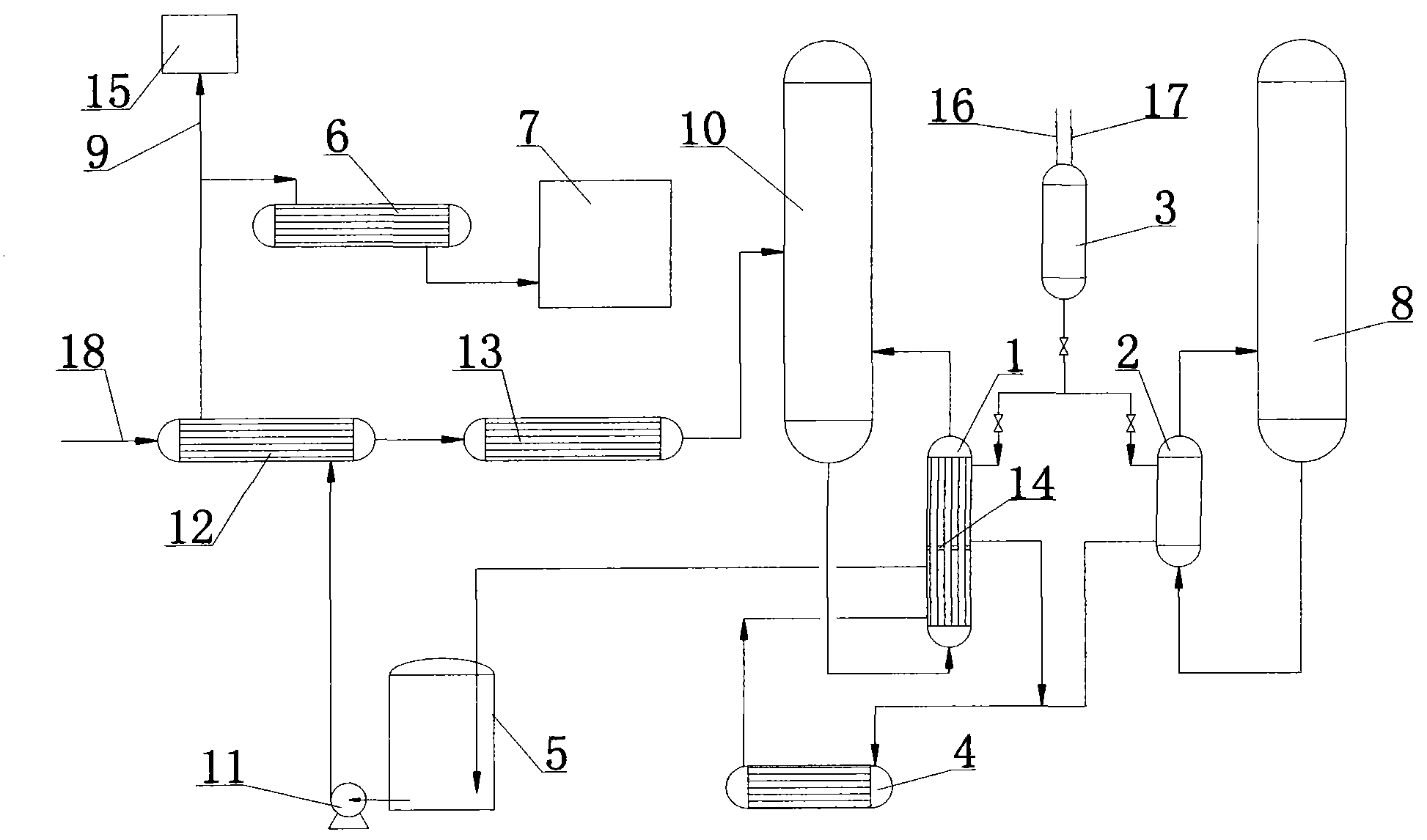

Kerosene-hydrogenation production process and system

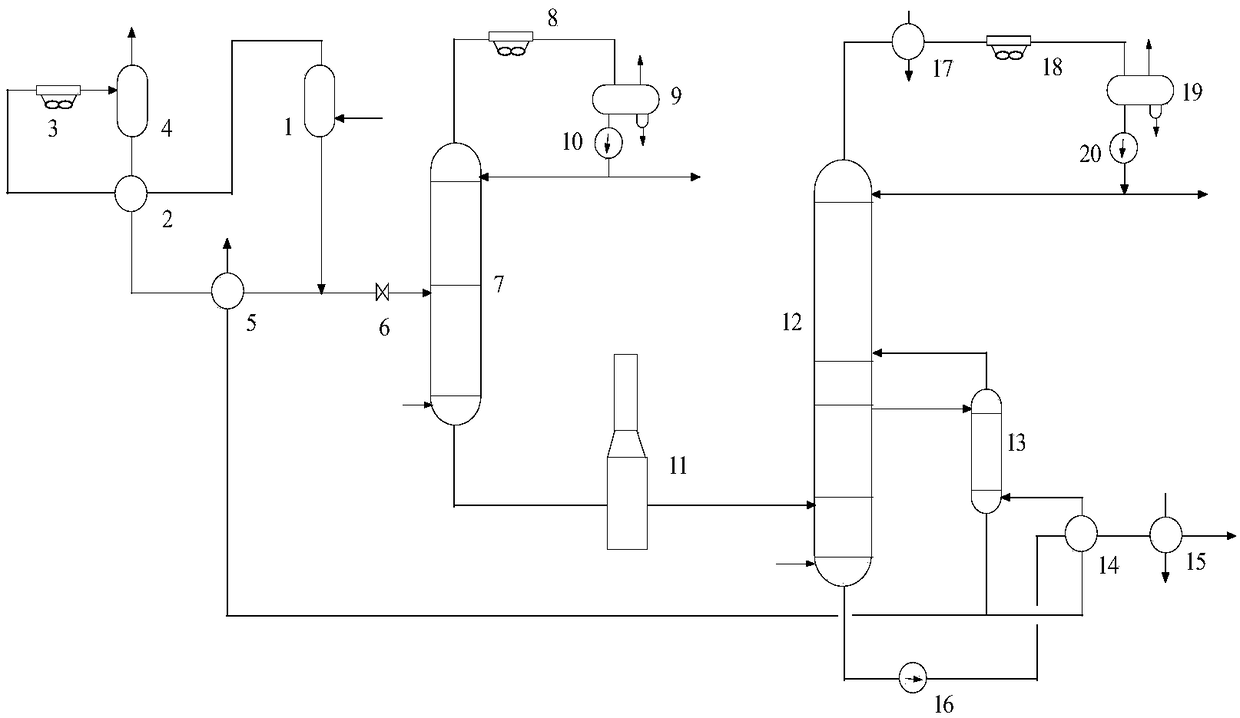

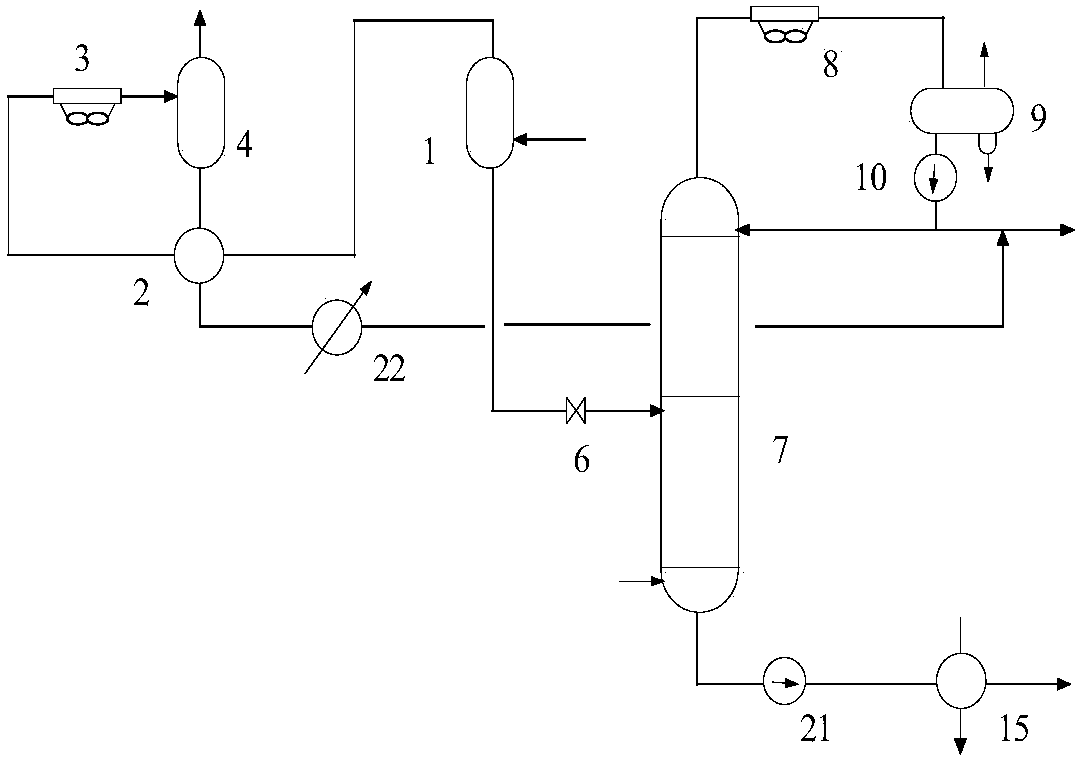

InactiveCN105670689AImprove recycling efficiencyReduce energy consumptionTreatment with hydrotreatment processesHydrogenKerosene

The invention discloses a kerosene-hydrogenation production process. The process comprises a reaction part and a fractionation part, wherein a reaction product of the reaction part directly enters a high-pressure hot separator without being cooled after exchanging heat with raw materials, a flash steam phase is cooled to about 50 DEG C through an air cooler after exchanging heat with recycle hydrogen or new hydrogen and then enters a high-pressure cold separator, and high-temperature reaction products separated from the bottoms of the high-pressure hot separator and the high-pressure cold separator exchange heat with refined kerosene from the bottom of a fractionating tower and are sent to the fractionation part. Compared with the prior art, the kerosene-hydrogenation production process is improved, the energy recycle efficiency of a device can be effectively improved and the energy consumption of the device is reduced with the process. The invention further provides a kerosene-hydrogenation production system adopting the kerosene-hydrogenation production process.

Owner:BEIJING YANSHAN YULONG PEC

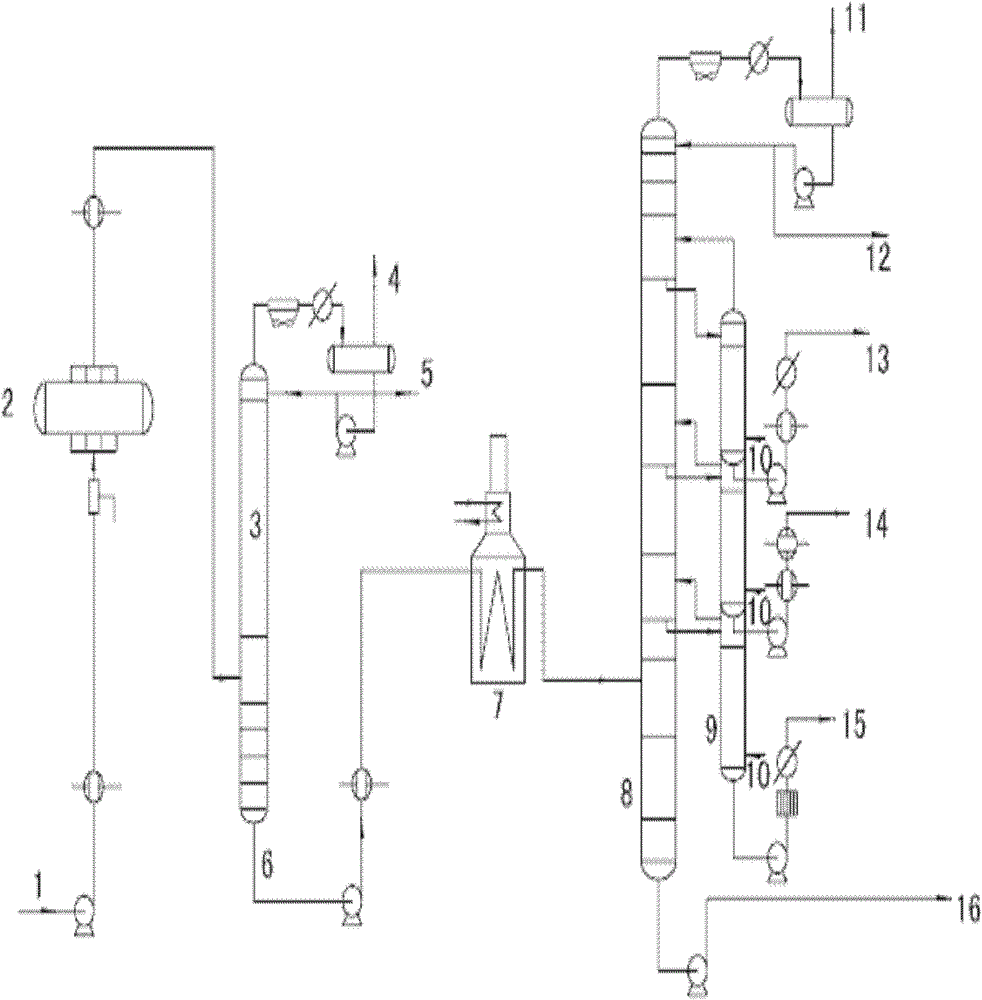

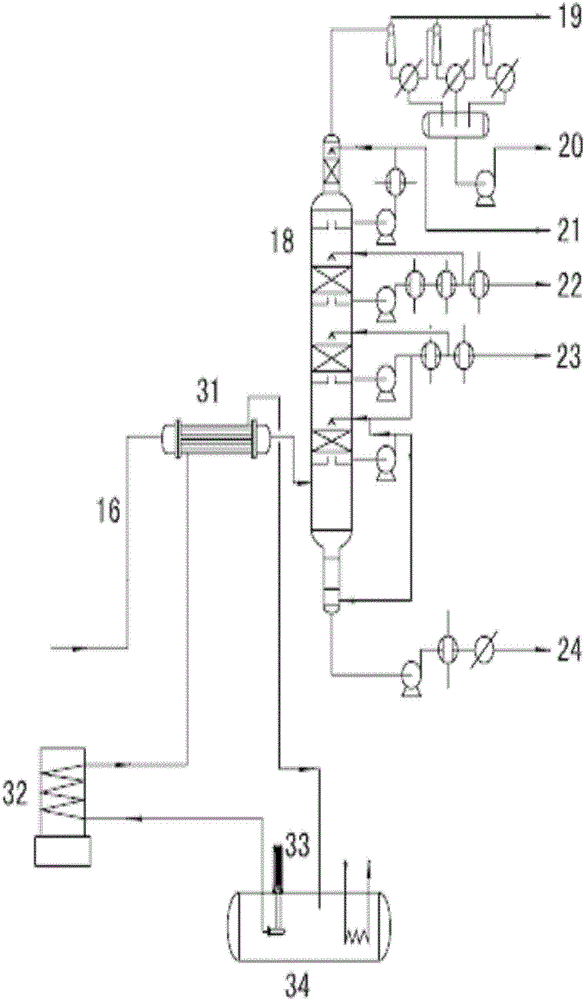

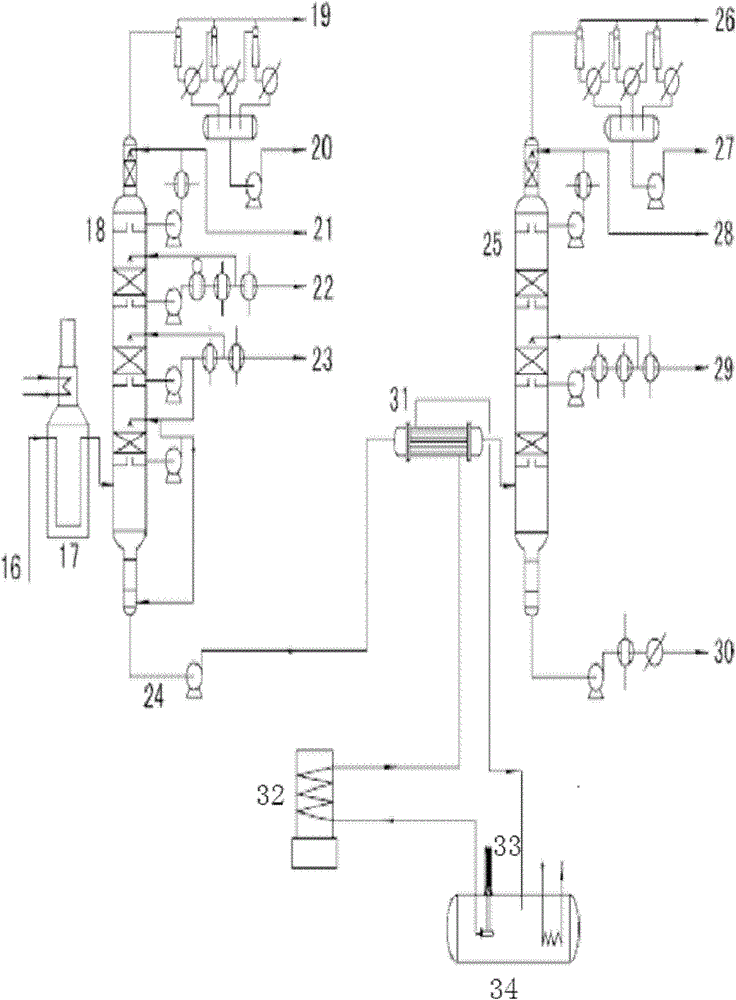

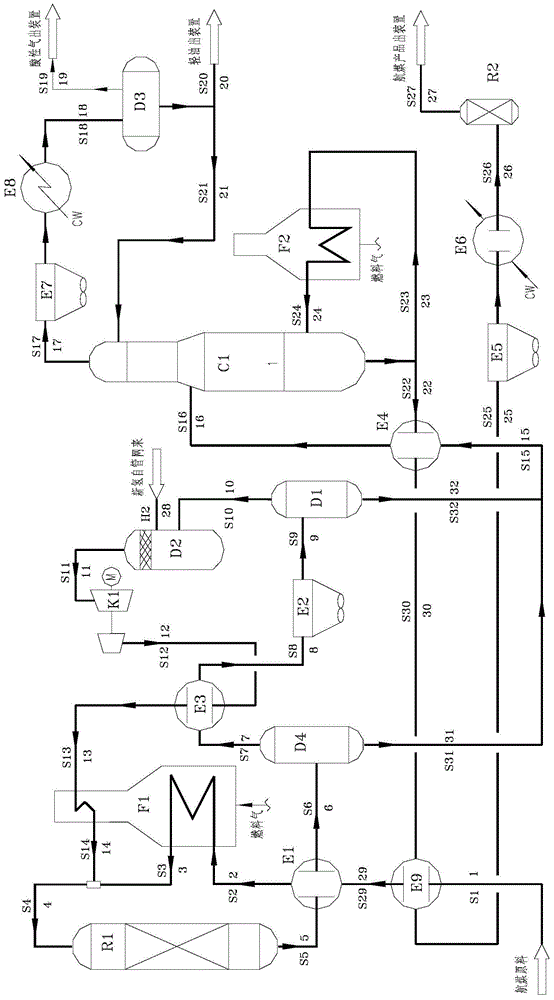

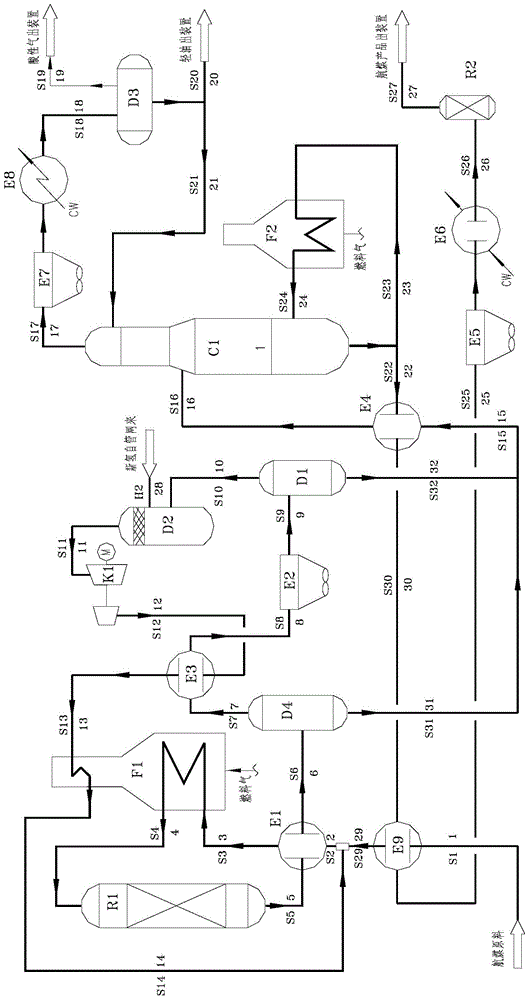

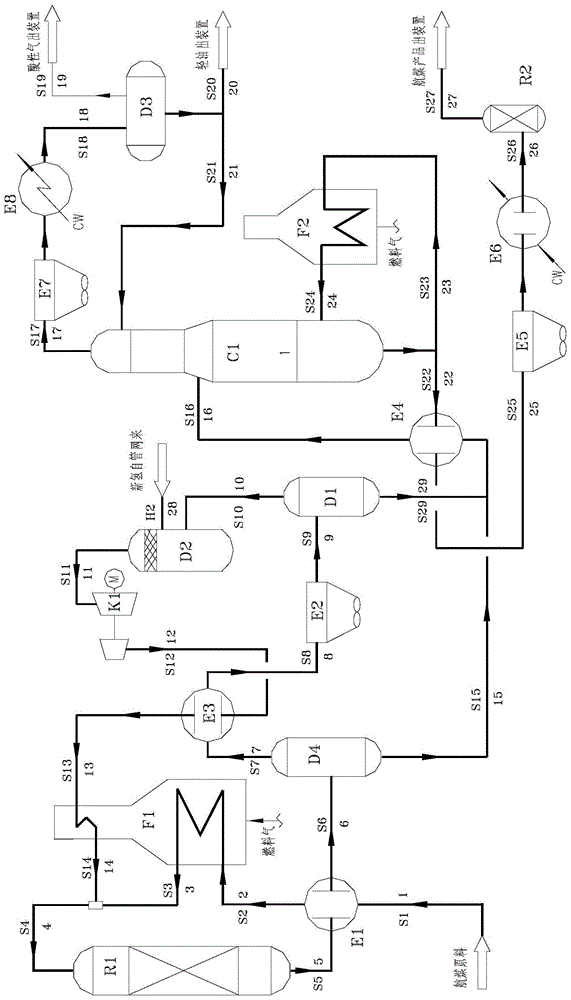

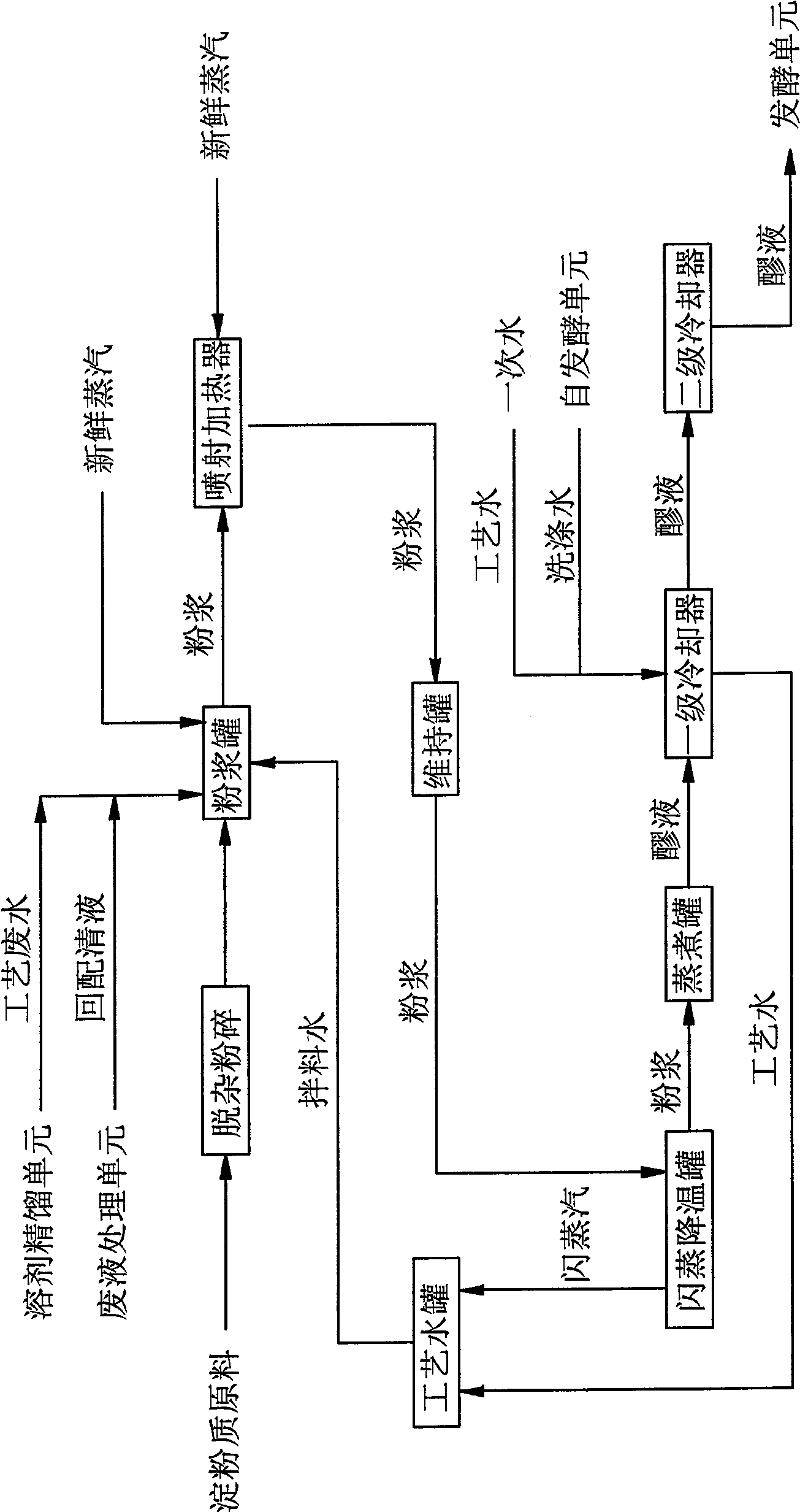

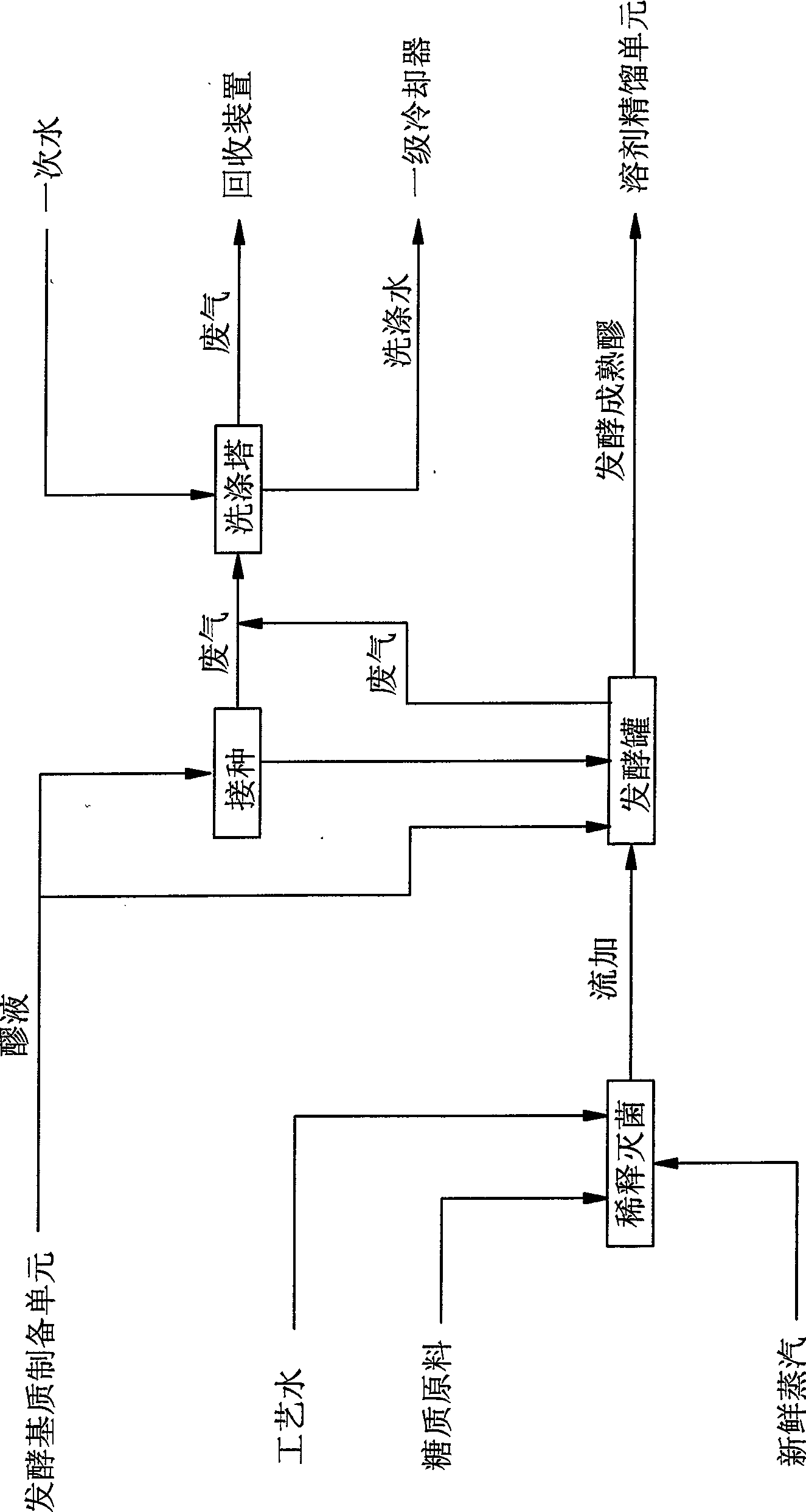

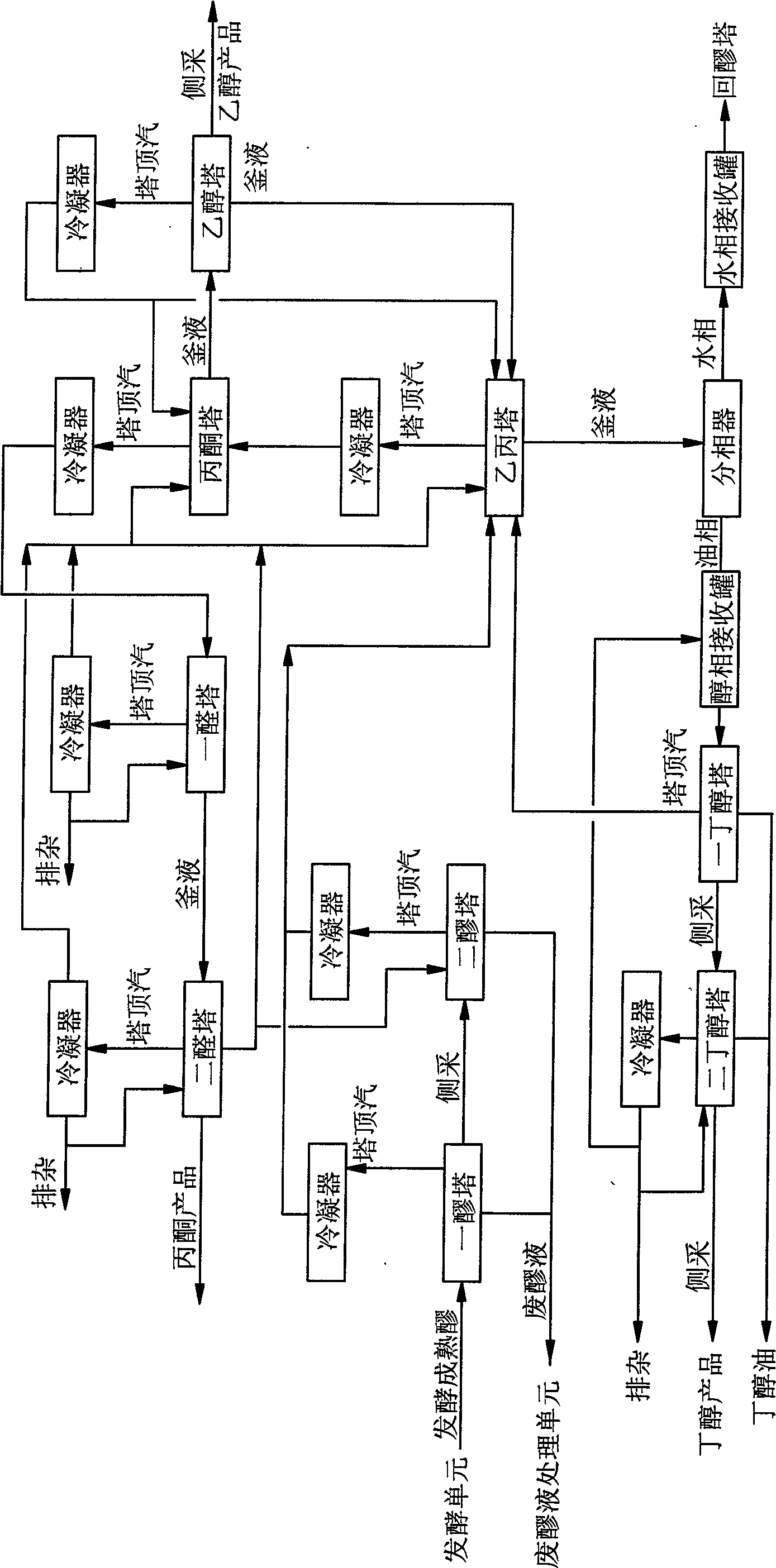

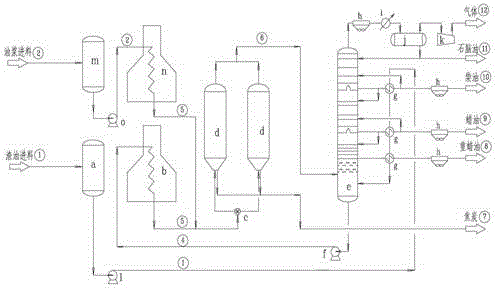

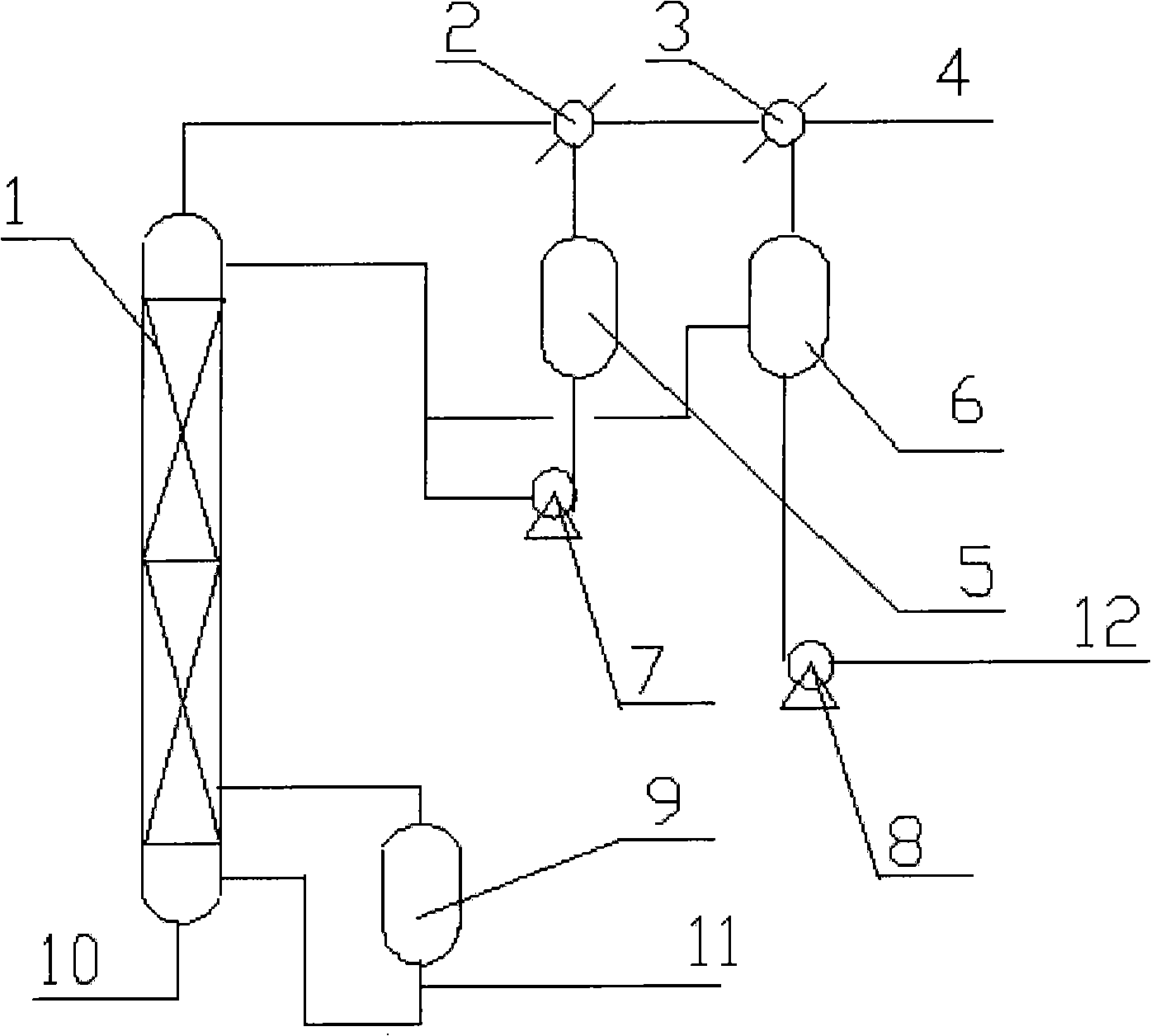

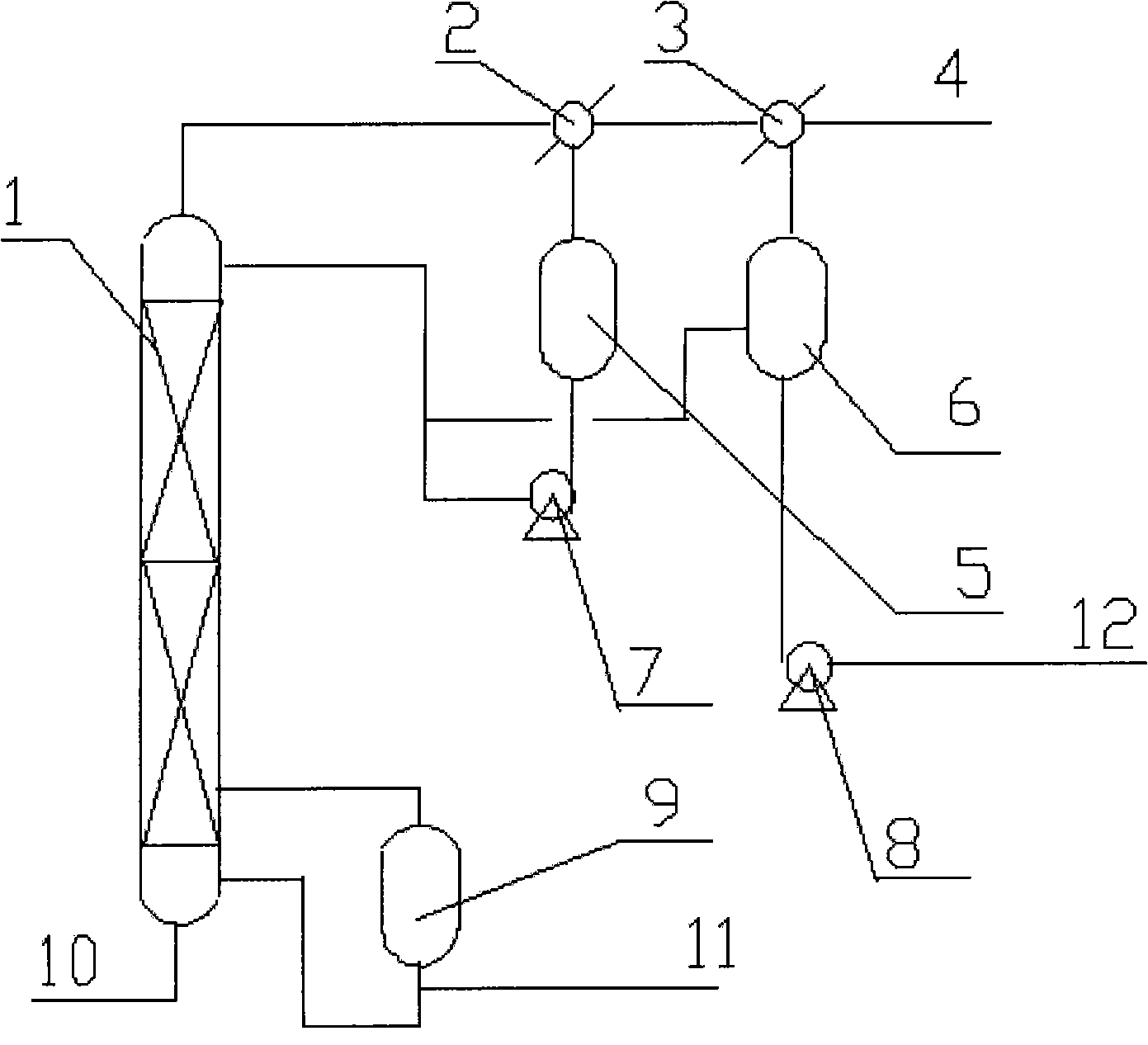

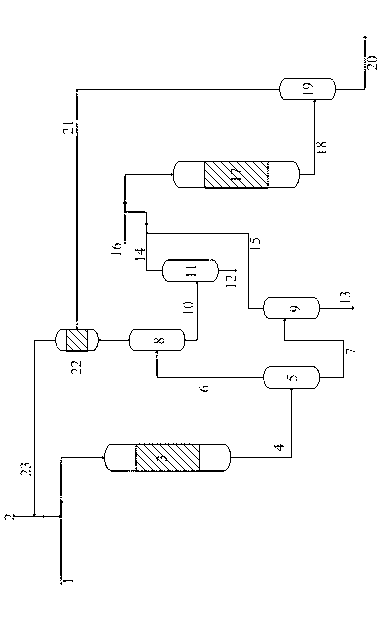

Method and apparatus for producing biological butanol

ActiveCN101497555AReduce energy consumptionReduce manufacturing costFermentationHydroxy compound separation/purificationSolventFermentation

The invention relates to a method and equipment for producing bio-butanol. The equipment comprises four production units, namely fermentation substrate preparation, fermentation, solvent rectification and waste mash treatment, wherein the rectification unit comprises beer columns, an ethylene-propylene tower, a butanol tower, an acetone tower, an aldehyde-removing tower and an ethanol tower, and comprises the following process flow: mature mash feed is delivered into a beer column I, is extracted from the side of the beer column I to enter a beer column II, and crude solvents with water content of between 30 and 80 percent extracted from the top of the beer column I and the beer column II are both delivered to the ethylene-propylene tower to be further rectified; the material is produced into crude butanol and mixture of acetone, ethanol and water through the ethylene-propylene tower; the crude butanol is refined into a butanol finished product through the butanol tower; the mixture of acetone, ethanol and water is produced into crude acetone and crude ethanol through the acetone tower; the crude acetone is refined into an acetone finished product through the aldehyde-removing tower; and the crude ethanol is refined into an ethanol finished product through the ethanol tower. The method and the equipment can effectively reduce material consumption and energy consumption in the process for producing the bio-butanol, reduce quantity of wastewater effluent in the production process, and improve market competitiveness of the bio-butanol product.

Owner:TIANJIN UNIV

Method for isomerization of light hydrocarbon

ActiveCN105820839ABoost octaneRaise feed temperatureTreatment with hydrotreatment processesAlkaneIsomerization

The invention relates to a method for isomerization of light hydrocarbon. According to the invention, a light hydrocarbon raw material which takes C5 and C6 alkanes as main components is introduced into an isopentane removal tower, a material flow at the top of the isopentane removal tower is taken as the isomerization product for eduction, a material flow at the bottom of the isopentane removal tower is introduced into an isomerization reaction unit, under existence of hydrogen, the material flow at the bottom is contacted with an isomerization catalyst in an isomerization reactor for an isomerization reaction, the reaction products are introduced into a pentane removal tower for being separated, a material flow at the top of the pentane removal tower and the light hydrocarbon raw material are mixed and introduced into the isopentane removal tower, a material flow at the bottom of the pentane removal tower is taken as the isomerization product for eduction, the pressure at the top of the pentane removal tower is 0.80-1.20 MPa, and the material flow at the top of the pentane removal tower is taken as a heat source of a reboiler of the isopentane removal tower. The method can fully use heat of condensation of the material flow at the top of the pentane removal tower during a separating process of n-alkanes and iso-paraffin, and the energy consumption of an light hydrocarbon isomerization apparatus is effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

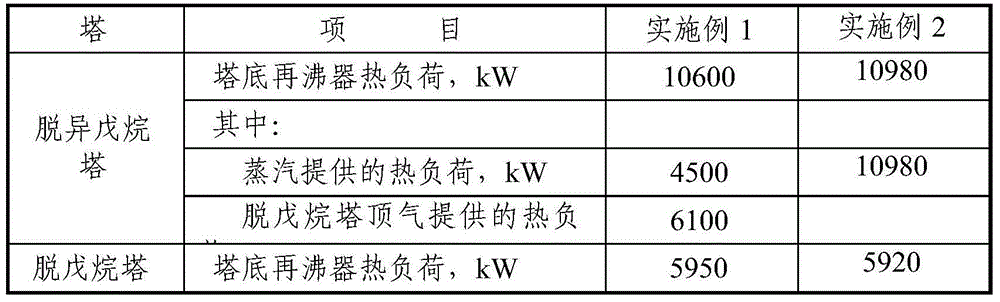

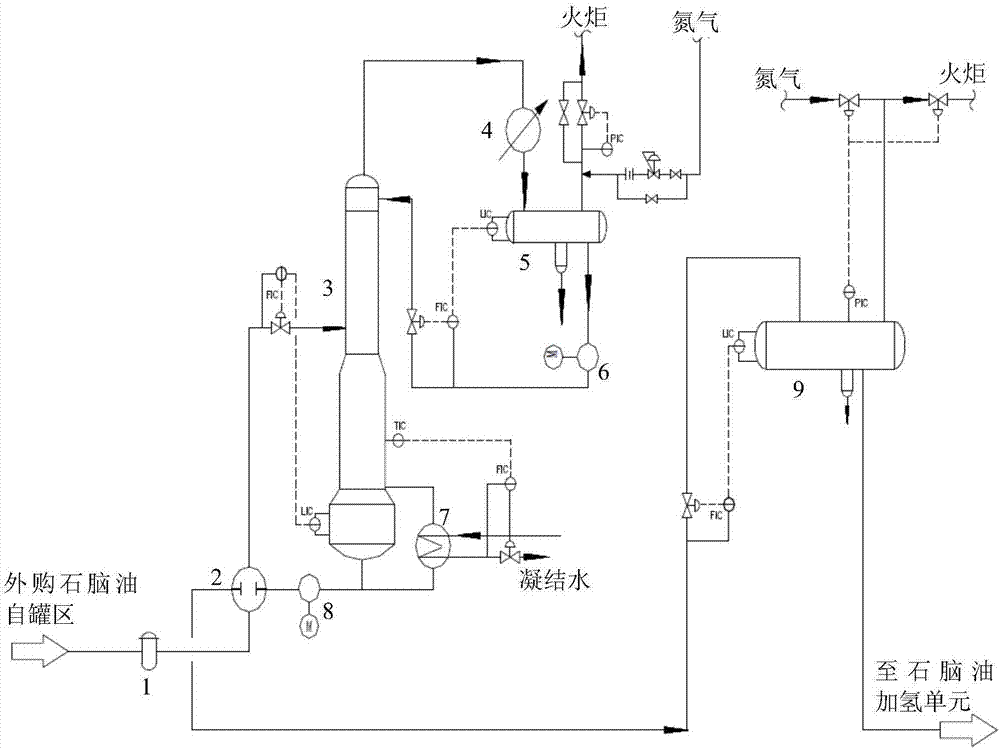

Method and system for optimizing hydrorefining low-pressure deoxygenation and feeding heat exchange for naphtha

ActiveCN105969421AReduce textureLower requirementTreatment with plural serial refining stagesTreatment with hydrotreatment processesNaphthaReboiler

The invention method and a system for optimizing hydrorefining low-pressure deoxygenation and feeding heat exchange for naphtha. The method includes that the naphtha is filtered and is subjected to heat exchange, then is fed into a deoxygenation tower to be subjected to deoxygenation treatment, the tower top pressures are flexibly controlled so that different working conditions can be adapted, tower-top gas phases are cooled and then are fed into a tower-top return tank, liquid phases completely return a tower top, and non-condensable gas on the top of the return tank is exhausted into a torch pipe network; a part of deoxygenated naphtha distilled at a tower bottom is fed into a reboiler at the bottom of the deoxygenation tower and is heated to obtain partial gas phases and partial liquid phases, and then the partial gas phases and the partial liquid phases return a tower kettle; heat is exchanged between another part of deoxygenated naphtha distilled at the tower bottom and filtered naphtha, and deoxygenated naphtha is used as a naphtha hydrogenation material after being subjected to heat exchange. The system comprises a naphtha feeding filter, a deoxygenation tower feeding and deoxygenated naphtha heat exchanger, the deoxygenation tower, a deoxygenation tower-top cooler, the deoxygenation tower-top return tank and the deoxygenation tower-bottom reboiler. The method and the system have the advantage that hydrorefining low-pressure deoxygenation and feeding heat exchange for the naphtha can be optimized by the aid of the method and the system.

Owner:BEIJING PETROCHEM ENG

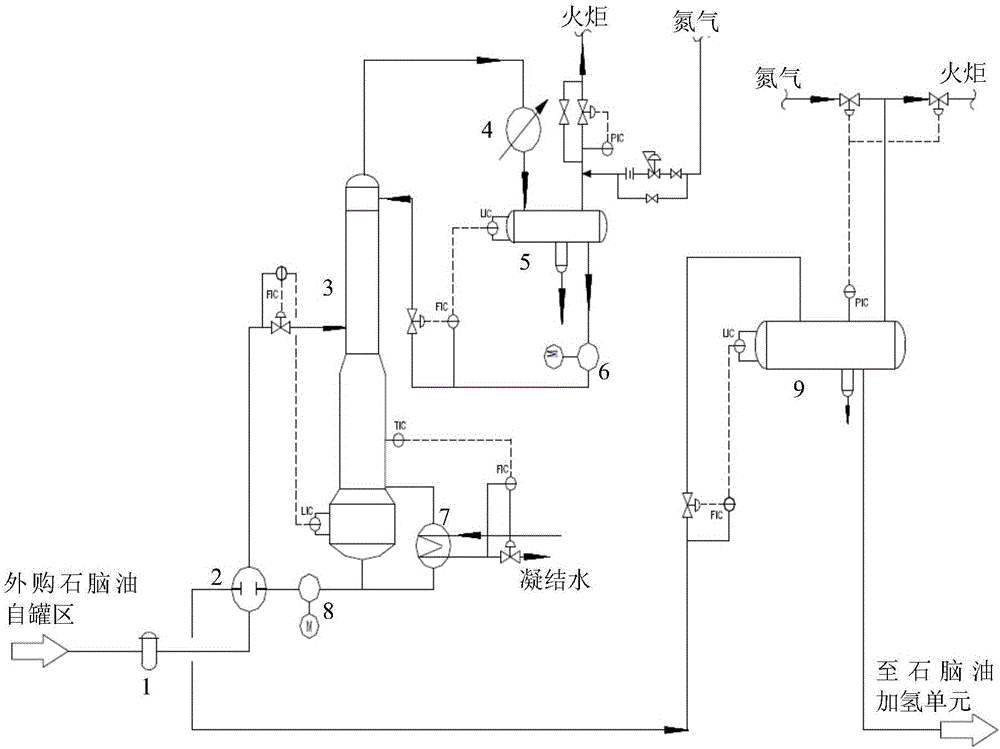

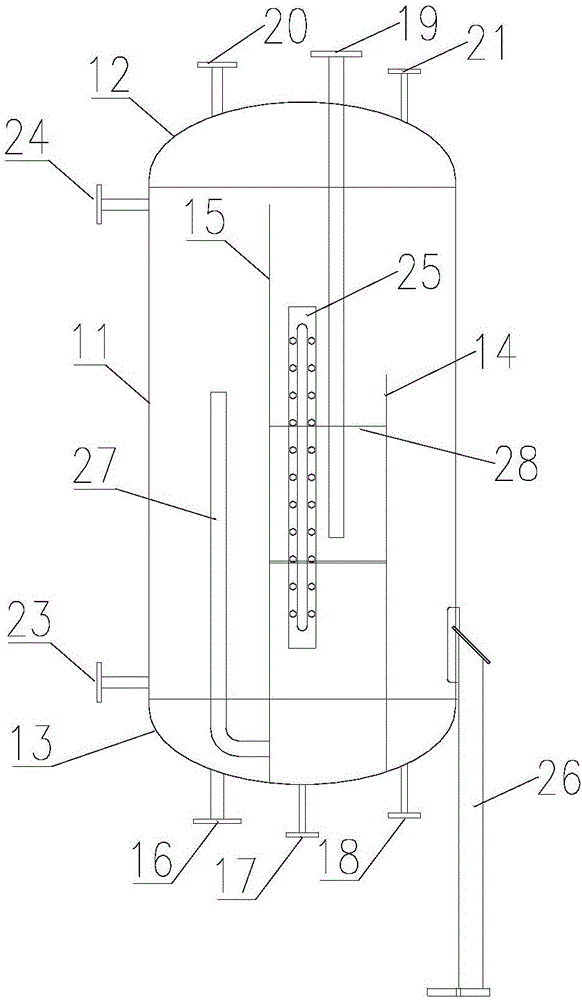

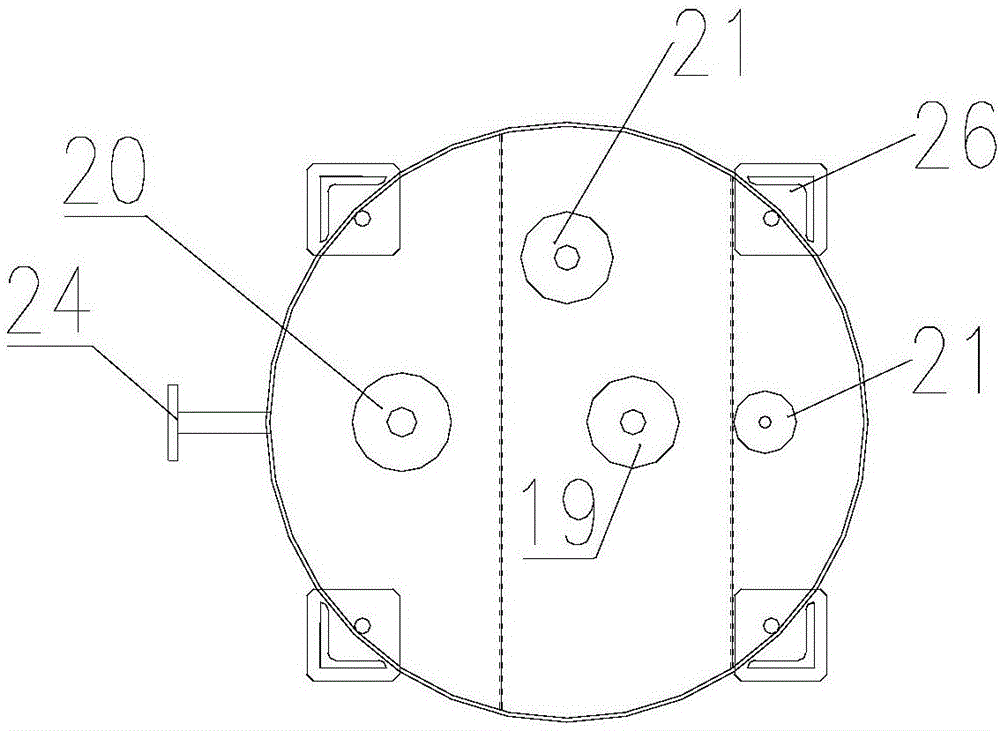

System and method for recovering alcohol ketone by using thermal energy of wastewater

InactiveCN106746118ARaise feed temperatureSave the use of external energyMultistage water/sewage treatmentNature of treatment waterChemistryKetone

The invention discloses a system and a method for recovering alcohol ketone by using thermal energy of waste water. The column top inlet of an extraction column communicates with a water inlet pipeline of process condensed water containing ketone alcohol; the column top outlet of the extraction column communicates with the middle inlet of an alkyl distillation column; the material outlet of the alkyl distillation column communicates with the column reactor inlet of the extraction column; the column top outlet of a wastewater stripping column communicates with the thermal medium inlet of a wastewater condenser; the thermal medium outlet of the wastewater condenser communicates with an alcohol ketone collection device; the column reactor outlet of the wastewater stripping column communicates with the thermal medium inlet of a wastewater heat exchanger; the thermal medium outlet of the wastewater heat exchanger communicates with the thermal medium inlet of a wastewater cooler; the cold medium inlet of the wastewater heat exchanger communicates with the column kettle outlet of the extraction column; the cold medium outlet of the wastewater heat exchanger communicates with the column top inlet of the wastewater stripping column; the thermal medium outlet of the wastewater cooler communicates with a wastewater conveying pipeline.

Owner:聊城鲁西甲酸化工有限公司

Method and system for naphtha hydrofining low-pressure deoxidation and feed heat exchange optimization

ActiveCN105969421BLower requirementPromote escapeTreatment with plural serial refining stagesTreatment with hydrotreatment processesNaphthaGas phase

The invention method and a system for optimizing hydrorefining low-pressure deoxygenation and feeding heat exchange for naphtha. The method includes that the naphtha is filtered and is subjected to heat exchange, then is fed into a deoxygenation tower to be subjected to deoxygenation treatment, the tower top pressures are flexibly controlled so that different working conditions can be adapted, tower-top gas phases are cooled and then are fed into a tower-top return tank, liquid phases completely return a tower top, and non-condensable gas on the top of the return tank is exhausted into a torch pipe network; a part of deoxygenated naphtha distilled at a tower bottom is fed into a reboiler at the bottom of the deoxygenation tower and is heated to obtain partial gas phases and partial liquid phases, and then the partial gas phases and the partial liquid phases return a tower kettle; heat is exchanged between another part of deoxygenated naphtha distilled at the tower bottom and filtered naphtha, and deoxygenated naphtha is used as a naphtha hydrogenation material after being subjected to heat exchange. The system comprises a naphtha feeding filter, a deoxygenation tower feeding and deoxygenated naphtha heat exchanger, the deoxygenation tower, a deoxygenation tower-top cooler, the deoxygenation tower-top return tank and the deoxygenation tower-bottom reboiler. The method and the system have the advantage that hydrorefining low-pressure deoxygenation and feeding heat exchange for the naphtha can be optimized by the aid of the method and the system.

Owner:BEIJING PETROCHEM ENG

Device for blending catalytic slurry oil in delayed coking technology and method thereof

ActiveCN103361112BRaise feed temperatureImprove liquid yieldTreatment with plural serial stages onlyTemperature controlSlag

The invention provides a device for blending catalytic slurry oil in delayed coking technology. The device comprises a slurry oil tank, a slurry oil pump and a slurry oil heating furnace, which are individually arranged, the slurry oil tank, the slurry oil pump and the slurry oil heating furnace are connected one by one, and the outlet of the slurry oil heating furnace is connected to the outlet of an oil slag heating furnace of a delayed coking device. The invention also provides a method for blending catalytic slurry oil in delayed coking technology by utilizing the device. The method comprises following steps: (1) high-temperature catalytic slurry oil is transported to a slurry oil tank by a catalytic cracking unit, then is transported to a slurry oil heating furnace by a slurry oil pump, and is heated to the temperature of 505 to 550 DEG C; (2) the high-temperature coking oil heated by the slurry oil furnace is mixed with the high-temperature coking oil in the outlet of the oil slag heating furnace of the delayed coking device, and then the mixture is transported to a coke drum to have consequent reactions. The device for blending catalytic slurry oil in delayed coking technology realizes individual temperature control of the oil slurry heating furnace outlet, increases the liquid yield of the coke drum and reduces the coke yield. The whole equipment abrasion and corrosion are changed to part abrasion and corrosion, so the maintenance cost of the equipment is reduced, and the general efficiency of the delayed coking device is improved.

Owner:天津市瑞德赛恩新材料开发有限公司

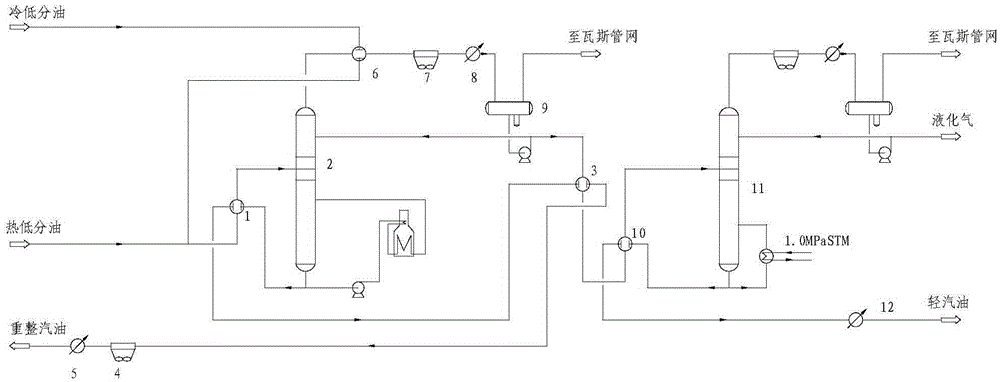

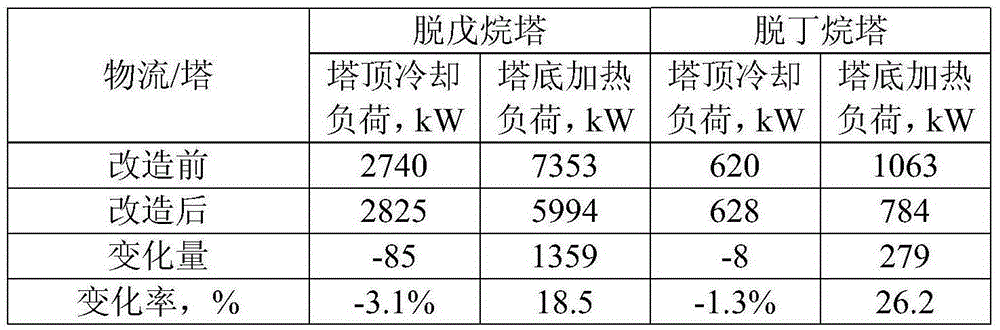

Reforming heat recycling technology and device

ActiveCN105331389AImprove heat transfer effectRaise feed temperatureCatalytic naphtha reformingProcess engineeringBase oil

The invention provides a reforming heat recycling technology and device. The technology comprises the steps of recycling top oil gas heat of a depentanizer, strengthening heat exchange of fed materials of the depentanizer and base oil of the depentanizer and improving heat exchange of the base oil of the depentanizer and fed materials of a debutanizer. The invention further provides the reforming heat recycling device, wherein cold low-separated oil and hot low-separated oil of a reaction oil gas separating unit are connected with a feeding port of the depentanizer through a heat exchange unit, and top oil of the depentanizer is connected with a feeding port of the debutanizer through the heat exchange unit. According to the reforming heat recycling technology and device, the temperature of the fed materials of the depentanizer and the debutanizer can be increased, and the load of a reboiling furnace at the bottom of the depentanizer and the heating load of the bottom of the debutanizer are reduced; compared with the prior art, fuel consumption of the depentanizer can be reduced by 10%-20%, steam consumption of the debutanizer can be reduced by about 10%-30%, and the obvious energy saving effect is achieved.

Owner:SHANGHAI YOUHUA PROCESS INTEGRATED TECH CO LTD

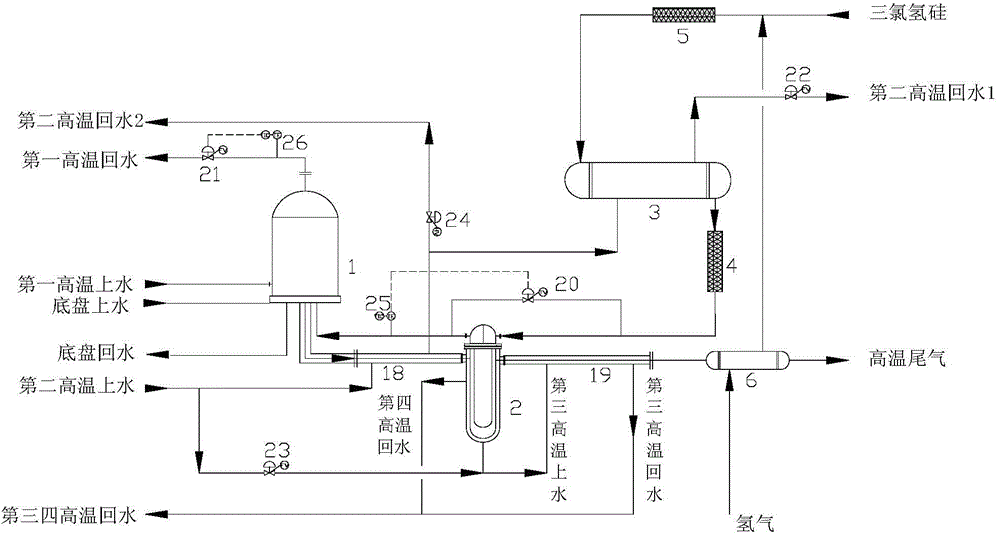

Energy-conserving process for washing and dedusting by methyl monomer synthesis gas

ActiveCN101337974BIncrease temperatureReduced light component contentGroup 4/14 element organic compoundsChemical industrySyngasReflux

The invention relates to a scrubbing dust-removal energy-saving process of organosilicon monomer synthesis gas. Scrubbing gas is processed through first condensation and second condensation; liquor condensate of a condensator with relatively higher boiling point is used for partial reflux, and contacts with high-temperature organic-chlorosilane synthesis gas containing dust in a converse manner so as to perform dust removal purification, so qualified organic-chlorosilane synthesis gas is obtained, and the purpose of energy conservation is served.

Owner:BEIJING PETROCHEM ENG +1

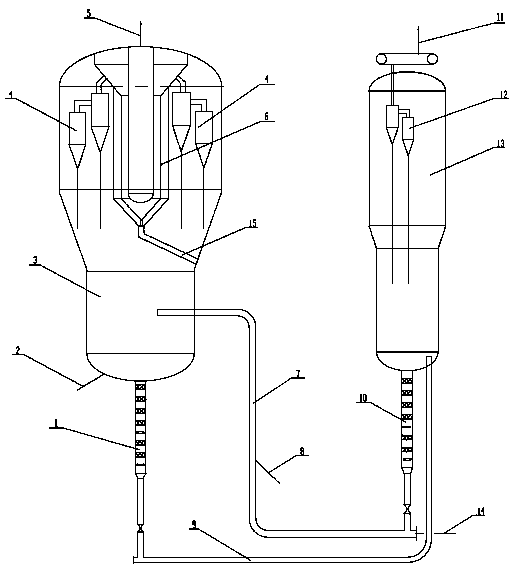

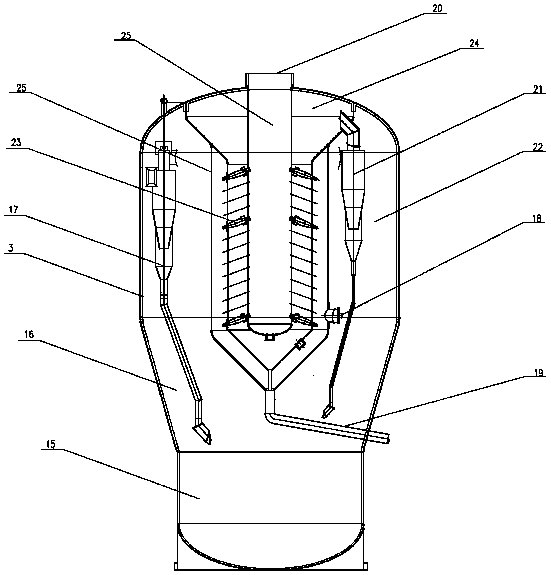

Method and equipment for improving selectivity of low-carbon olefins

ActiveCN110950730AReduce the temperatureReduced activityHydrocarbon from oxygen organic compoundsChemical recyclingPtru catalystProcess engineering

The invention discloses a method and equipment for improving the selectivity of low-carbon olefins. The method comprises the following steps that 1) an oxygen-containing compound raw material enters areactor, contacts with a regeneration catalyst from a pre-reaction section, and is subjected to an exothermic reaction; 2) after the carried catalyst is removed from the reaction gas in the step (1),the obtained reaction gas enters the built-in separation facility of the reactor to remove the carried catalyst, and then is led out; 3) the spent catalyst subjected to carbon deposition after the reaction in the step 1) enters a regenerator, and is subjected to scorching regeneration; 4) the spent catalyst in the step 3) enters a regeneration stream stripping device, and is subjected to steam stripping cooling, and the cooled catalyst enters a pre-reaction section; and 5) a pre-reaction medium is gasified, and the gasified pre-reaction medium enters the pre-reaction section, is subjected toan endothermic reaction with the regenerated catalyst, and then enters the reactor. The method and the equipment provided by the invention have the advantages that by arranging the pre-reaction section, the occurrence of non-target reaction is reduced, and the selectivity of low-carbon olefin is improved; and the bush is arranged in the reactor, so that the dilute phase space of the reactor is shortened, and the selectivity of low-carbon olefin is improved.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP +1

Method for producing low-carbon olefins from methanol and naphtha

ActiveCN102875286AHigh selectivityHigh yieldCatalytic crackingHydrocarbon from oxygen organic compoundsMolecular sieveNaphtha

The invention relates to a method for producing low-carbon olefins from methanol and naphtha to mainly solve a low low-carbon olefin yield problem in previous technologies. The method mainly comprises the following steps: 1, allowing a naphtha-containing raw material to enter a first reaction zone and contact with a molecular sieve catalyst, allowing a generated gas phase material flow and a catalyst to contact with a raw material which mainly comprises methanol and enters from the distribution tube positioned at the outlet end of the first reaction zone, and then allowing the gas phase material flow to enter a second reaction zone to generate a product material flow comprising the low-carbon olefins and simultaneously form a catalyst to be regenerated; 2, dividing the catalyst to be regenerated into at least two parts, allowing one part of the catalyst to be regenerated to enter a regenerator for regeneration to form a regenerated catalyst, and allowing the other part of the catalyst to be regenerated to go through an outer circuiting incline tube and then return to the second reaction zone; and 3, returning the regenerated catalyst to the first reaction zone, wherein the methanol entering the from the distribution tube contacts with the gas phase material flow formed in the first reaction zone in a countercurrent manner, and the feed temperature of the raw material mainly comprising methanol is 40-200DEG C. The above technical scheme well solves the problem, and the method can be used for the industrial production of the low-carbon olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

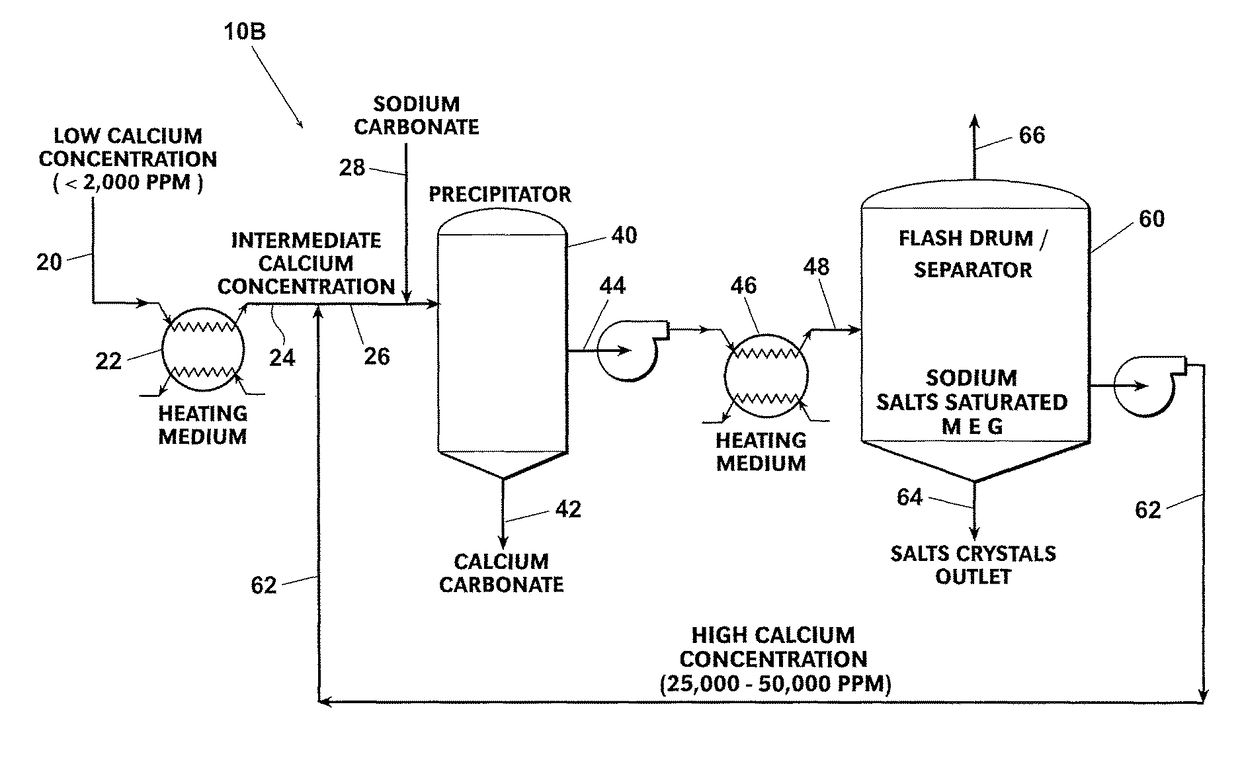

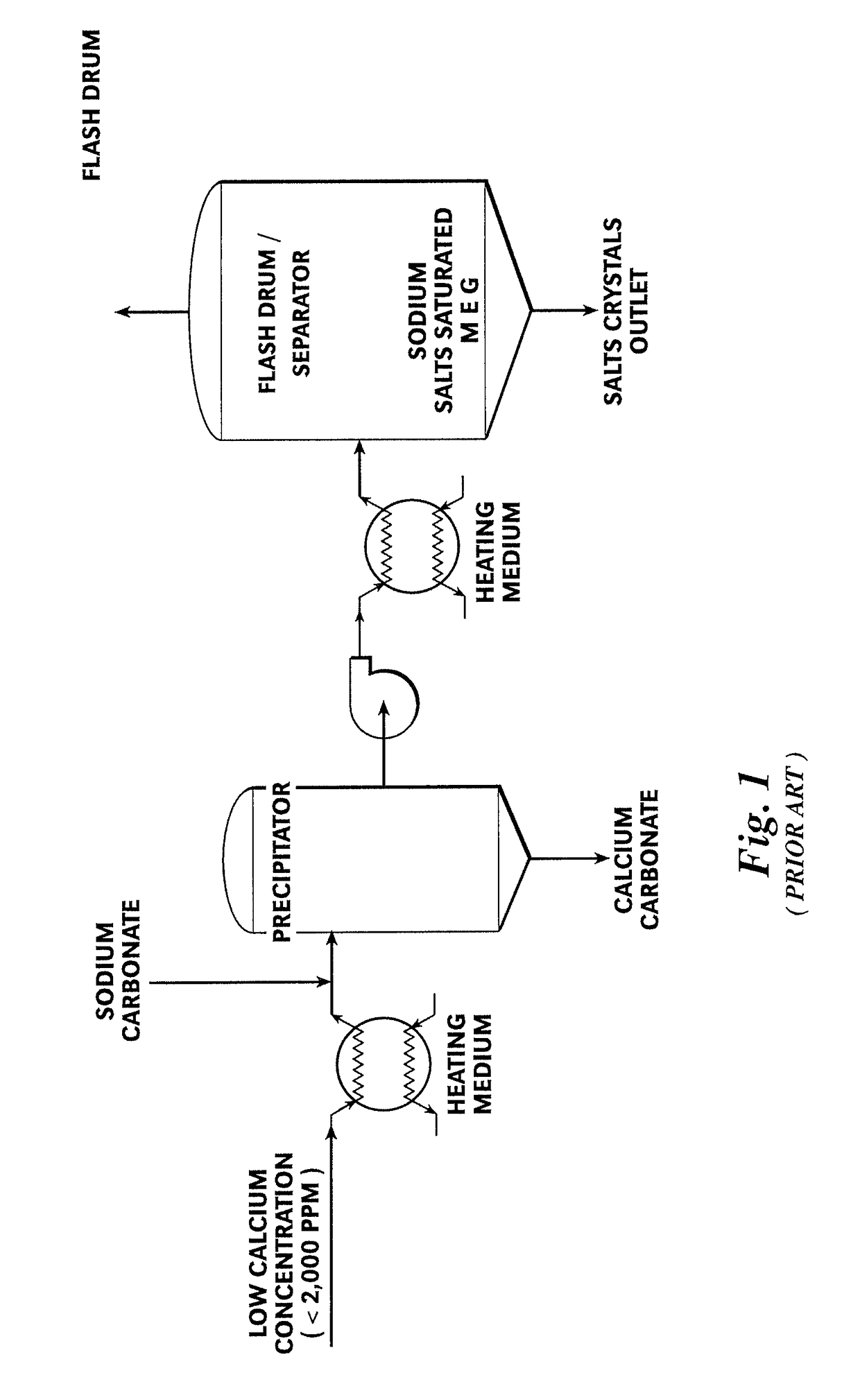

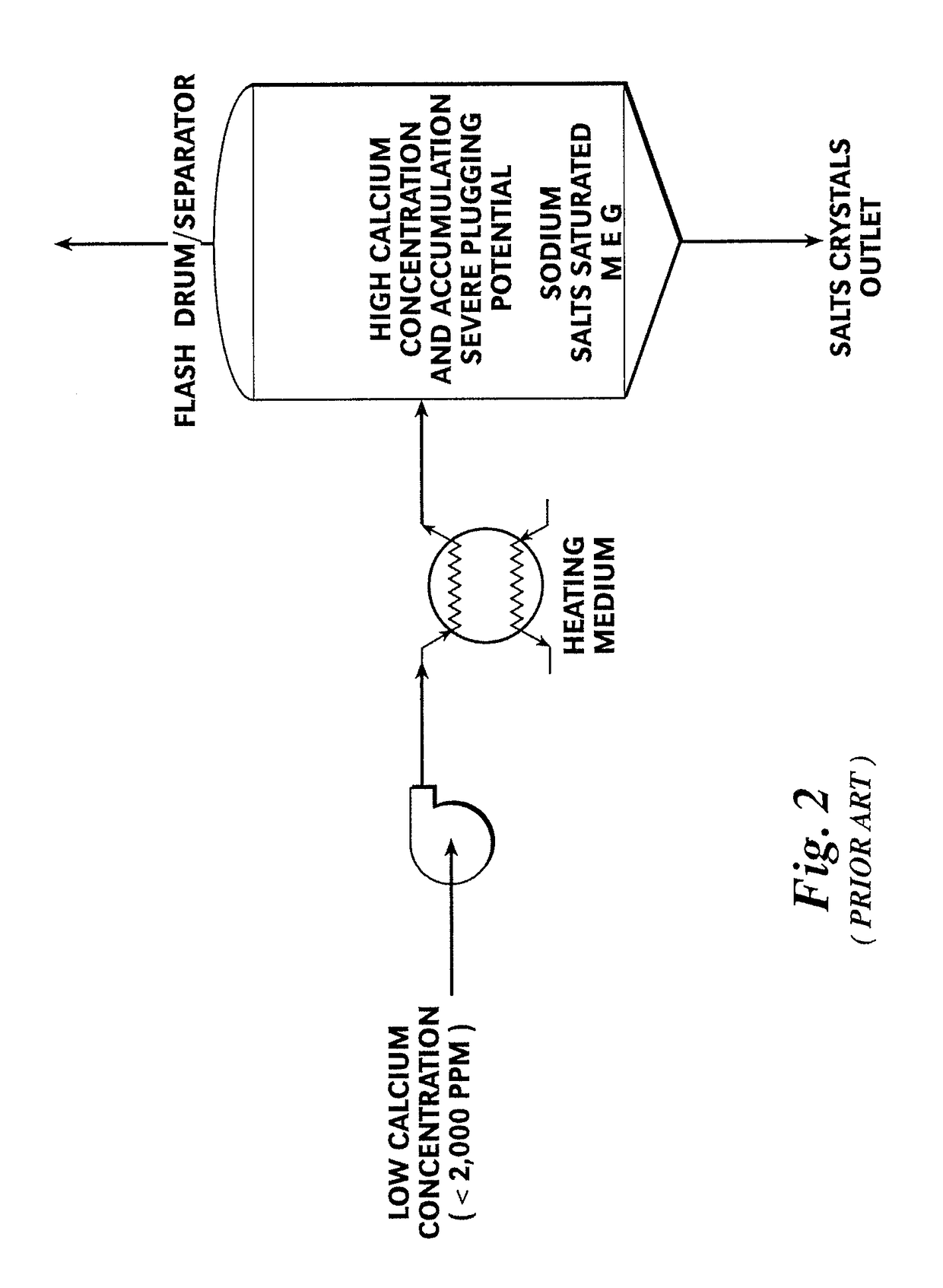

Process scheme to improve divalent metal salts removal from mono ethylene glycol (MEG)

ActiveUS9790153B2Speed reactionReduce solubilityGas treatmentMultiple-effect/fractional condensationStream flowDivalent metal

Owner:CAMERSON INT CORP

DMF (N,N-Dimethyl Formamide) rectification dehydration purification method

ActiveCN106220527ARaise feed temperatureReduce the temperatureChemical industryCarboxylic acid amide separation/purificationPhase splittingPurification methods

The invention discloses a DMF (N,N-Dimethyl Formamide) rectification dehydration purification method which is characterized by comprising the following steps: (1) feeding raw materials into a heat exchanger, performing heat exchange with a solvent obtained from the bottom of a rectifying column, and feeding the materials from the middle part of the rectifying column; (2) heating the materials falling into the bottom of the rectifying column, raising the materials to the top of the rectifying column, condensing the materials into a liquid by using a steam condenser at the top of the rectifying column, and feeding the liquid into a multifunctional tank; (3) performing phase splitting in the multifunctional tank, backflowing one part of water phase to the top of the rectifying column, and discharging one part of the water phase to a wastewater treatment section; (4) discharging a solvent at the bottom of the rectifying column, performing heat exchange with the raw materials, and discharging to an outside battery limit product storage tank. The DMF rectification dehydration purification method is energy-saving, low in cost and relatively good in practicability.

Owner:烟台国邦化工机械科技有限公司

Method and device for dehydration of glycol by extending coking period of tower-drier reboiler

InactiveCN1557795AExtend the coking cycleIncrease heat loadHydroxy compound separation/purificationPreparation by hydrolysisReboilerPulp and paper industry

The glycol dewatering method for delaying the scaling period of reboiler in drying tower includes the control on the material temperature of drying tower, and features that the glycol solution temperature is 95-130 deg.c. The present invention also provides a glycol dewatering apparatus related to the method for delaying the scaling period of reboiler in drying tower. The method of the present invention can decrease the scaling speed of the reboiler obviously to reduce stop loss, lower cost in descaling, reduce drained sewage and protect environment.

Owner:北京东方石油化工有限公司

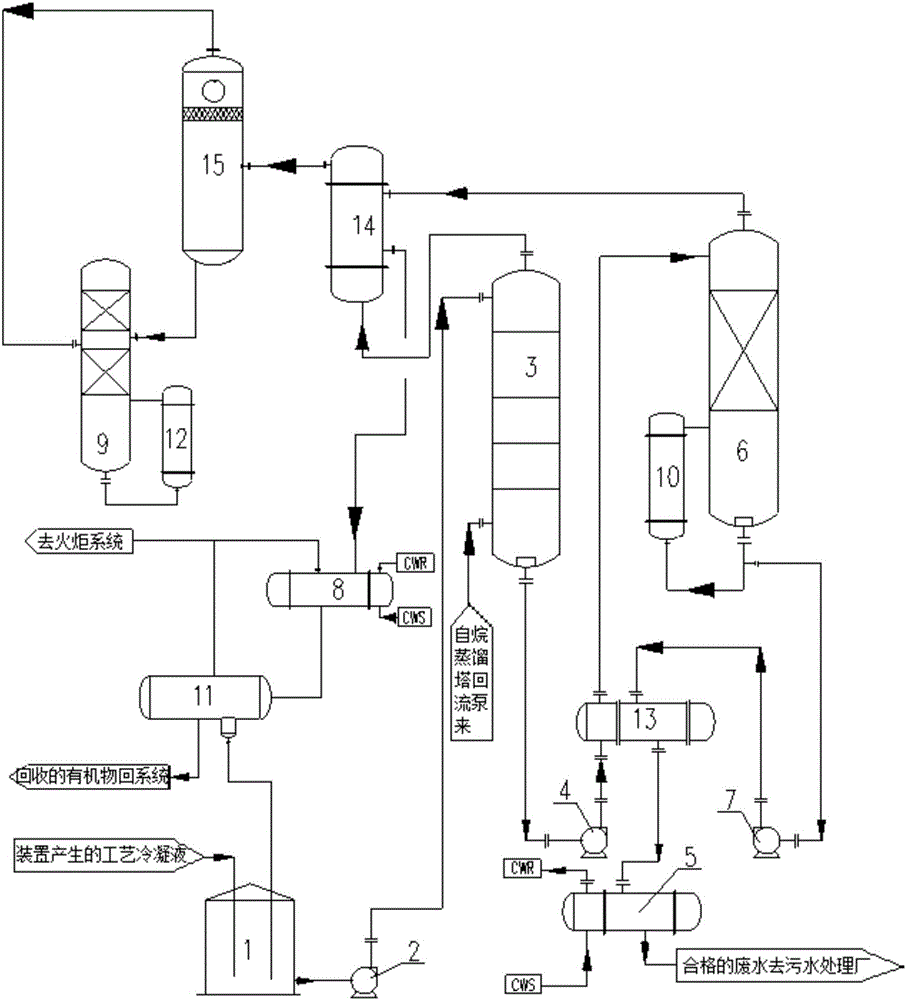

Combined hydrogenation method

InactiveCN102863985ASmall scaleSettle the lossTreatment with hydrotreatment processesThermodynamicsPtru catalyst

The invention discloses a combined hydrogenation method. In the method, a straight run distillation jet fuel hydrogenation deodorization device and at least one set of hydrocarbon raw material catalytic hydrogenation device are adopted. Effluent of the hydrocarbon raw material catalytic hydrogenation device is gas-liquid separated through a thermal high-pressure separator, a cold high-pressure separator, a cold low-pressure separator and a thermal low-pressure separator, gas-phase substance flow separated through the thermal low-pressure separator and the cold low-pressure separator is mixed with straight-run jet fuel raw materials and passes through a catalytic bed under the condition of jet fuel hydrogenation deodorization, and reaction effluent is gas-liquid separated. A liquid phase is gas stripped or distilled to obtain refined jet fuel, and a gas phase is used as supplement hydrogen of the hydrocarbon raw material catalytic hydrogenation device. By means of the method, a hydrogen extraction device can be omitted, or the scale of the hydrogen extraction device is reduced, and simultaneously the heat of the device is used reasonably, a deodorization effect of the jet fuel is improved, and therefore investment and operation cost of the device are reduced, and benefit of enterprises is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation process of vertraldethyde

InactiveCN102320944ALow costHigh purityCarbonyl compound preparation by condensationMethylanilineFormylation reaction

The invention discloses a preparation process of vertraldethyde; veratrole is used as a main synthetic raw material and a solvent; a formylation reaction is performed by veratrole and a complex generated by N-methylformanilide and phosphorus oxychloride; a product is obtained after hydrolyzation; the using amount of the solvent during the reaction is reduced, and the yield of a single batch is increased. Meanwhile, a lot of veratrole and N-methylaniline can be recovered for recycle, which reduces the production cost to a large extent. In addition, the charging temperature is increased, and thus complexation and the formylation reaction can be performed simultaneously, which saves a lot of time; and the product after distillation has purity of up to above 99%.

Owner:SHANDONG HOLLY PHARM CO LTD

Gradient utilization device for heat energy in methanol rectifying process and utilization method of gradient utilization device

ActiveCN103861312ARaise feed temperatureIncrease temperatureOrganic compound preparationHydroxy compound preparationThermal energyAlcohol

The invention belongs to a gradient utilization device for heat energy in a methanol rectifying process and a utilization method of the gradient utilization device. The gradient utilization device comprises a pressurizing rectifying tower and a system crude alcohol feeding pump pipeline which are connected with a middle part inlet of a pre-rectifying tower through a first-grade crude alcohol pre-heater pipe pass and a second-grade crude alcohol pre-heater pipe pass in sequence; the lower section of the pre-rectifying tower is connected with a tower bottom of the pre-rectifying tower by a pre-tower re-boiler pipe pass; a low-pressure steam pipeline and a middle-pressure steam pipeline are respectively connected with a steam buffering tank; an outlet of the steam buffering tank is communicated with a shell pass inlet in the upper section of a pre-tower re-boiler and the shell pass inlet of a pressurizing re-boiler respectively; a shell pass outlet of the pressurizing re-boiler is connected with a pipe pass inlet of a pre-tower post-methanol pre-heater by a pipeline; the shell pass outlet of the upper section of the pre-tower re-boiler is connected with a pipeline between the shell pass outlet of the pressurizing re-boiler and the pipe pass inlet of the pre-tower post-methanol pre-heater; the pipe pass outlet of the pre-tower post-methanol pre-heater is connected with a condensed liquid groove by a shell pass on the lower section of the pre-tower re-boiler. The gradient utilization device has the advantages of less investment and low operation cost.

Owner:HENAN XINLIANXIN FERTILIZER +2

Waste heat recovery system for table salt drying tail gas

PendingCN110701872AGuaranteed heat transfer efficiencyIncrease temperatureCombination devicesGas treatmentHot blastHeat transfer efficiency

The invention relates to a waste heat recovery system for table salt drying tail gas. A hot blast heater is connected to a fluidized gas inlet of a fluidized bed dryer, a gas outlet of a cyclone separator is connected to a first water absorption tower through a first gas inlet pipe, a gas outlet of the fluidized bed dryer is connected to an induced draft fan, and a gas outlet in the top end of thefirst water adsorption tower is connected to an air preheater. A material preheating unit comprises a slurry conveying pipe, a slurry pump and a heat exchange spray tower, the slurry pump is arrangedon the slurry conveying pipe, and the slurry conveying pipe passing the heat exchange spray tower is connected to a material inlet of the fluidized bed dryer. The waste heat recovery system is scientific and reasonable in design, can remove corrosion of table salt drying tail gas to the wall of a heat exchange tube, reduce humidity and dust of tail gas, prevent scaling of the heat exchange tube,and improve the heat transfer efficiency. Meanwhile, the waste heat recovery system can recycle heat of the tail gas, so that the utilization ratio of energy source is improved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Residual oil hydrogenation refining process for stopping and starting fractionating tower system and changing direction of cold low-fraction oil

ActiveCN108559545AQuality changeChange yieldTreatment with hydrotreatment processesHydrocarbon oils treatment productsChemical industryNaphtha

The invention belongs to the technical field of petroleum chemical industry, and discloses a residual oil hydrogenation refining process for stopping and starting a fractionating tower system and changing a direction of cold low-fraction oil. The cold low-fraction oil from a cold low-fraction tank does not enter an H2S stripping tower after the heat exchanging and is mixed with unstable naphtha onthe top of the H2S stripping tower, the mixture is sent into a gasoline-diesel hydrogenation refining apparatus to be separated, then fractionating tower system behind the H2S stripping tower is closed, and the bottom oil of the H2S stripping tower is used for directly enter the raw material primary heater to heat raw materials. The calculation shows that the investment is extremely small, the implementation performance is high, not only can the operation be simplified, but also the energy consumption can be reduced by about 60 percent, and no influence is produced on the quality of the yieldof the residual oil hydrogenation process and the refined residual oil. The residual oil hydrogenation refining process is suitable for improving an old apparatus and constructing a novel apparatus.

Owner:SOUTH CHINA UNIV OF TECH

A kind of preparation method of di-tertiary peroxide

ActiveCN107056670BRapid peroxidationWith operational continuityOrganic compound preparationPeroxy compound preparationDi-tert-butyl peroxideTert-butyl peroxide

The invention discloses a preparation method of di-tert-butyl peroxide. Tert-butyl alcohol, hydrogen peroxide and a catalyst are continuously introduced into a micro-reactor, so that tert-butyl alcohol and hydrogen peroxide are subjected to a peroxidation reaction, and a material flow containing a di-tert-butyl peroxide is prepared; the material flow containing the di-tert-butyl peroxide is led out from the micro-reactor, and the di-tert-butyl peroxide is obtained through separation, washing and drying, wherein the molar ratio of tert-butyl alcohol to hydrogen peroxide is 1:2-1:2.2, and the catalyst accounts for 10-20% of the total mass of tert-butyl alcohol, hydrogen peroxide and the catalyst. The process is simple, the micro-reactor good in safety is used for continuous production, the prepared di-tert-butyl peroxide is high in reaction selectivity and good in yield, the production procedures are reduced, and the production cost is reduced.

Owner:西安万德能源化学股份有限公司

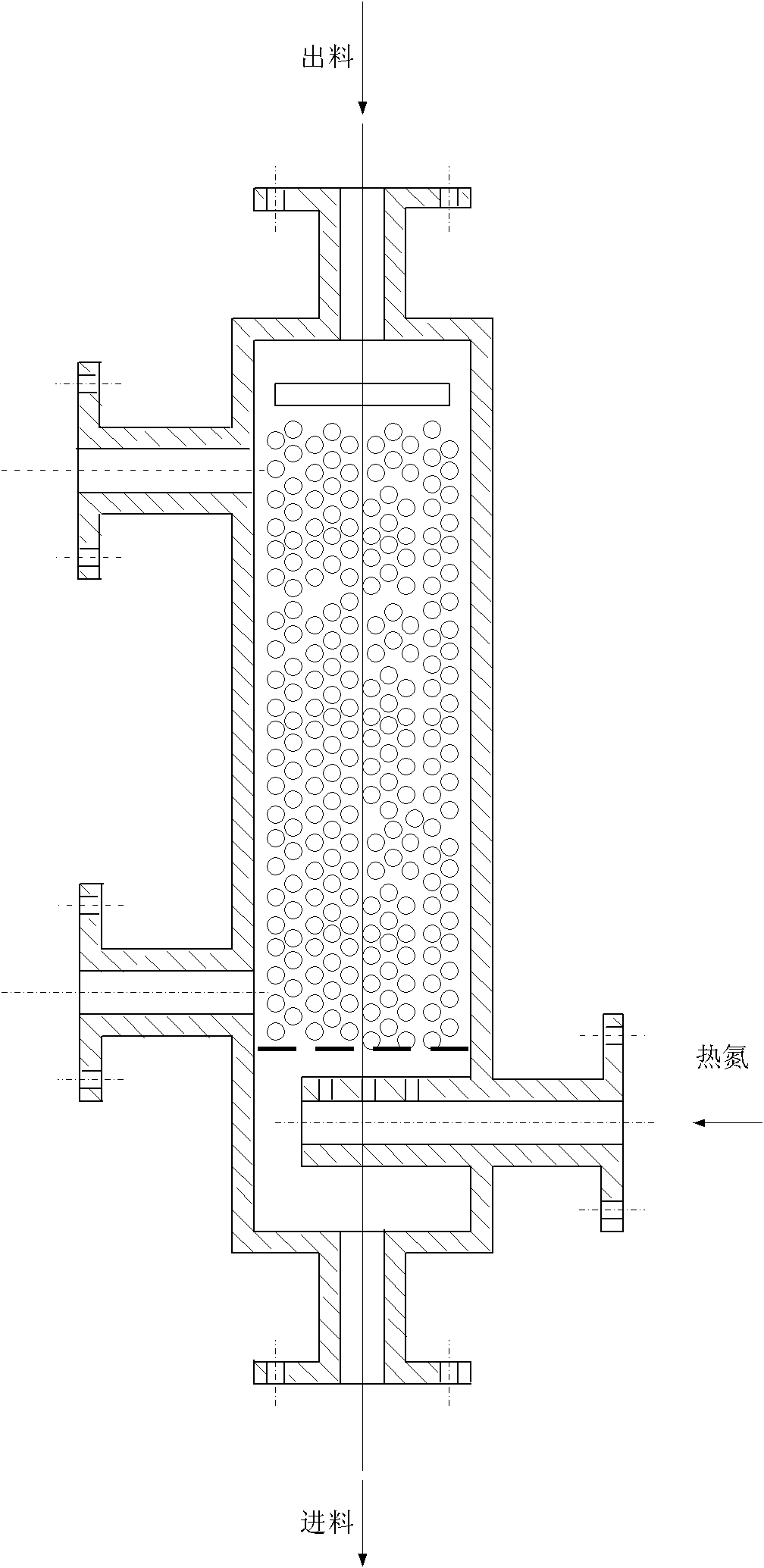

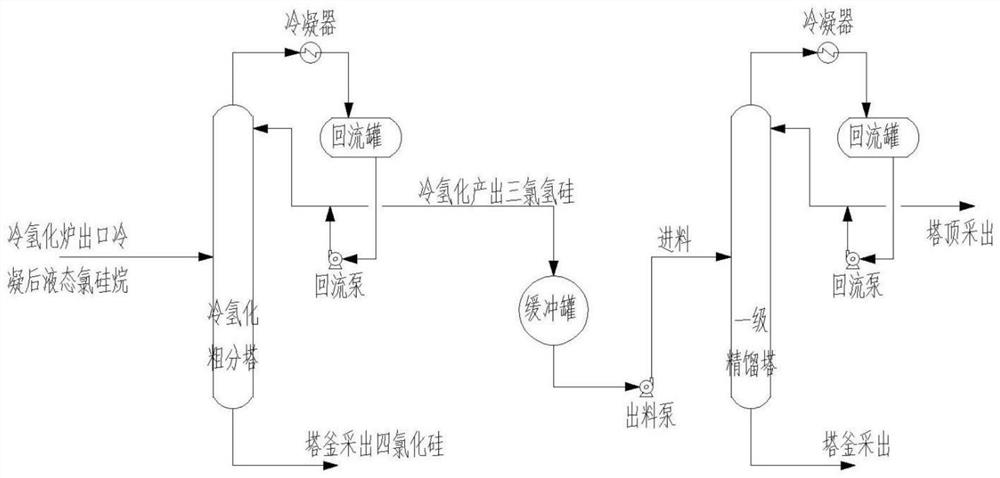

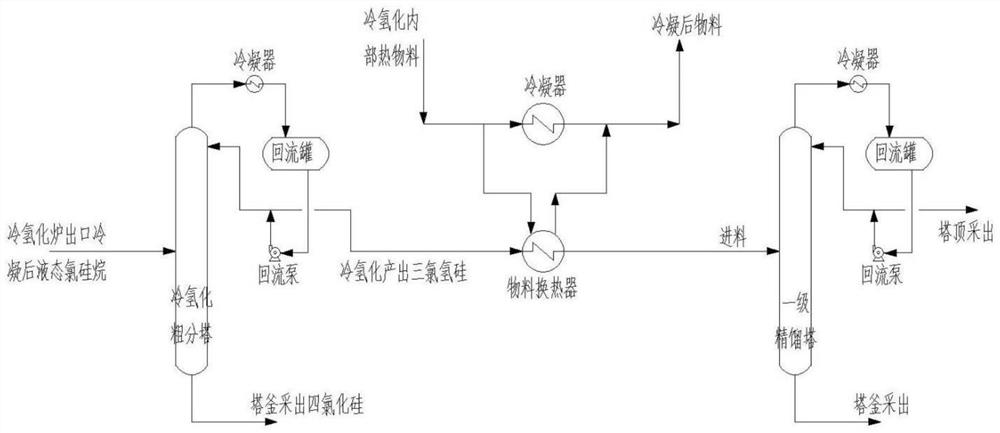

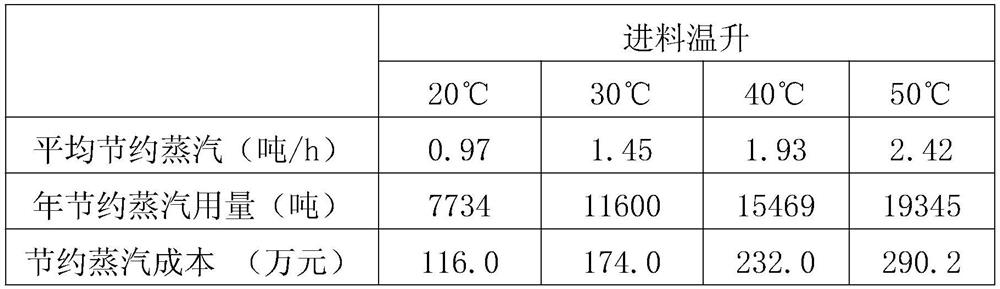

Trichlorosilane rectification process

PendingCN114014324AImprove recycling ratesRaise feed temperatureHalogenated silanesFractional distillationCooling towerFluid phase

The invention relates to a trichlorosilane rectification process. The rectification process comprises the following steps: carrying out heat exchange on a material 1 entering a cold hydrogenation coarse separation tower and a cooled tower top liquid-phase extracted material 2 of the cold hydrogenation coarse separation tower, and then entering the cold hydrogenation coarse separation tower, wherein the material 1 is a material with the outlet temperature of 80-150 DEG C of a cold hydrogenation furnace, and contains silicon trichloride and silicon tetrachloride. According to the trichlorosilane rectification process, the material at the temperature of 80-150 DEG C at the outlet of the cold hydrogenation reaction furnace is used for heating the produced trichlorosilane, the feeding temperature of the primary tower of the rectification system is increased, and the heated trichlorosilane directly enters the primary tower of the rectification system without passing through a buffer tank and a delivery pump, so that the energy consumption of the rectification process can be remarkably reduced.

Owner:XINJIANG DAQO NEW ENERGY

Method for reducing steam consumption in evaporation process

InactiveCN103101938AReduce water intakeReduce steam burdenAluminium oxides/hydroxidesCAUSTIC ALKALISChemistry

The invention relates to a method for reducing steam consumption in an evaporation process and belongs to the technical field of aluminum oxide production. The method comprises the following steps of: supplementing caustic alkali consumed by a system in a form of solid caustic alkali before an evaporation stock solution enters an evaporator set, uniformly mixing the solid caustic alkali with the evaporation stock solution in a stirring tank, dissolving the solid caustic alkali to release heat; absorbing the heat by the evaporation stock solution to heat up and then entering the evaporator set, and then entering an alkaline liquor blending tank after multiple-effect countercurrent evaporation, blending with partial unevaporated evaporation stock solution into a qualified alkaline liquor. The method has the following advantages and effects that useless water which enters a production system together with useful ingredient sodium hydroxide in a liquid caustic alkali can be reduced by the method, the water inflow of the system can be reduced, and the distilled water burden in the evaporation process can be reduced. By adopting the method, the alkalization process of the solid caustic alkali can be canceled, so that the primary investment and operating cost for constructing factories are reduced.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

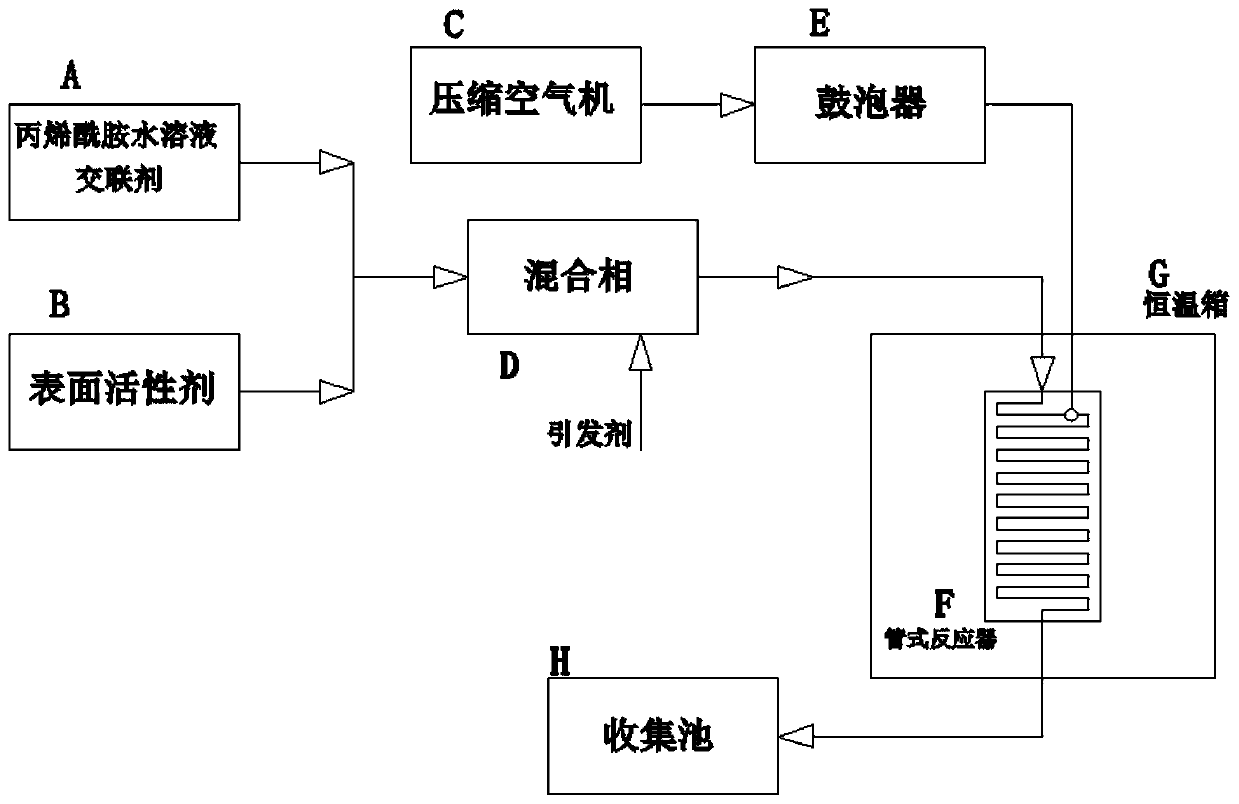

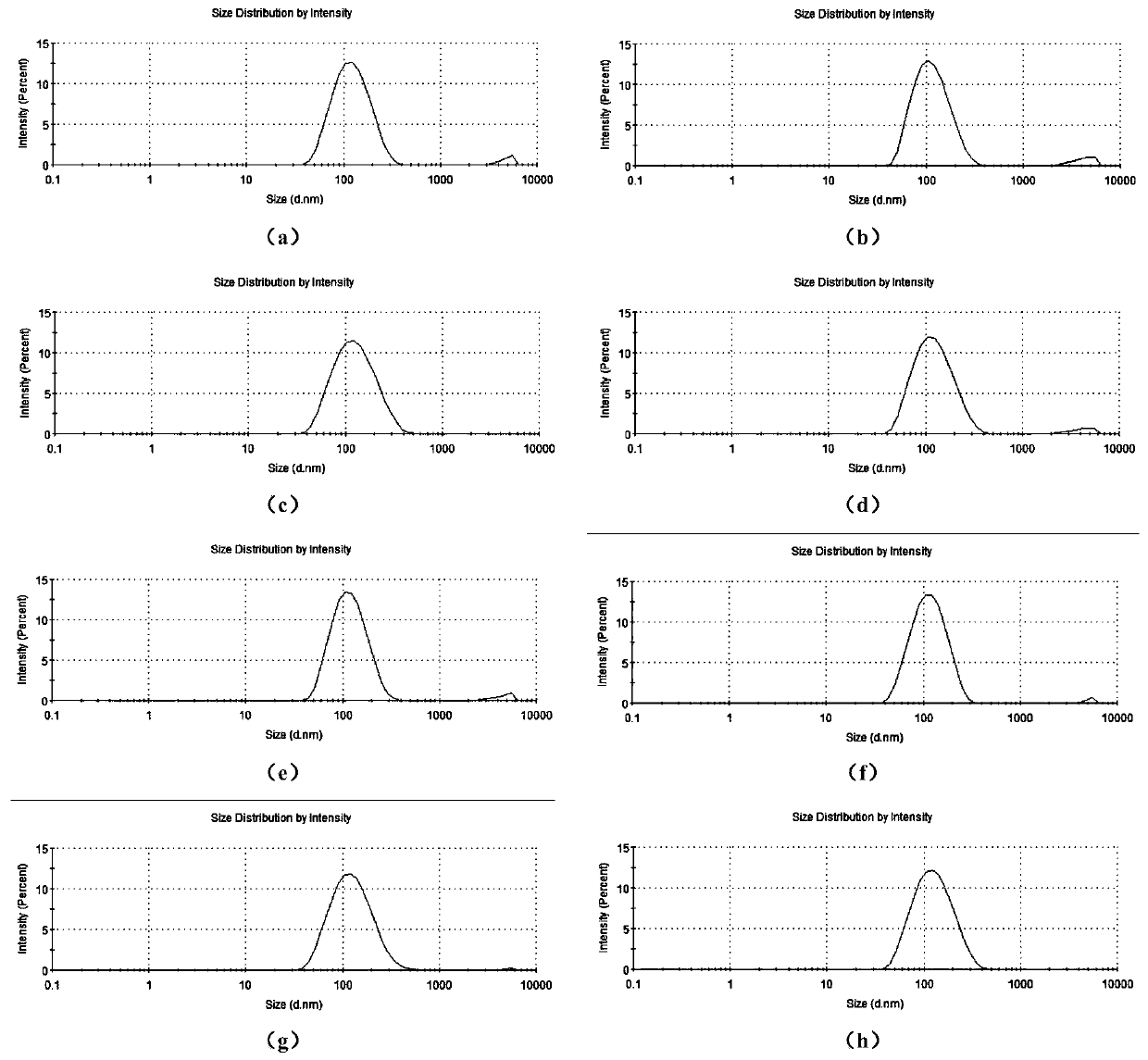

Preparation method and preparation device for polyacrylamide nanoparticles

ActiveCN110054727AFast polymerizationWith operational continuityMicroballoon preparationMicrocapsule preparationMicrosphereNanoparticle

The invention discloses a preparation method and a preparation device for polyacrylamide nanoparticles. The preparation method includes continuously introducing a liquid material, comprising acrylamide, crosslinking agents and initiators, and compressed air into a tubular reactor to decompose the initiators at a certain temperature to obtain free radicals, initiating polymerization of the acrylamide, guiding out a polyacrylamide-containing material from the tubular reactor, and collecting finished products of the polyacrylamide nanoparticles. The preparation method and the preparation device have the advantages that the process is simple, the high-safety tubular reactor is applied to continuous production, the prepared polyacrylamide nanoparticles have stable quality and uniform grain diameter, overflowing and colliding in a conventional kettle-type production process are avoided, and product quality and production efficiency are improved.

Owner:西安万德能源化学股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com