Method for reducing steam consumption in evaporation process

A technology of consumption and steam, which is applied in the field of reducing steam consumption and steam consumption in the evaporation process, and can solve the problems of unreasonable and effective use of heat energy, etc., to reduce primary investment and operating costs, reduce water intake, and reduce steaming water burden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

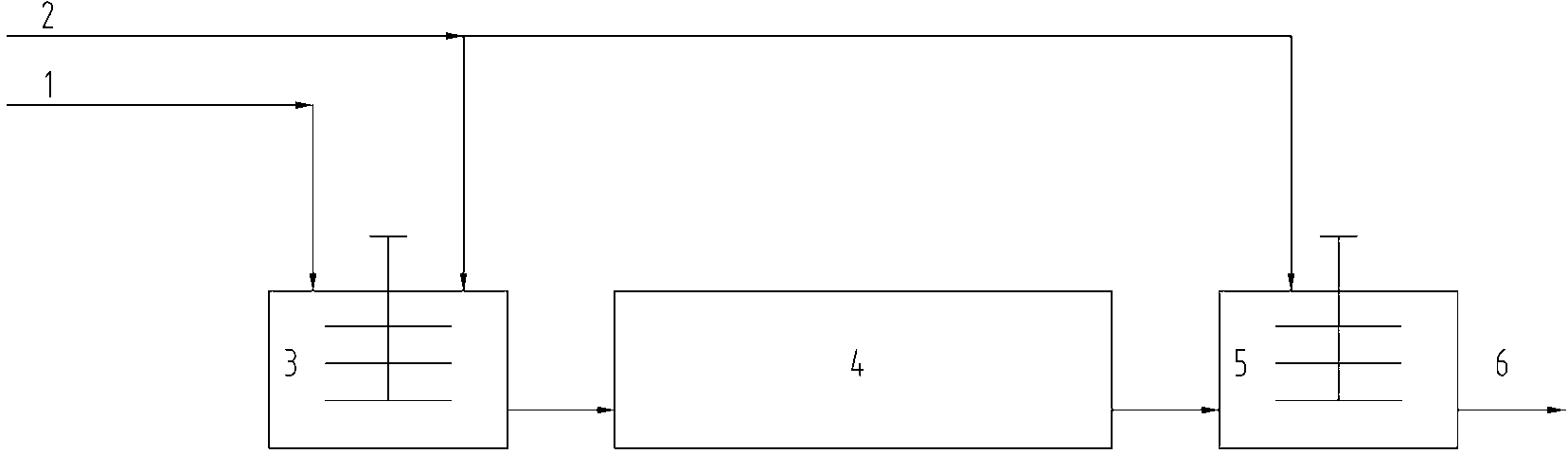

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

[0017] As shown in the figure, the method for reducing steam consumption in the evaporation process of the present invention supplements the caustic consumed by the system in the form of solid caustic 1, and the addition position is before the evaporation stock solution 2 enters the evaporator group 4, and the solid caustic 1 and the evaporation stock solution 2 Mix evenly in the stirring tank 3, the solid caustic 1 dissolves and releases heat, the evaporated stock solution 2 absorbs the heat and heats up, then enters the evaporator group 3, after multi-effect countercurrent evaporation, enters the lye preparation tank 4, and part of the unevaporated Evaporation stock solution 2 is allocated into qualified lye 6.

[0018] The solid caustic 1 is directly added to the stirring tank 3 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com