Mud and sand recovery and recycling process

A mud sand and process technology, which is applied in the field of mud sand recycling and reuse technology, can solve the problems of low recycling rate and small recycling amount, and achieve the effect of reducing environmental pollution and reducing water intake.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

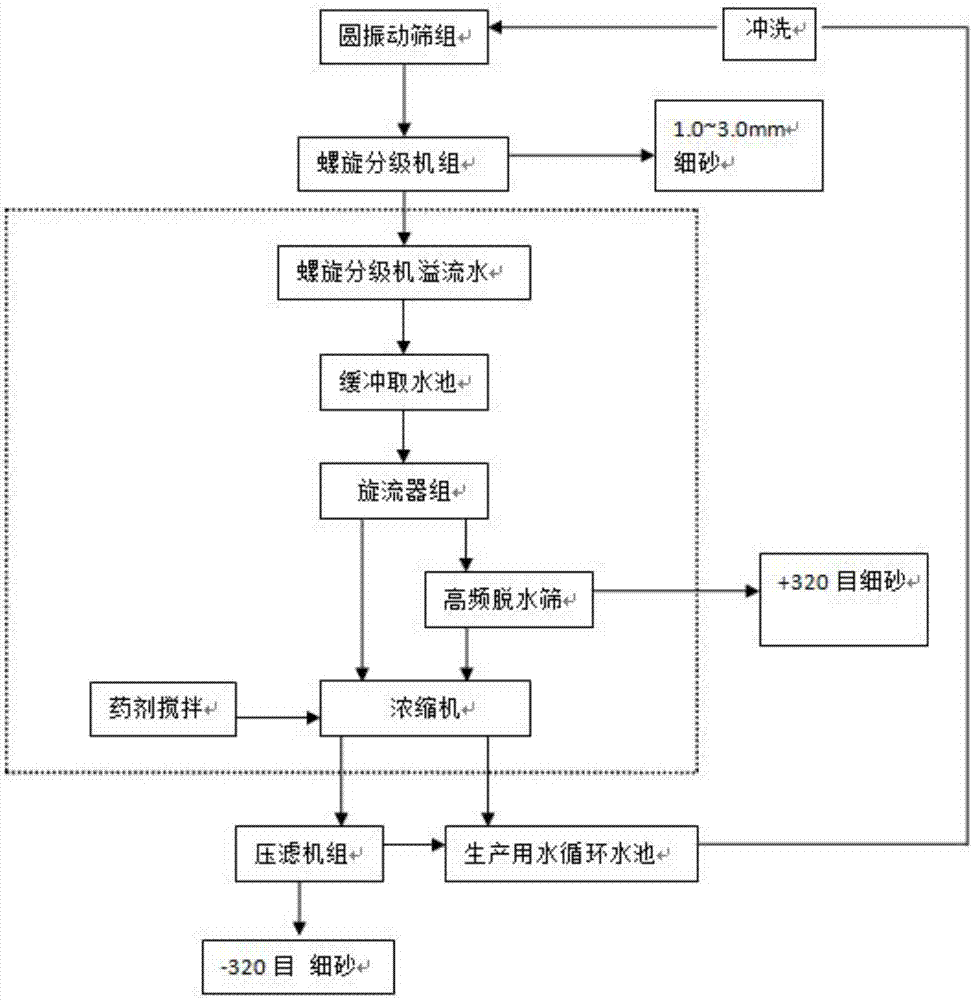

[0019] combined with figure 1 A mud sand recycling process of the present invention will be further described.

[0020] A kind of silt recycling process of the present invention comprises the following steps:

[0021] (1) Collection and washing: Set up a water circulation pool for stacking mud-sand-water mixture, and wash the mud and sand through water circulation;

[0022] (2) The first recovery: the washed mud-sand-water mixture is sequentially introduced into the circular vibrating screen group and the spiral classifier unit to extract 1.0-3.0mm fine sand;

[0023] (3) The mud and sand overflow water separated by the spiral classifying unit is introduced into the buffer water intake tank for collection;

[0024] (4) Pre-separation: The mud and sand overflow water is introduced into the cyclone group, the coarser mud and sand are discharged through the bottom outlet of the cyclone, and the mud and sand water mixed with finer particles is discharged from the cyclone overflo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com