Preparation method and preparation device for polyacrylamide nanoparticles

A polyacrylamide and nano-microsphere technology, which is applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of inaccurate temperature control, influence of reaction heat transfer, damage of stirring rod motor, etc., to avoid the phenomenon of automatic reaction acceleration, The effect of short reaction time and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

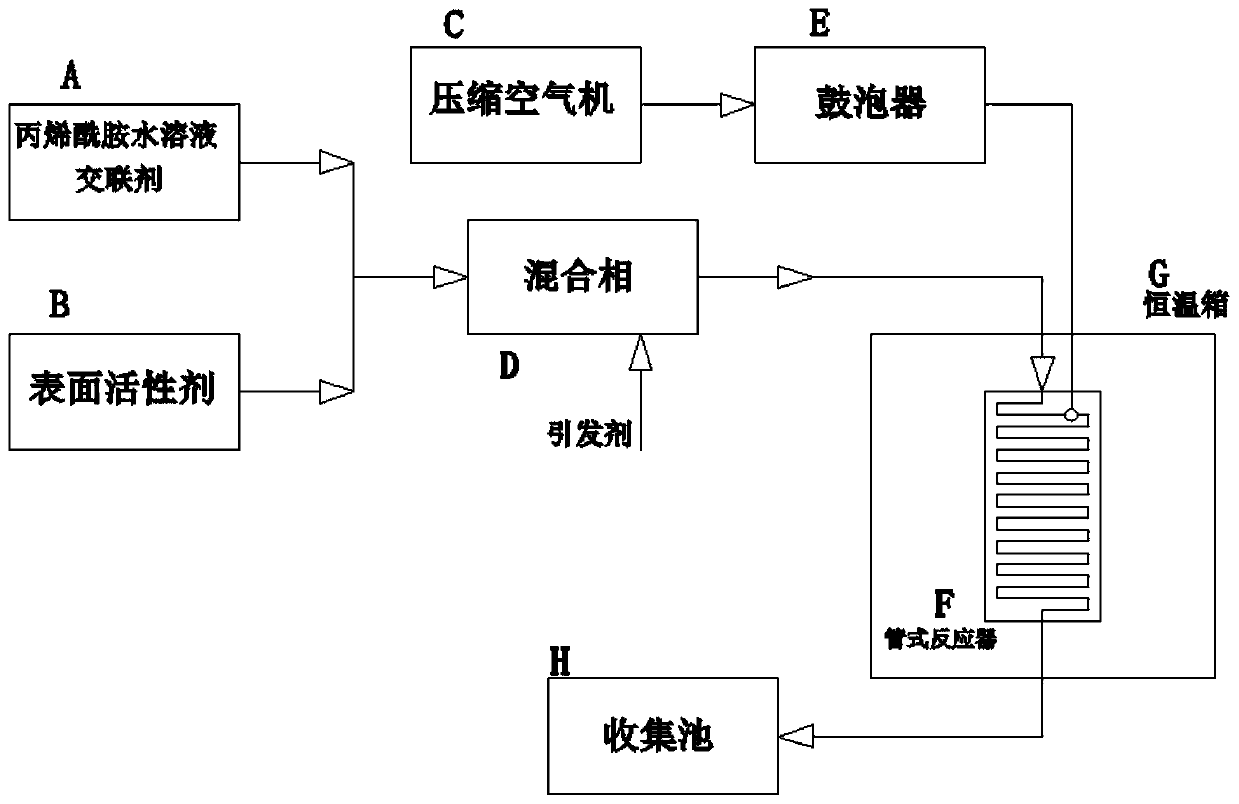

[0036] Such as figure 1 As shown, the acrylamide aqueous solution, crosslinking agent, and surfactant are transferred from A and B to the mixing tank by the mechanical pump, and then the initiator is added. After stirring and mixing evenly, the feed pump is transported to the tubular reaction At the same time, the air compressor was turned on, and the compressed air was pumped through the bubbler into the inlet of the front section of the microtube reaction at a frequency of 5 times / min. The total rate of liquid material and compressed air is 50mL / min, the molar ratio of acrylamide and crosslinking agent is 1:0.001, the amount of initiator is 0.01% of the total mass of acrylamide and crosslinking agent, and the volume of compressed air intake is as large as possible for liquid materials 0.1% by volume. The tubular reactor F has an inner diameter of 4 mm and a length of 80 m. It is placed in an incubator G with a reaction temperature of 55° C. and a reaction residence time of ...

Embodiment 2

[0040] Such as figure 1 As shown, the acrylamide aqueous solution, crosslinking agent, and surfactant are transferred from A and B to the mixing tank by the mechanical pump, and then the initiator is added. After stirring and mixing evenly, the feed pump is transported to the tubular reaction At the same time, the air compressor was turned on, and the compressed air was pumped through the bubbler into the inlet of the front section of the microtube reaction at a frequency of 15 times / min. The total rate of liquid material and compressed air is 60mL / min, the molar ratio of acrylamide and crosslinking agent is 1:0.01, the amount of initiator is 0.03% of the total mass of acrylamide and crosslinking agent, and the volume of compressed air intake is as large as possible for liquid material 0.3% by volume. The tubular reactor F has an inner diameter of 6 mm and a length of 50 m. It is placed in an incubator G with a reaction temperature of 60° C. and a reaction residence time of 1...

Embodiment 3

[0044] Such as figure 1 As shown, the acrylamide aqueous solution, crosslinking agent, and surfactant are transferred from A and B to the mixing tank by the mechanical pump, and then the initiator is added. After stirring and mixing evenly, the feed pump is transported to the tubular reaction At the same time, the air compressor was turned on, and the compressed air was pumped through the bubbler into the inlet of the front section of the microtube reaction at a frequency of 9 times / min. The total rate of liquid material and compressed air is 600mL / min, the molar ratio of acrylamide and cross-linking agent is 1:0.04, the amount of initiator is 0.12% of the total mass of acrylamide and cross-linking agent, and the volume of compressed air intake is as large as possible for liquid materials 0.5% by volume. The tubular reactor F has an inner diameter of 10 mm and a length of 80 m. It is placed in an incubator G with a reaction temperature of 62° C. and a residence time of 628 s....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com