A kind of bisbenzenesulfonate interfacial initiator and preparation method thereof

A bisbenzene sulfonate and initiator technology, applied in the preparation of sulfonate, organic chemistry, etc., can solve the problems of insufficient functionality of block polymers, inability to achieve cross-phase polymerization, insufficient improvement of initiators, etc., to achieve Fast polymerization reaction, high conversion rate, mild and controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

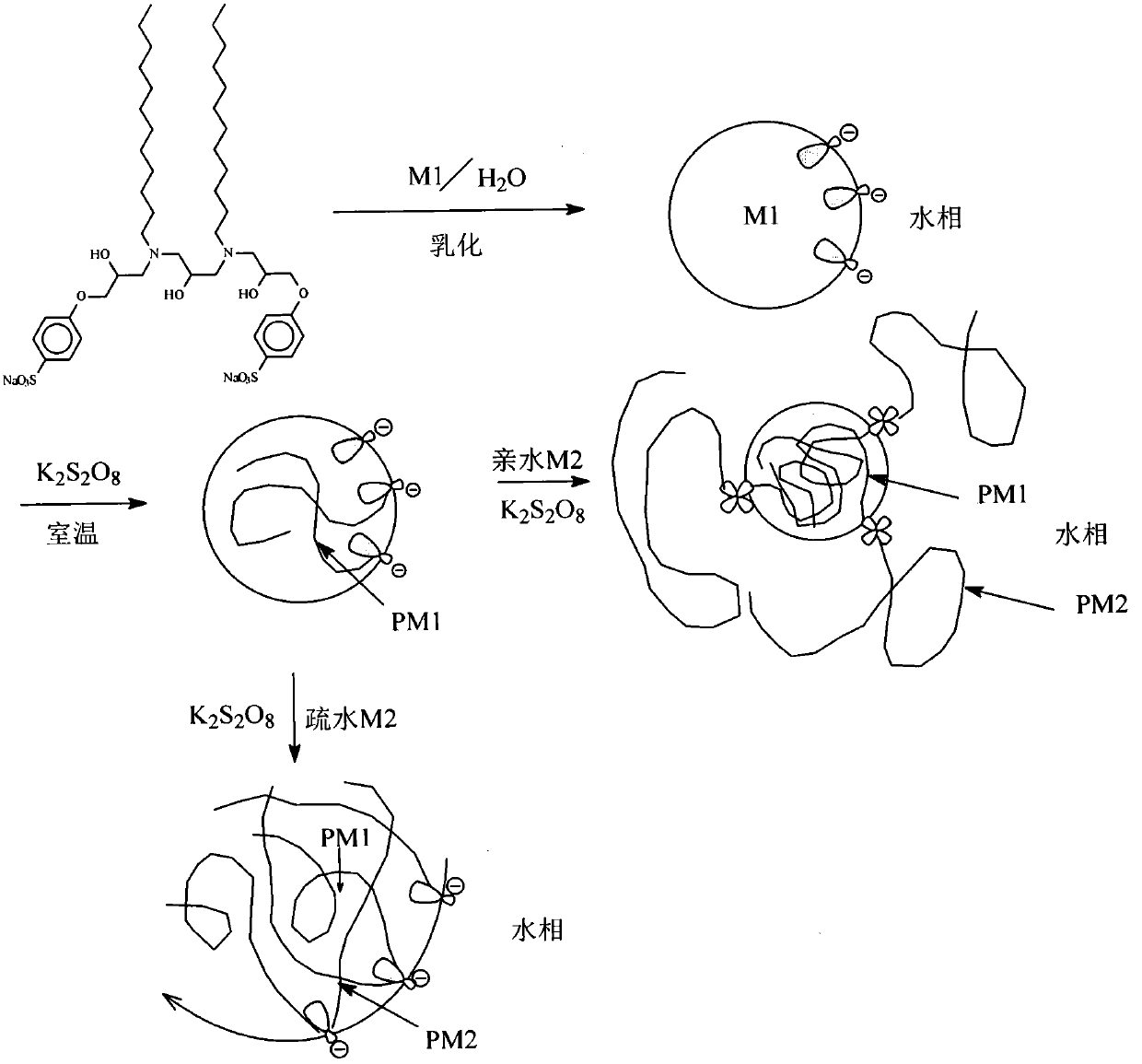

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention is described in further detail.

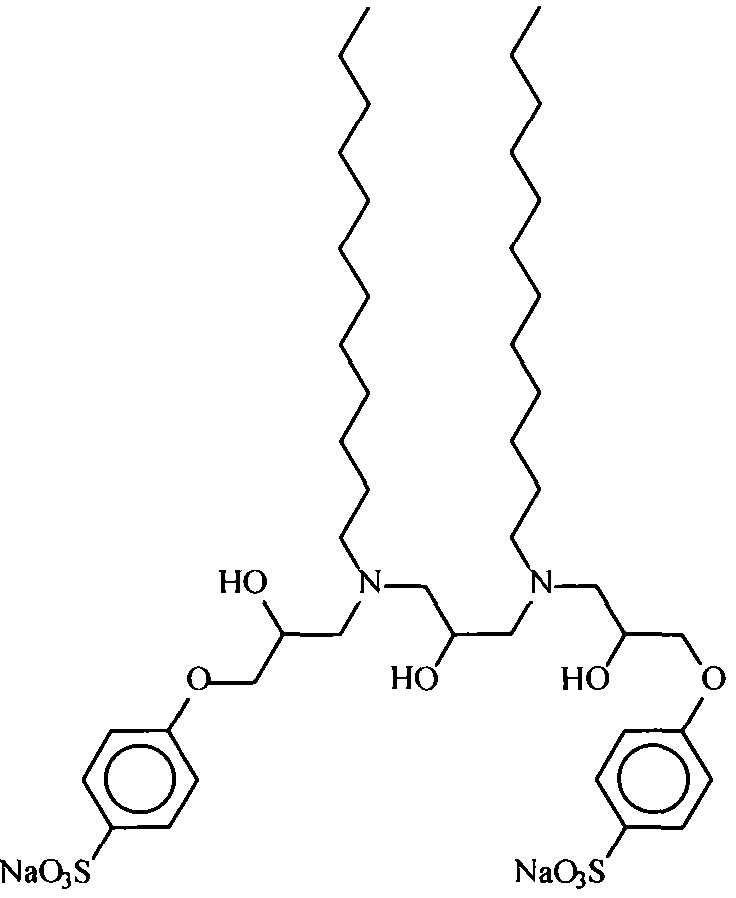

[0020] The preparation of bis-benzenesulfonate interfacial initiator:

[0021] 1. Mix and dissolve dodecylamine and epichlorohydrin in absolute ethanol as far as possible according to the molar ratio of 2:1. The weight ratio of dodecylamine to ethanol is controlled in the range of 1:4.5 to 1:5. Control the reaction temperature in the range of 50-60°C, and the reaction time is 3-4 hours. After the reaction is completed, cool to room temperature, add solid NaOH, and stir continuously to dissolve NaOH;

[0022] 2. Add epichlorohydrin to the above reaction liquid again, and control the molar ratio of epichlorohydrin to dodecylamine at 1:1 as much as possible, and control the reaction temperature in the range of 25-30°C under stirring, and react for 10-12 Cool to room temperature after 1 hour;

[0023] 3. Add solid NaOH and sodium p-hydroxybenzenesulfonate with the same number of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com