Cf/ZrB2-SiC ultrahigh-temperature ceramic matrix composite material of laminated structure and preparing method thereof

A technology of ultra-high temperature ceramics and layered structure, which is applied in the field of layered structure Cf/ZrB2-SiC ultra-high temperature ceramic matrix composite material and its preparation, can solve the problems of long preparation period, difficult to obtain, fiber/interface damage, etc. The effects of improving ablation resistance and oxidation resistance, simple and easy preparation process, and controllable matrix composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

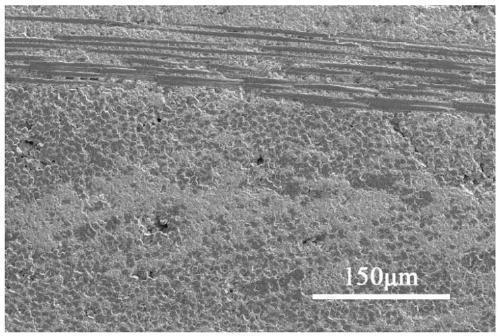

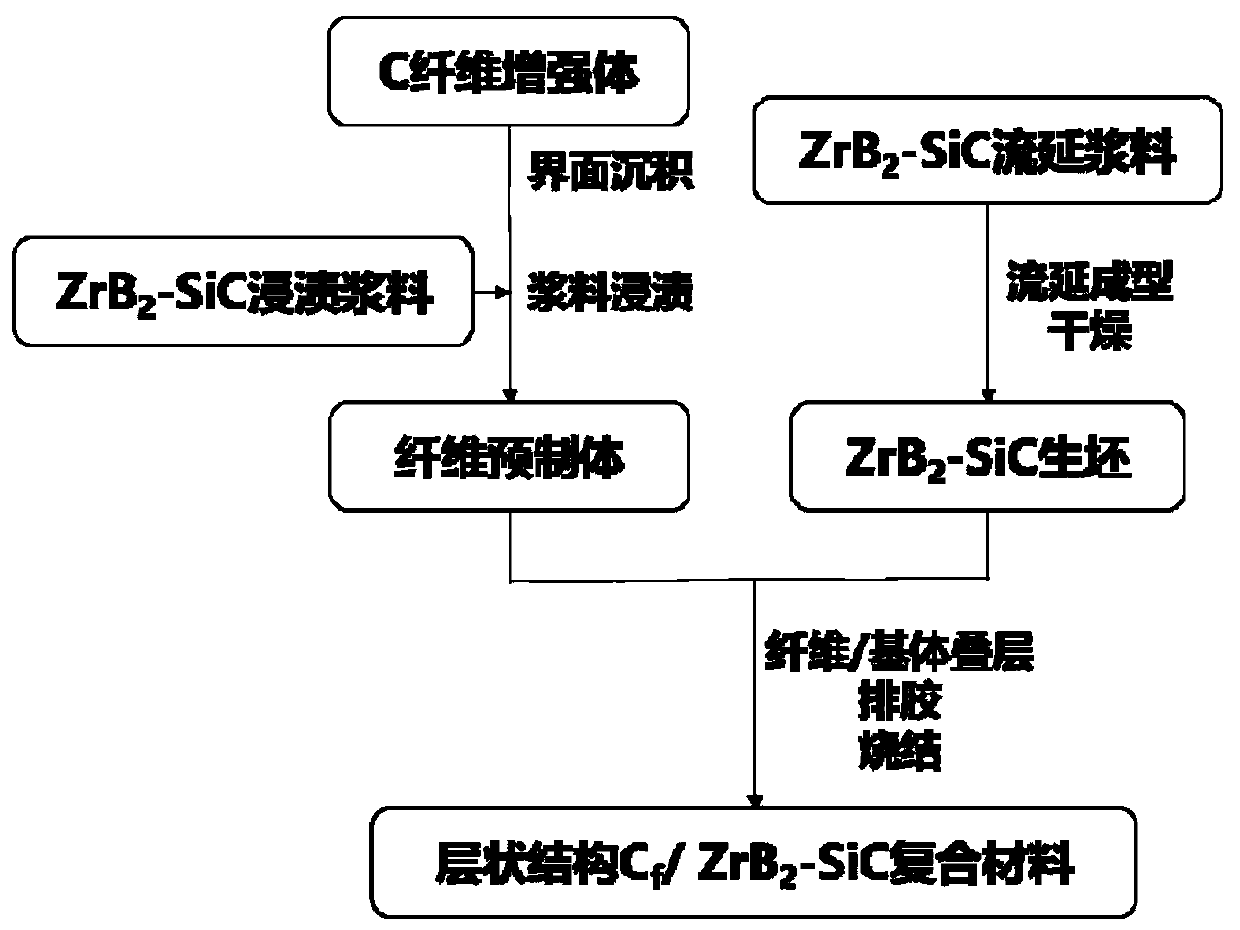

[0040] Fiber reinforcement interface deposition: select two-dimensional carbon fiber woven cloth (thickness 100 μm ~ 1mm) as the reinforcement, and use chemical vapor deposition method to deposit a PyC / SiC composite interface with a thickness of 100 nm on the surface of the fiber;

[0041] Slurry preparation: use absolute ethanol as solution, 15wt% (accounting for powder mass) polyvinylpyrrolidone as dispersant and binder, add ZrB pre-mixed by ball milling 2 - 20vol% SiC powder with a solid content of 60wt%. Ball milling for 24 hours to obtain a slurry for impregnation with good dispersibility and fluidity;

[0042] Impregnation: place the fiber reinforcement at the deposition interface in the slurry, and impregnate it for 30 minutes under the condition of vacuum degree -0.08MPa. After impregnating the obtained fiber cloth and drying it at 60°C, a carbon fiber preform is obtained;

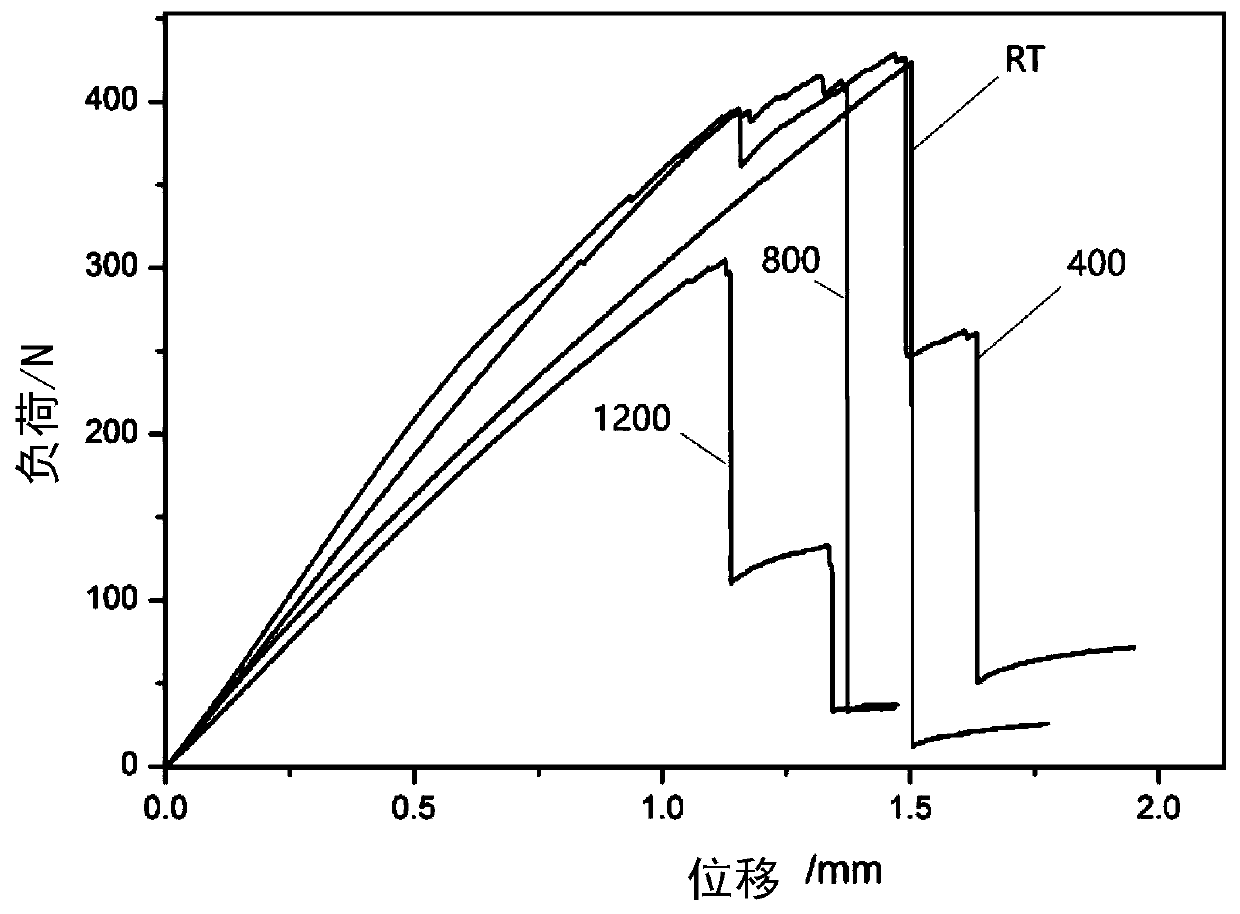

[0043] Preparation of cast green body: cast the above slurry into a film, dry at room tempera...

Embodiment 2

[0047] Similar to the steps in Example 1, the difference is that the fiber surface deposition thickness is 100nm P y C interface. The resulting layered structure C f / ZrB 2 - The content of carbon fiber in SiC ultra-high temperature ceramic matrix composite material is ~30vol%, the porosity is ~3.5%, ZrB 2 Content is ~55vol%, air plasma ablation 3MW / m 2 After 2 minutes of ablation, the line ablation rate was only ~1.8μm / s.

Embodiment 3

[0049] Similar to the steps in Example 1, the difference is that the dispersant is 5wt% polyvinyl chloride, and the binder is 10wt% polyvinyl butyral. The resulting layered structure C f / ZrB 2 - The content of carbon fiber in SiC ultra-high temperature ceramic matrix composite material is ~30vol%, the porosity is ~3.5%, ZrB 2 Content is ~55vol%, air plasma ablation 3MW / m 2 After 2 minutes of ablation, the line ablation rate was only ~1.8μm / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com