Carbon fabric integer fabric carbon-copper composite material and method of manufacturing thereof

A composite material and carbon fiber technology, which is applied in the field of carbon fiber integral fabric/carbon-copper composite material and its preparation, can solve the problems of poor wettability and achieve high conductivity, good conductivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

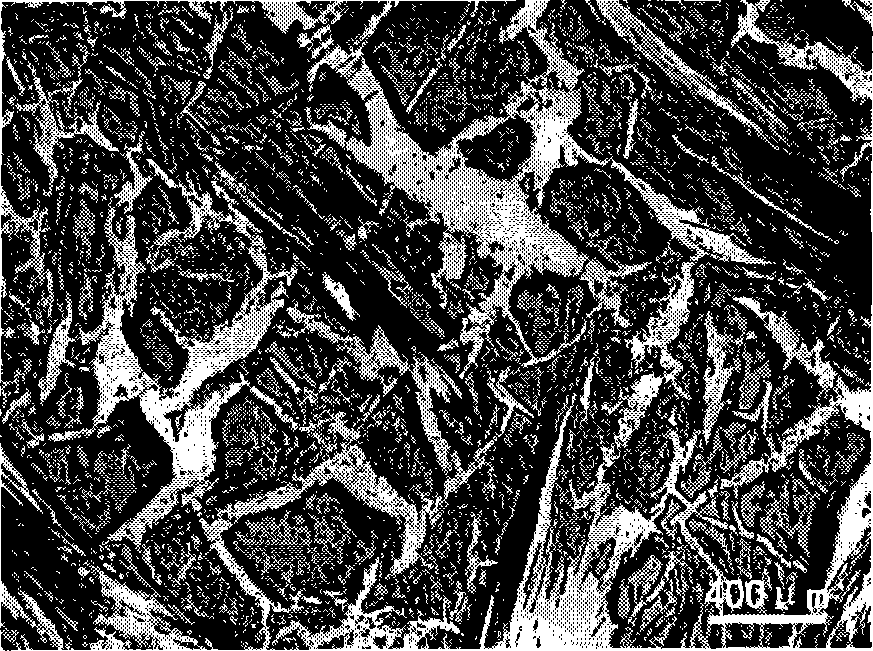

Image

Examples

Embodiment 1

[0019] Needle-punched integral felt made of polypropylene nitrile carbon fiber, densified to 0.7g / cm by chemical vapor infiltration 3 The porous carbon composite green body was tempered at 2500°C; an infiltration agent with a Cu / Ti mass ratio of 9.5:0.5 was prepared; the carbon green body was embedded with the prepared infiltration agent, and kept at 1100°C for 30 minutes under vacuum conditions , and the carbon fiber monolithic fabric / carbon-copper composite material was prepared.

[0020] Its main performance indicators are shown in the table below:

[0021] density

Embodiment 2

[0023] Needle-punched integral felt made of polypropylene nitrile carbon fiber, densified to 1.35g / cm by chemical vapor infiltration 3 The porous carbon composite green body was tempered at 2300°C; an infiltration agent with a mass ratio of Cu / Ti of 9:1 was prepared; the carbon green body was embedded with the prepared infiltration agent, and kept at 1300°C for 30 minutes under vacuum conditions , and the carbon fiber integral fabric / carbon-copper composite material was prepared.

[0024] Its main performance indicators are shown in the table below:

[0025] density

Embodiment 3

[0027] Needle-punched integral felt made of polypropylene nitrile carbon fiber, densified to 1.5g / cm by impregnation and carbonization 3 The porous carbon composite green body was tempered at 2000°C; an infiltration agent with a Cu / Ti mass ratio of 7.5:2.5 was prepared; the carbon green body was embedded with the prepared infiltration agent, and kept at 1450°C for 30 minutes under vacuum conditions , and the carbon fiber monolithic fabric / carbon-copper composite material was prepared.

[0028] Its main performance indicators are shown in the table below:

[0029] density

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com