Sprayable silicone rubber-based lightweight ablation-resistant thermal insulation coating and application thereof

A heat-insulating coating and ablation-resistant technology, applied in fire-resistant coatings, coatings, filling pastes, etc., can solve the problems of inability to cure, inability to bond metal substrates, etc., to improve the interface bonding force, facilitate construction, and facilitate construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

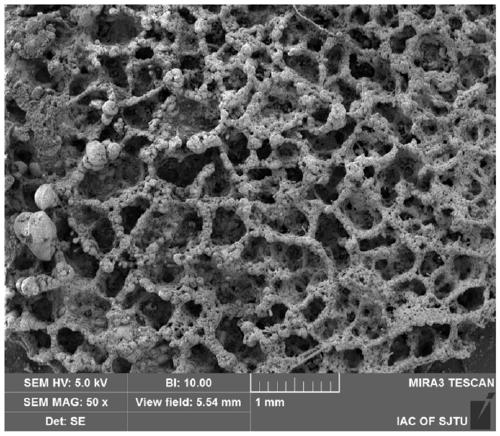

[0035] The sprayable silicone rubber-based lightweight ablation-resistant paint of the invention is composed of two components, A and B, in certain parts by mass. 100 parts of room temperature vulcanized silicone rubber, 45 parts of flame retardant filler, 3.2 parts of carbon-based reinforcing filler, 10 parts of silicon-based reinforcing filler, 0.1 part of dispersing aid, 5 parts of coupling agent, 120 parts of solvent,

[0036] Among them, the room temperature vulcanized silicone rubber is preferably methylphenyl vinyl silicone rubber with a viscosity of 5000 mpa.s.

[0037] Among them, the flame-retardant filler is preferably a combination of iron oxide, magnesium hydroxide, montmorillonite and cork powder, and the ratio of parts by mass is 6:25:4:10.

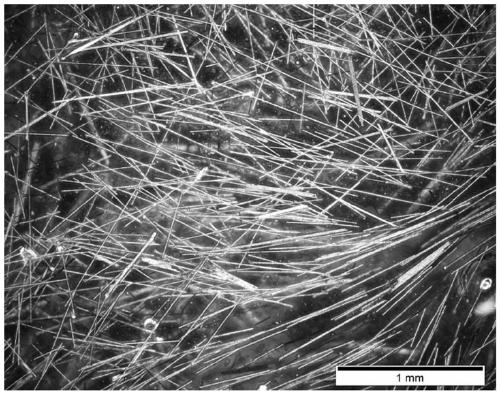

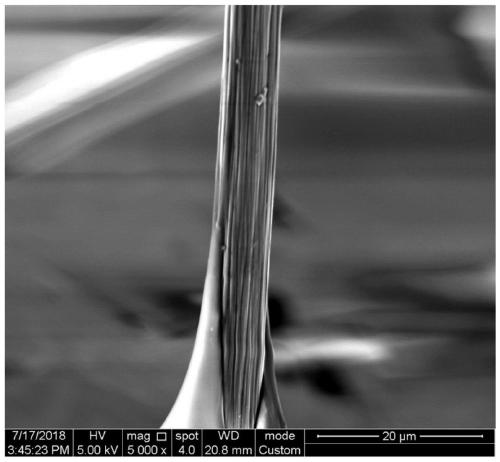

[0038]Wherein, the chopped carbon fiber modified coupling agent is KH-550; the preferred chopped carbon fiber has a diameter of 7 μm and a length of 1 mm. The modified carbon fiber is first oxidized in a muffle furnace at ...

Embodiment 2

[0061] The sprayable silicone rubber-based lightweight ablation-resistant paint of the invention is composed of two components, A and B, in certain parts by mass. 80 parts of room temperature vulcanized silicone rubber, 45 parts of flame retardant filler, 5 parts of carbon-based reinforcing filler, 10 parts of silicon-based reinforcing filler, 0.1 parts of dispersing aid, 5 parts of coupling agent, 100 parts of solvent,

[0062] Among them, the room temperature vulcanized silicone rubber is preferably methylphenylvinyl silicone rubber and dimethyl silicone rubber with a viscosity of 2000mpa.s, and the mass ratio is 2:1.

[0063] Among them, the flame-retardant filler is preferably a combination of iron oxide, magnesium hydroxide, montmorillonite and cork powder, and the ratio of parts by mass is 6:25:4:10.

[0064] Wherein, the chopped carbon fiber modified coupling agent is KH-550; the preferred chopped carbon fiber has a diameter of 7 μm and a length of 1 mm. The modified c...

Embodiment 3

[0071] The sprayable silicone rubber-based lightweight ablation-resistant paint of the invention is composed of two components, A and B, in certain parts by mass. 110 parts of room temperature vulcanized silicone rubber, 45 parts of flame retardant filler, 4 parts of carbon-based reinforcing filler, 10 parts of silicon-based reinforcing filler, 0.1 parts of dispersing aid, 5 parts of coupling agent, 150 parts of solvent,

[0072] Among them, the room temperature vulcanized silicone rubber is preferably methylphenylvinyl silicone rubber and dimethyl silicone rubber with a viscosity of 7000mpa.s, and the mass ratio is 3:1.

[0073] Among them, the flame-retardant filler is preferably a combination of iron oxide, magnesium hydroxide, montmorillonite and cork powder, and the ratio of parts by mass is 6:25:4:10.

[0074] Wherein, the chopped carbon fiber modified coupling agent is KH-550; the preferred chopped carbon fiber has a diameter of 7 μm and a length of 1 mm. The modified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com