Patents

Literature

50results about How to "Improve pullout strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

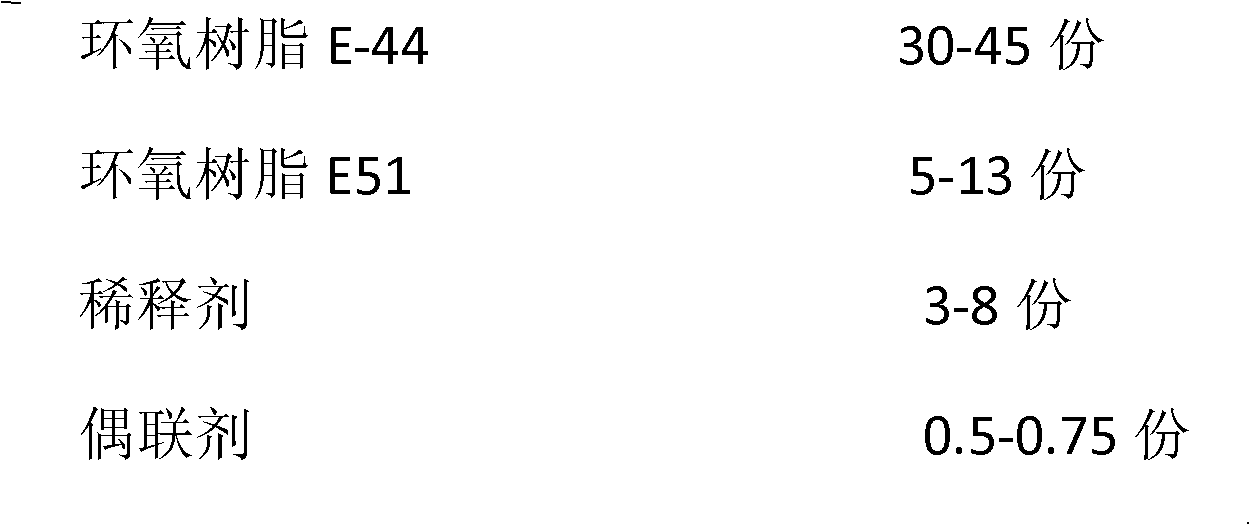

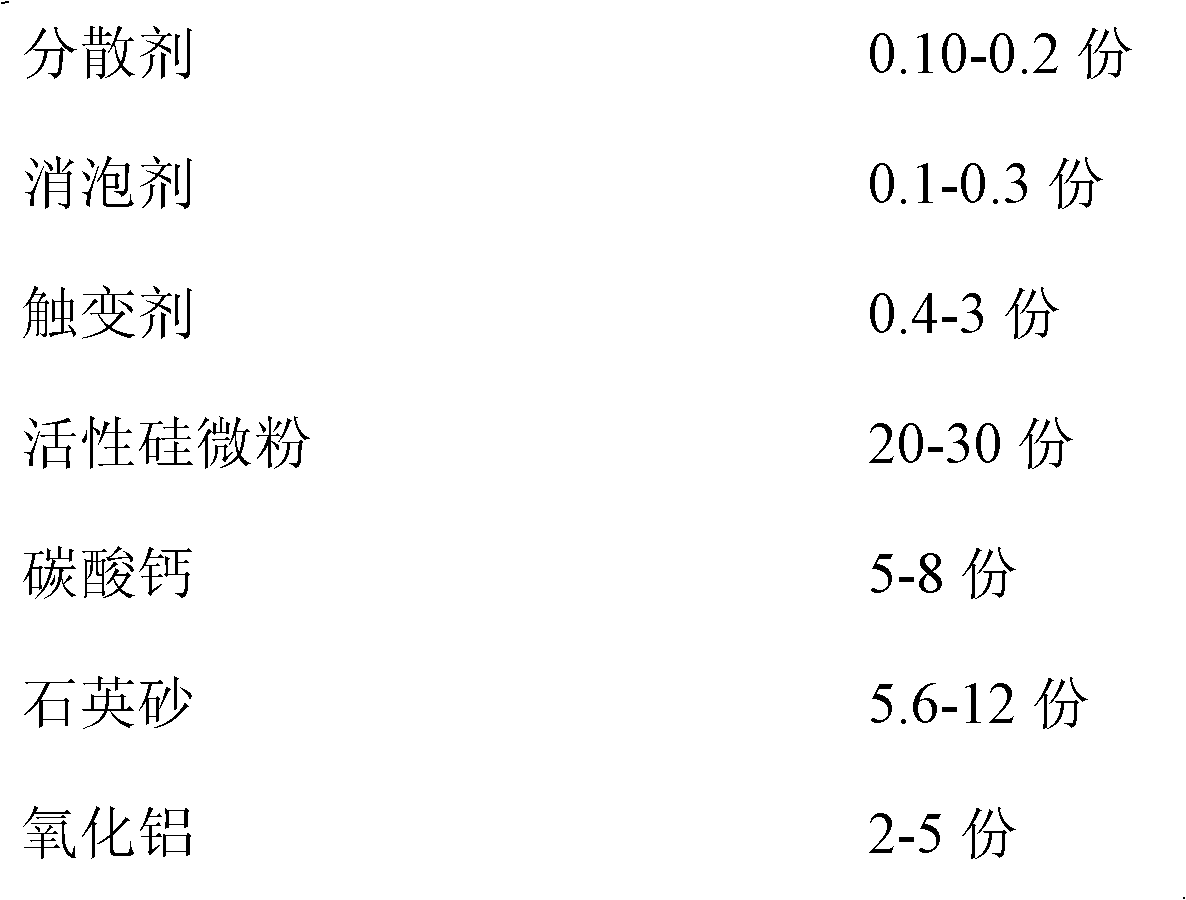

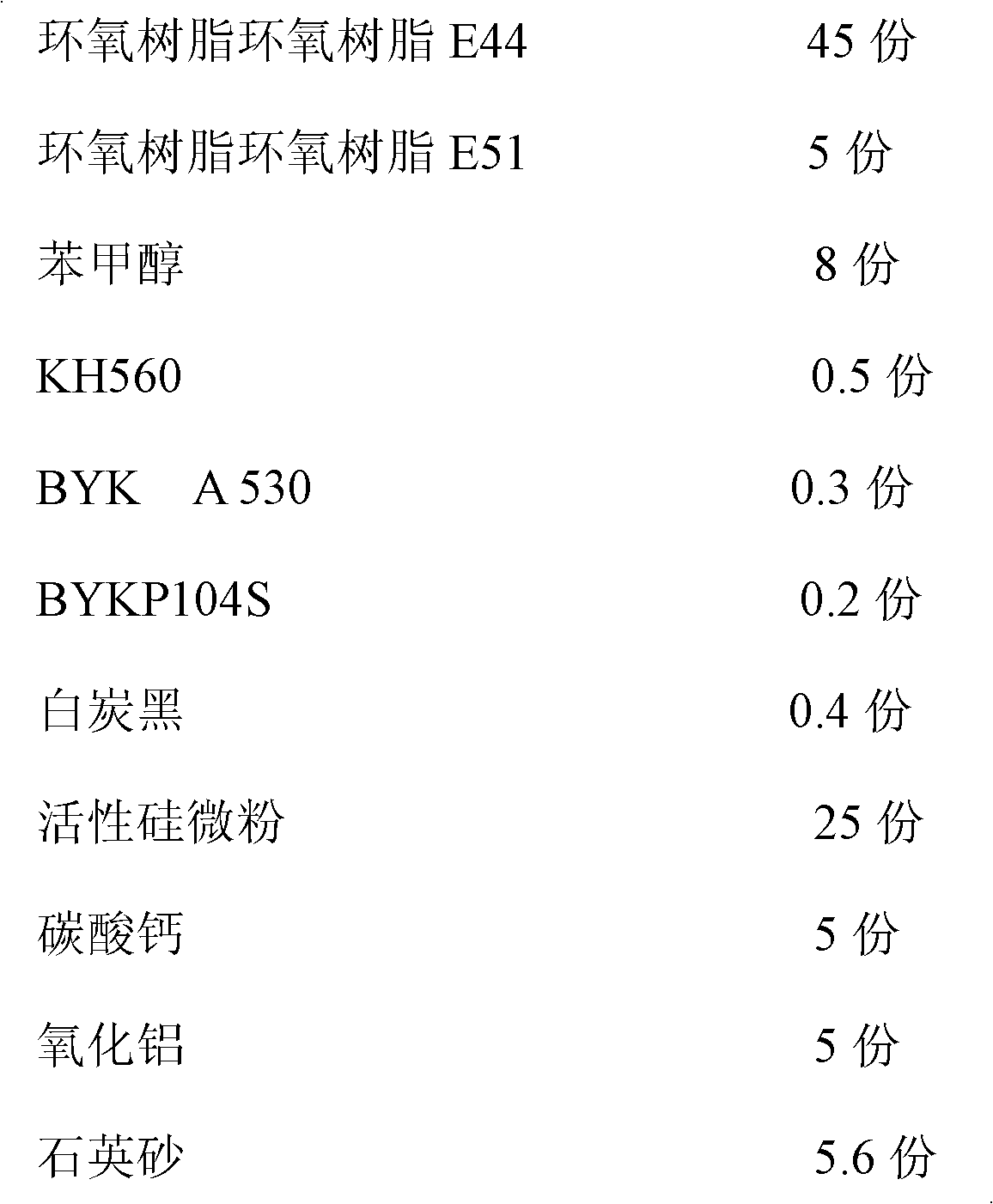

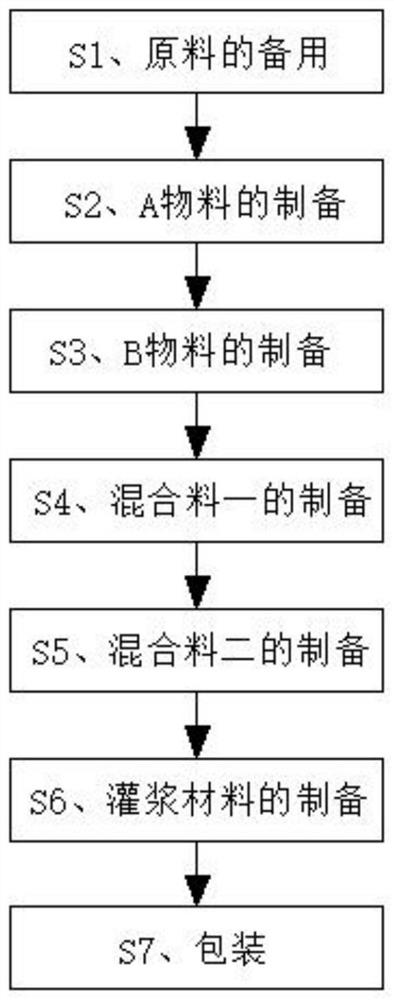

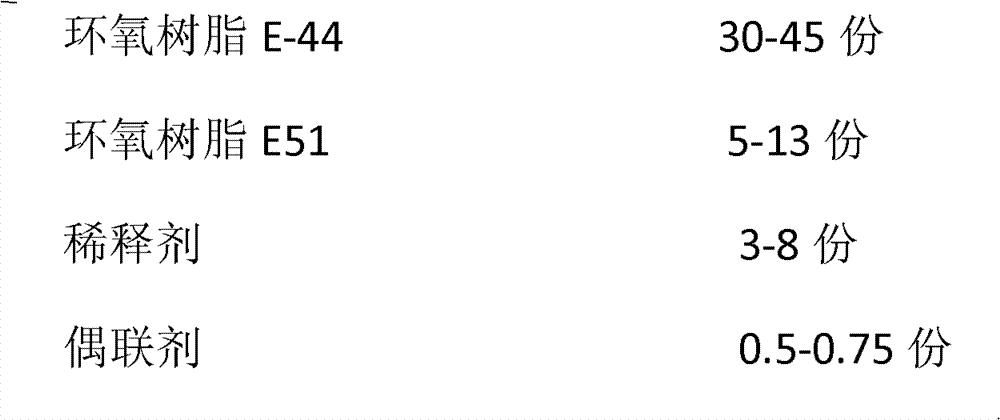

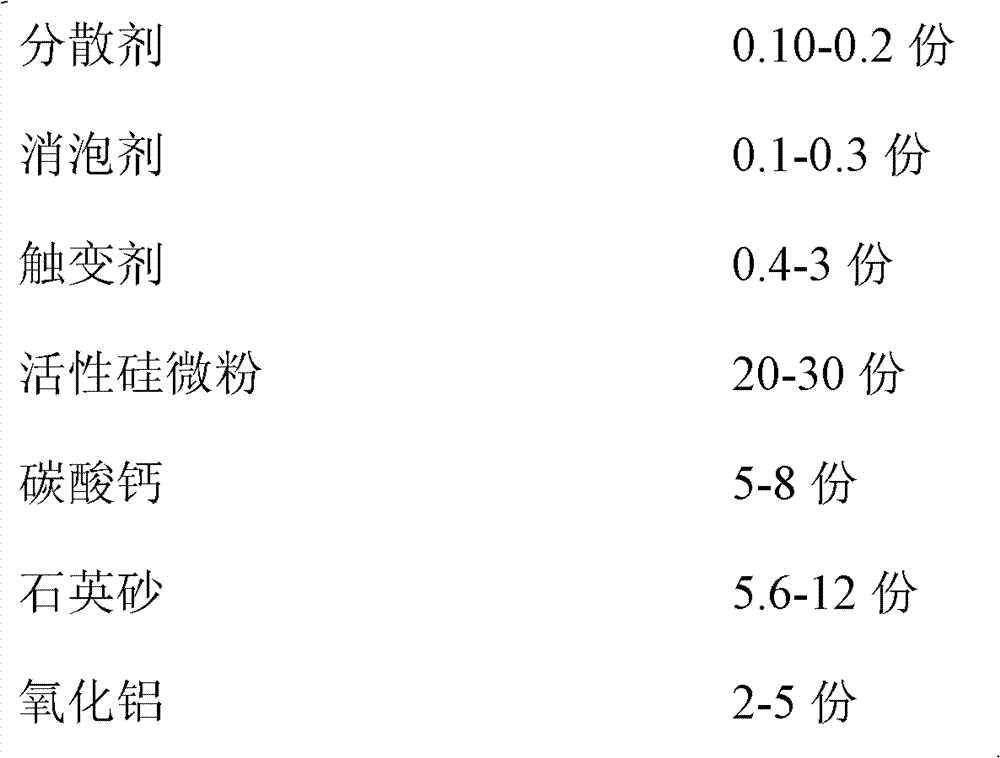

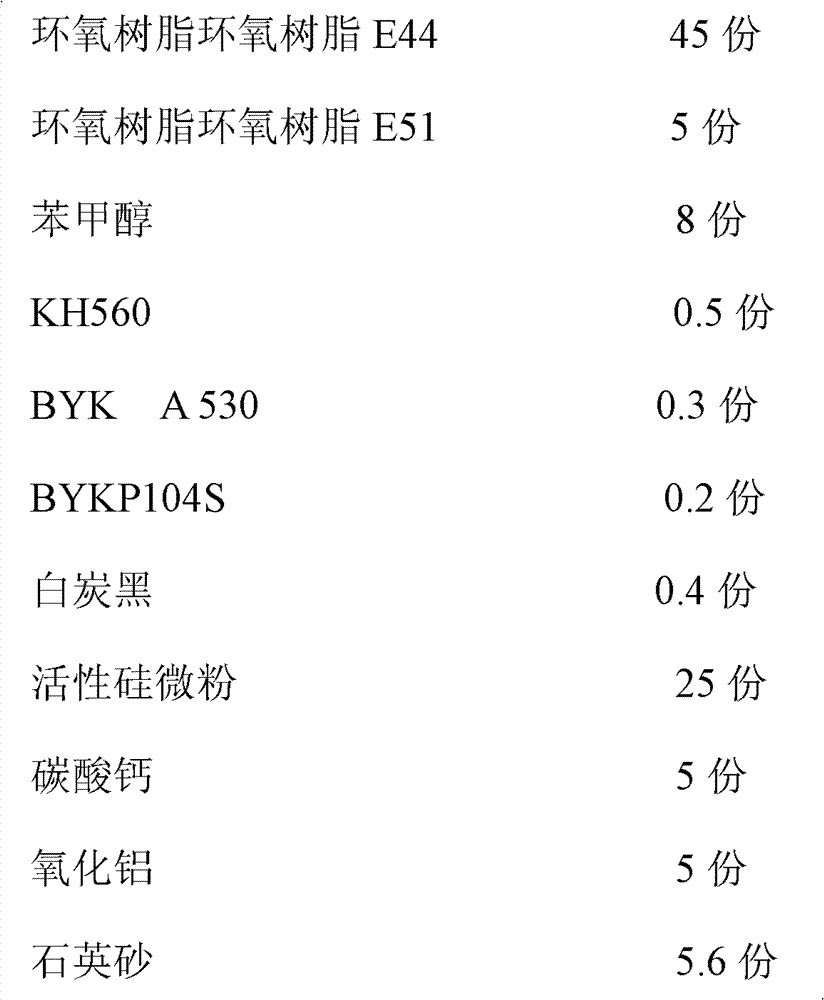

Underwater solvent-free epoxy anchoring adhesive and preparation method thereof

The invention provides an underwater solvent-free epoxy anchoring adhesive and a preparation method thereof. The underwater solvent-free epoxy anchoring adhesive consists of a component A and a component B in the weight percentage of 1:1, wherein the component A consists of the following components in parts by weight: 30-45 parts of epoxy resin E-44, 5-13 parts of epoxy resin E51, 3-8 parts of diluting agent, 0.5-0.75 part of coupling agent, 0.1-0.2 part of dispersant, 0.1-0.3 part of antifoaming agent, 0.4-3 parts of thixotropic agent, 20-30 parts of active micro silicon powder, 5-8 parts ofcalcium carbonate, 5.6-12 parts of quartz sand and 2-5 parts of aluminum oxide; the component B consists of the following components in parts by weight: 48-54 parts of completely-underwater epoxy curing agent 1085A, 44-50 parts of active micro silicon powder and 0.2-0.4 part of thixotropic agent; the diluting agent is benzyl alcohol; the coupling agent is ND-42 or KH 560; the dispersant is BYK P104S; the antifoaming agent is BYKA530; and the thixotropic agent is bentonite or white carbon black or a mixture of the bentonite and the white carbon black. The underwater solvent-free epoxy anchoring adhesive is prepared by mixing the prepared component A with the prepared component B in the weight ratio of 1:1.

Owner:长沙普照材料科技有限责任公司

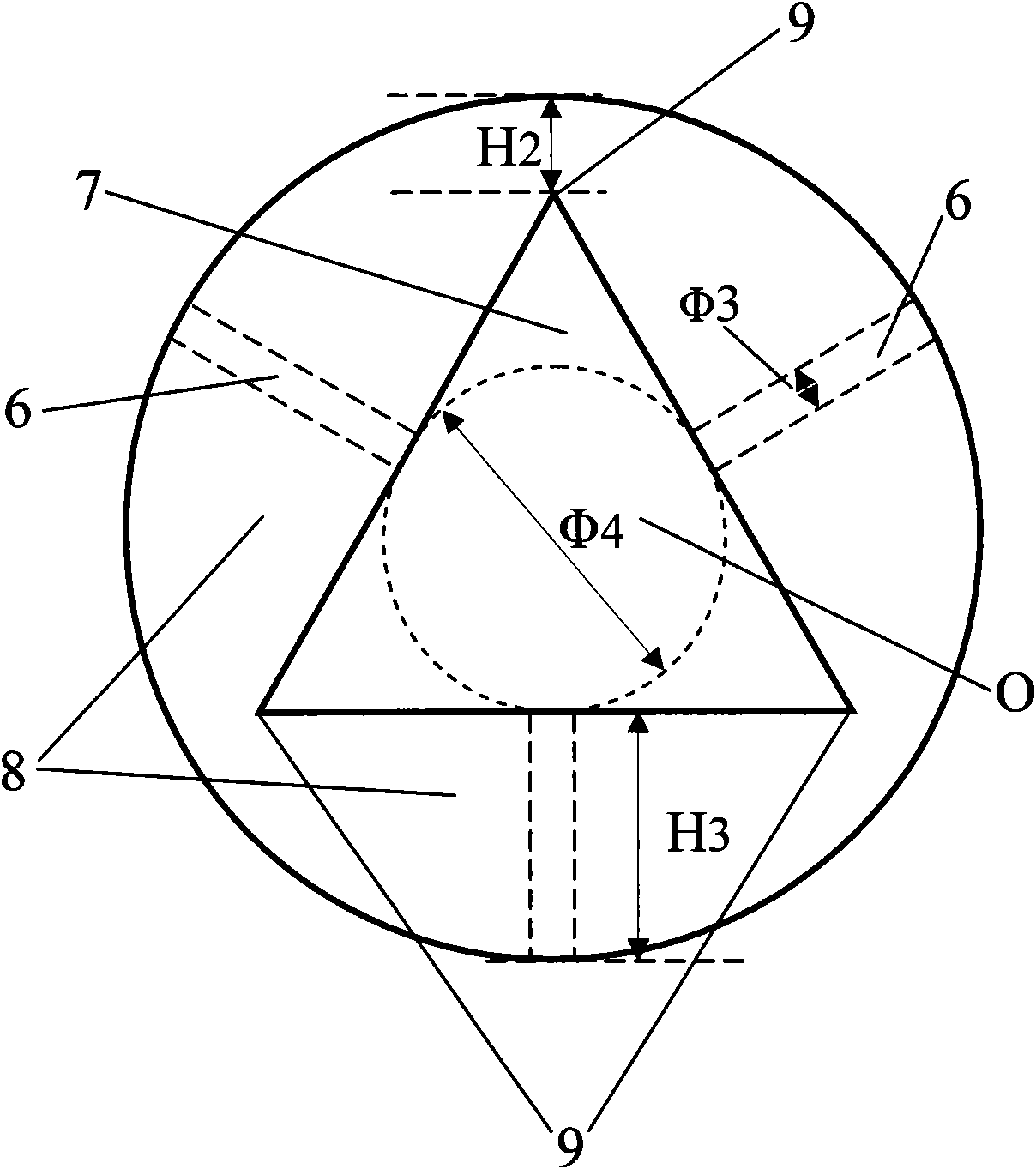

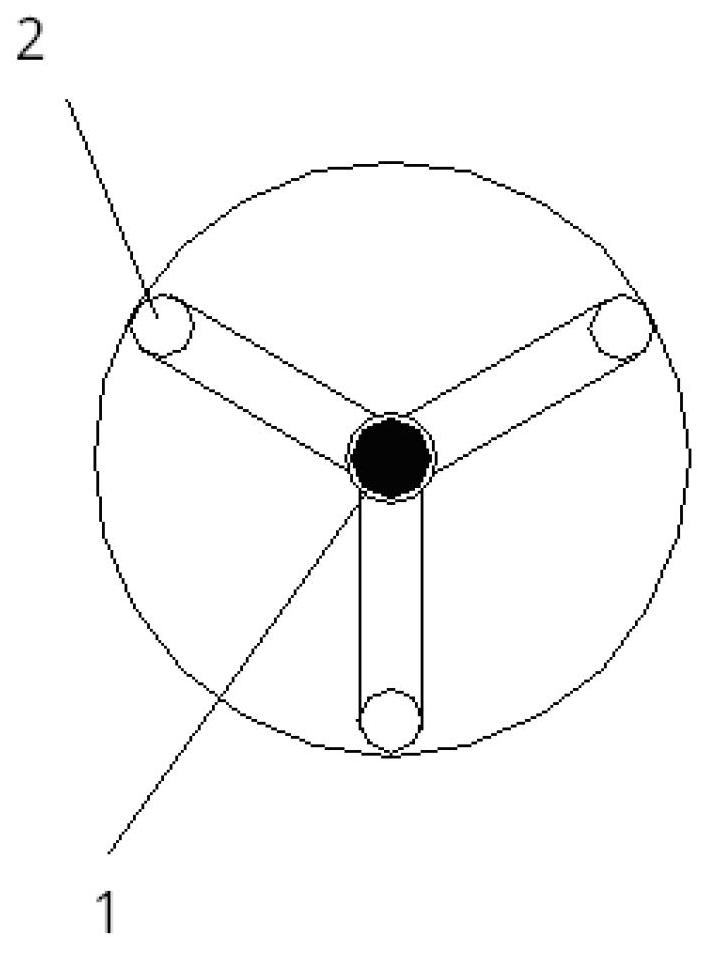

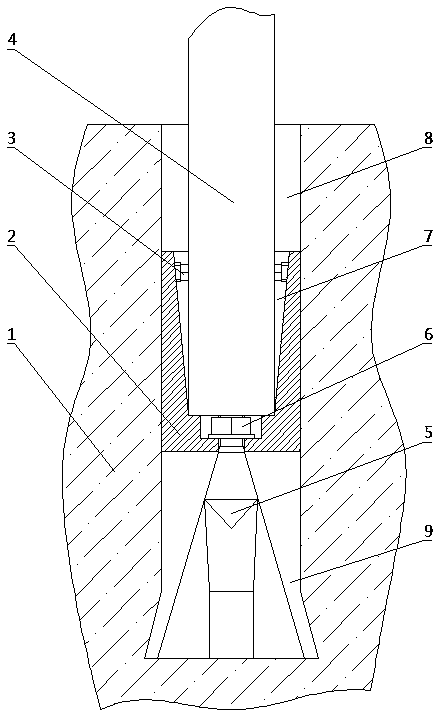

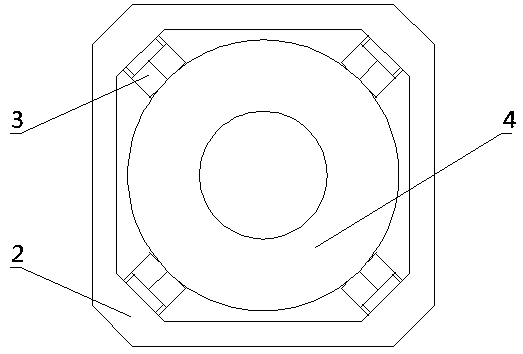

Medical vertebral arch pedicle renovating screw assembly

InactiveCN101669837ANo side effectsGood biocompatibilityInternal osteosythesisFastenersSpinal columnInternal fixation

The invention discloses a medical vertebral arch pedicle renovating screw assembly which comprises a screw sheath and a screw which are mutually matched, wherein the screw sheath has certain mechanical strength and toughness, and the medical absorbable material can effectively maintain the mechanical strength for 2 to 3 months in vivo; the screw sheath is divided into a head end and a sheath body;the head end is a cone with a sealed front end, and the sheath body is a cylinder; external threads are arranged on the outer surface of the cylinder, and a longitudinally extended triangular prism-shaped cavity is arranged in the cylinder; the cylinder is divided into three side walls by the cavity, and internal threads are designed on the inner wall of the cavity; the screw is made of medical titanium alloy and comprises a thread section and a tail part; the thread section is formed by connecting a screw tip and a screw body, and both the screw tip and the screw body are in external threaddesign; the tail part is provided with a radially communicated U-shaped groove, and internal threads are arranged on the inner wall of the U-shaped groove. The invention can improve the internal fixation stability and reliability of the spinal column in a renovating operation or the secondary screw arranging process, reduce the occurring rate of vertebral arch pedicle screw loosening and even separation and lower the failure rate of operations.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

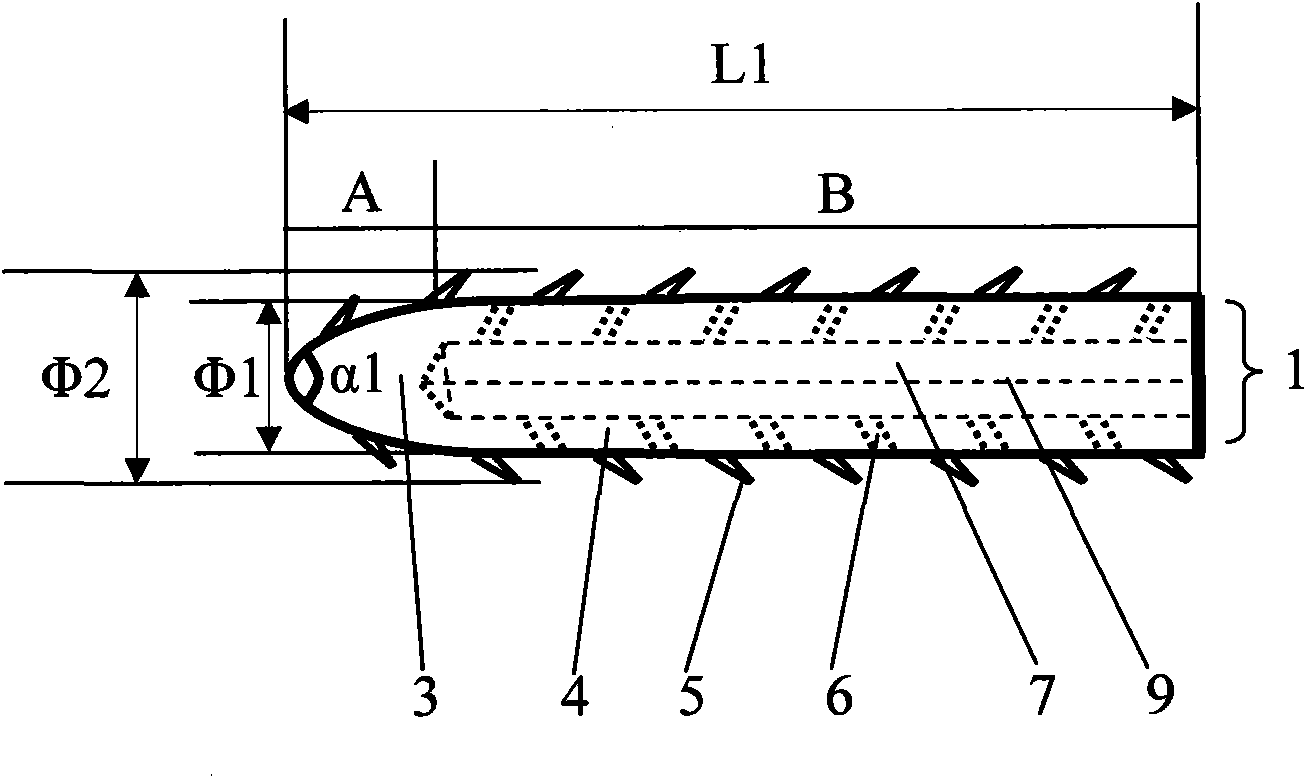

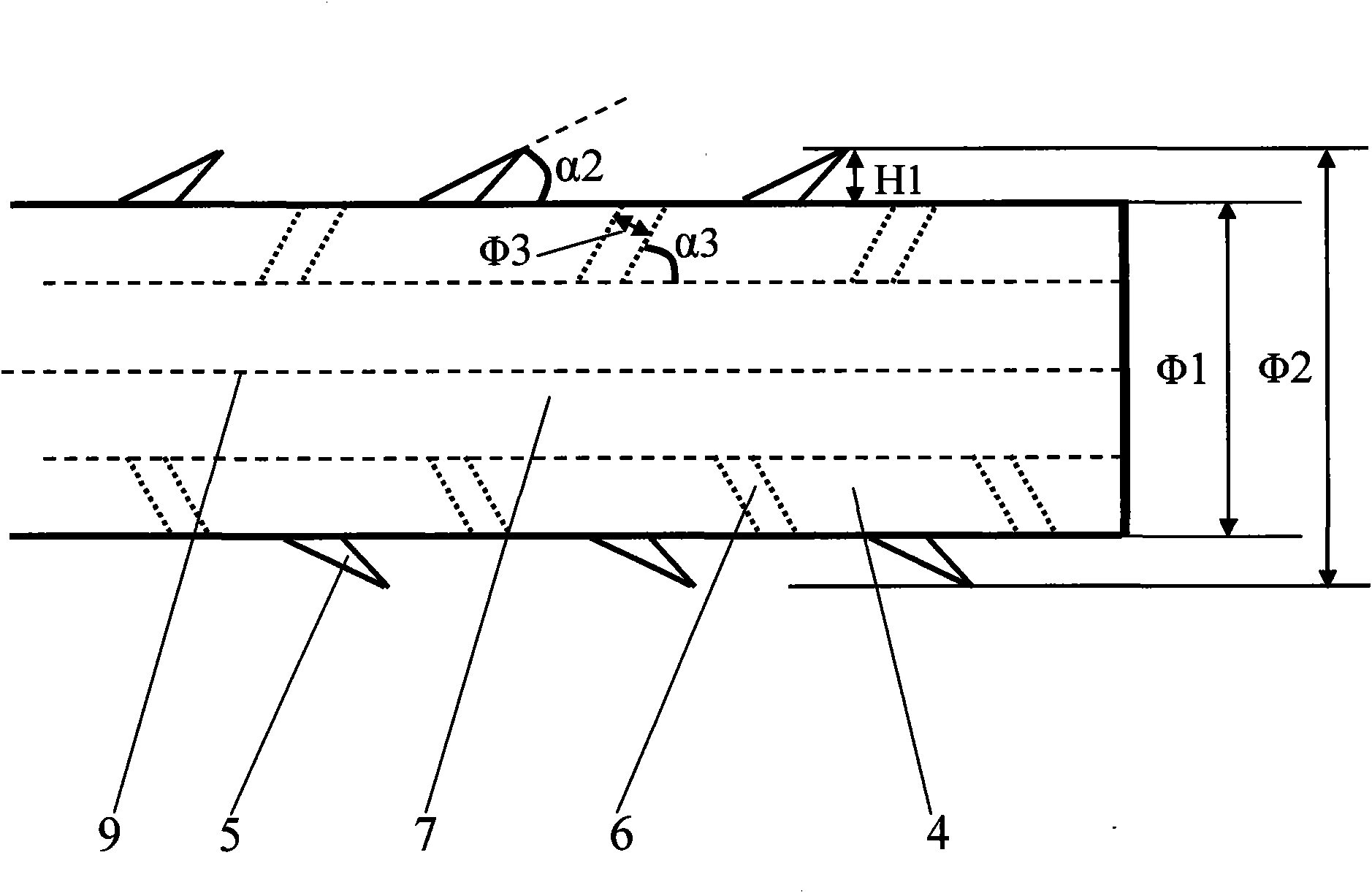

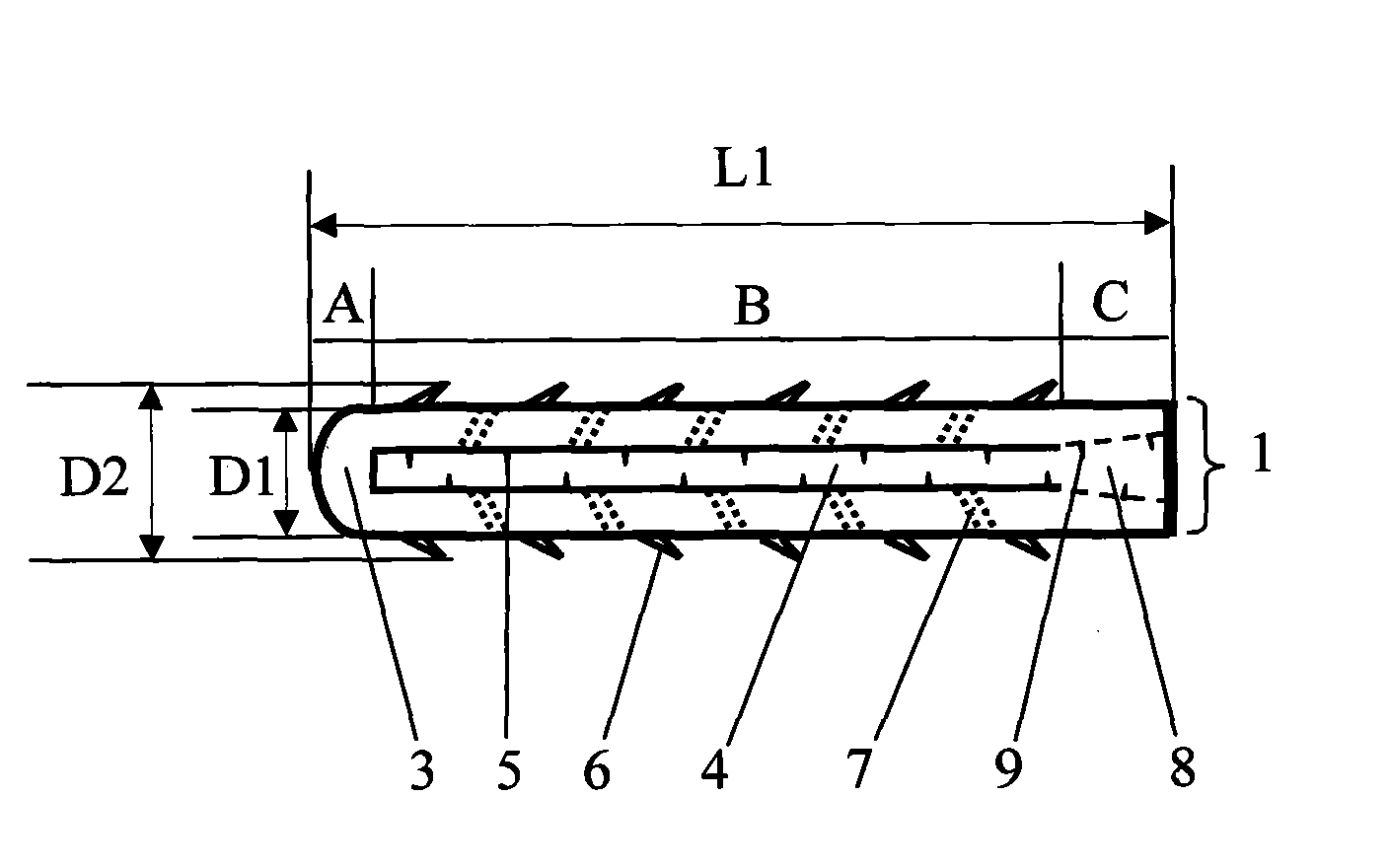

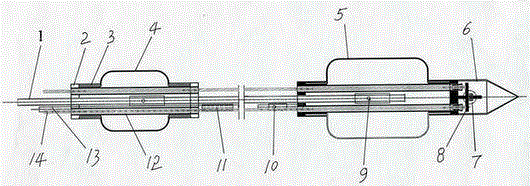

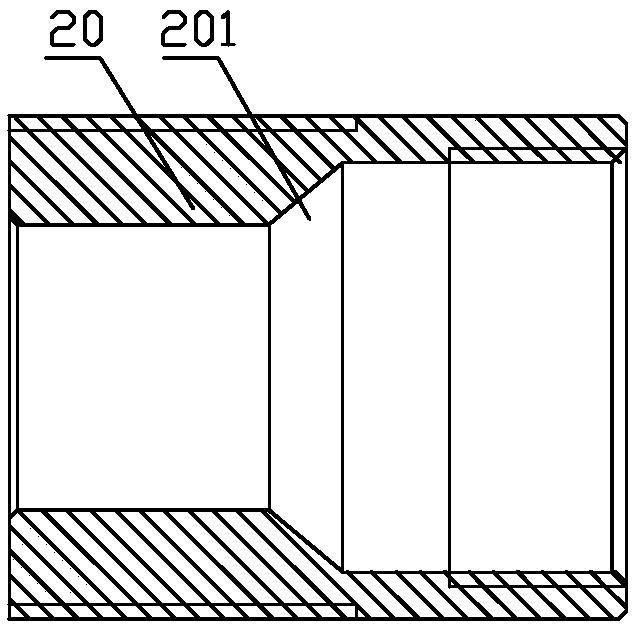

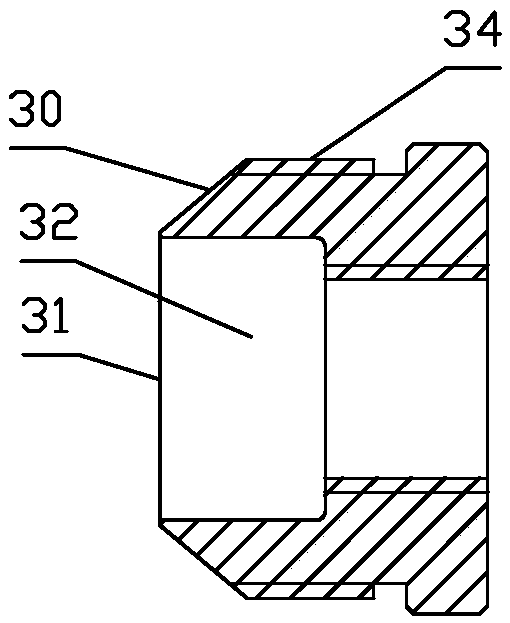

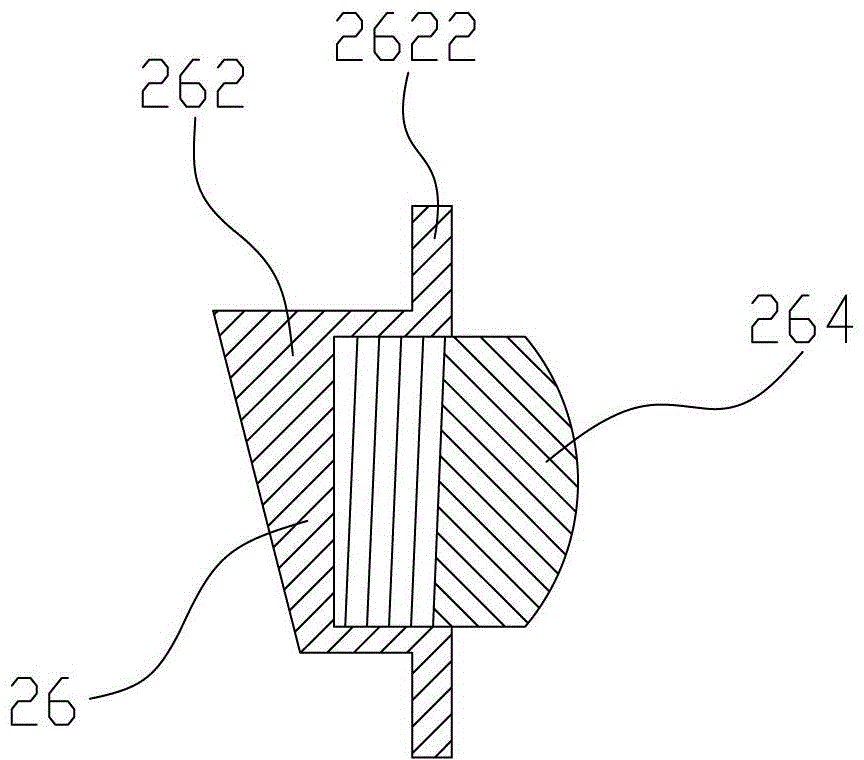

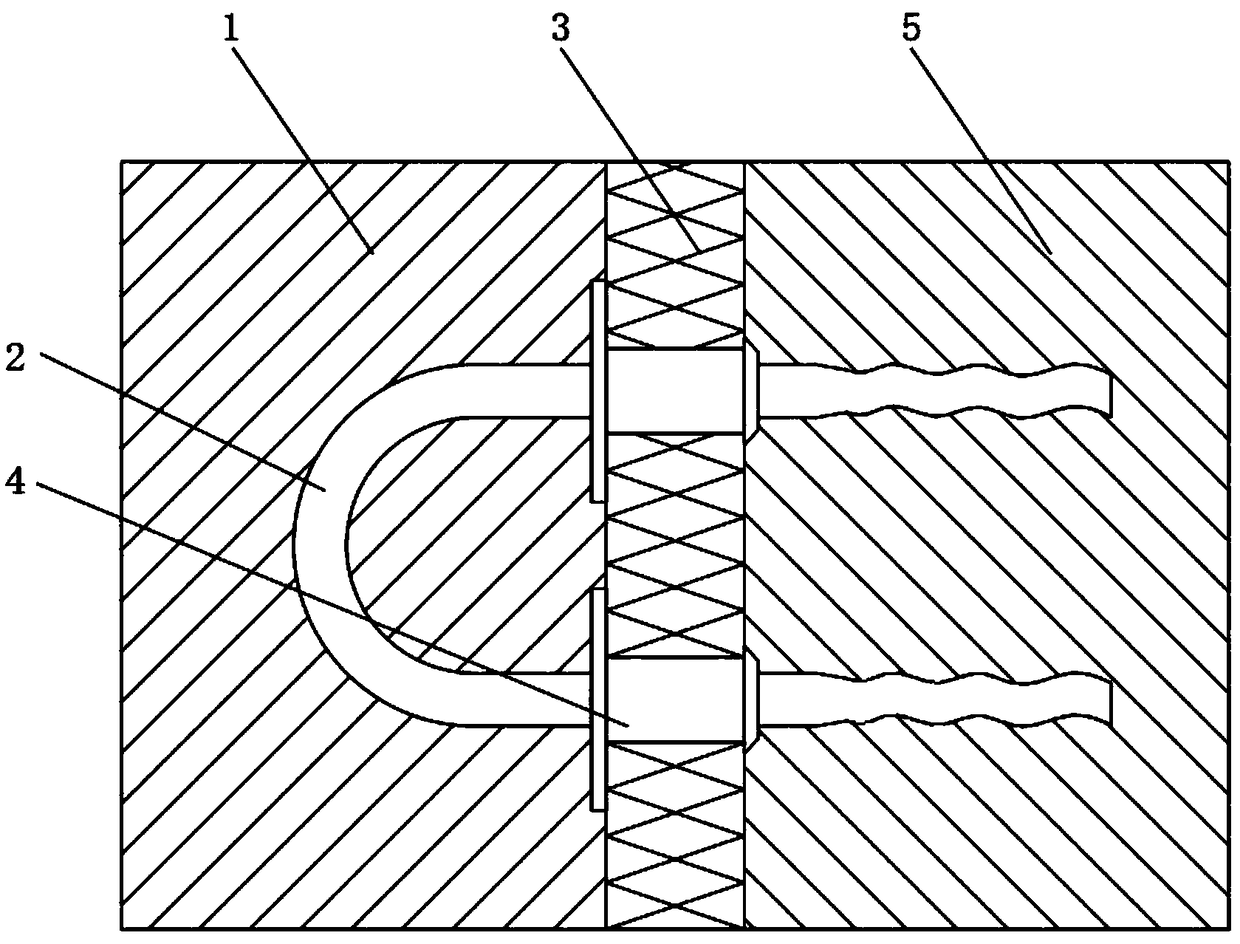

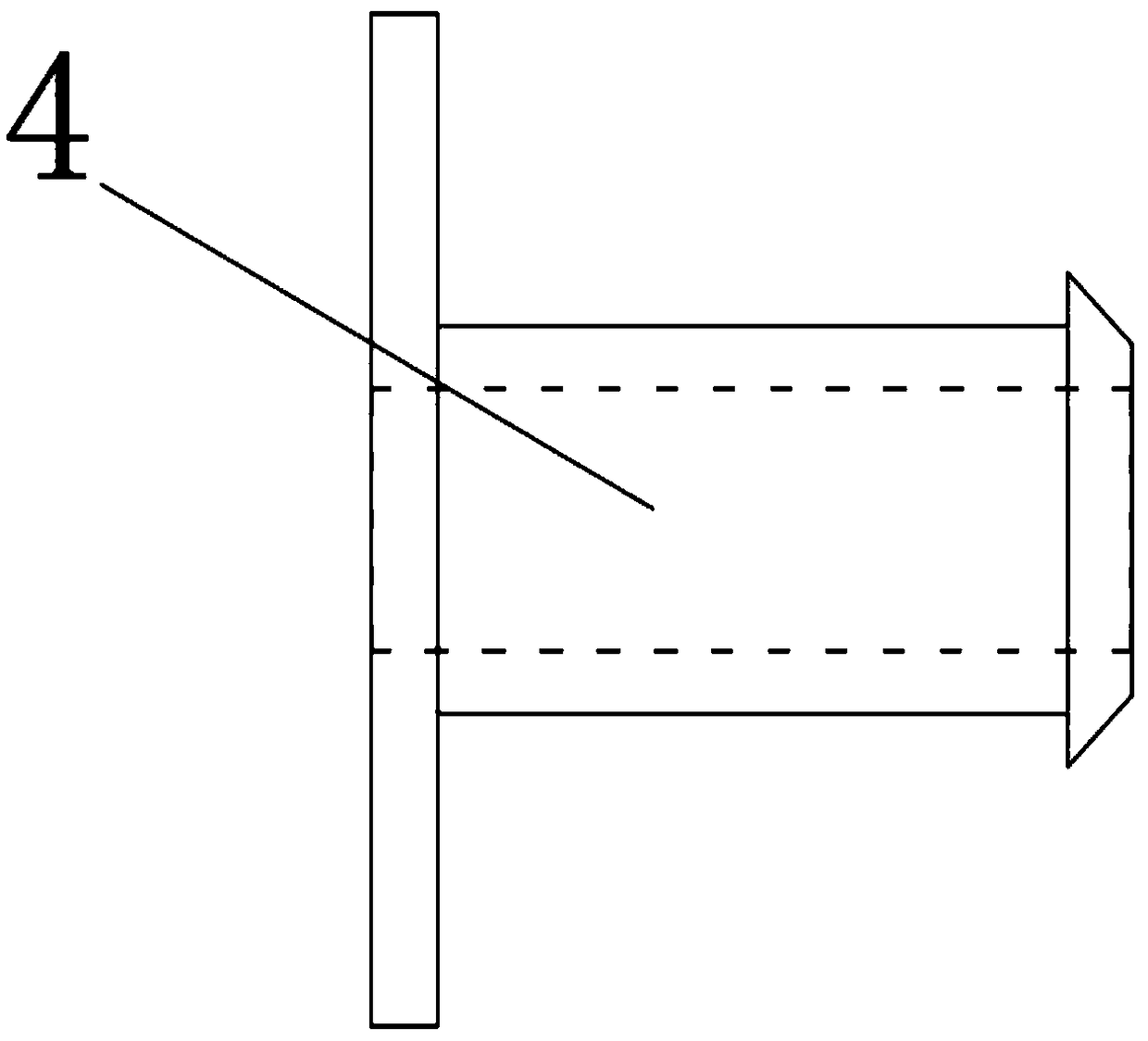

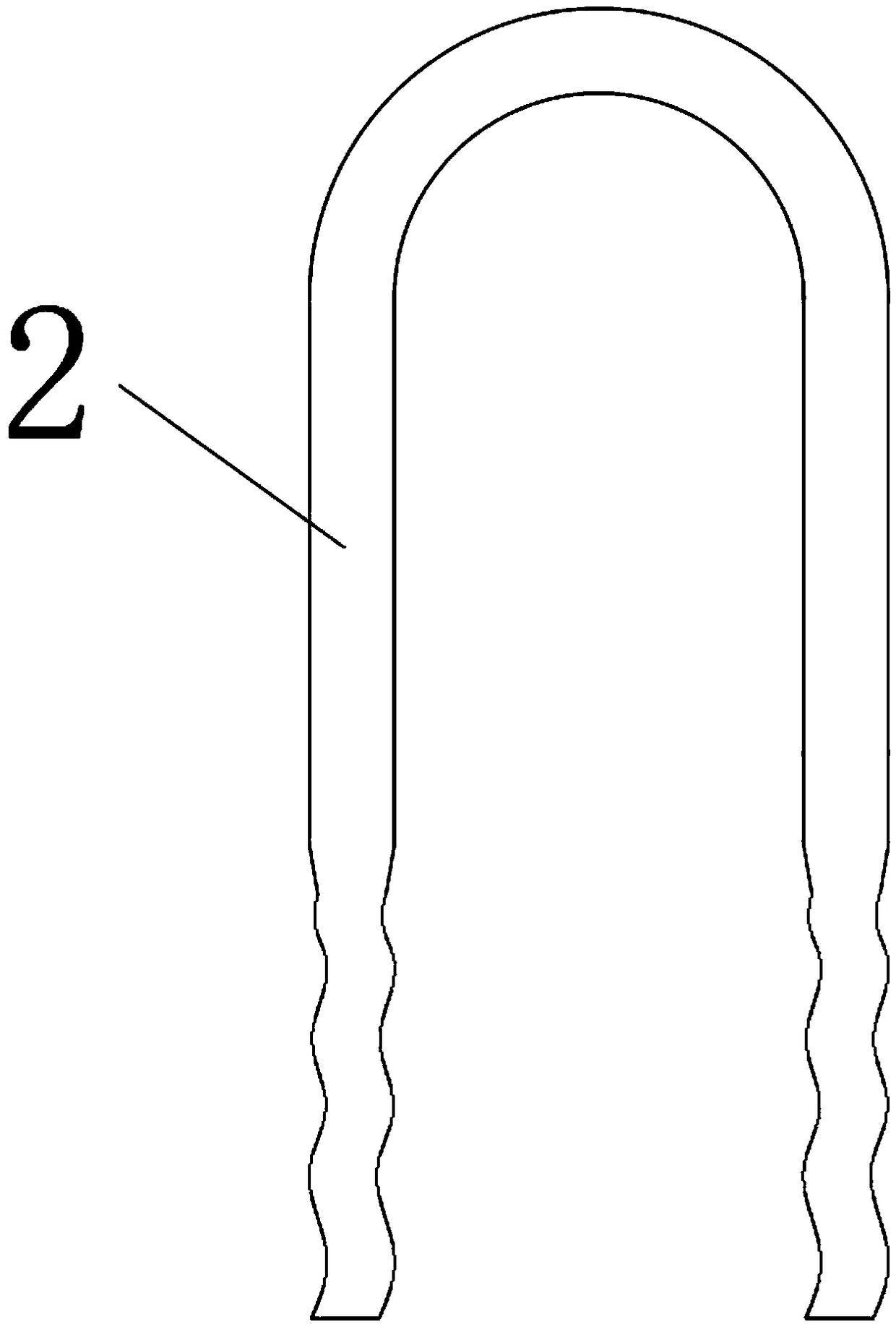

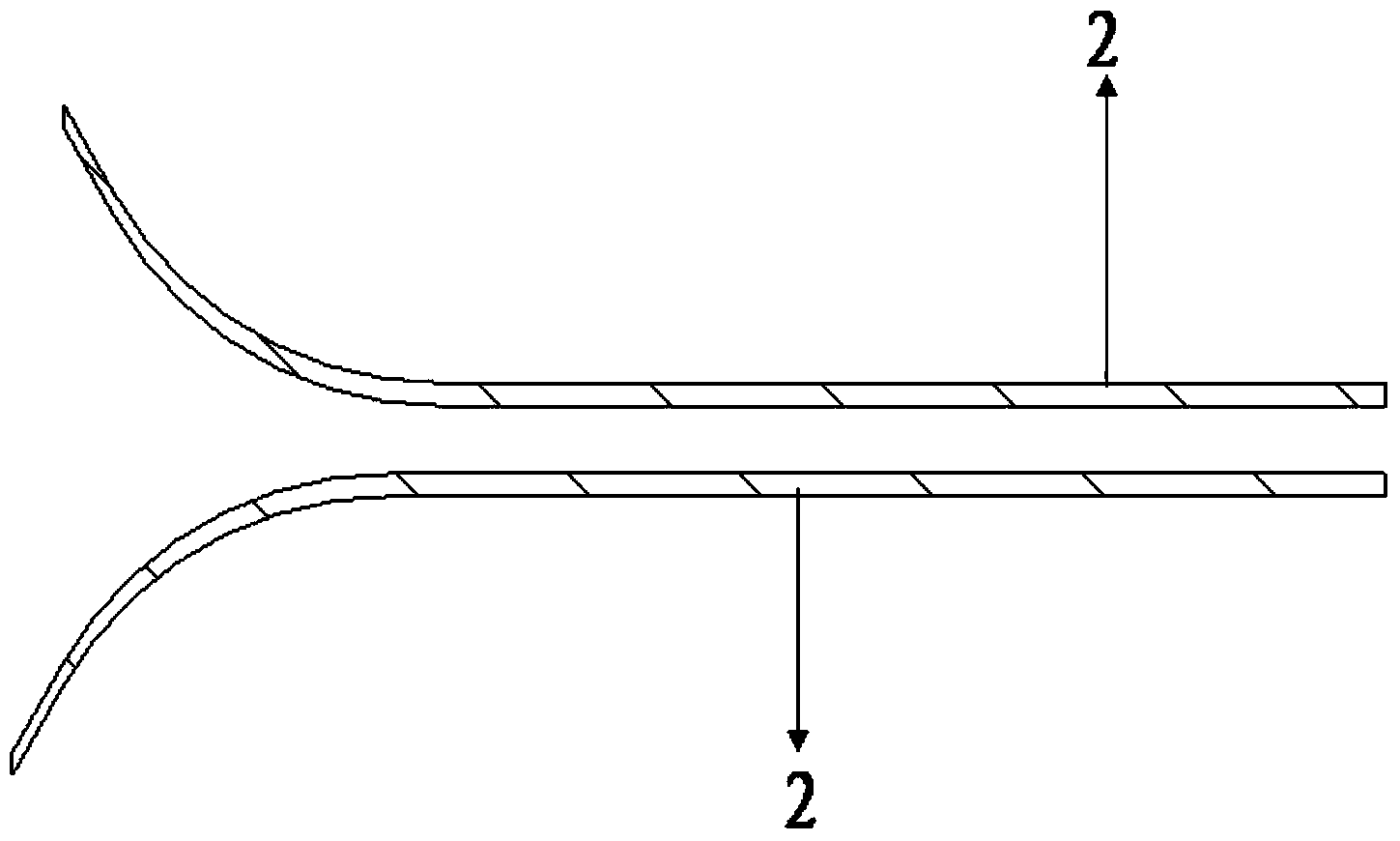

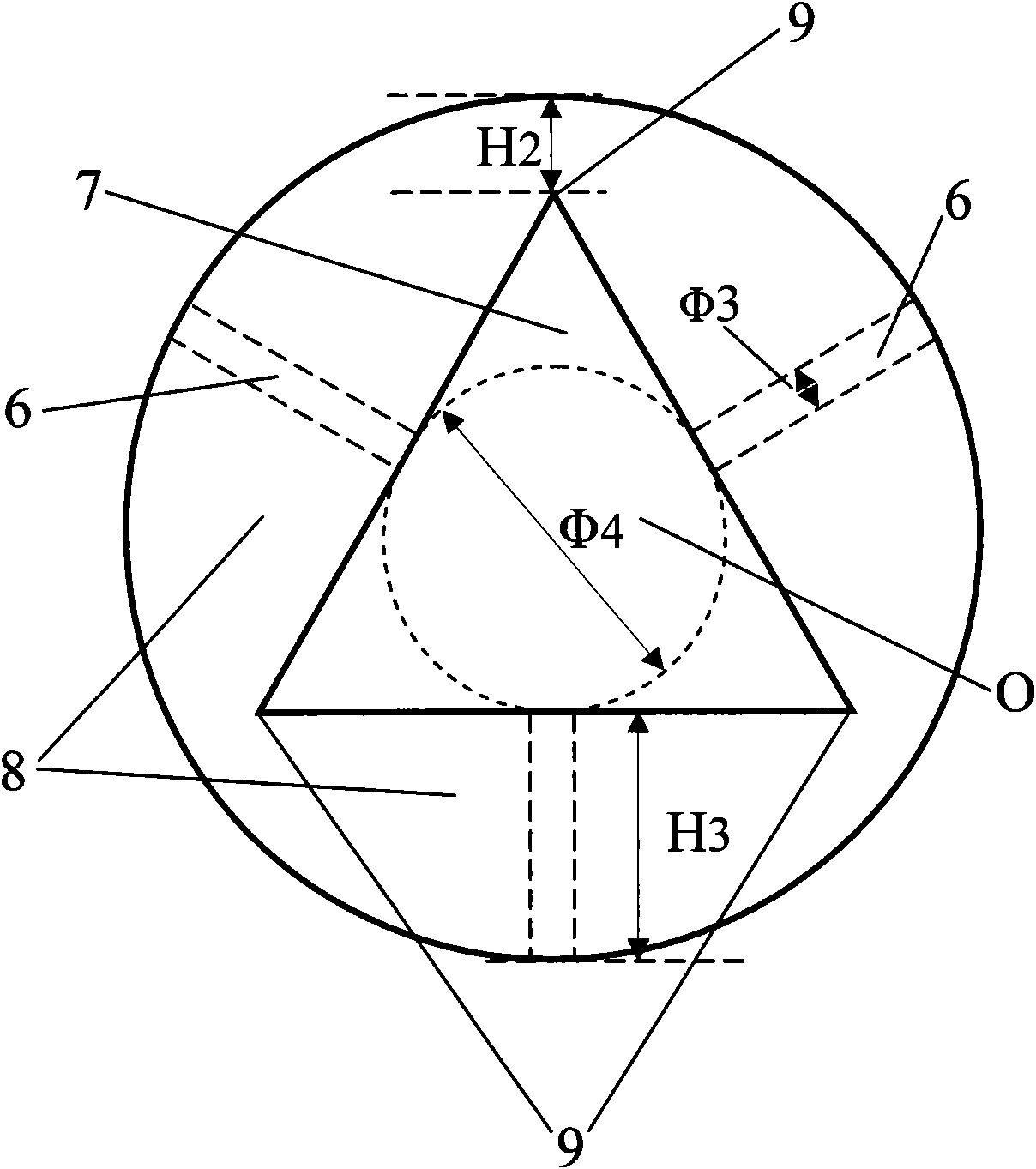

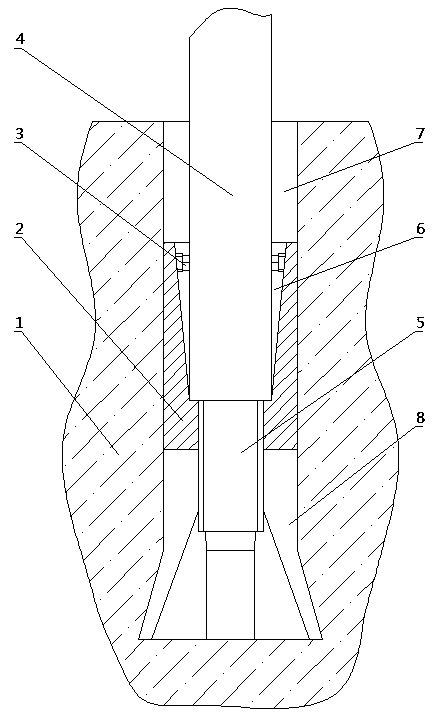

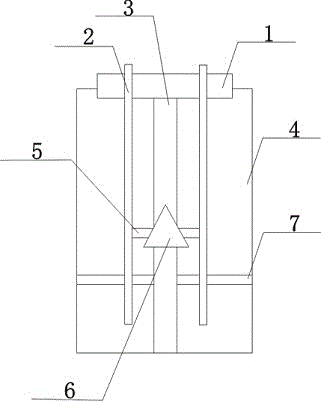

Medical vertebral pedicle strengthening screw

InactiveCN101632601AImprove pullout strengthEasy to take outInternal osteosythesisFastenersFailure rateInternal fixation

The invention discloses a medical vertebral pedicle strengthening screw consisting of a screw sleeve and a self-tapping screw in mutual fit, wherein, the screw sleeve is made from medical absorbable materials and has certain mechanical strength and toughness; the medical absorbable materials can effectively maintain the mechanical strength in vivo for 2 to 3 months; the screw sleeve is divided into a head end, a middle section and a tail end, wherein, the head end of the screw sleeve is sealed up and in a hemispherical shape, the middle section is provided with a longitudinal crack, and a cone-shaped hollow cavity is formed at the tail end thereof; and the self-tapping screw is made of medical titanium alloy and consists of a thread section and a tail part, wherein, the thread section is formed by connecting a cone-shaped tip part and a cylinder in external-thread design, a U-shaped groove penetrating in a radial direction is formed at the tail part, and internal threads are formed on the inner wall of the U-shaped groove. The invention is able to improve the stability of internal fixation in the process of the primary screw placement in an osteoporosis situation and reduce the incidence that the pedicle screw becomes loosened or even prolapsed, thus enhancing the stability and reliability of the internal fixation of spines and lowering the failure rate of operations.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Construction method for indoor light block wall stone dry-hanging

InactiveCN106223566AIncrease headroomHigh tensile strengthCovering/liningsCement mortarEnergy conservation

The invention depicts a construction method for indoor light block wall stone dry-hanging. The construction method is applied in the technical field of indoor wall base layer stone dry-hanging. The method is characterized in that a construction procedure of a wall body rear mortar embedded part is adopted, that is, rear holes are formed in a wall body, expansive cement mortar is poured in the rear holes and full-thread lead screws are partly embedded in the expansive cement mortar; by increasing the tensile area of the wall body, the tensile strength is improved, the anti-uplift strength of the rear mortar embedded part is met, and finally stone is anchored with the wall body through the rear mortar embedded part; lots of materials and labor are saved, manufacturing cost is reduced, the net indoor space is properly increased, and energy conservation and environment protection are achieved.

Owner:江西奇信集团股份有限公司

Integrated double-bag enlarged anchor cable

ActiveCN104912071AQuality improvementImprove pullout strengthBulkheads/pilesAnchoring boltsReverse osmosisEngineering

The invention discloses an integrated double-bag enlarged anchor cable which comprises a positioning head guard and a grouting pipe. A reverse-osmosis hole sealing bag and a reverse-osmosis enlarged bag are respectively fixed to the positions, close to two ends, on the grouting pipe by using a pair of press hoops, a clamping head is installed on the outer sides of the press hoops at two ends of two bag bodies respectively in a tightly-attached mode, symmetric through holes are formed in two sides of each clamping head respectively, a gland is arranged at the position of a grouting hole formed in the head guard, a locking nut is arranged at the center of the gland, guide pipes passing through the bags are respectively fixed in the through holes formed in the clamping heads corresponding to the two bag bodies, an anchor cable from the gland to the rear end of the grouting pipe penetrates into the cavities of the guide pipes, corresponding to the two bag bodies, on two sides respectively, a one-way grouting valve is arranged on the grouting pipe sections in the two bag bodies respectively, and a water-air separating filter valve is arranged in the airtight section between the hole sealing bag and the enlarged bag. The two bag bodies are both made of reverse-osmosis antiseptic cloth.

Owner:XINXIANG JIAHUI TECH

Conical nut wall-linking element of outer wall scaffold

The invention discloses a conical nut wall-linking element of an outer wall scaffold. The conical nut wall-linking element comprises a conical nut body and a wall-linking rod piece which are buried in the side face of a concrete structural beam / slab / column. The wall-linking rod piece is composed of a steel pipe, a steel plate and a threaded rod welded to the center of the steel plate. The threaded rod is matched with the conical nut body in specification, and the steel pipe is welded to the steel plate. In the using process, the threaded rod of the wall-linking rod piece and the conical nut body are screwed and fixed, the wall-linking rod piece is fixed to and buckled with an upright tube of the scaffold through a fastener, and thus, the conical nut wall-linking element is connected with the scaffold. The wall-linking element is simple in structure, convenient to operate, high in anti-uplift strength and good in safety property, the cost is reduced, the overall stability of the scaffold can be guaranteed, the working efficiency is improved, and the construction period is shortened.

Owner:桂林建安建设集团有限公司

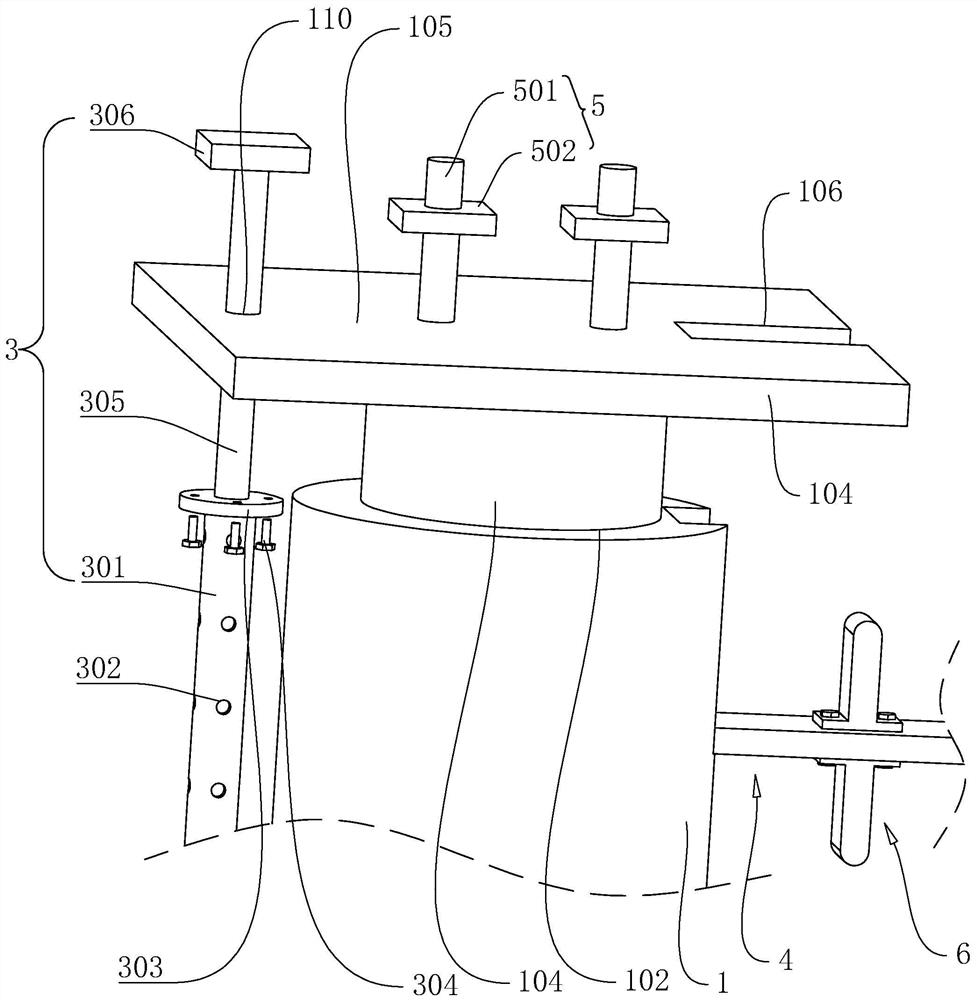

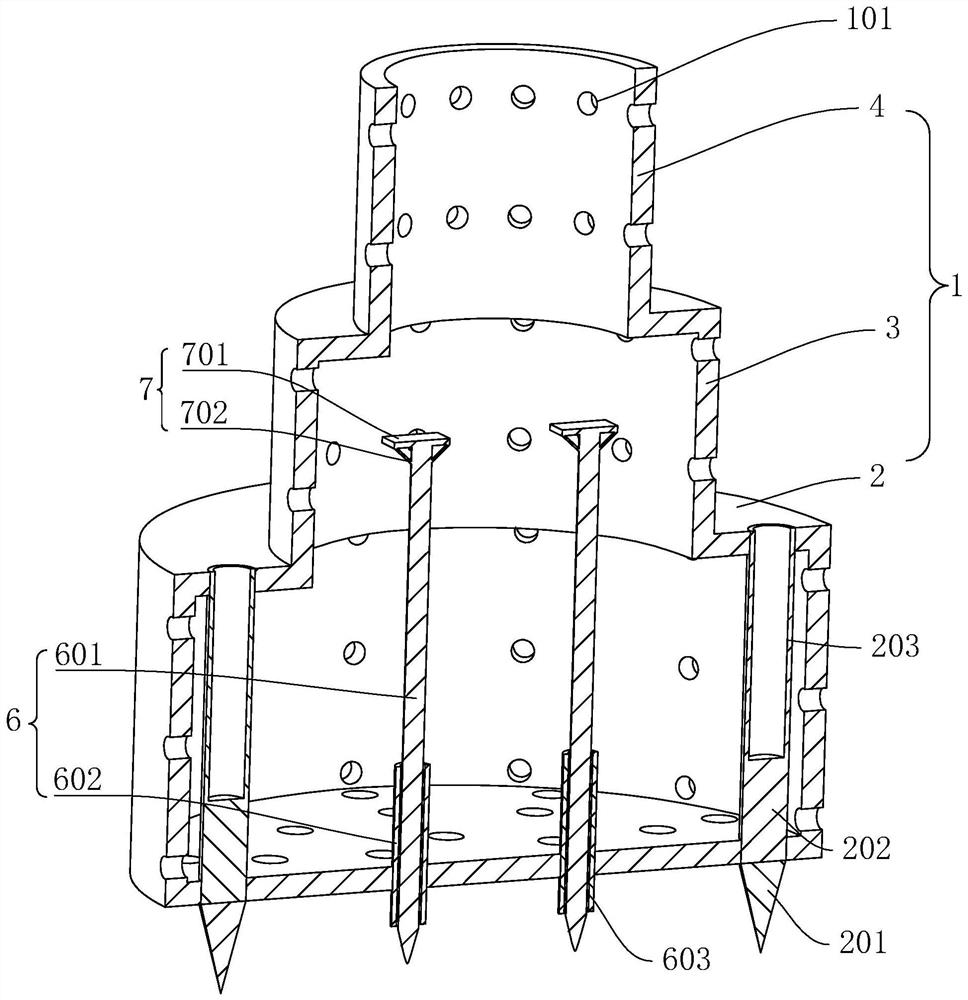

Geological reinforcement device capable of effectively improving connection stability

InactiveCN112227402AImprove connection stabilityImprove positional stabilityBulkheads/pilesHeadwallGeotechnical engineering

The invention relates to a geological reinforcement device capable of effectively improving the connection stability. The device comprises multiple settlement piles, a drilling probe is arranged at one end of each settlement pile in the length direction, a containing groove is formed in the end wall in the direction, away from the corresponding drilling probe, of each settlement pile, and balancing weights are arranged in the containing grooves. An extending side plate is arranged at the end in the direction, away from the corresponding settlement pile, of each balancing weight, and fixed assemblies are arranged among the extending side plates, the balancing weights and the settlement piles. Opposite-pull assemblies are arranged at one ends in the direction, away from the settlement piles,of the extending side plates, a connecting assembly is arranged between the adjacent settlement piles jointly, and a top connecting plate is arranged on the top walls of all the extending side platesjointly. The geological reinforcement device has the effect of effectively improving the stability that the geological reinforcement device is connected with adjacent land parcels.

Owner:福建新华夏建工集团有限公司

High-performance polyurethane synthesizing sleeper and preparation method thereof

The invention relates to a high-performance polyurethane synthesizing sleeper and a preparation method thereof. The high-performance polyurethane synthesizing sleeper is obtained by using glass fiberas a framework, impregnating the glass fiber into foamed polyurethane to obtain a sleeper foamed base material, and further processing, wherein the foamed polyurethane comprises the following components in parts by weight: 50-60 parts of polyether polyol A, 10-20 parts of polyether polyol B, 30-40 parts of polyester polyol, 10-15 parts of a flame retardant, 0.2-0.4 part of an accelerator, 0.1-0.3part of an antioxidant, 0.1-0.3 part of an ultraviolet absorbent, 1-3 parts of a foam stabilizer, 0.3-0.5 part of nanoscale cellulose and 92-100 parts of isocyanate. Compared with the prior art, the high-performance polyurethane synthesizing sleeper provided by the invention has the advantages as follows: a product is moulded at one time, the obtained sleeper has excellent mechanical properties and high stability and the like.

Owner:瑞尔华(上海)交通科技有限公司

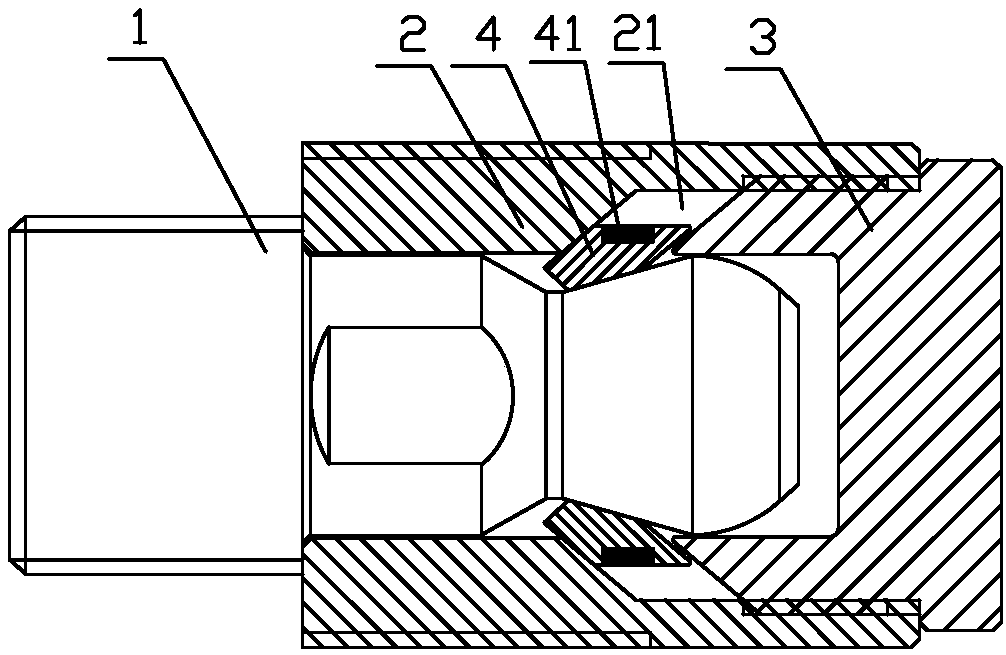

Concrete member plug connector and connection structure

The invention discloses a concrete member plug connector comprising a connector, a connecting sleeve, a guide element and a split snap ring. The concrete member plug connector is characterized in thatthe inner side of one end of the connecting sleeve is provided with a radially inwardly protruding card table, while the other end of the connecting sleeve is fixed with the guide element; one end, facing the guide element, of the card table is provided with a circular cone-shaped clamping surface; one end, facing the card table, of the guide element is a guide end which is provided with a circular cone-shaped guide surface; the clamping surface and the guide surface relative to each other form a guide groove for accommodating the split snap ring; the guide end is provided with a correction cavity capable of correcting the insertion direction of the connector; the split snap ring includes more than three circumferentially stitched latches; the outer side of each latch is sleeved with an elastic ring with radial elasticity; the connector can pass through the split snap ring to expand the split snap ring in the guide groove, and the connector is snapped and fixed by the rebound of the elastic ring. The concrete member plug connector has various advantages such as a simple structure, and easy and highly-efficient plug connection.

Owner:天海钢棒(张家港)有限公司

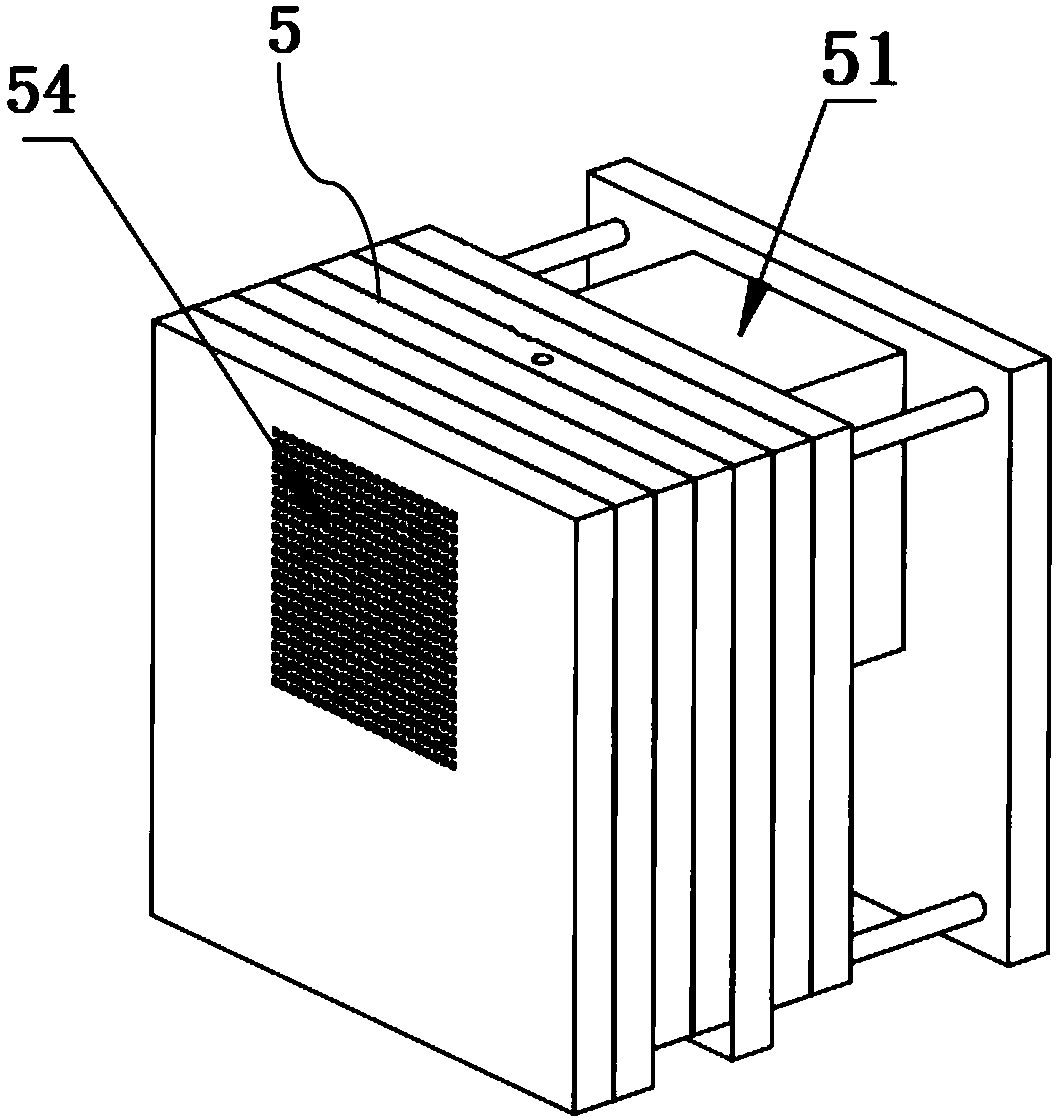

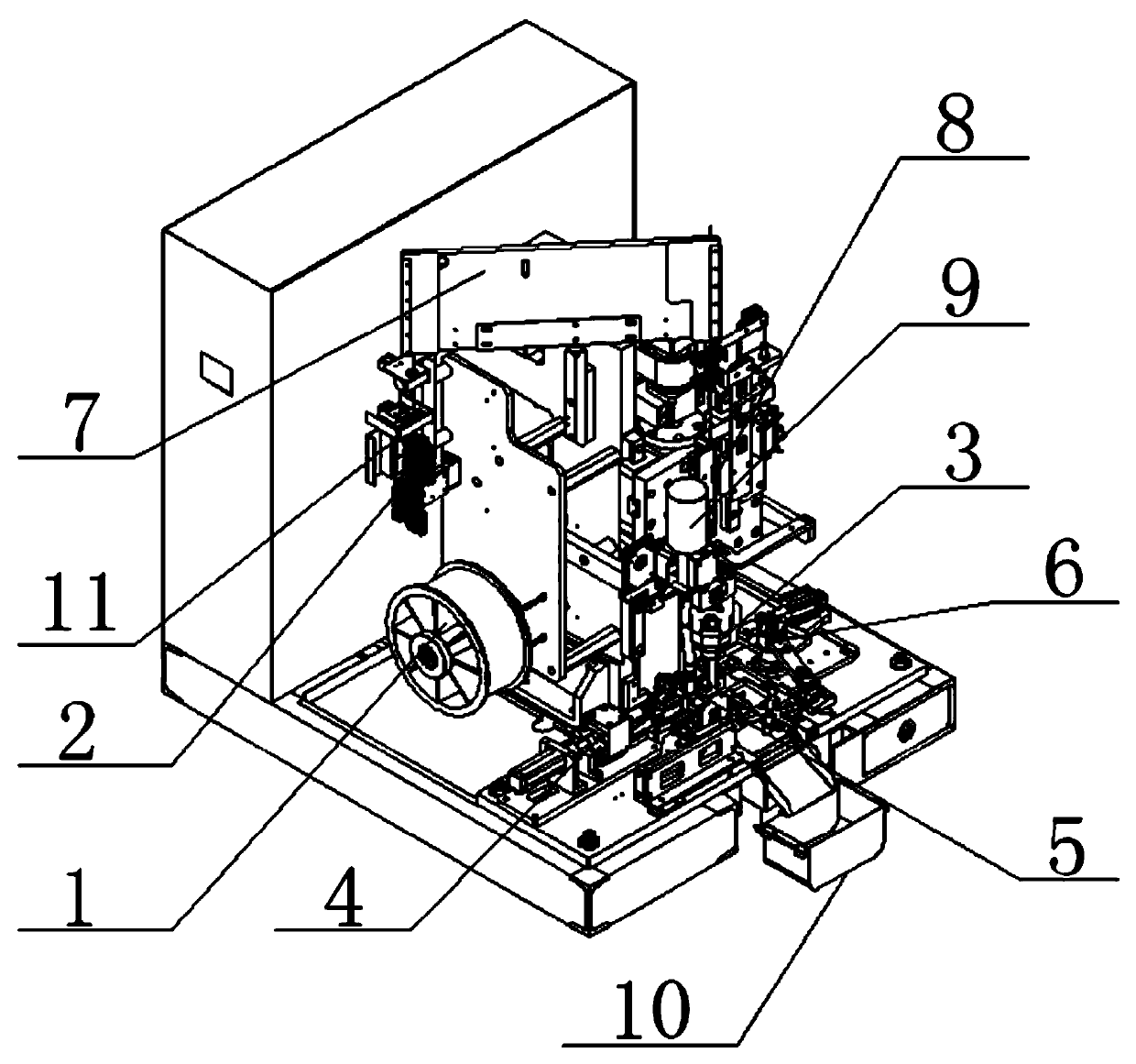

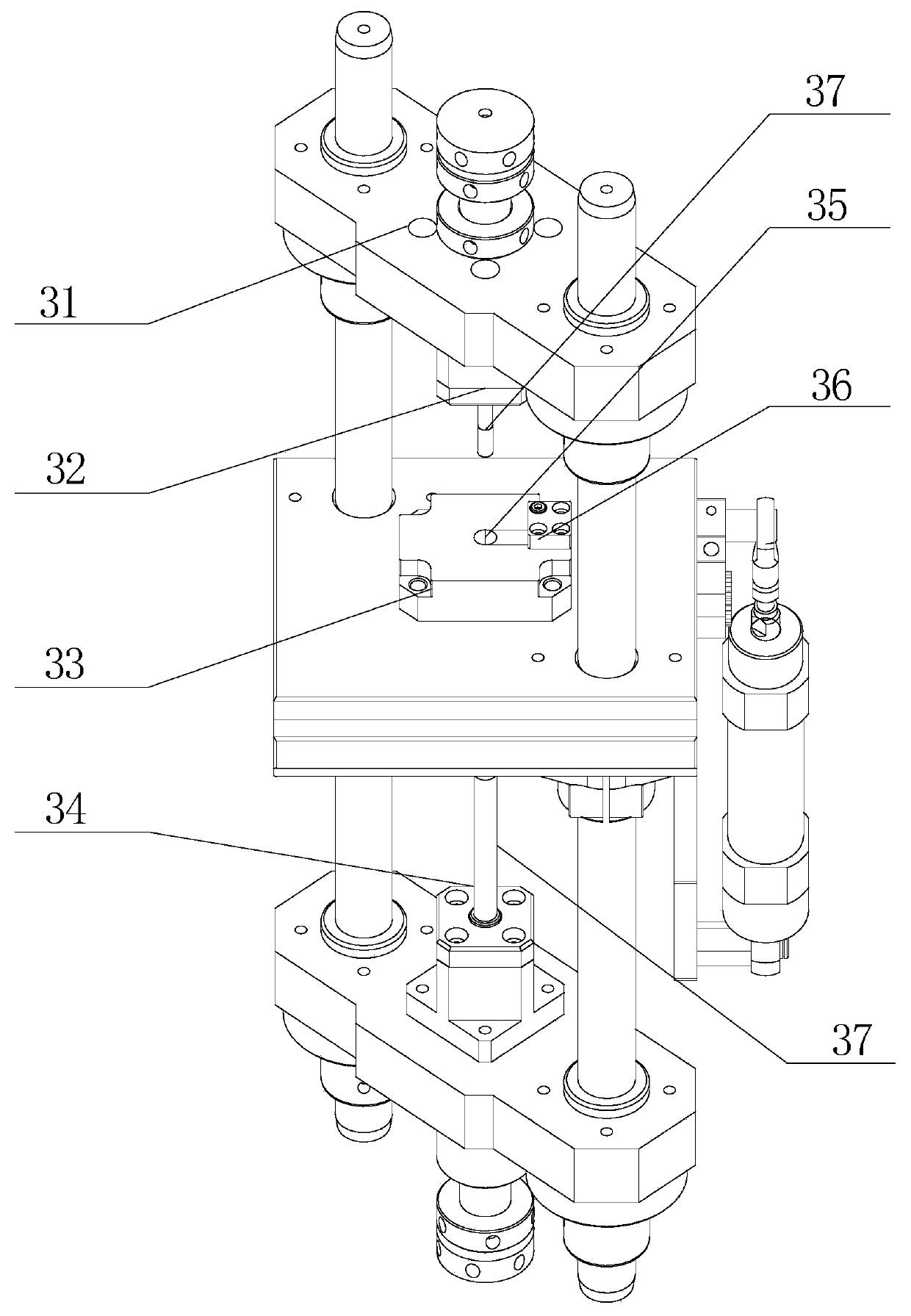

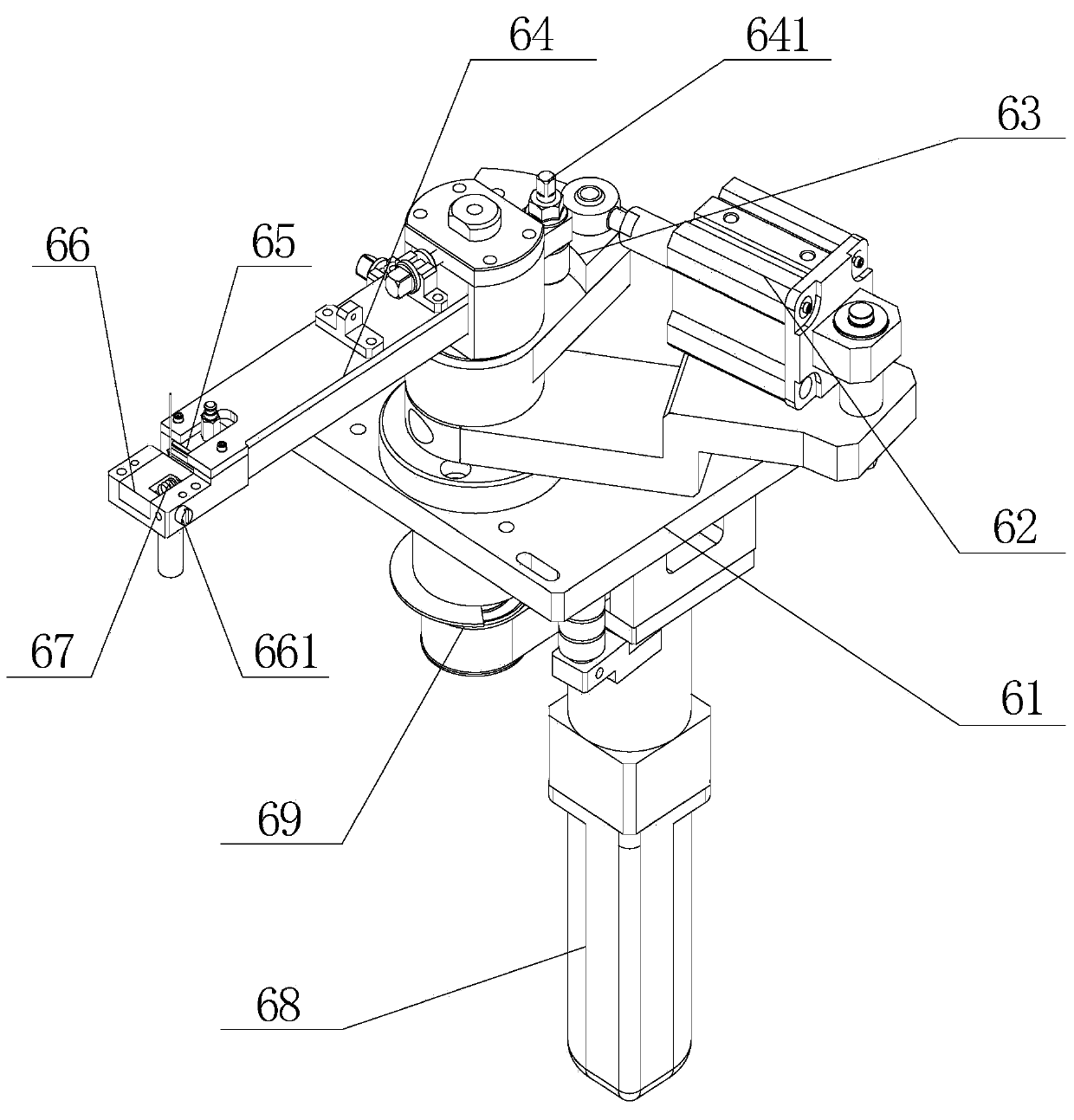

Automatic vertical forming machine

ActiveCN104259457AAvoid situations where tantalum powder is not embeddedEasy weightMolding machineStructural engineering

The invention discloses an automatic vertical forming machine. The machine comprises a rolled tantalum wire disc which is arranged at the position, on the side face of a vertical mounting frame, above a rack; a tantalum wire is led out of the rolled tantalum wire disc to penetrate into a one-time straightening mechanism above the rolled tantalum wire disc, then penetrate into a tantalum wire supply mechanism above the one-time straightening mechanism, and finally stretch into a mould cavity of a mould in the middle of a horizontal mounting plate in the middle of the rack; a powder shaking mechanism on the left side of the horizontal mounting plate feeds tantalum powder into the mould cavity from a powder shaking box, the tantalum powder allowing the tantalum wire to be inserted is formed through the mould, the tantalum is cut off through a cutting-off flattening mechanism on the right side of the horizontal mounting plate, the head end of the tantalum wire is flattened, and a finished product after compression moulding is fed out. According to the machine, digital control automatic machining is achieved, the machining efficiency is high, the weight and the size of a tantalum block are easy to regulate and control, the quality is better, the mass deviation is not large, one person can control multiple devices to work, manual input is reduced, the machining cost is reduced, and the good use value and economical value are achieved.

Owner:贵阳立特精密机械有限公司

Anchoring agent with good thermal stability for coal mine

InactiveCN106280351AIncrease contact areaImprove stabilityBuilding insulationsHalloysiteFumed silica

The invention discloses an anchoring agent with good thermal stability for a coal mine. The anchoring agent comprises a main material, a curing agent, a filling agent and distilled water. The main material comprises the following components in parts by weight: 100 parts of terephthalic unsaturated polyesters, 1-5 parts of dimethyl-p-toluidine, 2-6 parts of dimethylaniline and 5-15 parts of fumed silica. The curing agent comprises the following components in parts by weight: 100 parts of peroxycyclohexanone, 2-6 parts of carboxymethylcellulose and 2-7 parts of diethylene glycol. The filling agent comprises the following components in parts by weight: 15-30 parts of modified asphalt, 10-30 parts of calcium phosphate bone cement, 5-15 parts of hydroxyapatite, 15-30 parts of calcined clay, 2-10 parts of organobentonite, 5-15 parts of halloysite, 10-20 parts of kieselguhr, 20-40 parts of mica powder, and 15-35 parts of talcum powder. The weight part ratio of the main material, the filling agent and the distilled water is 100: 10-18: 20-40:50-150.

Owner:梁冬

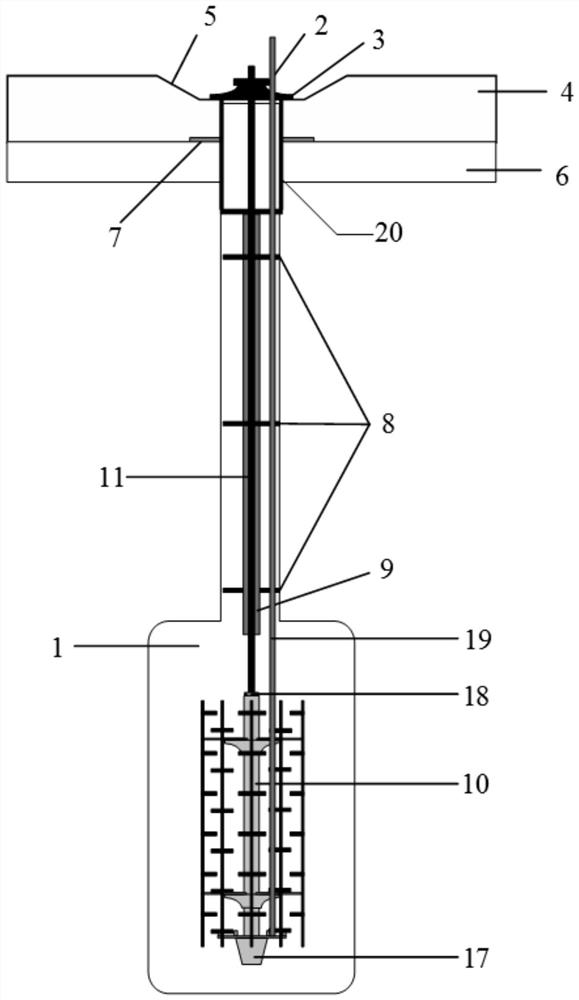

Prestressed expanded-head anti-floating anchor rod and construction method

The invention belongs to the technical field of rock-soil anchoring, and relates to a prestressed expanded-head anti-floating anchor rod and a construction method.The variable-diameter reinforcement cage is installed on the anchoring section of an anchor rod body, the outer side of the free section of the anchor rod body is sleeved with an anti-corrosion lantern ring, an anchor rod centering device is arranged on the free section of the anchor rod body, and the upper portion of the anchor rod body is sleeved with a second steel sleeve; the bottom of the second steel sleeve is connected with the top of the anti-corrosion lantern ring, and the top of the second steel sleeve is aligned with the bottom face of the anchor pit in parallel and connected with a stress diffusion anchor disc which is fixed through a fastening nut. The anchor rod impermeable layer is arranged between the building foundation bottom plate and the foundation waterproof layer, and the grouting pipe is arranged on one side of the anchor rod body; when the variable-diameter reinforcement cage is unfolded, the contact area of the anchor rod body and an anchoring body can be increased, bonding of the anchor rod body and the anchoring body is enhanced, the uplift bearing capacity of the anchor rod is improved, cracking of anchoring section concrete is effectively controlled, and the integrity of the anchor rod is enhanced. The variable-diameter reinforcement cage is opened by means of grouting pressure and the gravity of the device, and construction is simple and fast.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Interfacial adhesive for steel bridge surface paving

InactiveCN1305990CImprove pullout strengthEasy curingEpoxy resin adhesivesHigh resistancePolysulfide rubber

The steel bridge surface paving interface adhesive is for adhering spread layer to the steel bridge surface. The adhesive includes component an and component B in the ratio of 10 to 3-4. the component A consists of bisphenols A type epoxy resin CYD-128 in 90 wt% and phenol-phenolic epoxy resin-5 in 10 wt%; and the component B consists of polyamide-650 in 50 wt%, polysulfide rubber in 18 wt%, amine curing agent T31 in 30 wt% and coupling agent KH-550 in 2 wt%. The adhesive of the present invention has excellent tension resisting performance, excellent shear resisting performance, high heat resistance, high ageing resistance, and easy curing.

Owner:李宇峙

Building low-toxicity epoxy resin grouting material and preparation method thereof

The invention discloses a building low-toxicity epoxy resin grouting material and a preparation method thereof, and relates to the technical field of grouting materials. The building low-toxicity epoxy resin grouting material comprises the following components in parts by weight: 50-60 parts of bisphenol A epoxy resin, 30-50 parts of a curing agent, 10-20 parts of a diluent, 3-5 parts of a coupling agent, 7-10 parts of a defoaming agent, 60-80 parts of quartz sand, 50-80 parts of slag, 60-80 parts of cement, 10-15 parts of an expanding agent and 80-100 parts of water. According to the invention, the grouting material prepared by the invention has good flowability by adding the diluent, has very good mechanical properties and medium corrosion resistance after being cured, has the characteristics of high strength, high flowability, low toxicity and the like; and due to the mixed addition of cement, quartz sand and slag and the synergistic effect of the curing agent, the coupling agent and the expanding agent, the raw materials in the components are promoted to be fused, the compressive strength, breaking strength, pulling strength, creep resistance and other properties of the grouting material are improved, especially the shrinkage rate of the grouting material is reduced, and various comprehensive properties of the epoxy resin grouting material are improved.

Owner:ZHENGZHOU SINO SINA BUILDING MATERIALS CO LTD

Underwater solvent-free epoxy anchoring adhesive and preparation method thereof

ActiveCN102211894BThere will be no "whitening" phenomenonImprove wettabilityNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxySodium Bentonite

The invention provides an underwater solvent-free epoxy anchoring adhesive and a preparation method thereof. The underwater solvent-free epoxy anchoring adhesive consists of a component A and a component B in the weight percentage of 1:1, wherein the component A consists of the following components in parts by weight: 30-45 parts of epoxy resin E-44, 5-13 parts of epoxy resin E51, 3-8 parts of diluting agent, 0.5-0.75 part of coupling agent, 0.1-0.2 part of dispersant, 0.1-0.3 part of antifoaming agent, 0.4-3 parts of thixotropic agent, 20-30 parts of active micro silicon powder, 5-8 parts ofcalcium carbonate, 5.6-12 parts of quartz sand and 2-5 parts of aluminum oxide; the component B consists of the following components in parts by weight: 48-54 parts of completely-underwater epoxy curing agent 1085A, 44-50 parts of active micro silicon powder and 0.2-0.4 part of thixotropic agent; the diluting agent is benzyl alcohol; the coupling agent is ND-42 or KH 560; the dispersant is BYK P104S; the antifoaming agent is BYKA530; and the thixotropic agent is bentonite or white carbon black or a mixture of the bentonite and the white carbon black. The underwater solvent-free epoxy anchoring adhesive is prepared by mixing the prepared component A with the prepared component B in the weight ratio of 1:1.

Owner:长沙普照材料科技有限责任公司

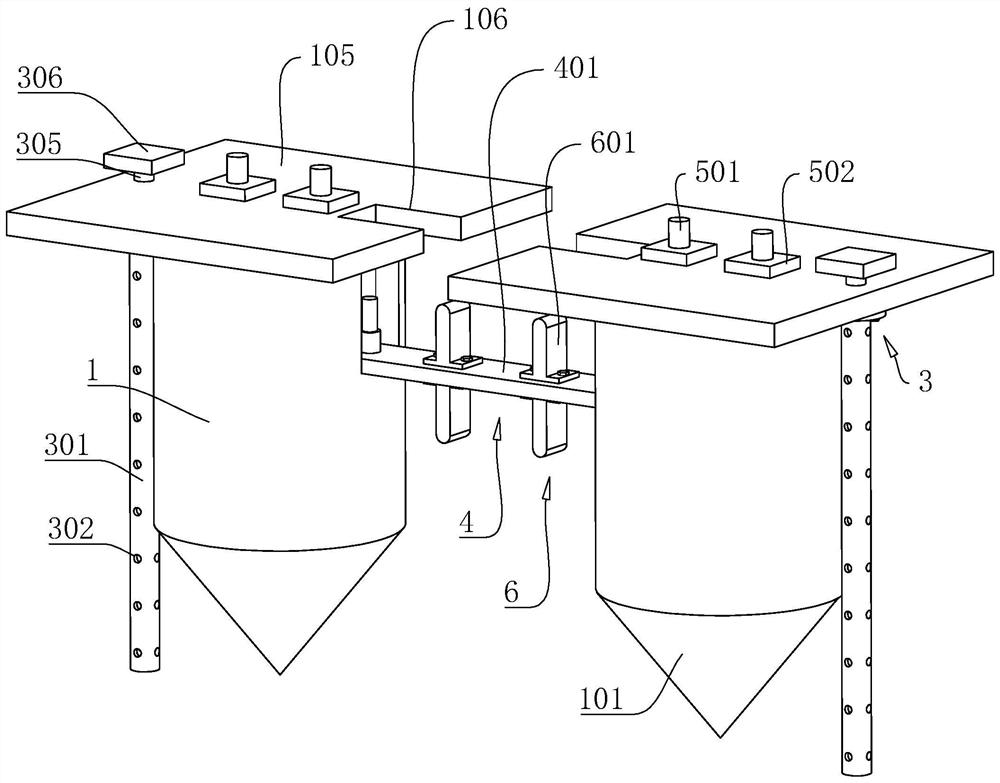

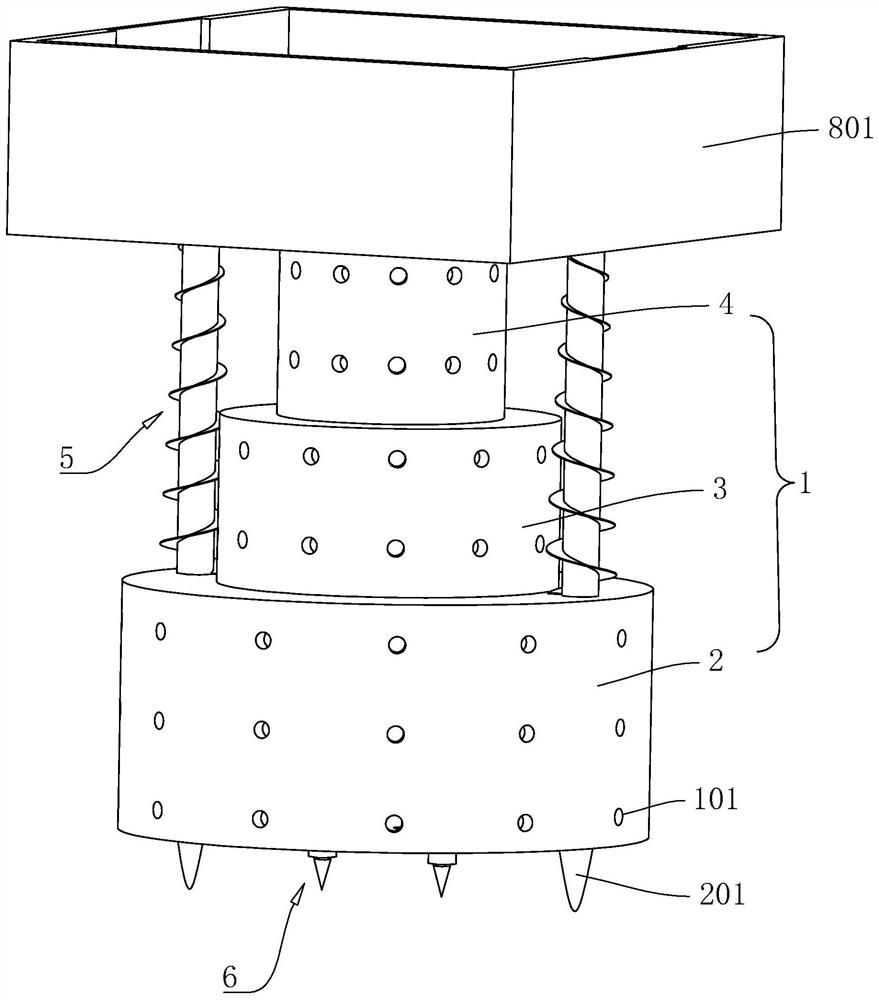

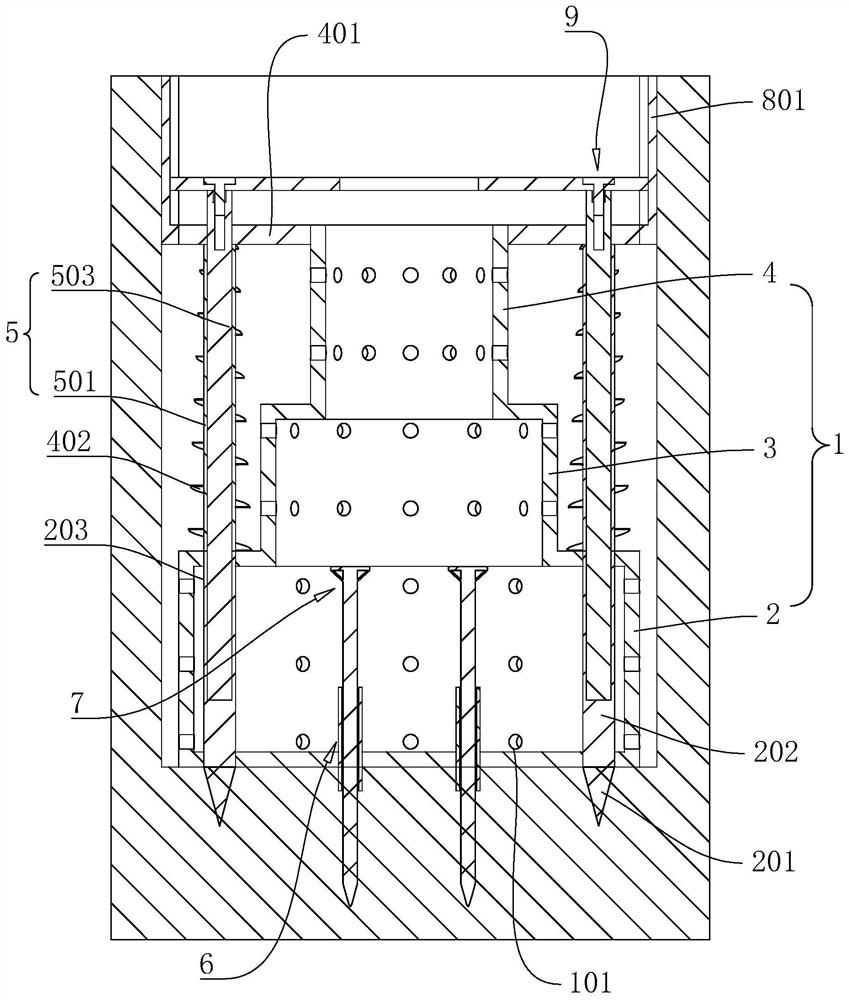

Foundation reinforcing device with high pulling strength for rotary jet grouting drilling machine

ActiveCN112227360AIncrease static frictional resistanceEnsure positional stabilityBulkheads/pilesStructural engineeringUltimate tensile strength

The invention relates to a foundation reinforcing device with high pulling strength for a rotary jet grouting drilling machine. The foundation reinforcing device with high pulling strength for the rotary jet grouting drilling machine comprises a limiting barrel, and a plurality of permeation holes are formed in the outer side wall of the limiting barrel; the limiting barrel comprises a positioningcavity, an isolation cavity and an end cavity, the positioning cavity and the end cavity are located at the two ends of the isolation cavity in the length direction correspondingly, the inner diameter of the positioning cavity is larger than that of the isolation cavity, and the inner diameter of the isolation cavity is larger than that of the end cavity; a plurality of bearing columns are arranged in an inner cavity of the positioning cavity, and a positioning cone is arranged on the outer side wall of the positioning cavity; a top connecting plate is arranged on the outer side wall of the end cavity, and a positioning assembly is arranged between the top connecting plate and the positioning cavity; and a connecting assembly for limiting the position of the positioning cavity is arrangedon the positioning cavity. The foundation reinforcing structure has the effects that the anti-pulling strength of a concrete block body and the limiting barrel in the foundation is improved, and theposition stability and the punning property after the foundation is reinforced are effectively guaranteed.

Owner:福建新华夏建工集团有限公司

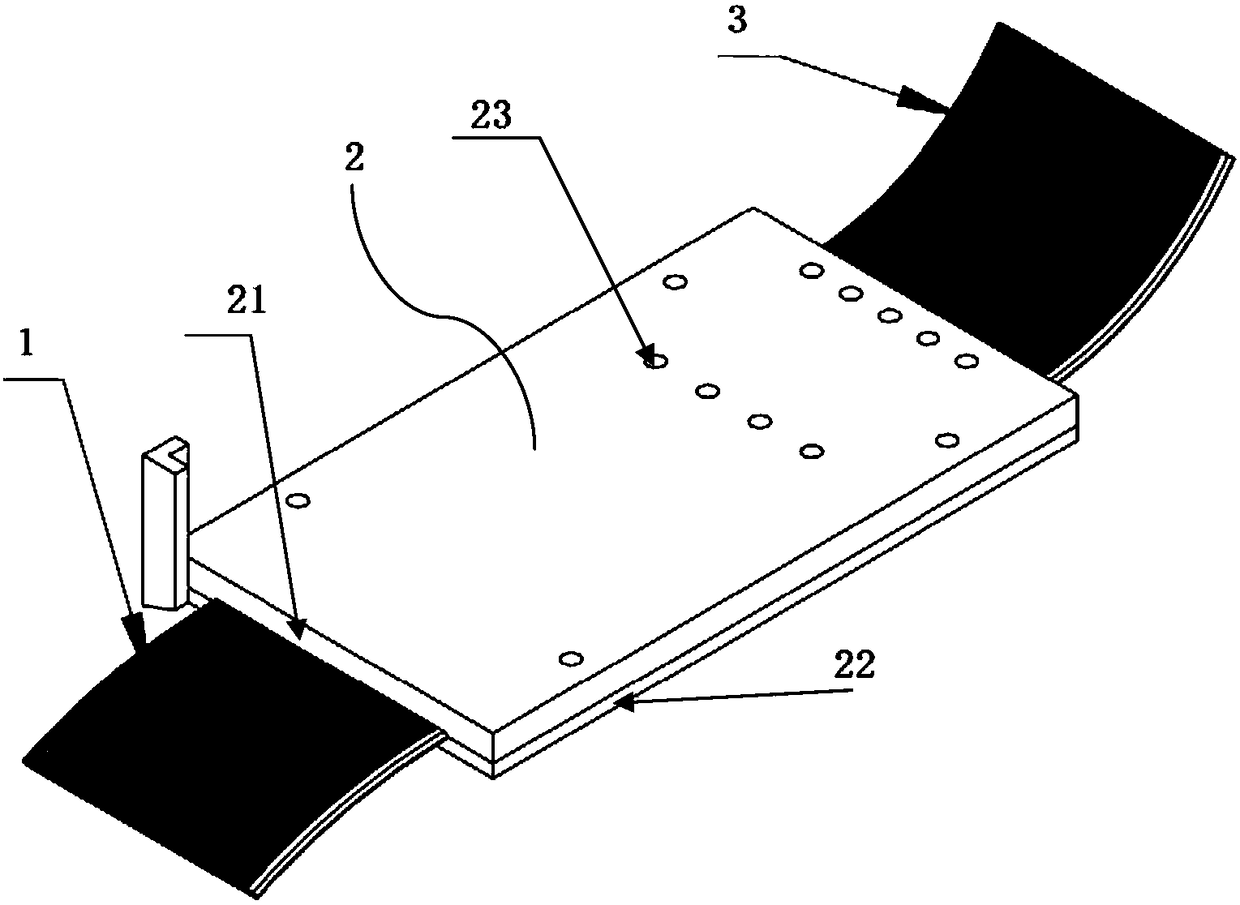

Cast-in-place pile structure

ActiveCN104372791AStrong carrying capacityImprove pullout strengthBulkheads/pilesEngineeringPre stress

The invention discloses a cast-in-place pile structure. The cast-in-place pile structure comprises an anchor plate. Annular plates are arranged on the two sides of the anchor plate, the annular plates are formed by splicing two plate bodies, and the annular plates and the anchor plate are connected through pin shafts. The annular plates are provided with cast-in-situ bored piles, the number of the cast-in-situ bored piles is two, and the cast-in-situ bored piles are vertically arranged on the anchor plate. The top ends of the cast-in-situ bored piles extend to the outer side of the upper surface of the anchor plate, and the bottoms of the cast-in-situ bored piles penetrate through a pre-stressed anchor cable to extend to the outer side of the lower surface of the pre-stressed anchor cable. A main reinforcement bar is arranged between the two cast-in-situ bored piles, and the two ends of the main reinforcement bar are fixed on the cast-in-situ bored piles. A bag is further included, the top of the bag is placed on the lower surface of the anchor plate, and the bottom of the bag is placed on the inner bottom faces of the annular plates. A reinforcing plate is arranged at the connecting position of the bag and the main reinforcement bar. The cast-in-place pile structure is high in single-pile bearing capacity, high in pulling resistance, capable of enabling cast-in-place piles to be kept at the centers of pile holes as far as possible in the burying process, capable of avoiding excessive rod moving data, easy to construct, capable of driving piles into the earth conveniently, sturdy and durable, and capable of effectively achieving a reinforcement effect.

Owner:浙江原野建设有限公司

High-density high-mechanical-strength anchoring agent for coal mine

InactiveCN106189155AIncrease contact areaImprove stabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPhosphoric acidFumed silica

The invention discloses a high-density high-mechanical-strength anchoring agent for a coal mine. The anchoring agent is prepared from, by weight, 100 parts of main ingredients, 14-22 parts of curing agent, 25-45 parts of filler and 100-160 parts of distilled water; the main ingredients comprise, by weight, 100 parts of isophthalic unsaturated polyester, 10-20 parts of fumed silica, 3-7 parts of dimethyl-p-toluidine and 4-8 parts of dimethylaniline; the curing agent is prepared from, by weight, 100 parts of dibenzoyl peroxide, 5-10 parts of diethylene glycol and 6-10 parts of microcrystalline cellulose; the filler is prepared from, by weight, 20-35 parts of modified asphalt, 10-20 parts of calcined clay, 15-35 parts of calcium phosphate bone cement, 20-35 parts of clay, 20-40 parts of glass beads, 25-45 parts of sodium lignin sulfonate, 10-20 parts of talcum powder, 4-12 parts of sepiolite powder and 15-25 parts of wollastonite powder.

Owner:梁冬

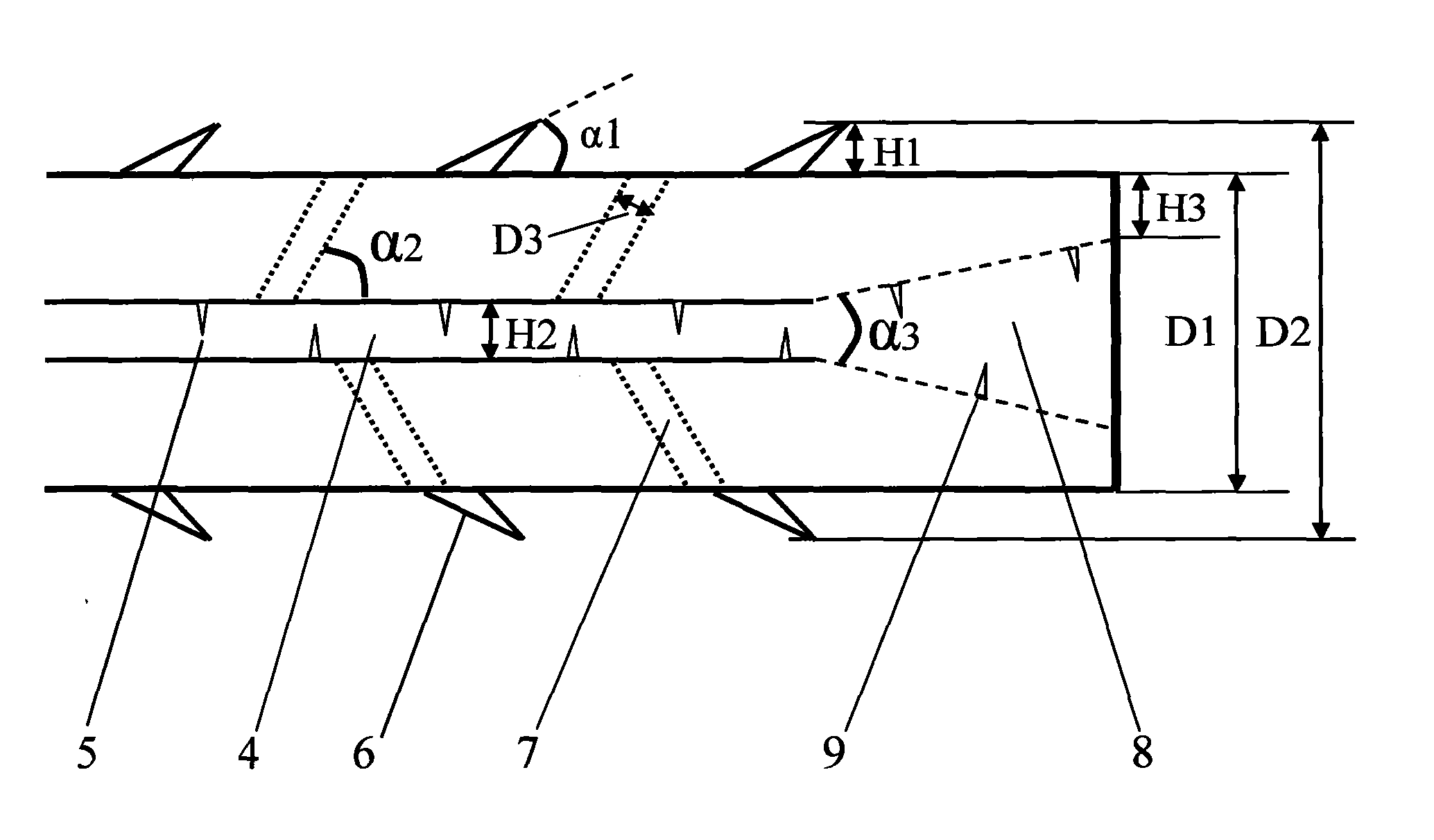

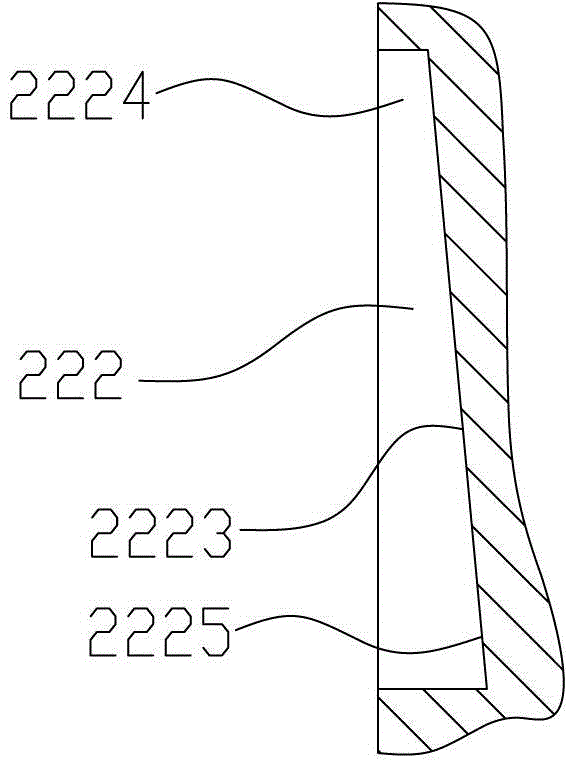

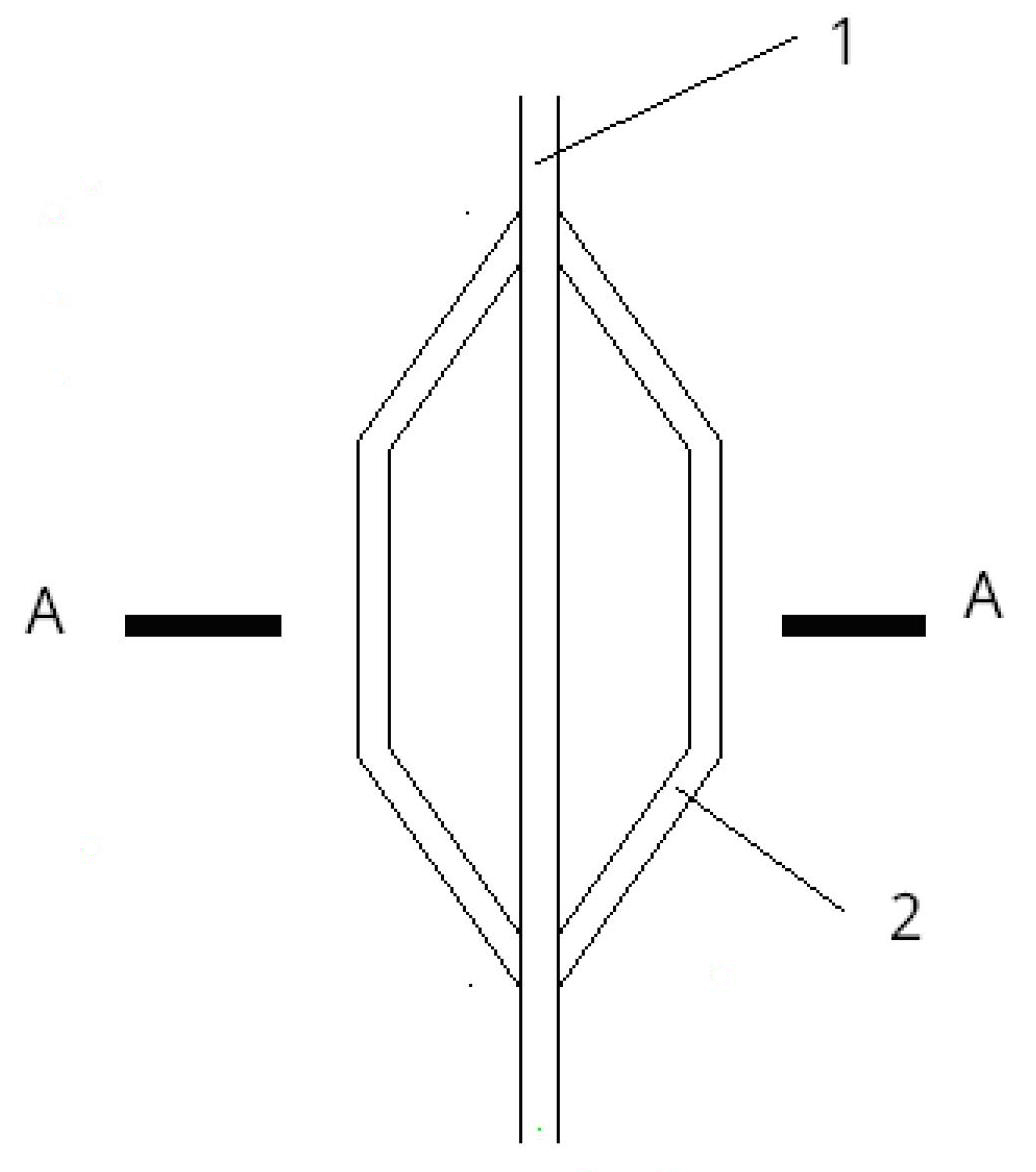

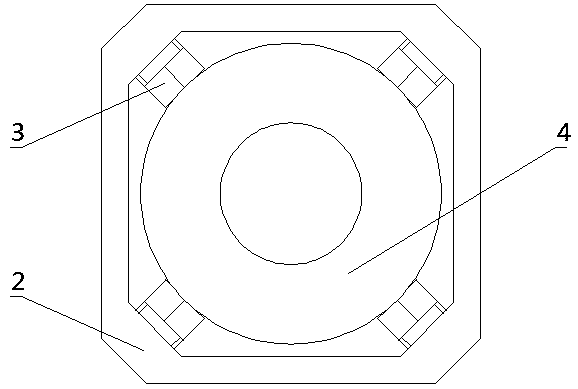

A reaming drill bit

The invention discloses a reamer bit which comprises a drilling unit and a reaming unit. The drilling unit and the reaming unit rotate synchronously along with a drill pipe. The reaming unit comprises a fixing portion, a locating ring and a reaming cutter. A guiding chute is concavely formed in the outer side face of the fixing portion and comprises a first inclining side wall and a second inclining side wall. The depth of one end of the guiding chute is larger than that of the other end of the guiding chute. The locating ring penetrates through the fixing portion and arranged on the fixing portion in a sleeved mode, a through hole is formed in the locating ring, and the reaming cutter is contained in the guiding chute and the through hole. When the drilling unit rotates forwards and conducts drilling, the reaming cutter abuts against the first inclining side wall and moves to one end of the guiding chute along the first inclining side wall, and therefore the reaming cutter is separated from the side wall of a hole. When the reaming unit rotates reversely, the reaming cutter abuts against the second inclining side wall and moves to the other end of the guiding chute along the second inclining side wall, so that the reaming cutter extends out of the through hole and conducts cutting on the side wall of the hole. The reaming cutter can cut the side wall of the drilled hole, so that the reamer bit has the advantage of reaming.

Owner:XIAMEN TEFANG CONSTR ENG GRP

Resin adhesive with high mechanical strength and good heat stability

InactiveCN106381118AEasy full length anchoringImprove self-carrying capacityNon-macromolecular adhesive additivesMacromolecular adhesive additivesDimethylaniline N-oxideAluminium hydroxide

The invention discloses a resin adhesive with high mechanical strength and good heat stability. The resin adhesive comprises a main material and a curing agent. The weight ratio of the main material to the curing agent is 10: 1-3. The main material comprises, by weight, 60-100 parts of 138 unsaturated polyester resin, 20-30 parts of heavy calcium carbonate, 10-16 parts of clay, 6-10 parts of asbestos powder, 15-25 parts of wollastonite, 10-16 parts of mica powder, 15-25 parts of aluminium hydroxide, 8-14 parts of fumed silica, 10-18 parts of attapulgite, 12-22 parts of glass beads, 1.5-2.5 parts of triethylene tetramine and 1.4-2.4 parts of dimethylaniline. The curing agent comprises, by weight, 15-25 parts of 1,1-Di(tert-butylperoxy)cyclohexane, 8-16 parts of diglycol and 6-12 parts of carboxymethyl cellulose. The resin adhesive has good heat stability, high density, high mechanical strength and high pull-out strength. Stable mechanical strength can be maintained for a long time. Thus, use safety is effectively raised. Meanwhile, cost is low.

Owner:ANHUI SKY EYE INTELLIGENT TECH

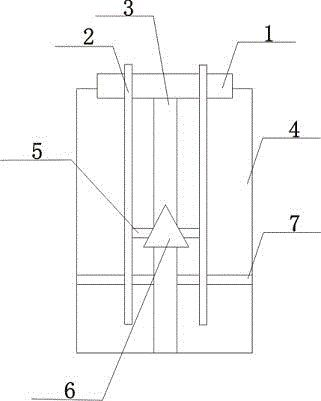

Anti-pull anchor rod

InactiveCN102677669AImprove pullout strengthResolve upward pull forces and groundwater buoyancyBulkheads/pilesPull forceEngineering

The invention discloses an anti-pull anchor rod. The anti-pull anchor rod comprises a columnar anchor rod body, wherein the anchor rod body is vertically provided with at least one positioner; the positioner comprises three positioning convex rings which are uniformly arranged on the outer circumference of the anchor rod body; and the positioning convex rings form an isosceles trapezoid structure by taking the anchor body as a bottom side. The anchor rod body is vertically provided with at least one positioner, so that the anti-pull strength is improved and the problems about the upward pull force of a pipe truss on a buttress and the floating force of underwater are solved.

Owner:ZHONGTIAN CONSTR GROUP

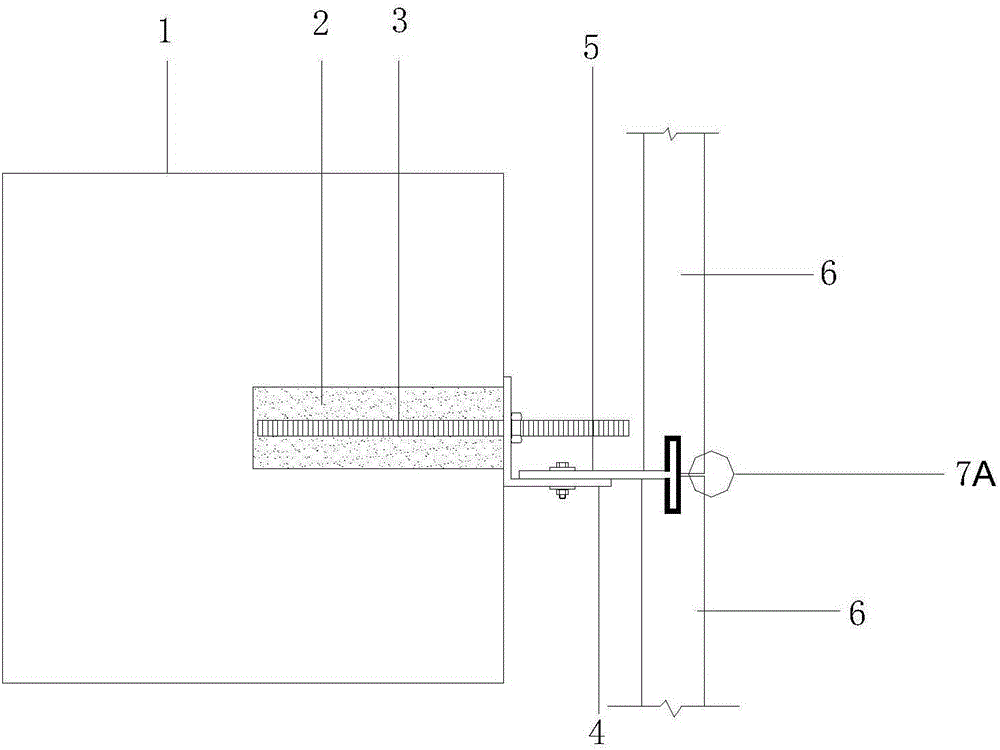

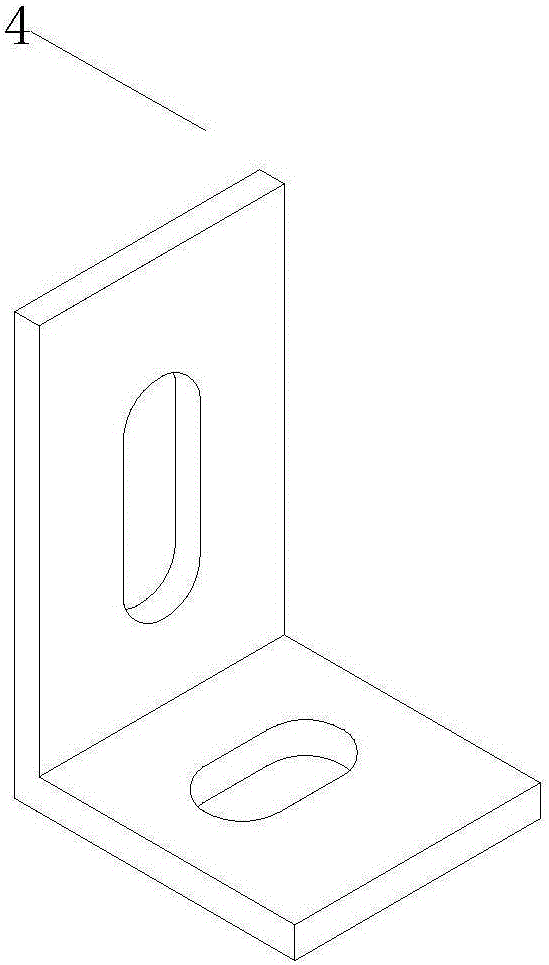

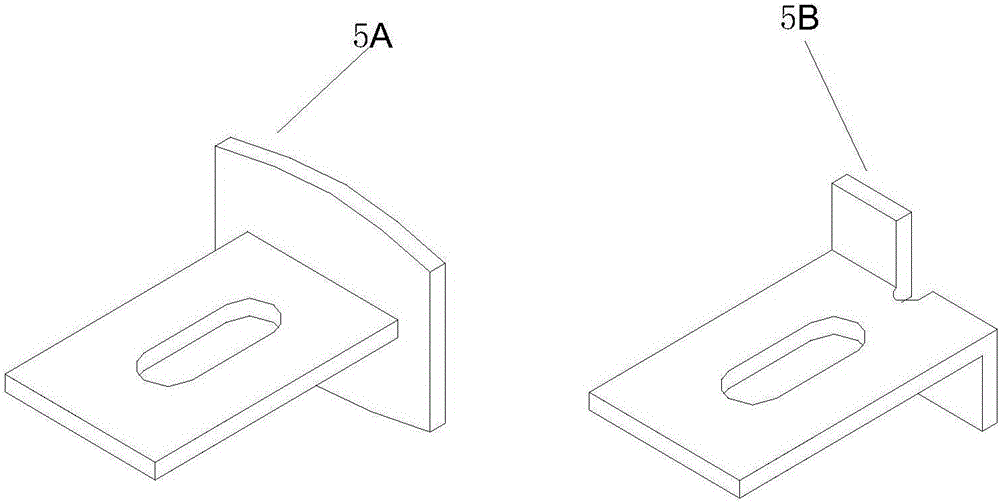

Novel prefabricated sandwiched heat-preserving wall compound connector and connection method thereof

PendingCN108978883ASimple structureEasy to manufactureWallsHeat proofingUltimate tensile strengthWall plate

The invention discloses a novel prefabricated sandwiched heat-preserving wall compound connector and a connection method thereof. The novel prefabricated sandwiched heat-preserving wall compound connector is arranged in an internal concrete wallboard, a heat-preserving board and an external concrete wall. The compound connector comprises a steel connector and a fiber reinforced plastic sleeve. Thesteel connector comprises upper, middle and lower sections. The upper section and the lower section are arranged in the external concrete wall and the internal concrete wallboard. The upper section of the steel connector is circularly connected. The lower section of the steel connector is of a curved shape. The fiber reinforced plastic sleeve is closely arranged in the middle section of the steelconnector. The length of the fiber reinforced plastic sleeve is equal to the thickness of the heat-preserving board. The invention relates to the technical field of assembly-type buildings. The novelprefabricated sandwiched heat-preserving wall compound connector and the connection method thereof are low in weight, low in heat conduction coefficient, high in shear strength, good in corrosion resistance and easy and convenient in construction.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

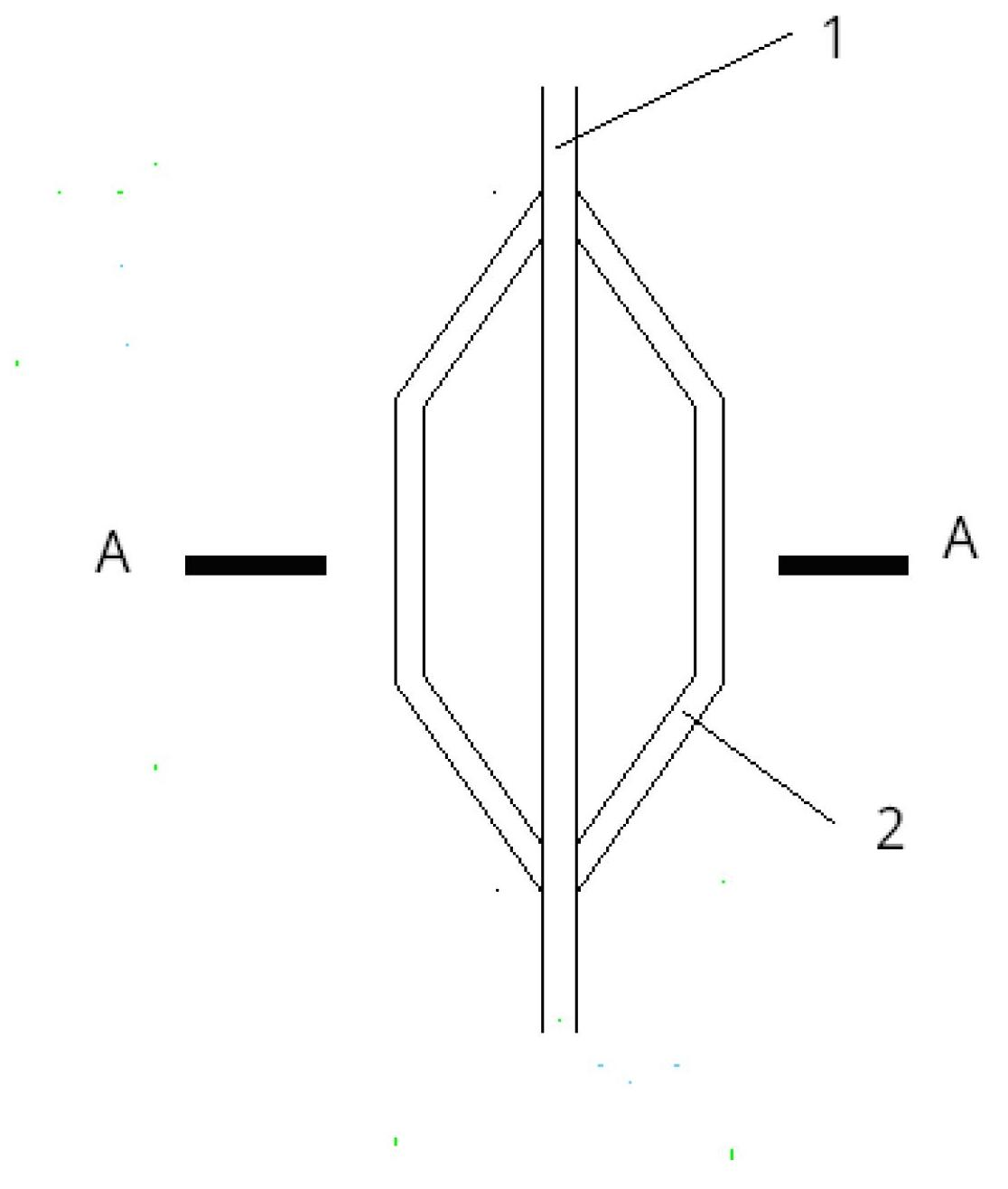

Medical anchor type vertebral pedicle screw

ActiveCN103860251AImprove pullout strengthImprove stabilityInternal osteosythesisFastenersSpinal columnVertebral pedicle

The invention discloses a medical anchor type vertebral pedicle screw which is mainly used for the spine surgery of an osteoporosis patient. The vertebral pedicle screw comprises a vertebral pedicle screw body with outer threads, wherein the vertebral pedicle body is provided with two symmetrical J-shaped hole passages which are respectively communicated with the outside by a hole between the screw pitch of the outer threads, the position of the hole of one J-shaped hole passage at the screw pitch of the vertebral pedicle screw is half of the screw pitch higher than the position of the hole of the other hole passage, two fixing pins which are inserted in the two hole passages and the vertebral pedicle body form an anchor type structure. An anchoring method is used for changing the contact mode between the cancellous bone screw and a centrum, so that the anti-pullout-force strength of the vertebral pedicle screw can be effectively improved.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Medical vertebral arch pedicle renovating screw assembly

InactiveCN101669837BNo side effectsGood biocompatibilityInternal osteosythesisFastenersSpinal columnInternal fixation

The invention discloses a medical vertebral arch pedicle renovating screw assembly which comprises a screw sheath and a screw which are mutually matched, wherein the screw sheath has certain mechanical strength and toughness, and the medical absorbable material can effectively maintain the mechanical strength for 2 to 3 months in vivo; the screw sheath is divided into a head end and a sheath body; the head end is a cone with a sealed front end, and the sheath body is a cylinder; external threads are arranged on the outer surface of the cylinder, and a longitudinally extended triangular prism-shaped cavity is arranged in the cylinder; the cylinder is divided into three side walls by the cavity, and internal threads are designed on the inner wall of the cavity; the screw is made of medical titanium alloy and comprises a thread section and a tail part; the thread section is formed by connecting a screw tip and a screw body, and both the screw tip and the screw body are in external threaddesign; the tail part is provided with a radially communicated U-shaped groove, and internal threads are arranged on the inner wall of the U-shaped groove. The invention can improve the internal fixation stability and reliability of the spinal column in a renovating operation or the secondary screw arranging process, reduce the occurring rate of vertebral arch pedicle screw loosening and even separation and lower the failure rate of operations.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

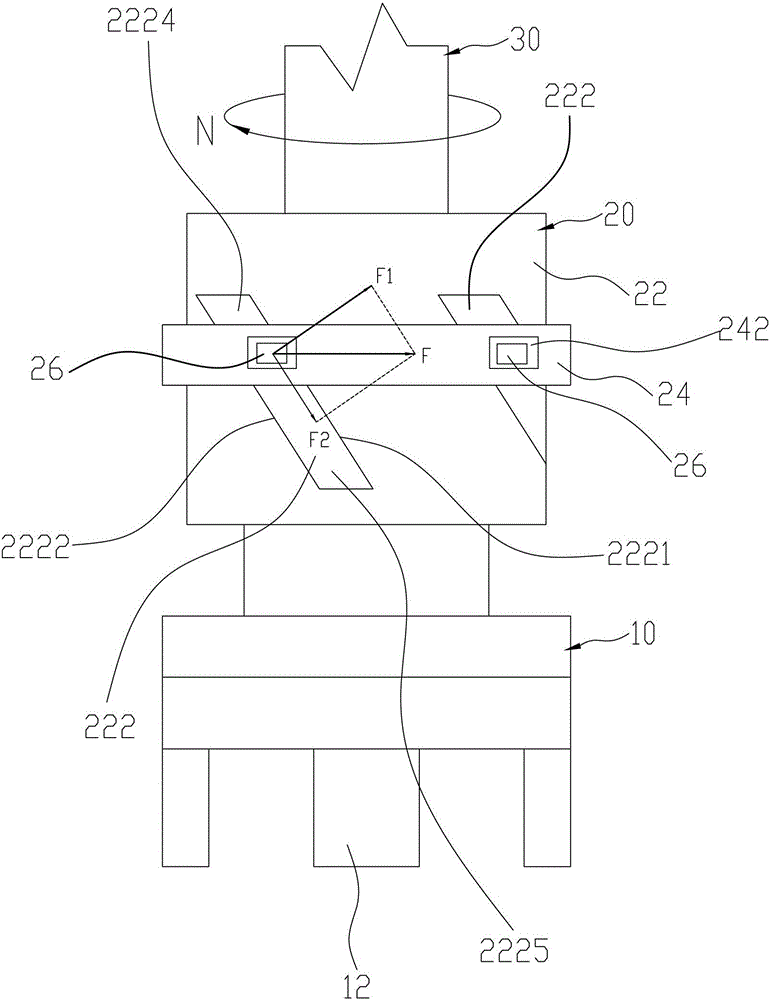

Wind-resistant and overturn-preventing external expansion pole foundation for electric power

InactiveCN111042186APay attention to reinforcementDoes not affect aestheticsFoundation engineeringTowersControl theoryElectric power

The invention provides a wind-resistant and overturn-preventing external expansion pole foundation for electric power. The pole foundation is arranged underground and used for supporting a pole, so that the pole has better wind-resistant, overturn-preventing and anti-pulling capacity; and the foundation can be reused during pole replacement or line transfer in the future, and investment is not wasted. The foundation is characterized in that the foundation is placed on the ground and directly driven or pressed underground after being straightened; a four-way expansion board is arranged at the lower part of the foundation and can be increased and decreased according to actual conditions, a nut is tightened to allow a two-way conical screw to rise, the expansion board expands in each direction, and the lower part of the expansion board is claw-shaped to strengthen the stability and anti-pulling capacity of the foundation; an inverted horn-shaped countersink is formed in the upper part ofthe foundation, and positioning bolts are arranged on the periphery of the upper part of the inverted horn-shaped countersink; and a heavy electric pole is placed in the inverted horn-shaped countersink, the lower end of the heavy electric pole is clamped at the bottom of the inverted horn-shaped countersink, the positioning bolts adjusts the vertical degree of the heavy electric pole, then, a wedge block is plugged in the inverted horn-shaped countersink to further fix the heavy electric pole, and finally, the countersink is filled with soil.

Owner:张若玮

Electric power anti-wind anti-overturning inner expansion electric pole foundation

InactiveCN111042187APay attention to reinforcementDoes not affect aestheticsFoundation engineeringTowersControl theoryMechanical engineering

The invention provides an electric power anti-wind anti-overturning inner expansion electric pole foundation which is arranged below the ground and is used for supporting an electric pole, so that theelectric pole has better wind resistance, overturning resistance and pulling resistance; when the electric pole is replaced or a line is migrated in the future, the foundation can be reused, and investment is not wasted. The electric power anti-wind anti-overturning inner expansion electric pole foundation is characterized in that the foundation is placed on the ground, and is directly driven orpressed into the ground after being straightened; the lower part of the foundation may be provided with four expansion plates, the expansion plates can be separately expanded in all directions by screwing a screw rod, and the lower part is claw-shaped so as to enhance the stability and the pulling resistance of the foundation; and the upper part of the foundation is provided with an inverted horn-shaped counter bore, positioning bolts are arranged around the upper part of the inverted horn-shaped counter bore, a heavy-duty electric power pole is placed in the inverted horn-shaped counter bore,the lower end of the heavy-duty electric power pole is clamped at the bottom of the inverted horn-shaped counter bore, the vertical degree of the heavy-duty electric power pole is firstly adjusted bythe positioning bolts, then a wedge block is inserted into the inverted horn-shaped counter bore to further fix the heavy-duty electric power pole, and finally a hole pit is filled with soil.

Owner:张若玮

Slurry injection anchoring capsule

PendingCN107460874AImprove solidification qualityEfficient replacementBulkheads/pilesReverse osmosisEngineering

The invention discloses a slurry injection anchoring capsule. A slurry injection pipe sequentially penetrates an upper clamping head, a capsule body and a lower clamping head from top to bottom and then extends into a positioning protection head. The part, inside the capsule body, of the slurry injection pipe is provided with a low-pressure slurry injection check valve, and the part, inside the positioning protection head, of the slurry injection pipe is provided with a high-pressure slurry injection check valve. The outer wall of the positioning protection head is provided with at least one slurry draining hole, and one-way valves are arranged on portions of the slurry draining holes. A cavity of the positioning protection head is internally provided with a round supporting plate through a suspender. One or more guiding pipes are connected in the center axis direction of the upper clamping head and the lower clamping head through the capsule body. The capsule body is made of reverse osmosis anticorrosion cloth. By means of the improvement, cement slurry can be smoothly injected into the capsule body, clay grout around the capsule body can be effectively replaced, the solidification quality of the capsule body is effectively improved, and the anti-drawing strength is improved.

Owner:XINXIANG JIAHUI TECH

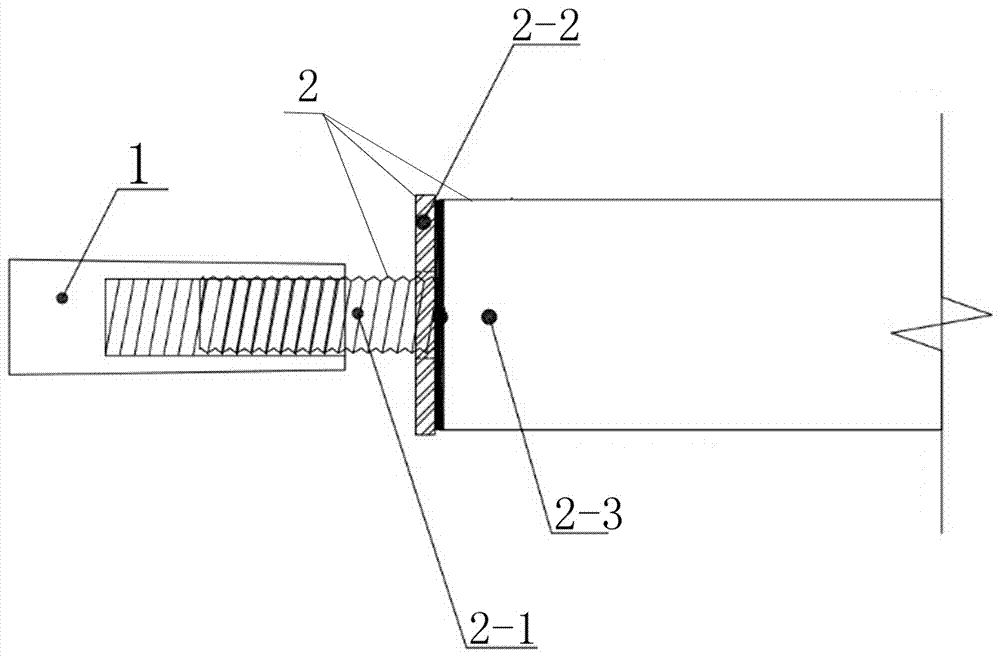

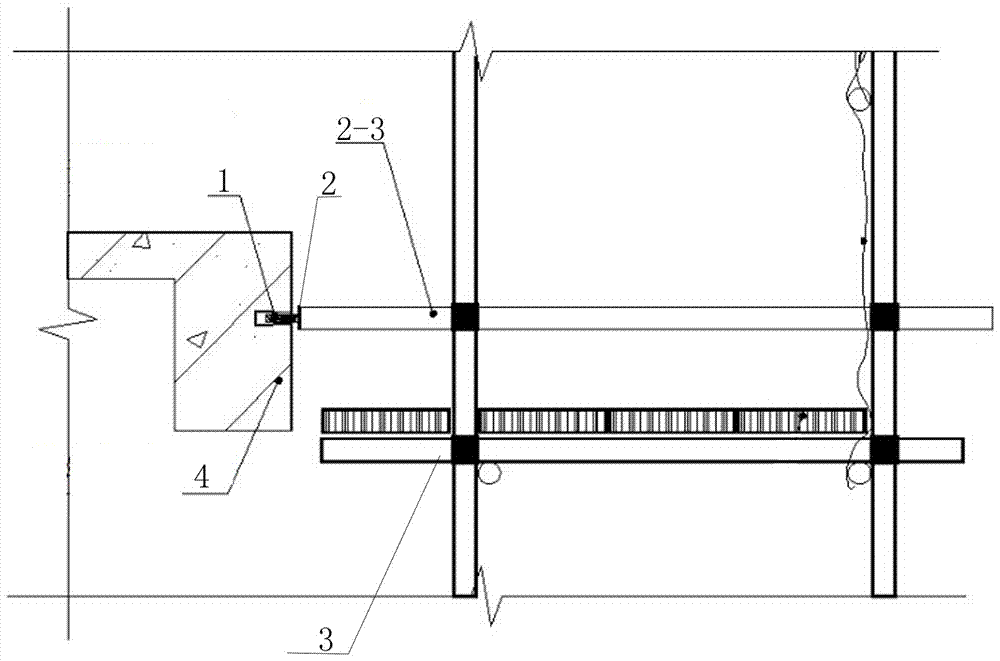

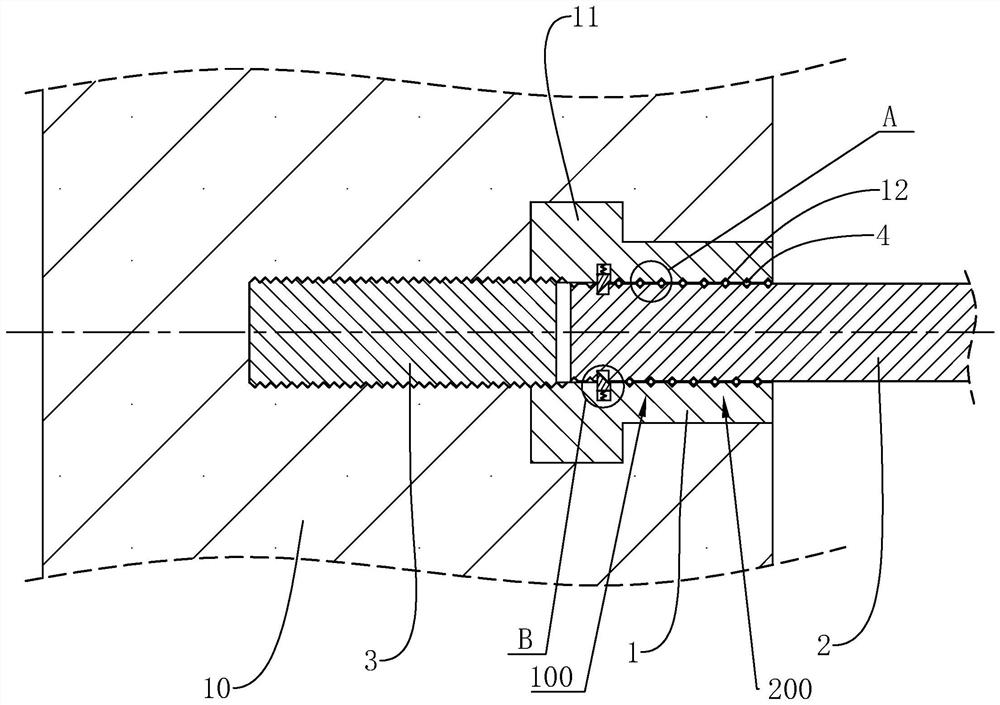

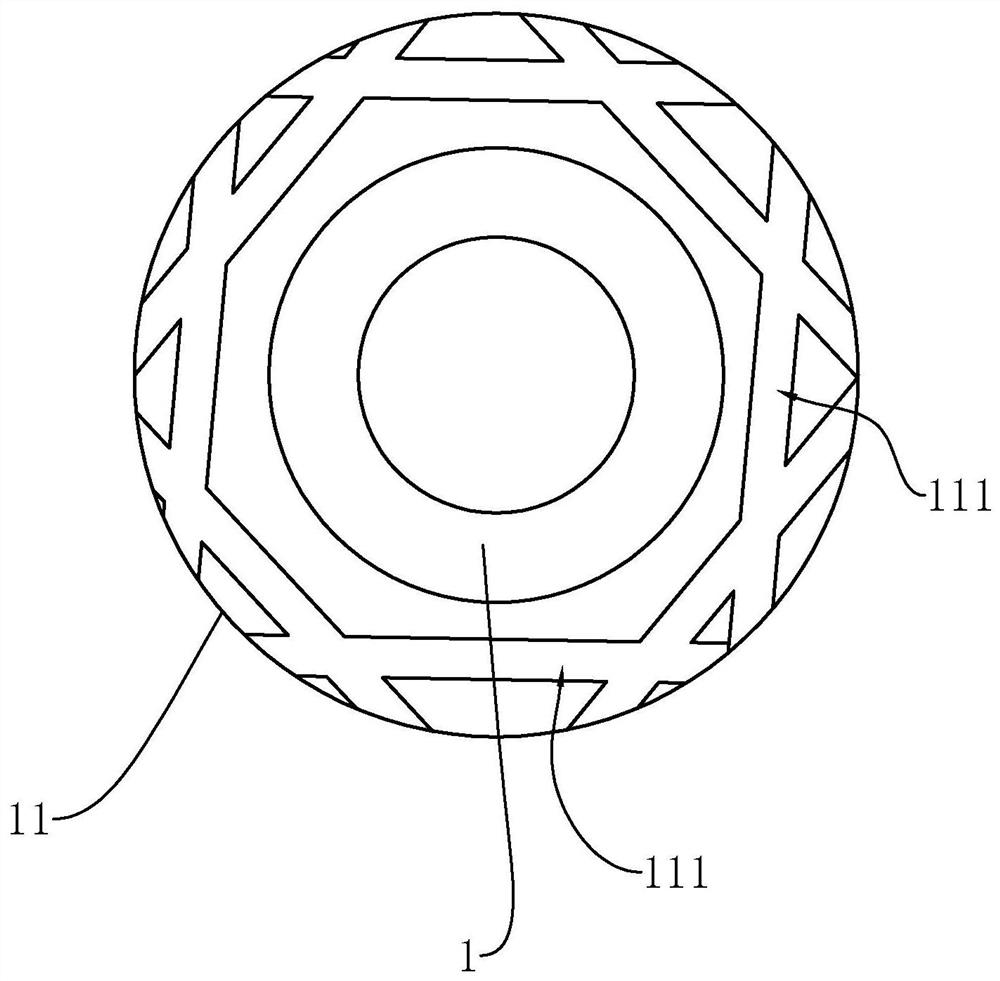

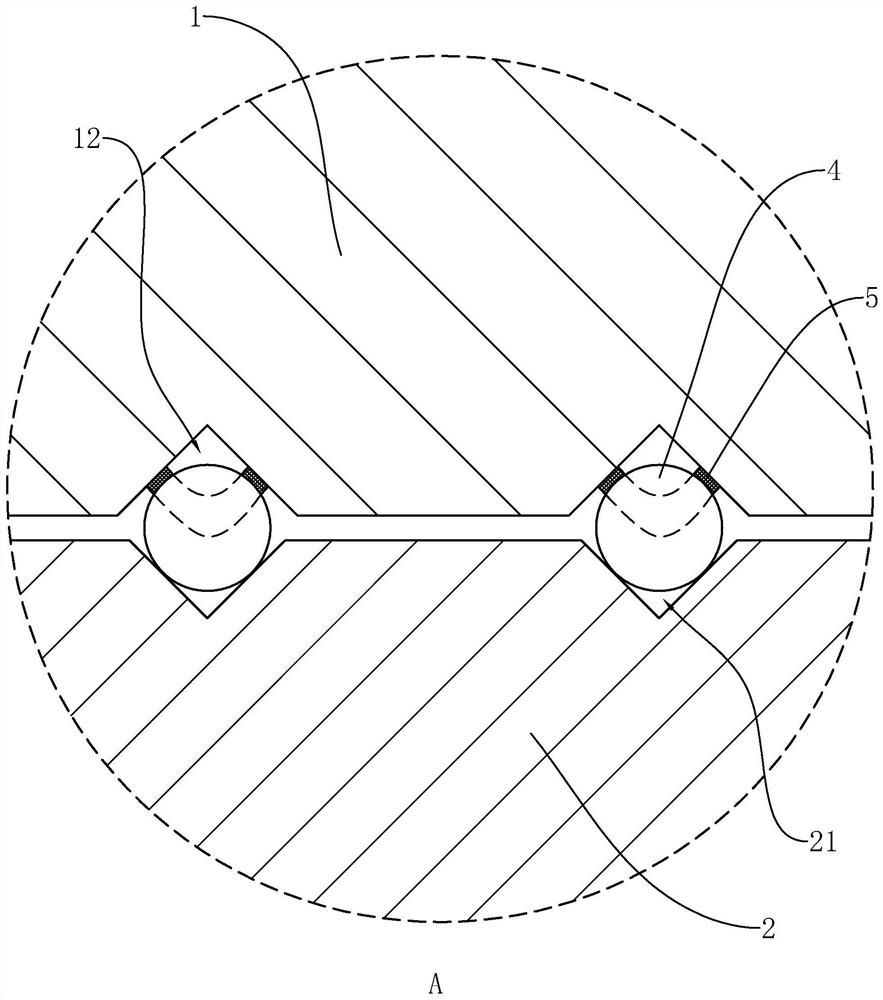

A pre-embedded component of wall tie bars and its construction method

The present application relates to a pre-embedded assembly of wall tie bars, including a pre-embedded sleeve pre-embedded in the wall and a tie piece connected to the pre-embedded sleeve. The inner peripheral wall of the pre-embedded sleeve is provided with a second A helical groove, the tie is a columnar structure, the outer peripheral wall of the tie is provided with a second helical groove, the first helical groove and the second helical groove are combined to form a helical cavity, and the helical cavity The inside is filled with a plurality of steel balls along its own spiral path. In this application, by setting the steel balls stuck between the first helical groove and the second helical groove at the same time, the pulling force on the tie piece is converted into the shear stress on the steel balls, and the structure of the steel balls is denser and stronger. , not easy to be crushed, and the steel ball can effectively resist the shear stress, thereby greatly improving the pull-out strength of the tie.

Owner:中建协和建设有限公司

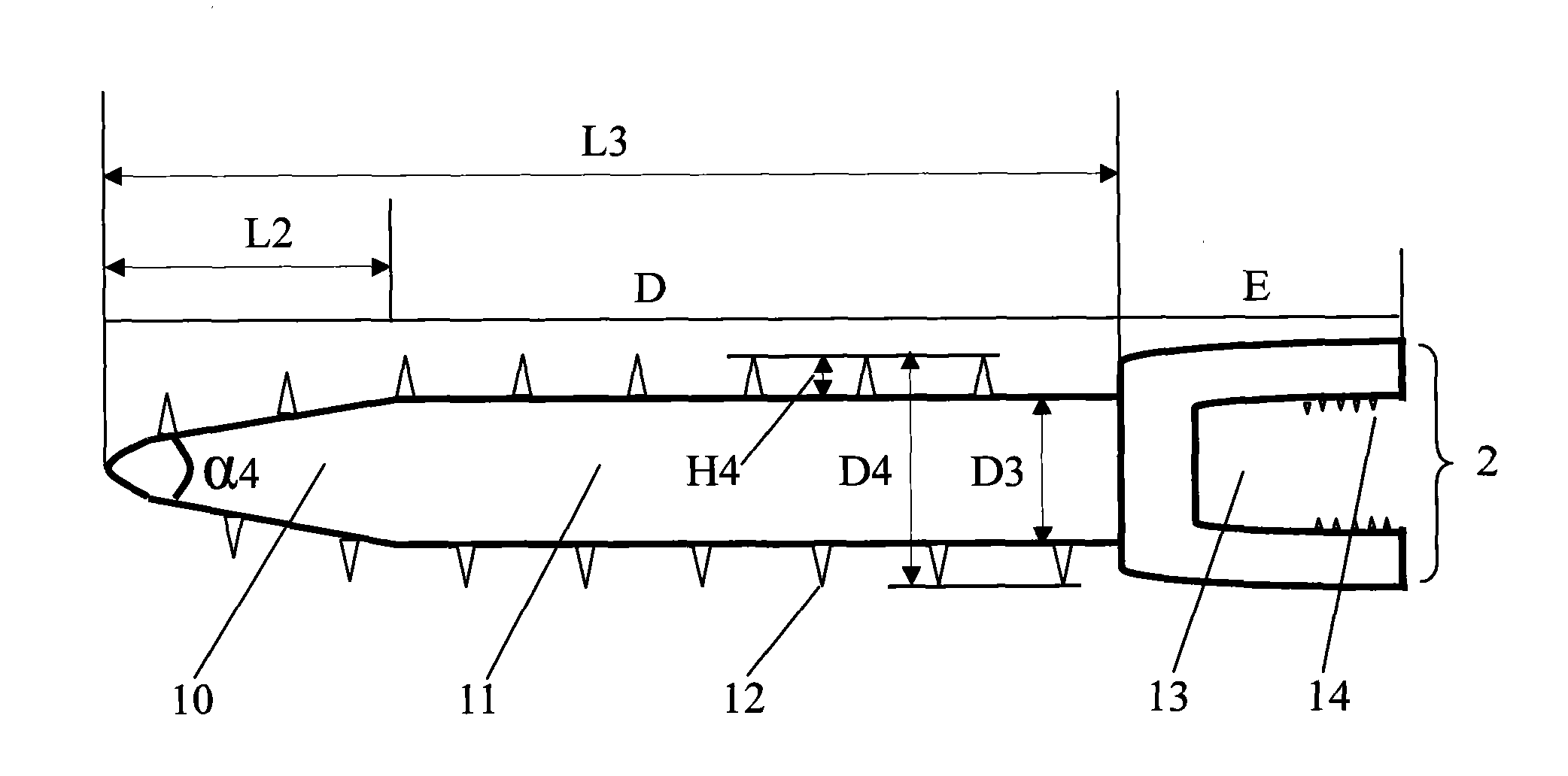

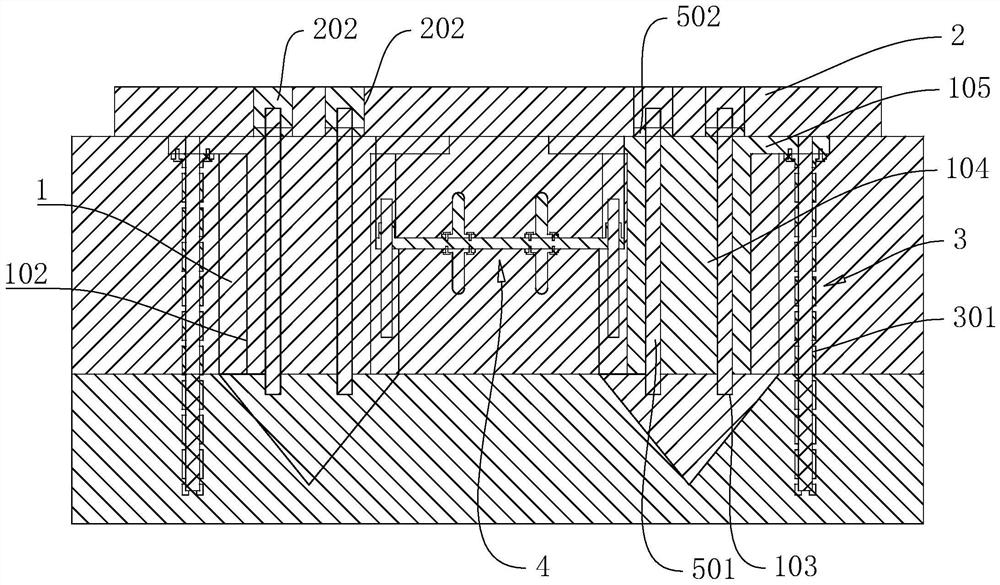

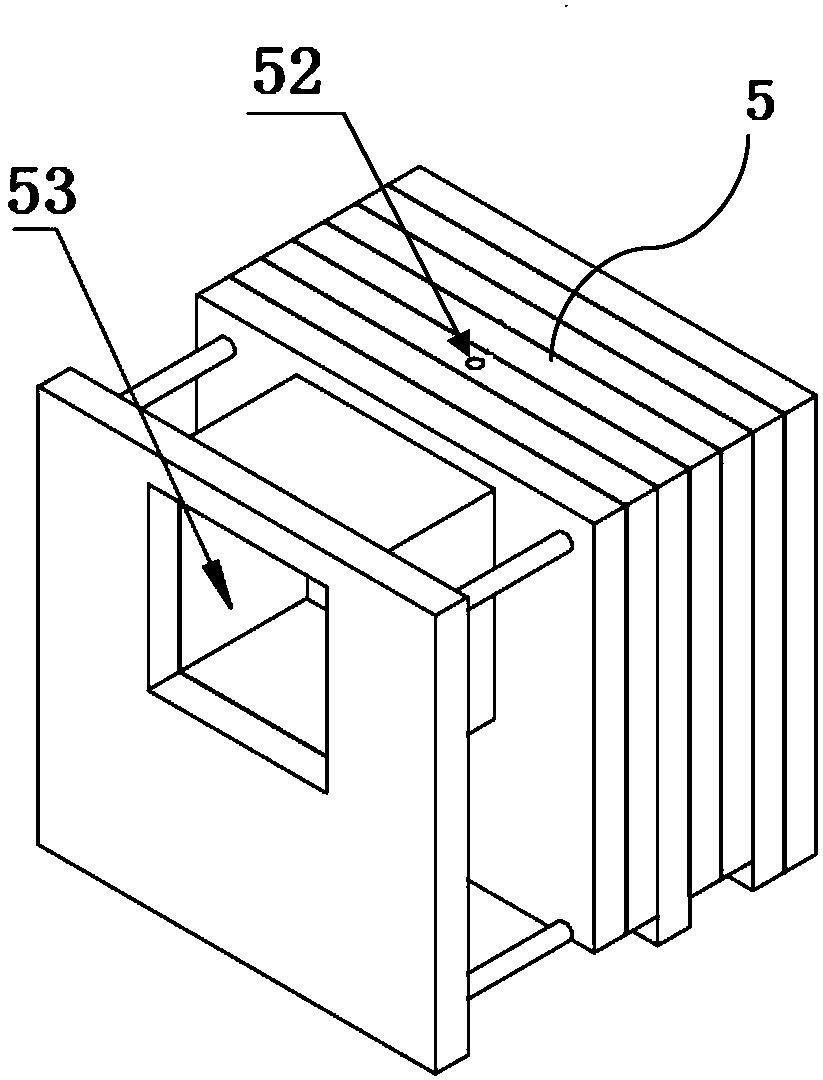

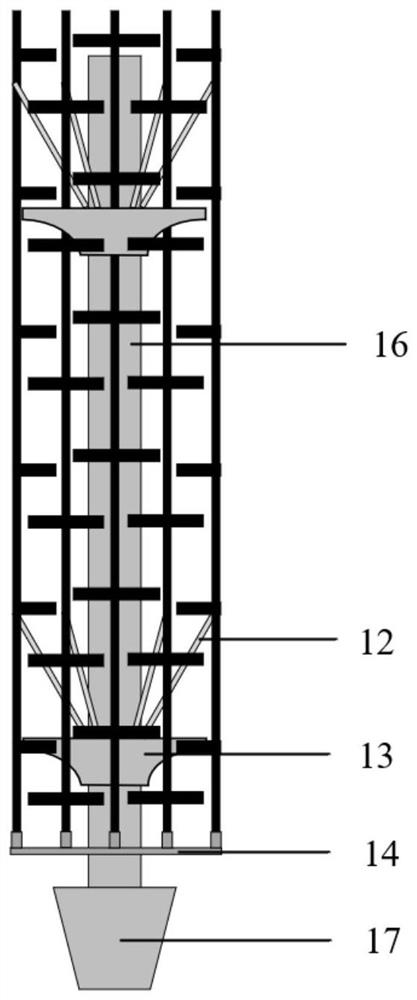

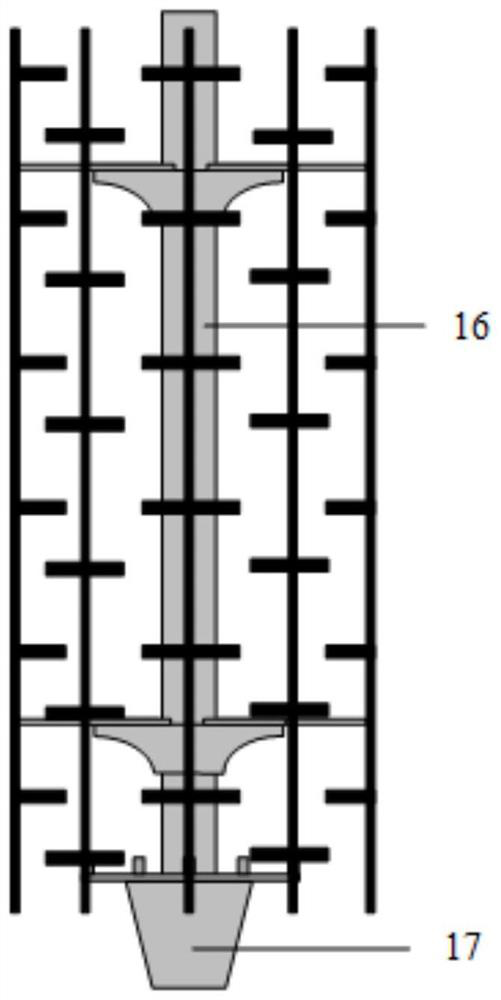

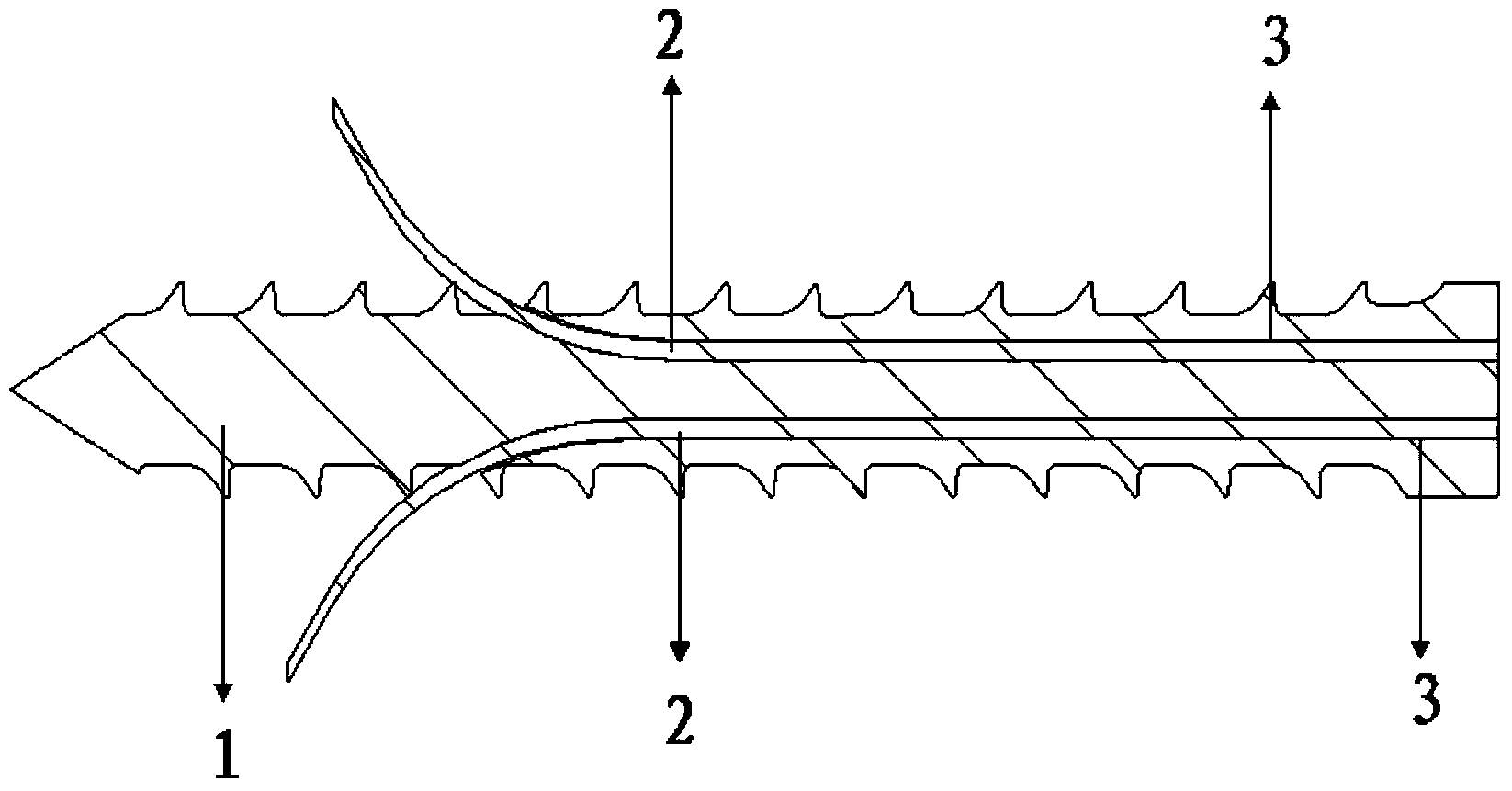

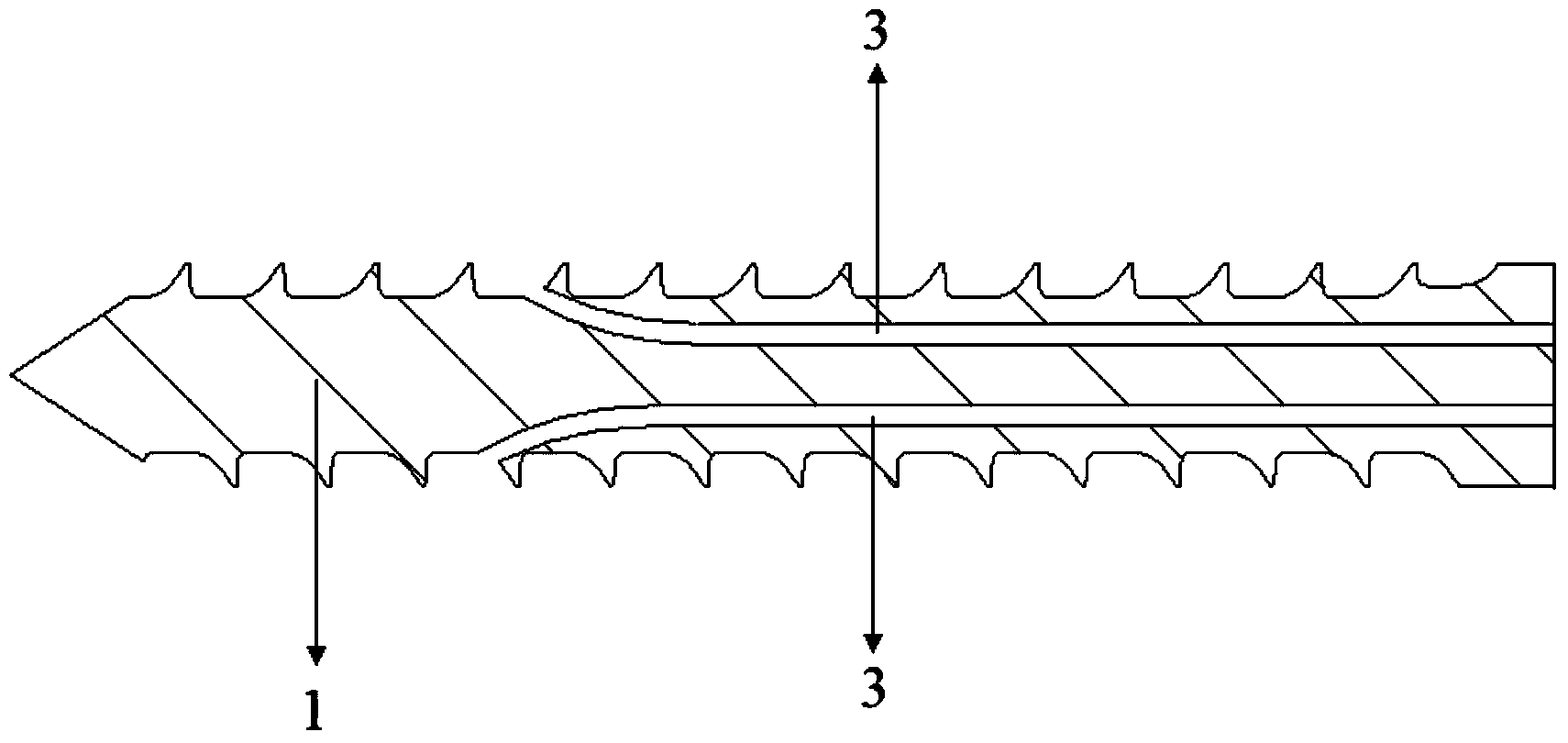

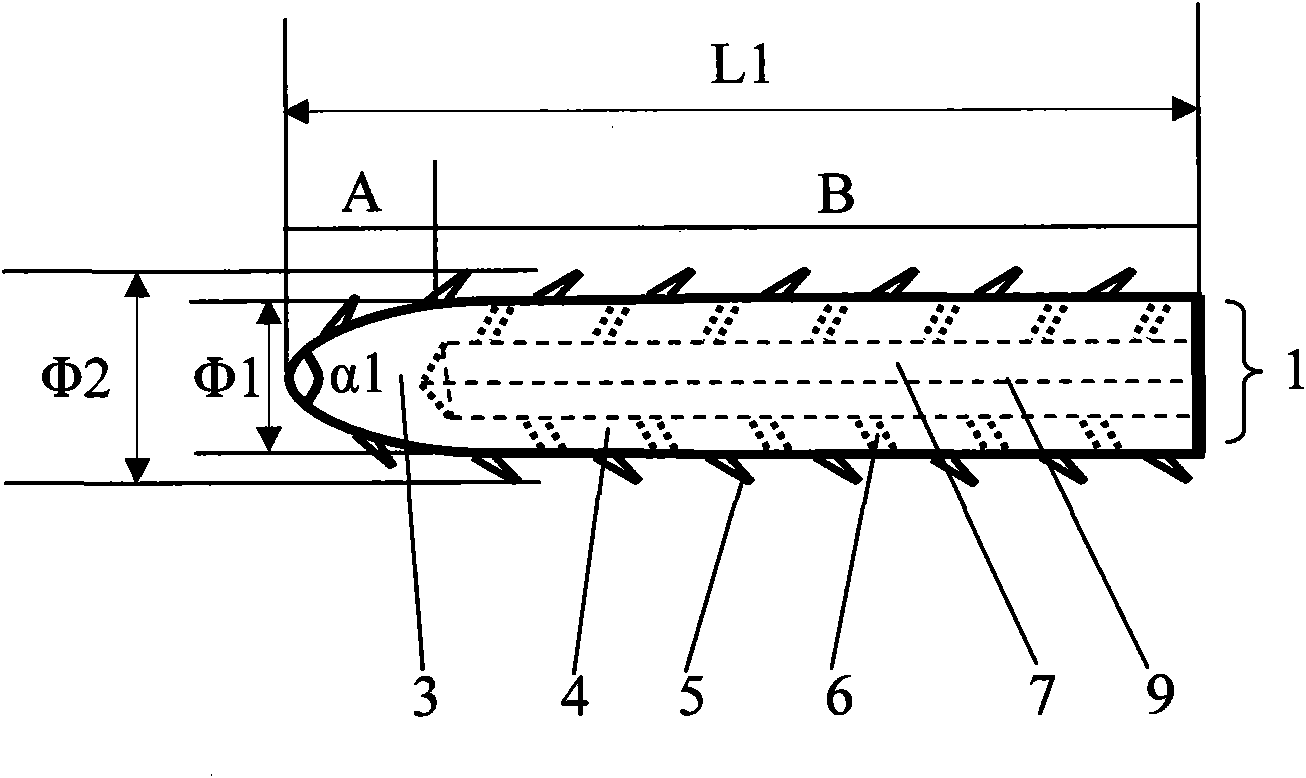

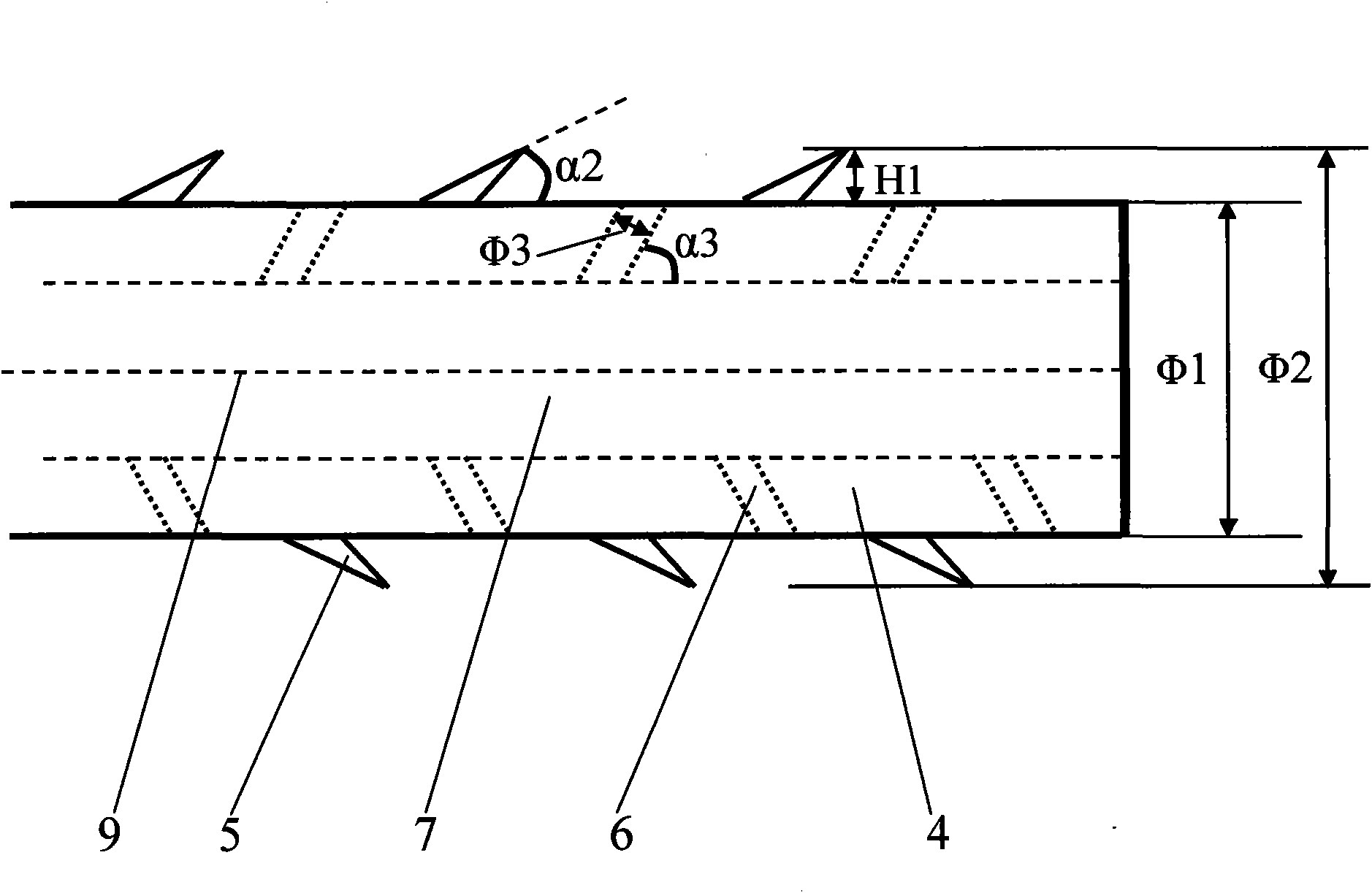

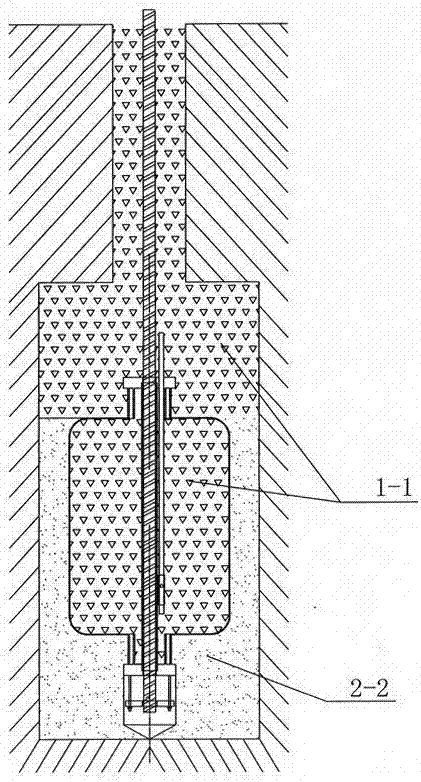

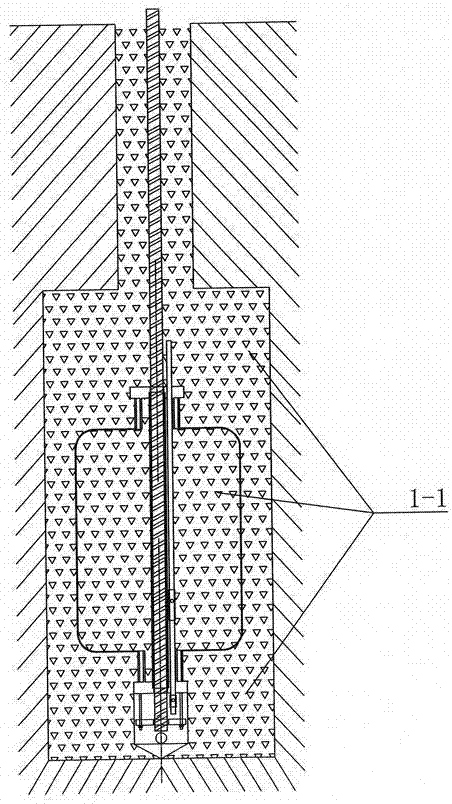

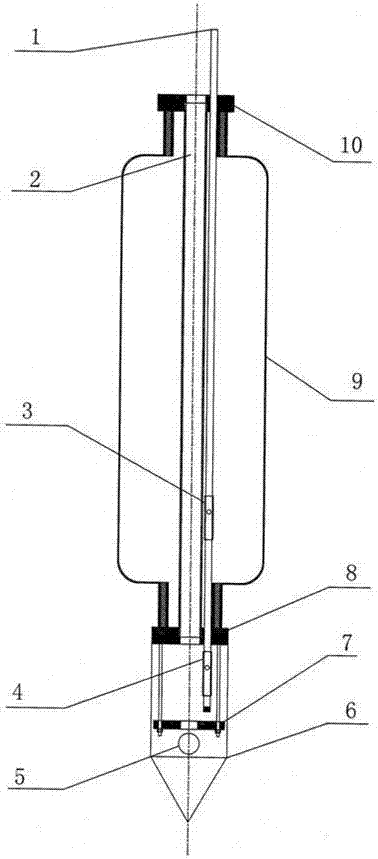

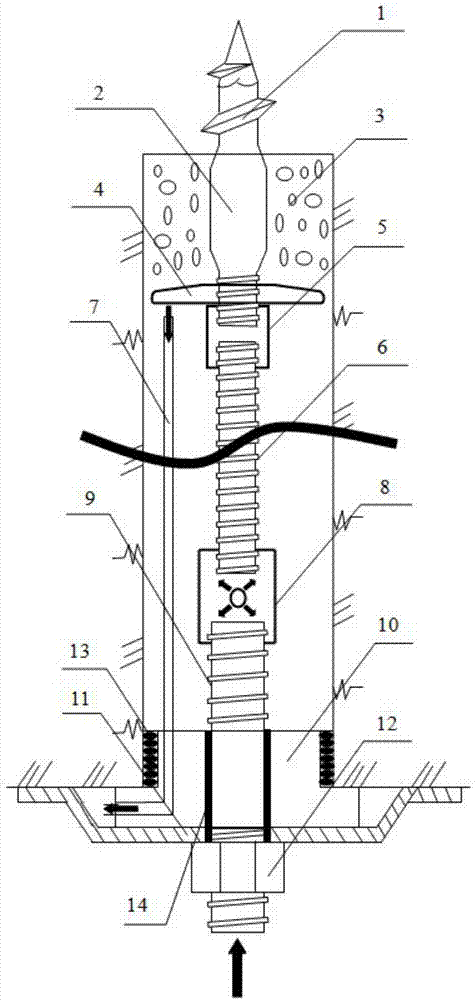

A Three-Stage Anchor Combined Hollow Grouting Anchor

ActiveCN105604593BCrushed fullyPlay an initial anchoring roleBulkheads/pilesAnchoring boltsThree stageHelical blade

The invention relates to a three-stage anchoring combined type hollow anchor rod for grouting. The anchor rod comprises anchor heads, a metal pressure ring (4), a front connector (5), a solid twisted steel rod body (6), a rear connector (8), a hollow grouting anchor rod body (9), a stop-grouting plug (10) provided with an exhaust porous channel and an flexible exhaust pipe (7). The anchor heads comprise the main anchor head (1) and the subsidiary anchor head (2), the main anchor head (1) is provided with a helical blade with the diameter increased gradually, and the rear end of the subsidiary anchor head (2) is provided with a thread; the anchor heads rotationally penetrate through the metal pressure ring (4) and then are fixedly connected with the solid twisted steel rod body (6) through the front connector (5); the rear connector is used for fixedly connecting the solid twisted steel rod body (6) with the hollow grouting anchor rod body (9), a grout outlet is formed in the side face of the rear connector, and the grout outlet is communicated with the interior of the hollow grouting anchor rod body (9). By means of the three-stage anchoring combined type hollow grouting anchor rod, the three-stage anchoring effect with the novel anchor heads, an anchoring agent, the anchor rod and mortar acting in a combined mode can be achieved.

Owner:TIANJIN UNIV

Cast-in-situ pile structure

ActiveCN104372791BImprove carrying capacityImprove pullout strengthBulkheads/pilesUltimate tensile strengthBearing capacity

Owner:浙江原野建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com