Construction method for indoor light block wall stone dry-hanging

A construction method and technology of dry-hanging stone, applied in covering/lining, construction, building structure, etc., can solve the problems of low tensile strength of lightweight blocks, small contact area between walls and expansion bolts, large span, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

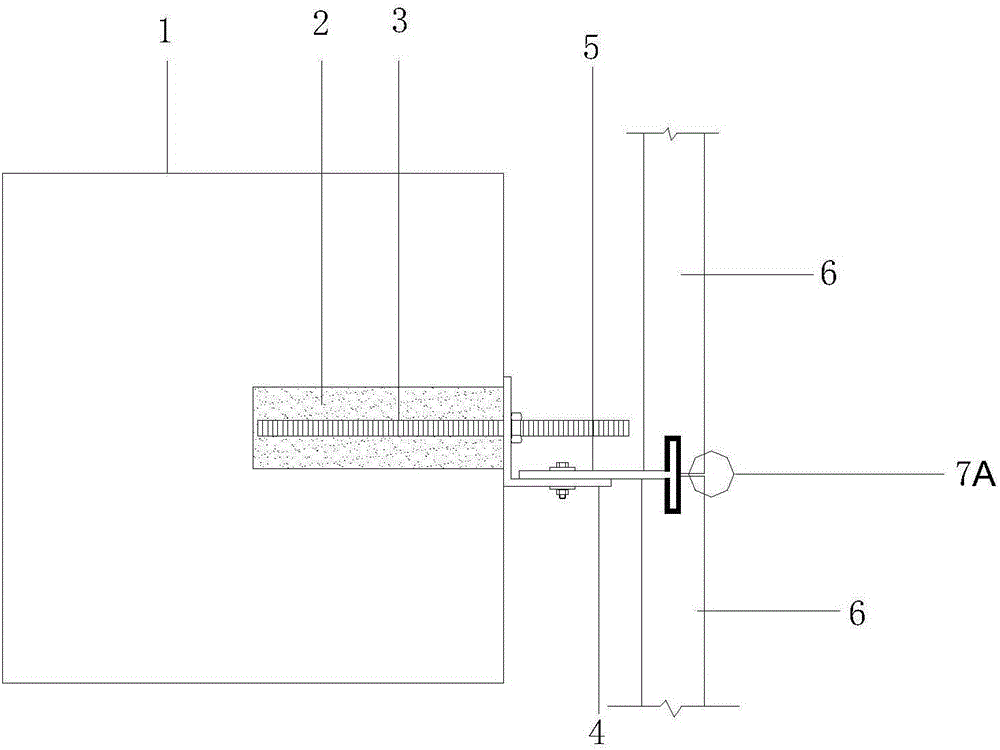

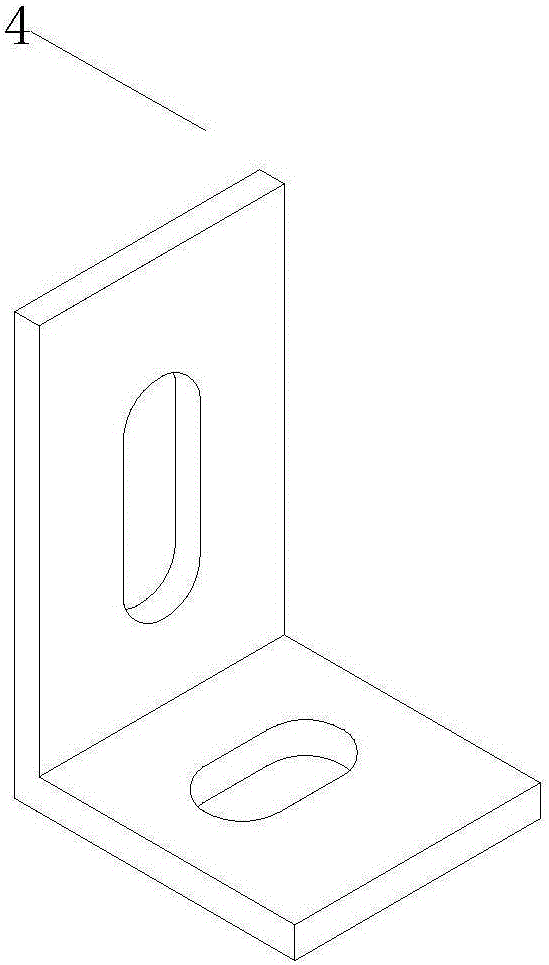

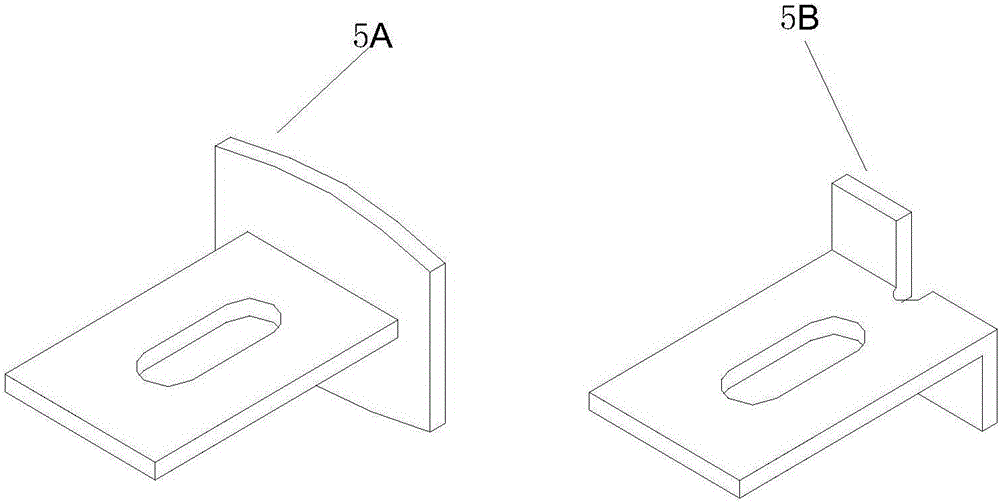

[0035] Attached below Figure 1-Figure 5 The present invention will be further described in detail with specific embodiments.

[0036] In order to solve the above problems, the present invention provides a construction method for indoor dry hanging of light block wall stone, comprising the following steps:

[0037] Step 1, base surface treatment, remove attachments, laitance, dust, etc. on the wall base surface 1;

[0038] Step 2. According to the construction drawings, determine the positions of drilling holes, embedded parts, corner codes, pendants, and stone materials in sequence, and mark them on the base surface in the form of crosshairs;

[0039] Step 3, post mortar embedded parts construction process, the process includes the following steps,

[0040] Step 31, the rear hole drilling process, use the percussion drill to drill a 32mm, 100mm deep rear hole 2 on the positioning point of the embedded part on the wall;

[0041] Step 32, the cleaning and drying process of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com