Vibration-damping temperature-insulation elemental-plate-type ballast-less track structure

A technology of ballastless track and unit slab, applied in the direction of track, road, ballast layer, etc., can solve the problems of subgrade frost heaving, etc., achieve the effect of weakening dynamic load, reducing thickness, and clear force transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

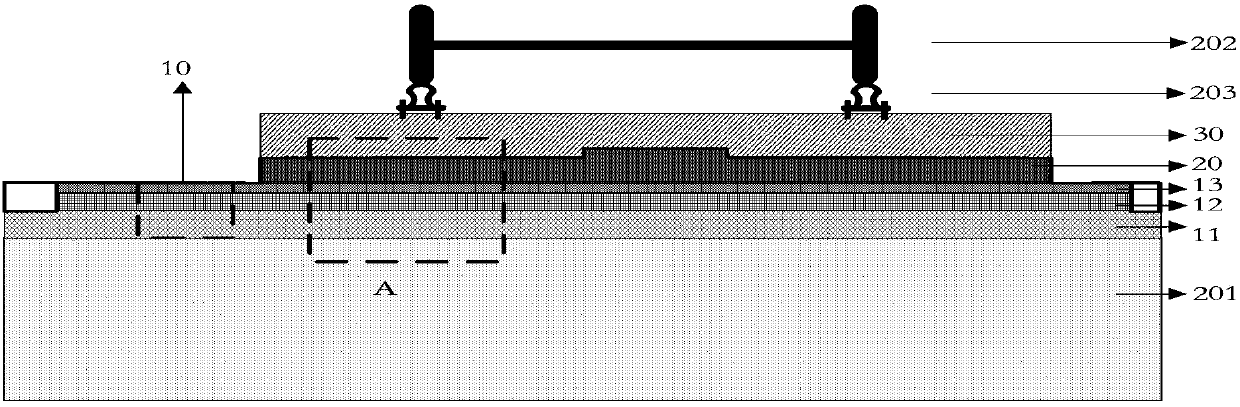

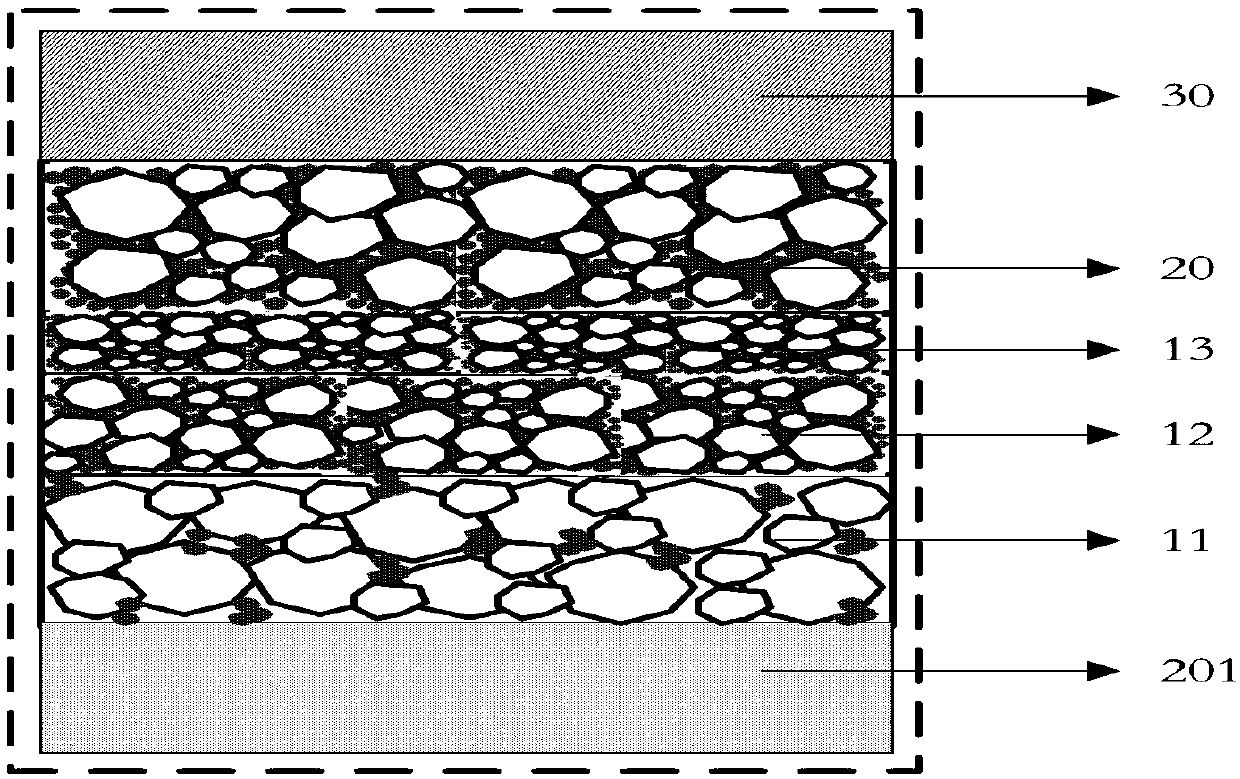

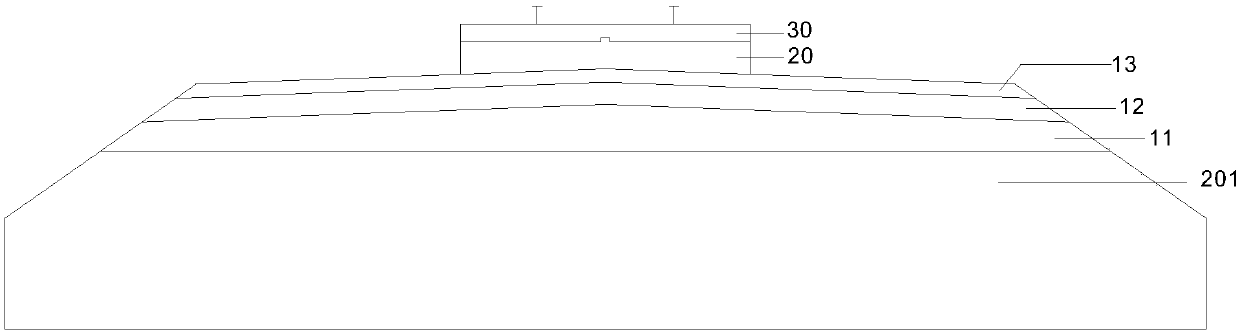

[0028] Such as Figure 1-2 As shown, it is a vibration-damping and temperature-insulating unit slab ballastless track structure of a preferred embodiment of the present invention, including a three-point asphalt graded crushed stone subbase 10 and a rubber-modified asphalt layer 20 paved sequentially from bottom to top. And the track surface layer 30, the three-point asphalt graded crushed stone subbase 10 includes a graded crushed stone layer 11, an asphalt crushed stone mixture layer 12, an asphalt concrete mixture layer 13, and a three-point asphalt grade The porosity of the mixed crushed stone subbase 10 gradually increases from top to bottom, and the graded crushed stone layer 11 is paved on the foundation bed fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com