Patents

Literature

65results about How to "Ensure positional stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

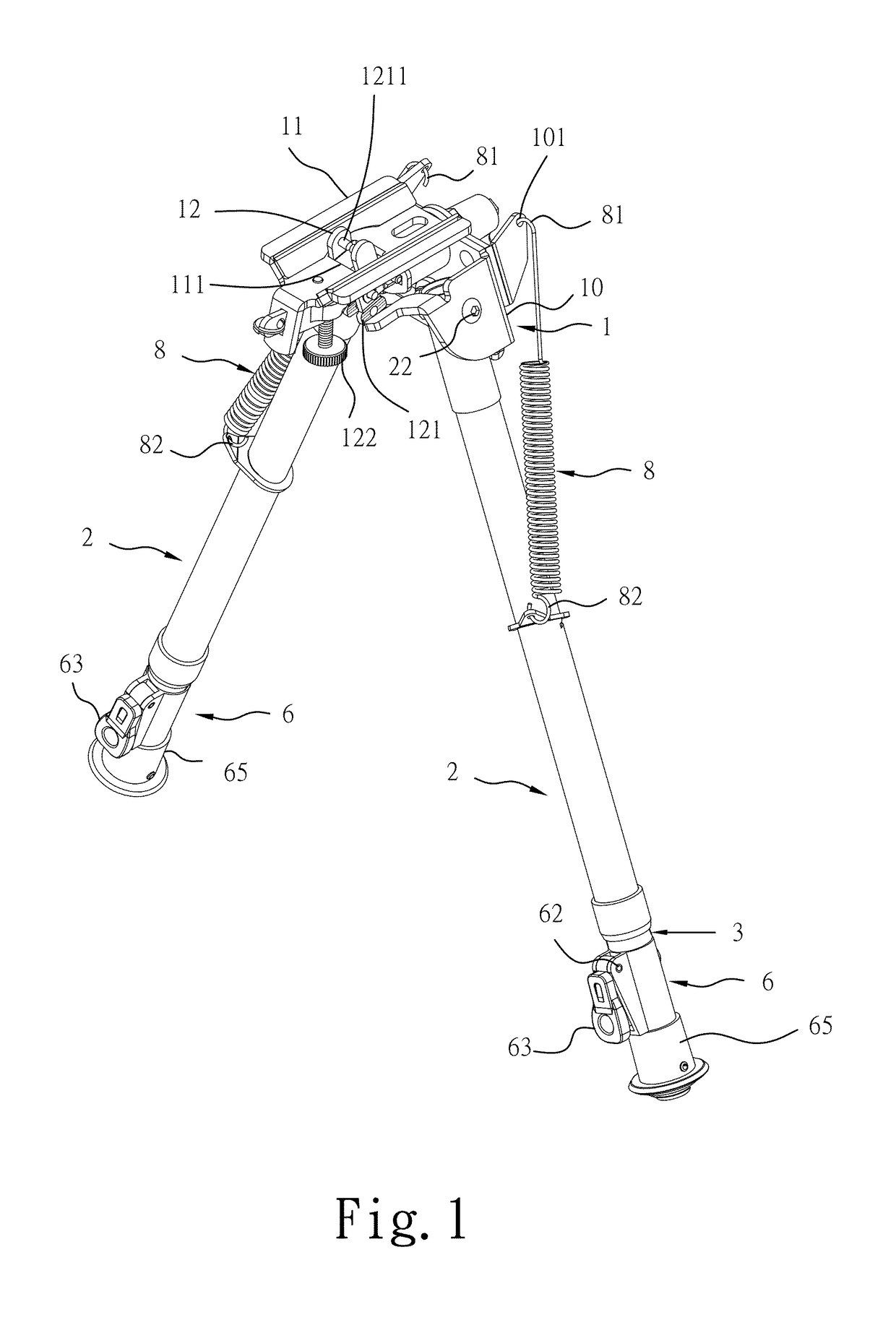

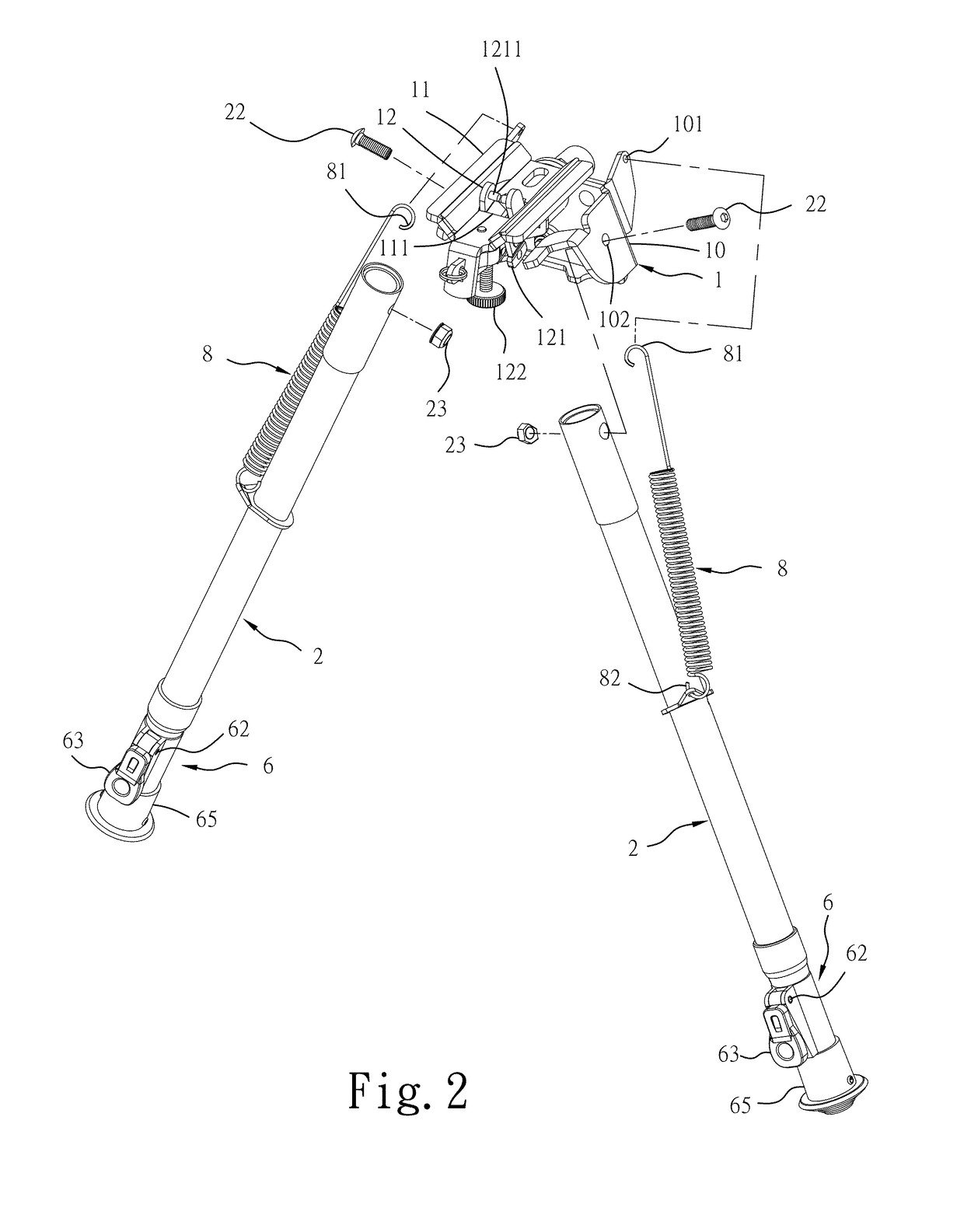

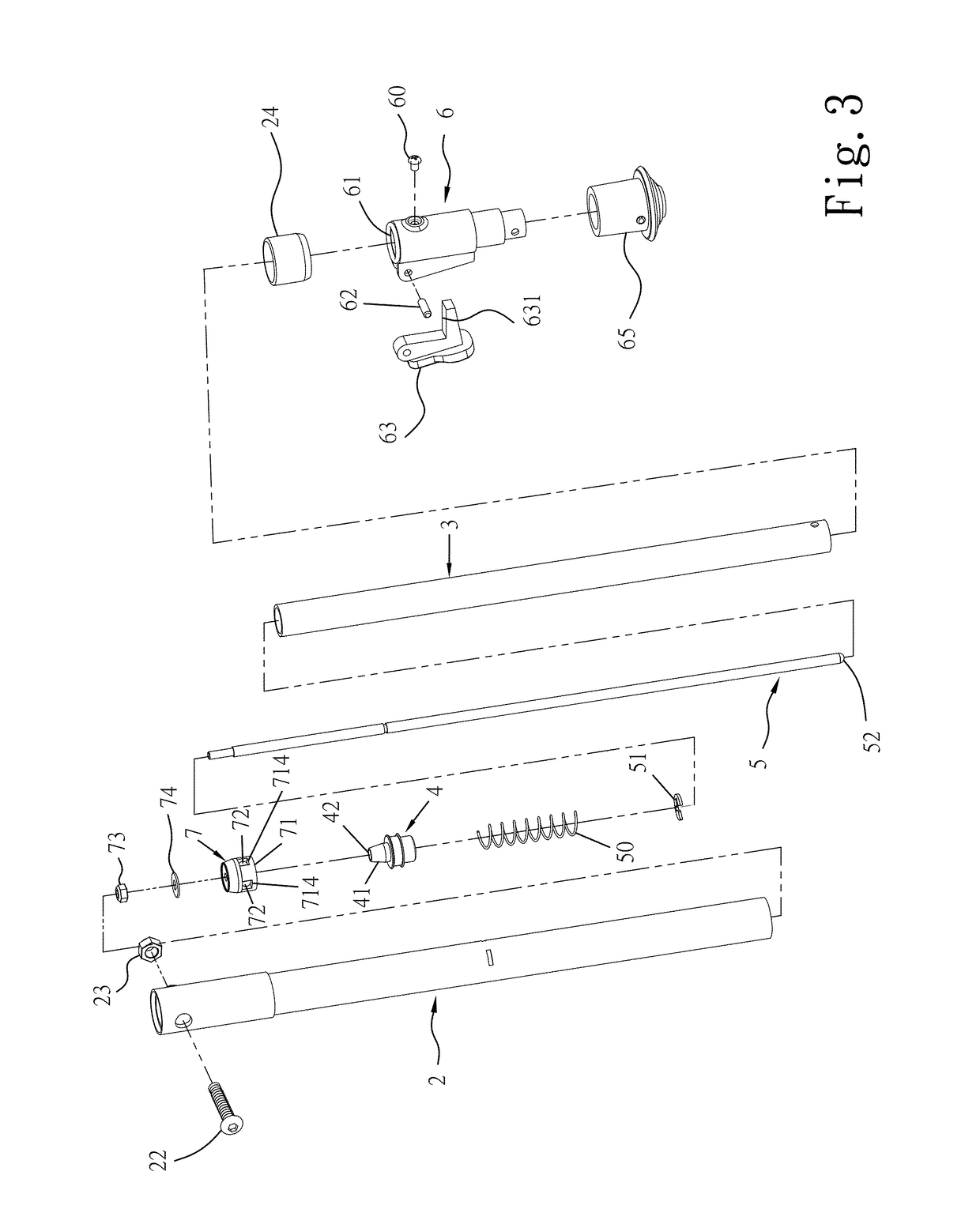

Bipod

A bipod consisting of a support frame unit, left and right outer tubes, left and right inner tubes, left and right guide blocks, left and right links, left and right pressure handle holders, left and right ball bearings and left and right torsion springs is disclosed for easy carrying with an attached gun to enhance application flexibility and mobility. The user can use one hand to bias the left / right pressure handle with the left / right inner tube through 360-degrees to any desired angle and then downwardly adjust the elevation of the left / right inner tube relative to the left / right outer tube, or press the left / right pressure handle with one hand. When released the hand from the left / right pressure handle, the balls in the left / right ball bearing are engaged between the top cone of the left / right guide block and the inside wall of the left / right outer tube.

Owner:LIU CHEH KANG

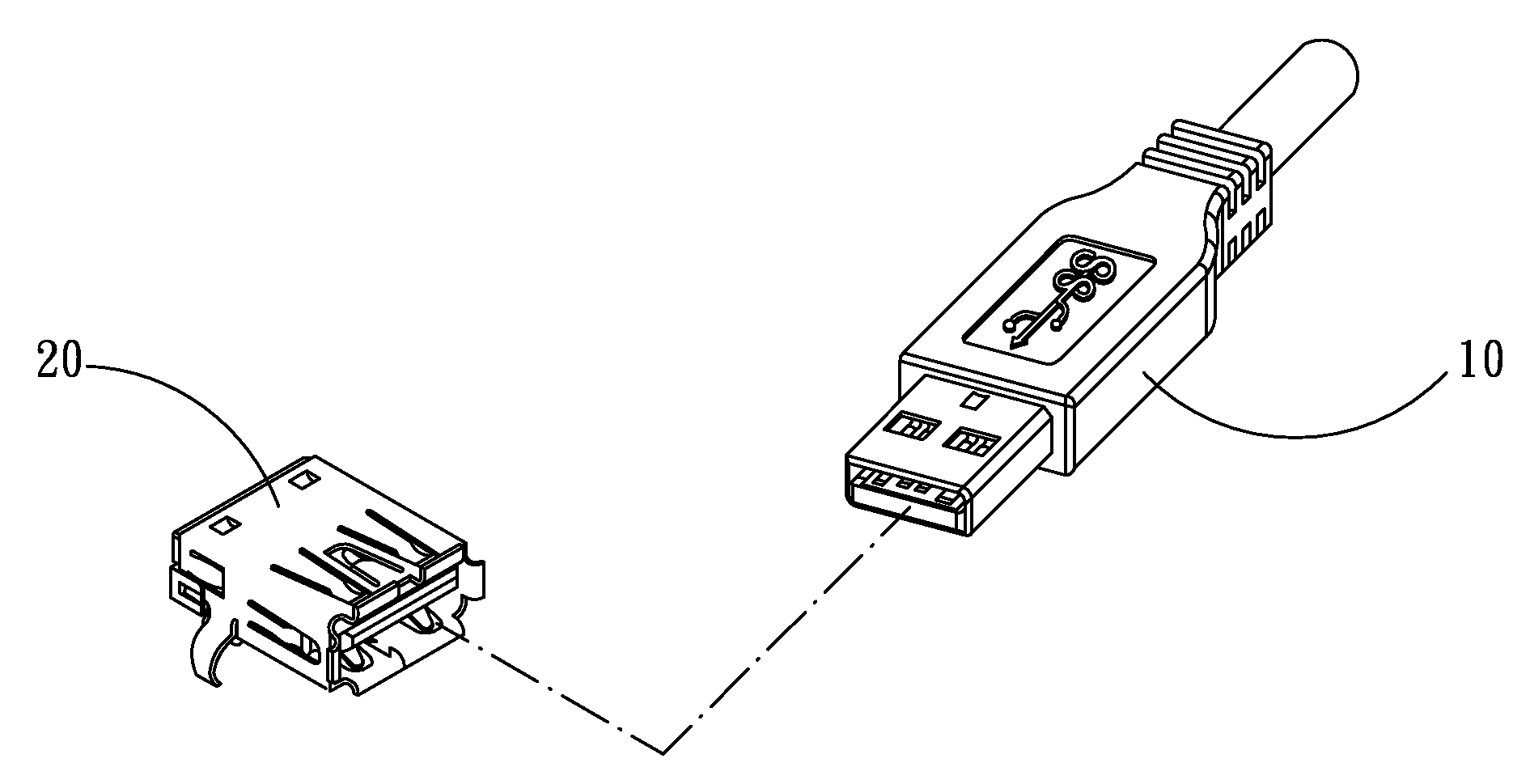

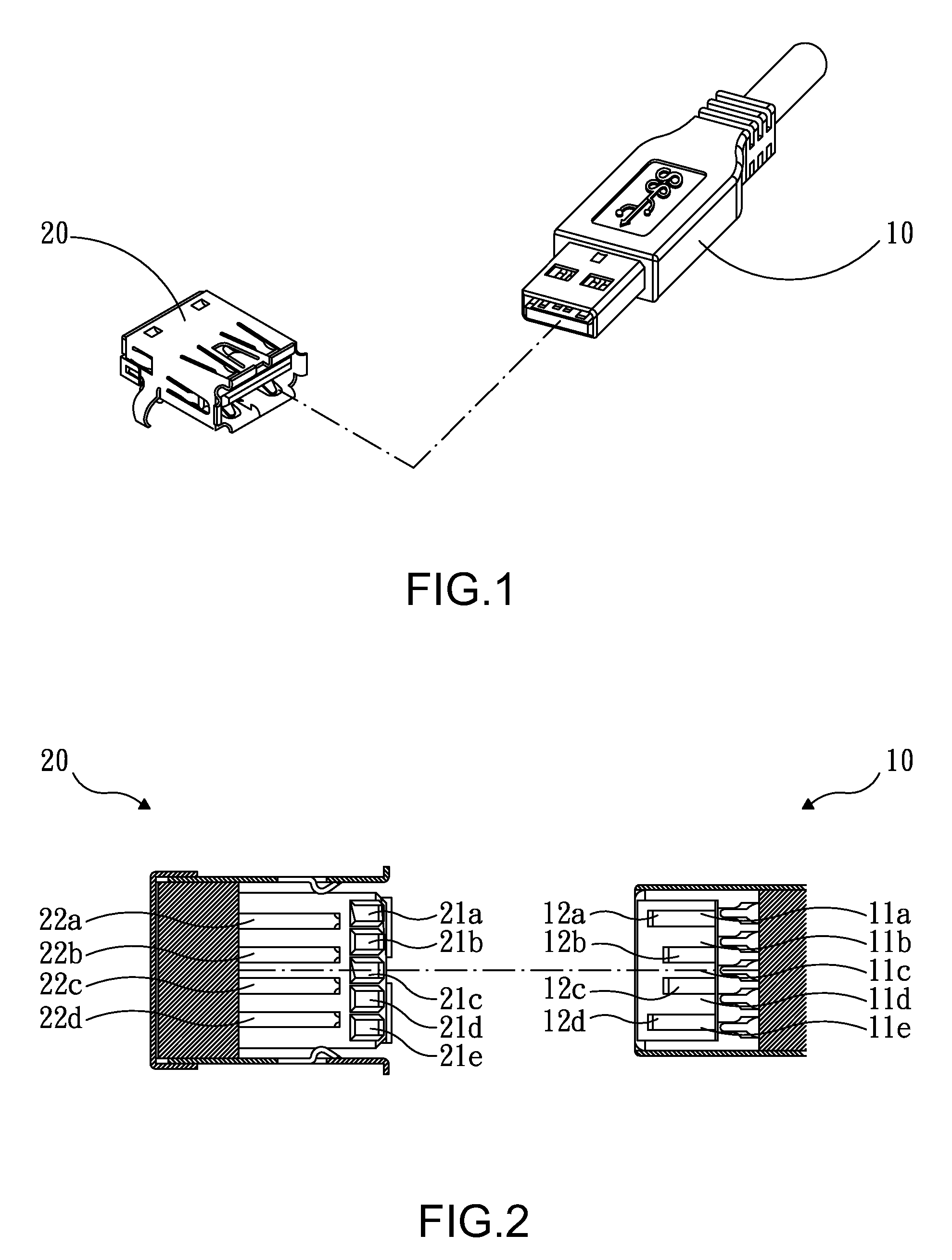

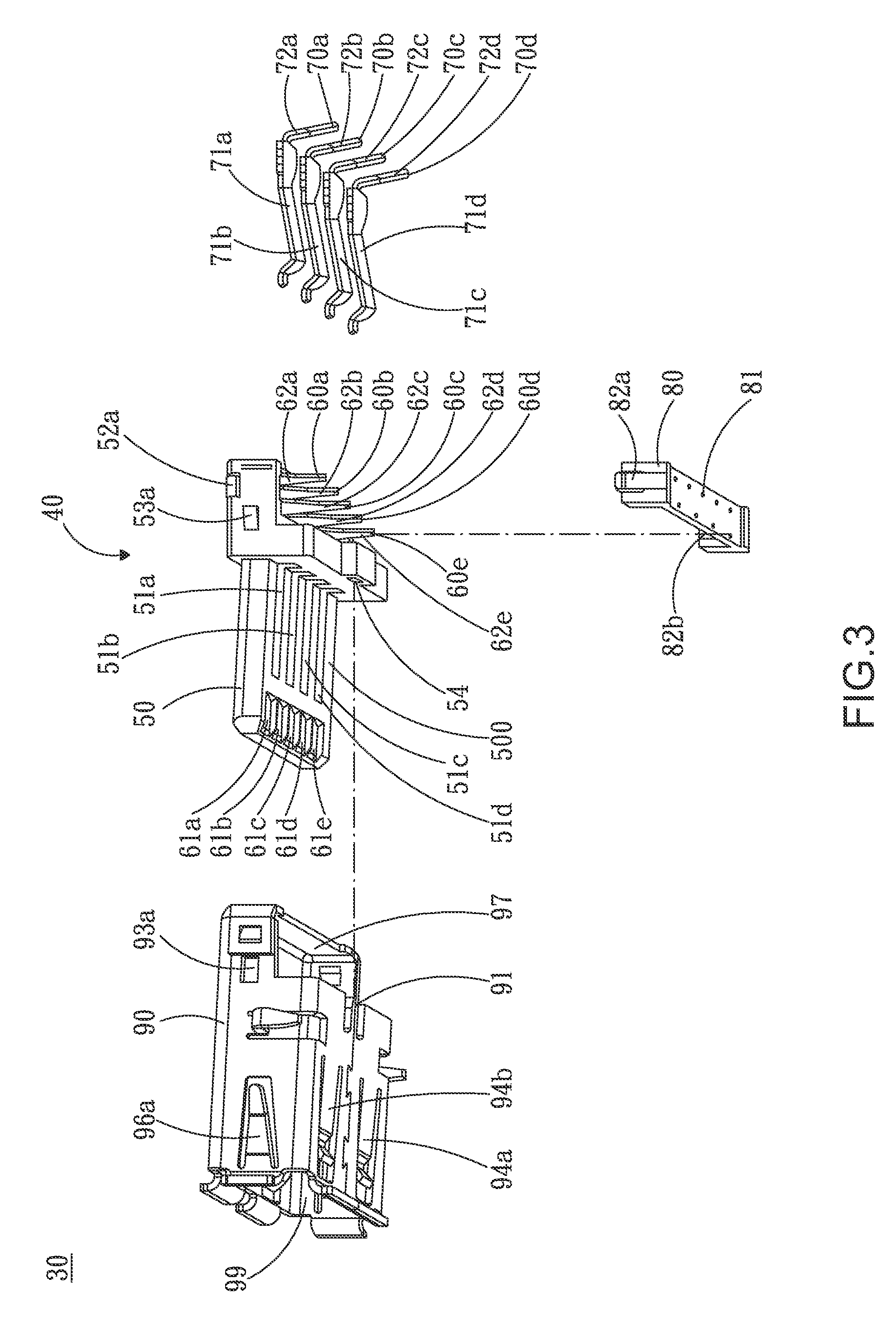

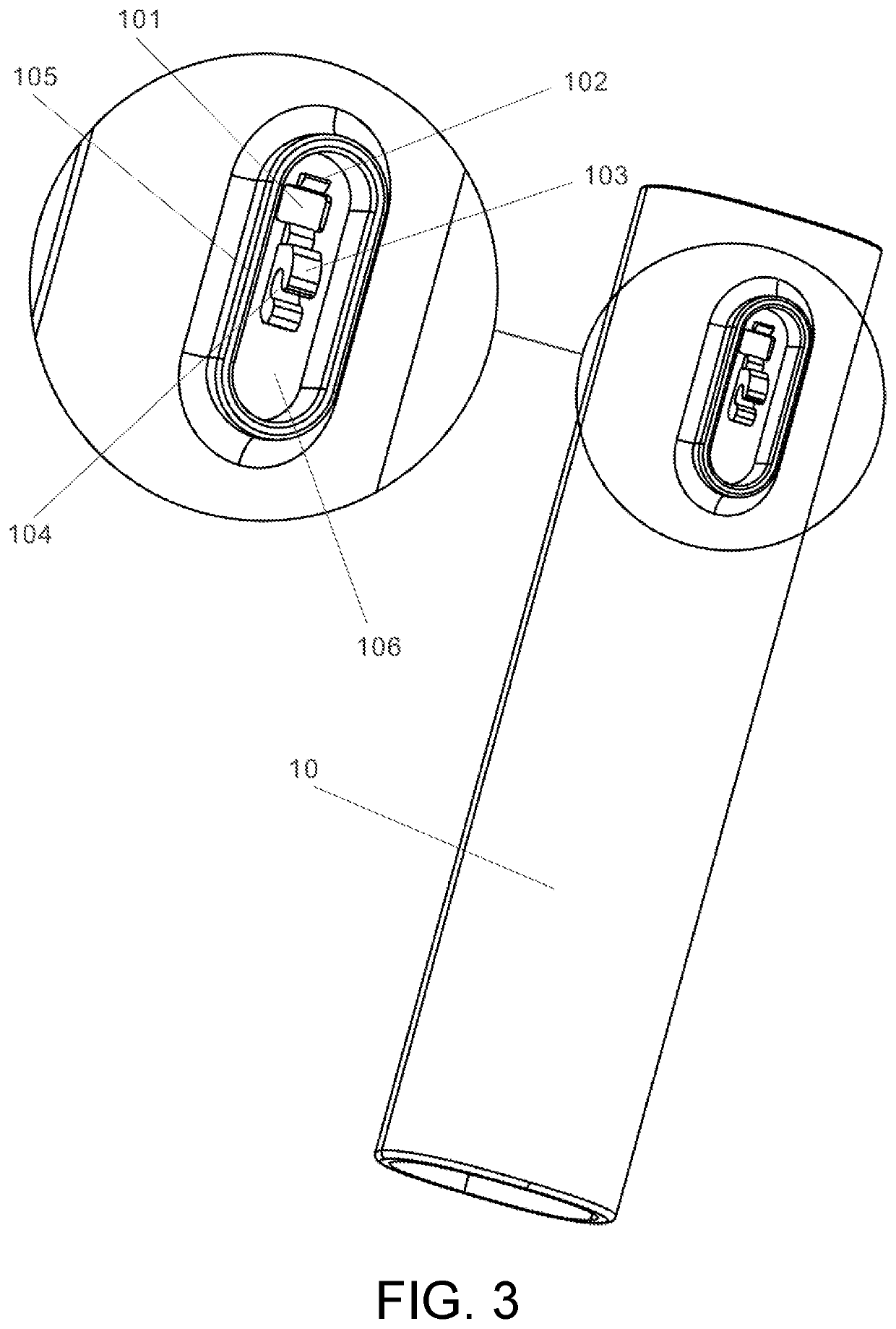

USB a-type socket

InactiveUS20110009008A1Improve electronic performanceImprove positional stabilityElectric discharge tubesTwo-part coupling devicesEngineeringUSB

A USB (Universal Serial Bus) A-type socket configured for coupling with a USB A-type plug complies with the USB 3.0 specification and includes a composite member, a plurality of second terminals, and a metal housing. The composite member includes a plurality of first terminals and an insulating body, wherein the insulating body partially wraps and firmly holds the first terminals. The second terminals are assembled to guiding rails provided on the composite member. The metal housing encloses the composite member. Since the first terminals and the insulating body are integrated as the one-piece composite member, positional stability of the first terminals is ensured.

Owner:COMPUPACK TECH

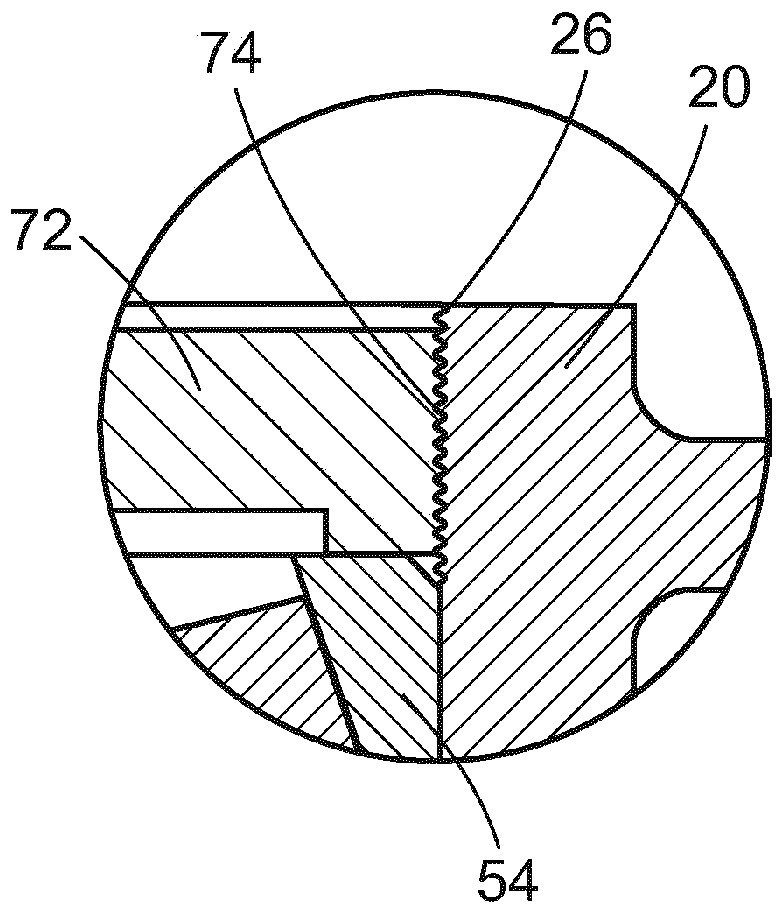

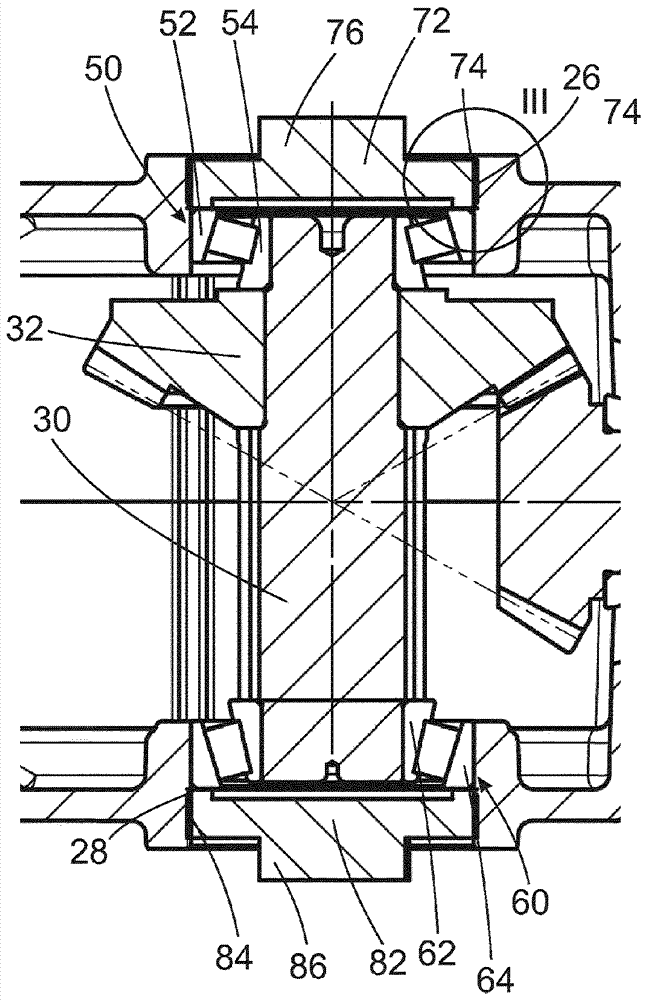

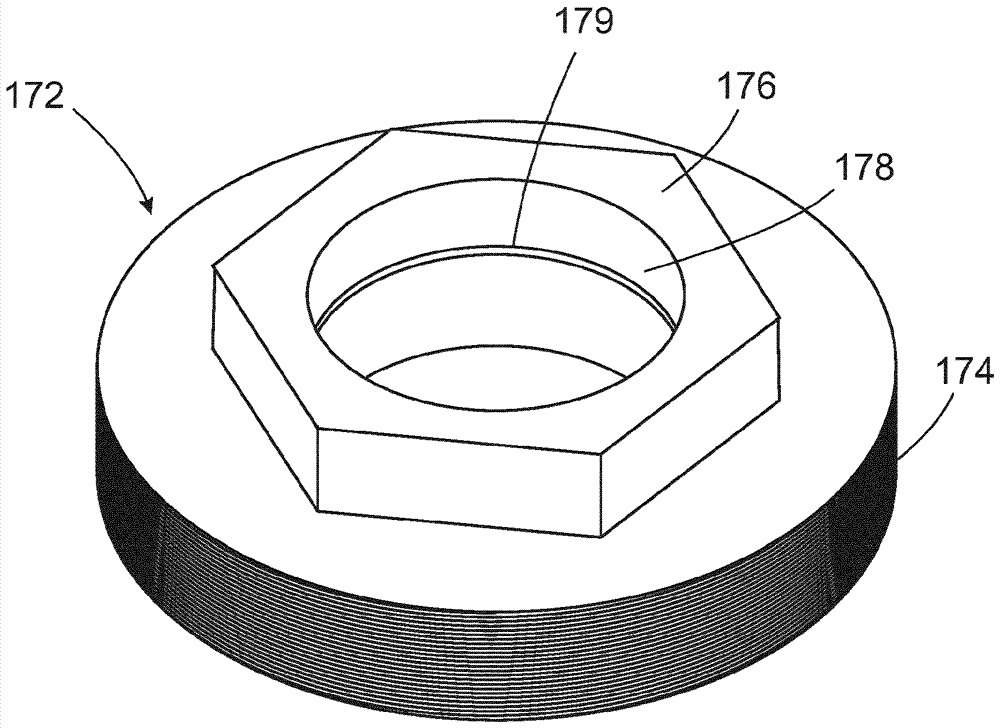

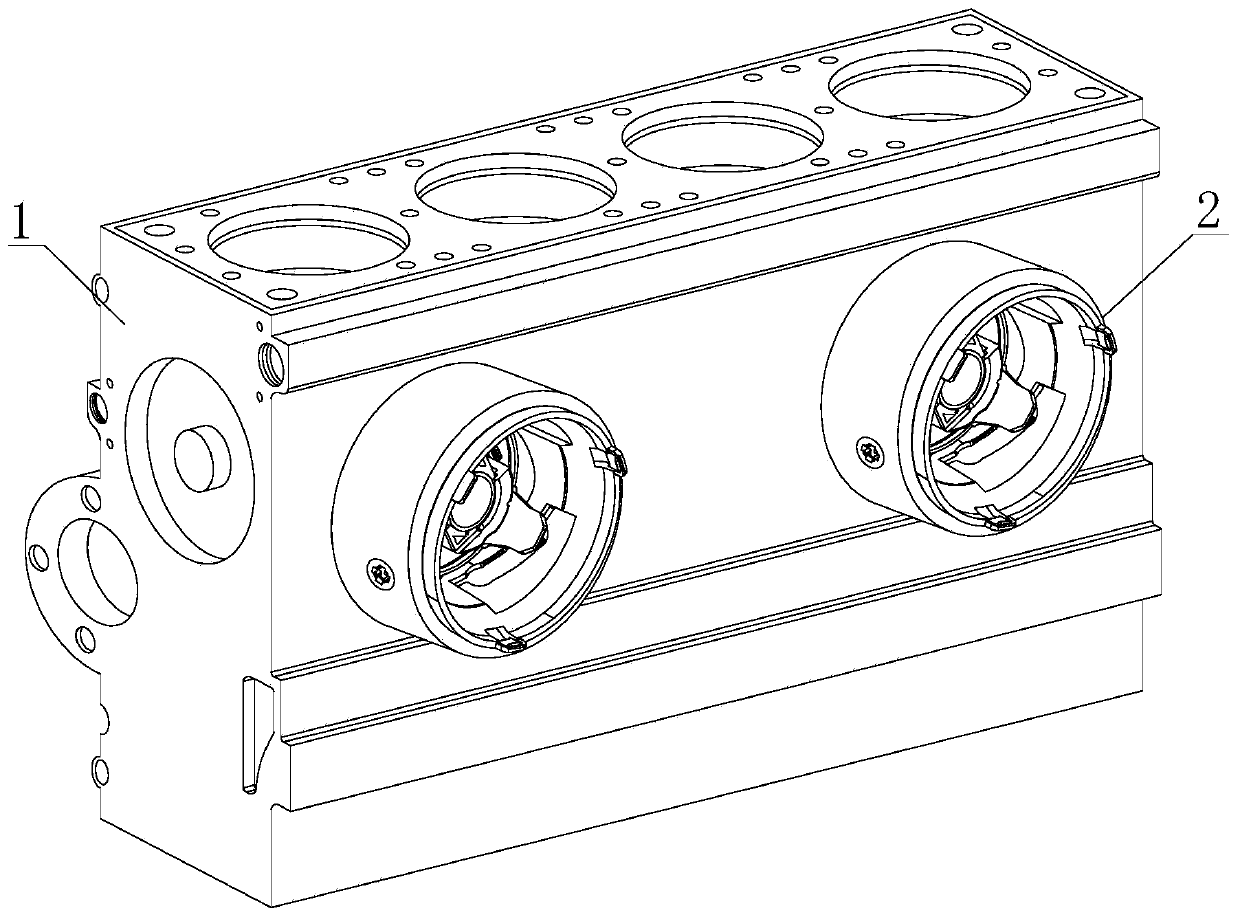

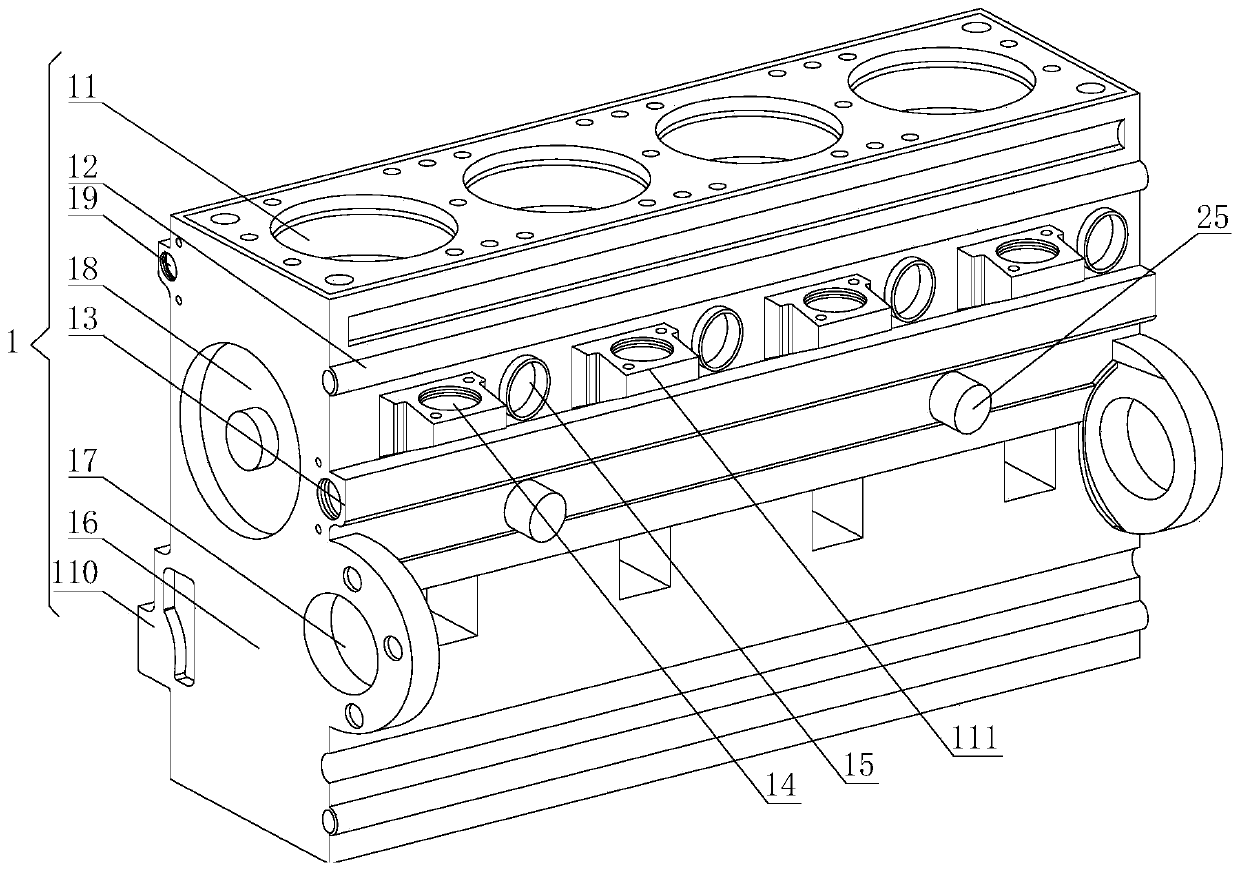

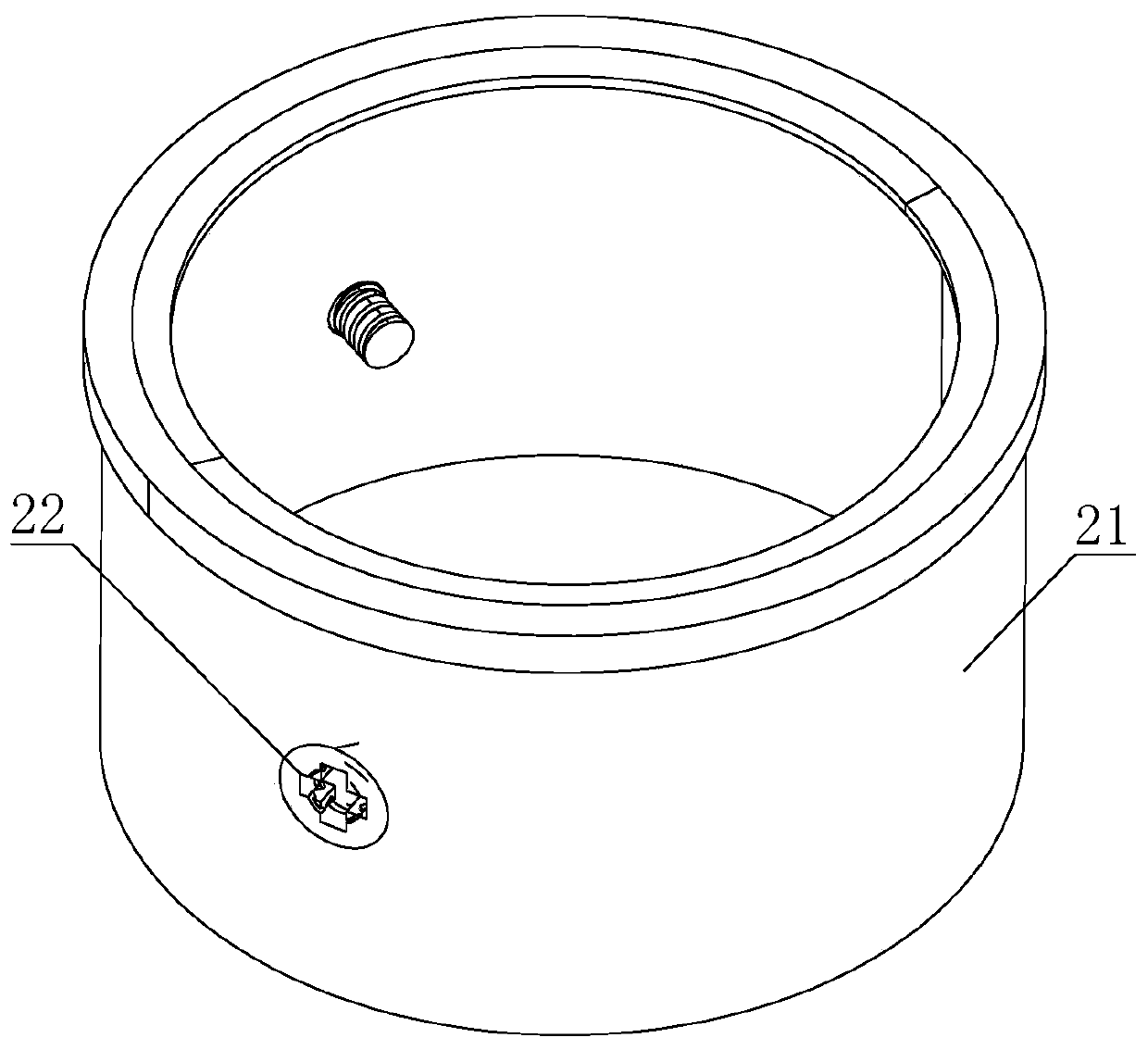

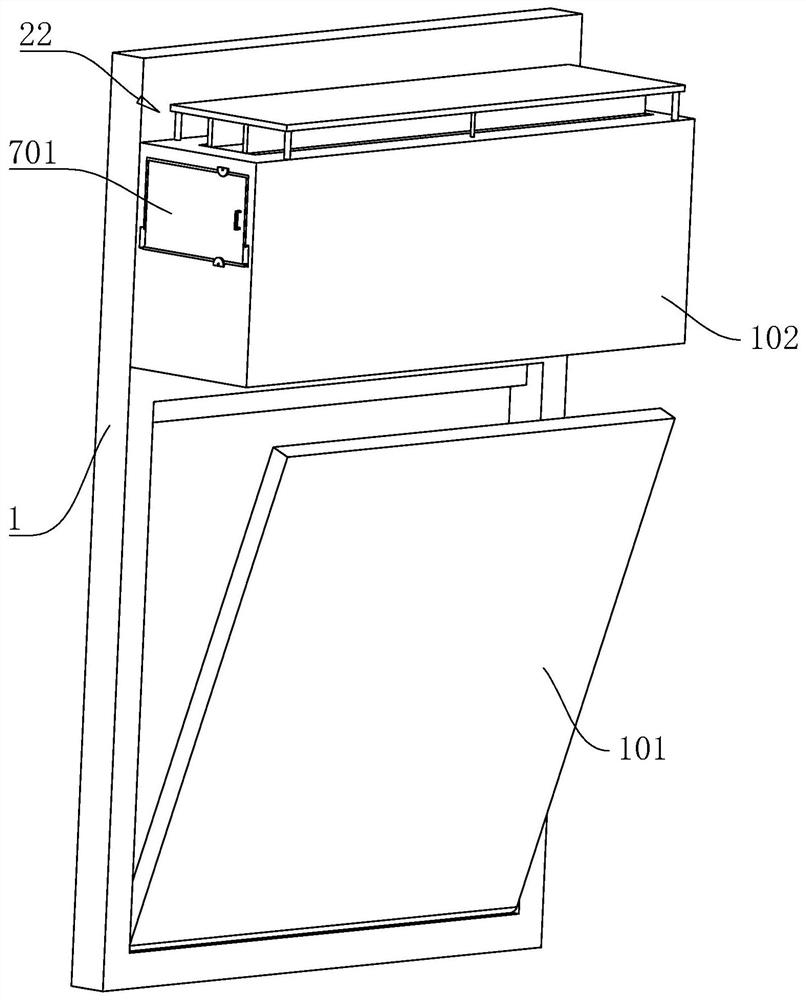

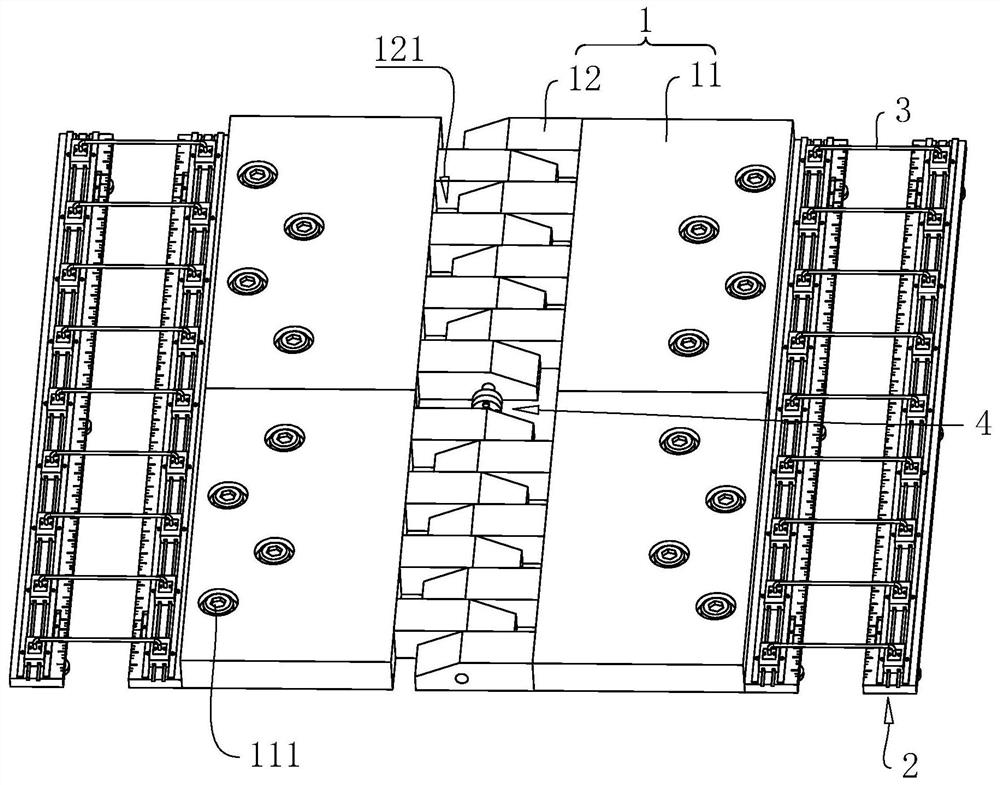

Transmission and method for adjusting the circumferential backlash of the transmission

ActiveCN107110330AEasy to adjustFine tuning feasibilityRolling contact bearingsBearing assemblyEngineeringSupport surface

The invention relates to a transmission (10) that has a housing (20) and a first and a second shaft (30, 40), each of which has a bevel gear wheel (32, 42), said bevel gear wheels (32, 42) being in meshing engagement with each other. The first shaft (30) with a first bevel gear wheel (32) is designed as an axially adjustable shaft and is supported by two rolling bearings (50, 60) on both sides of the bevel gear wheel (32) for this purpose, and each of the rolling bearings (50, 60) has a shaft-side inner ring (52, 62) and a housing-side outer ring (54, 64). The shaft-side inner rings (52, 62) are provided on the first shaft (30) in a defined axial position, whereas the housing-side outer rings (54, 64) of the rolling bearings (50, 60) are guided on respective housing-side support surfaces (22, 24) and are restricted from moving towards each other solely by the inner rings and the shaft. The axial position of the housing-side outer rings (54, 64) of the rolling bearings (50, 60) can be adjusted on the side facing away from the bevel gear wheel (32) by a respective adjusting device (70, 80). Each of the adjusting devices (70, 80) has an adjusting element (72, 82) with an outer thread (74, 84) on the respective outer ring (54, 64) side facing away from the bevel gear wheel (32), said outer thread being inserted into a housing-side inner thread (26, 28). The inner thread (26, 28) and the outer thread (74, 84) are designed as fine threads, preferably with a pitch of maximally 0.75 mm.

Owner:LENZE DRIVES

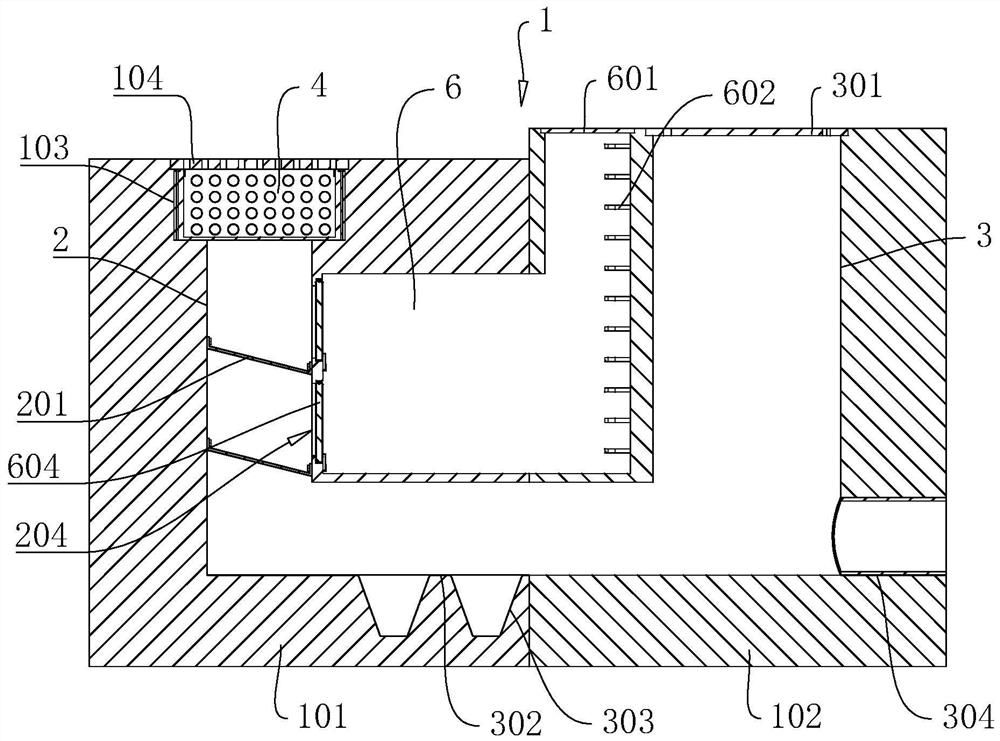

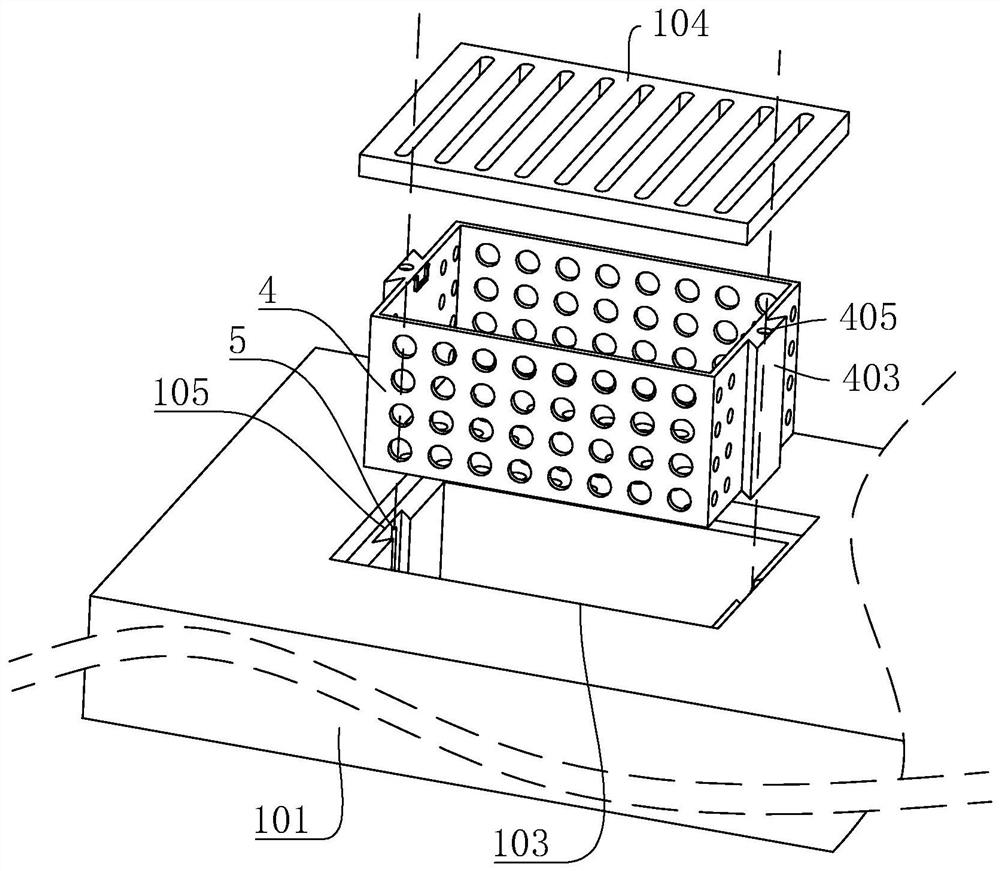

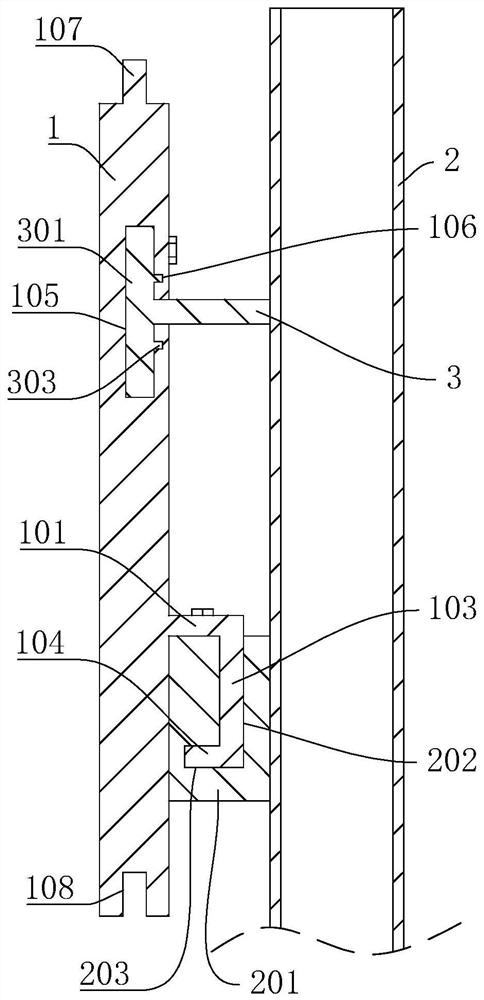

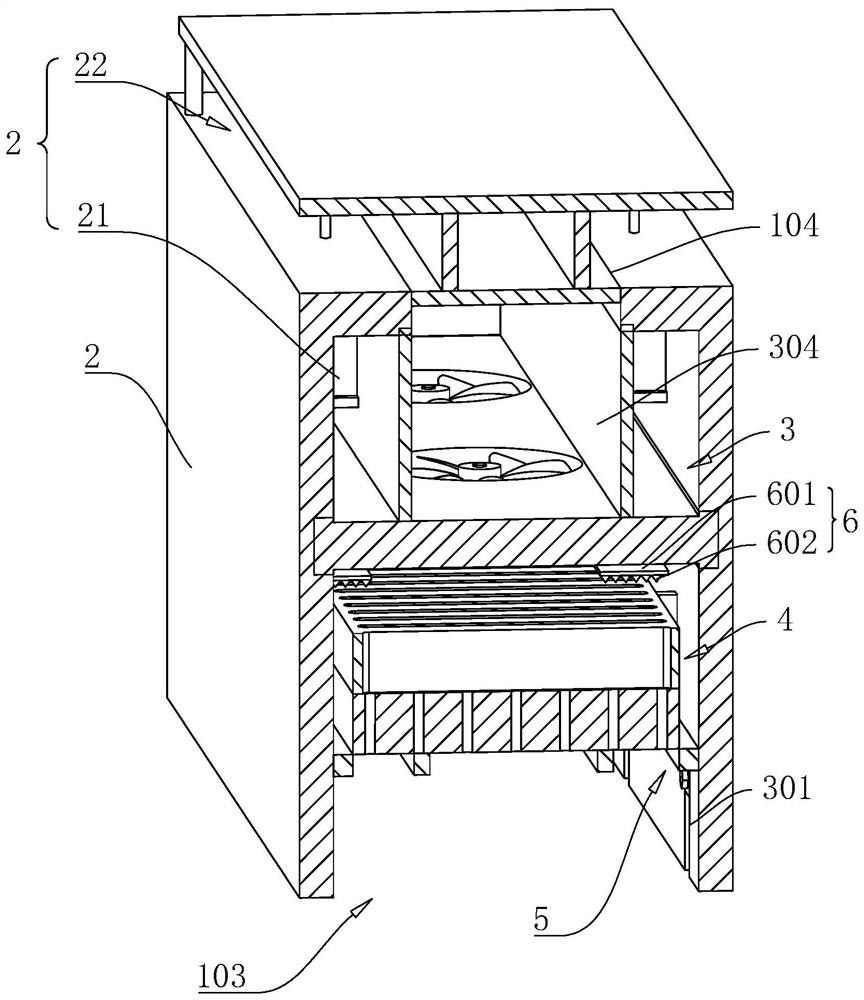

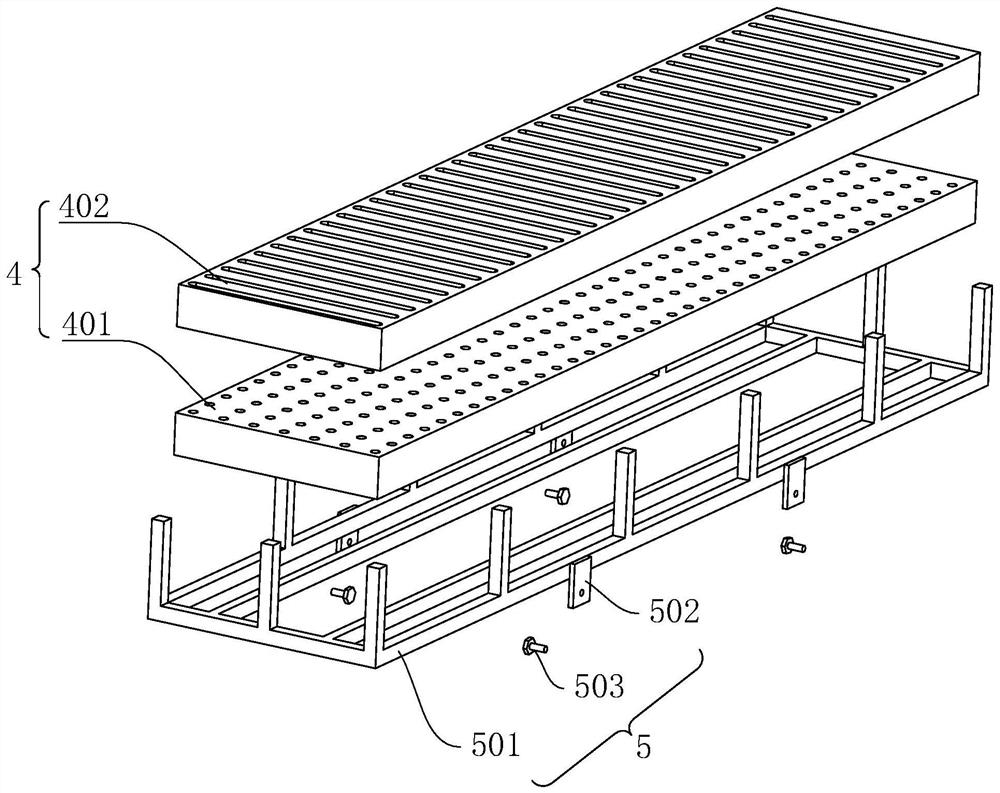

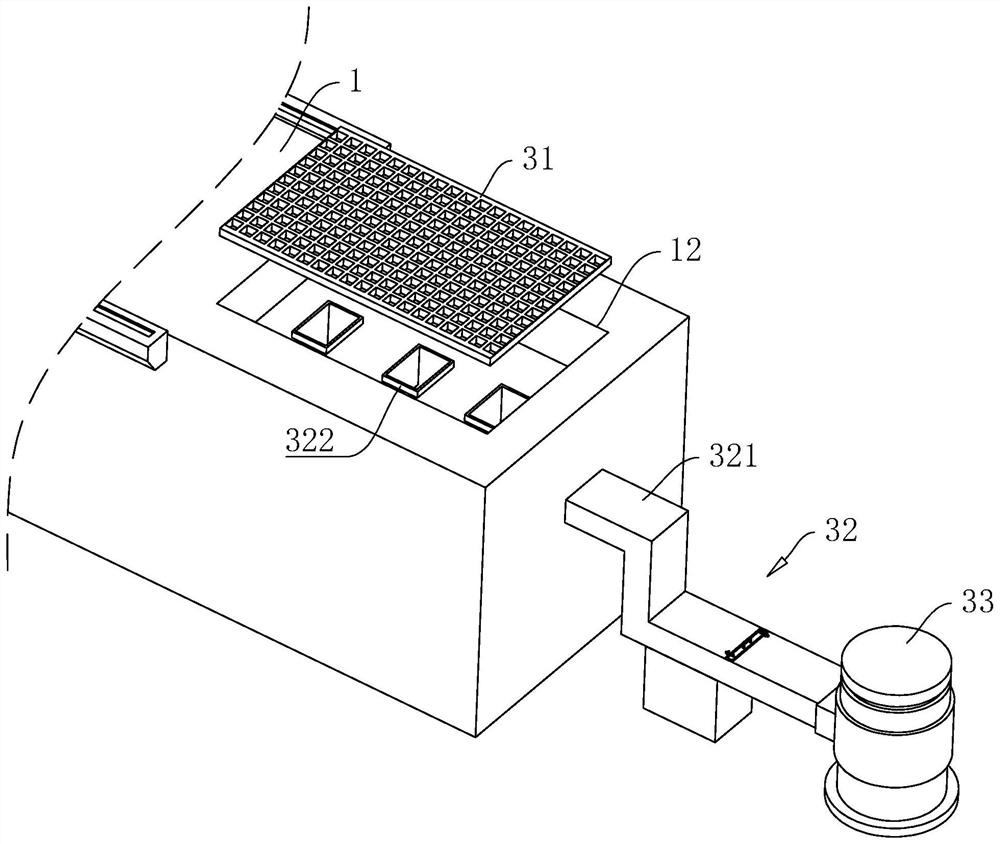

Municipal road drainage network

InactiveCN111794344AGuarantee exhaust efficiencyReduce accumulationSewerage structuresFiltration circuitsEnvironmental engineeringDrainage tubes

The invention relates to a municipal road drainage network. The municipal road drainage network comprises a road body, a plurality of drainage wells and collection wells are arranged in the road body,rainwater strainers are arranged at the tops of the drainage wells, well lids are arranged at the tops of the collection wells, a communication pipe is jointly arranged between the drainage wells andthe collection wells, drainage total pipes are arranged on the sides, away from the communication pipe, of the collection wells, settling tanks are arranged on the periphery, around each drainage well, of the top wall of the road body, and filtering pieces are arranged in the settling tanks; and a plurality of separating screen plates are obliquely arranged in the drainage wells, and a pluralityof sedimentation tanks are arranged on the inner bottom wall of the communication pipe at intervals. The municipal road drainage network has an effect of improving the drainage efficiency of a municipal road drainage system.

Owner:广东珠江建筑工程设计有限公司

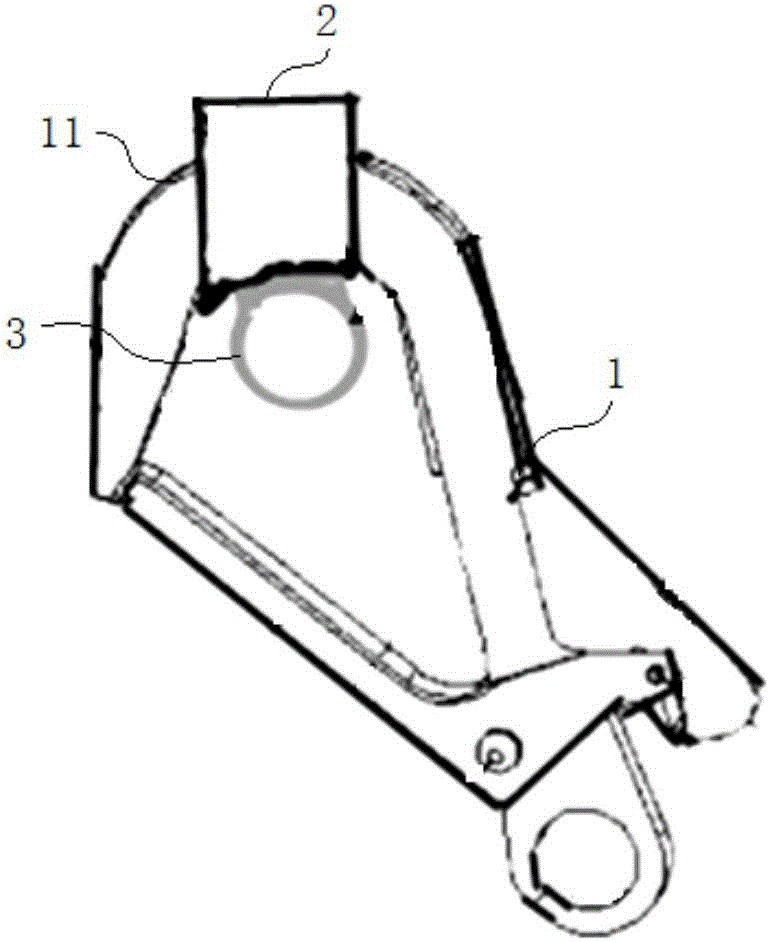

Safety hook for monitoring hanging state of safety rope in real time and monitoring method thereof

ActiveCN106581887ARealize real-time monitoringRemind you to fasten correctlySafety beltsReliability engineeringProduction control

The invention discloses a safety hook for monitoring a hanging state of a safety rope in real time and a monitoring method thereof, and belongs to the field of safety belts. The safety hook comprises a safety hook body and a monitoring device; the monitoring device includes a force transfer part; a cavity for penetrating through an upper hook part of the safety hook body is formed in the force transfer part; the force transfer part is in clearance fit with the upper hook part; a magnetic absorbing body and a trigger device are arranged in the force transfer part; the trigger device is connected with a monitoring circuit; and the magnetic absorbing body is used for controlling the upper hook part to trigger / cut off the trigger device through absorbing the upper hook part so as to control communication / separation of the monitoring circuit. The safety hook can judge the hanging state of the safety rope in real time, is convenient to timely remind aerial staff and ground managers, realizes real-time monitoring and timely intervention, and is wide in application to the safety production management aspect in aerial operation.

Owner:张峰

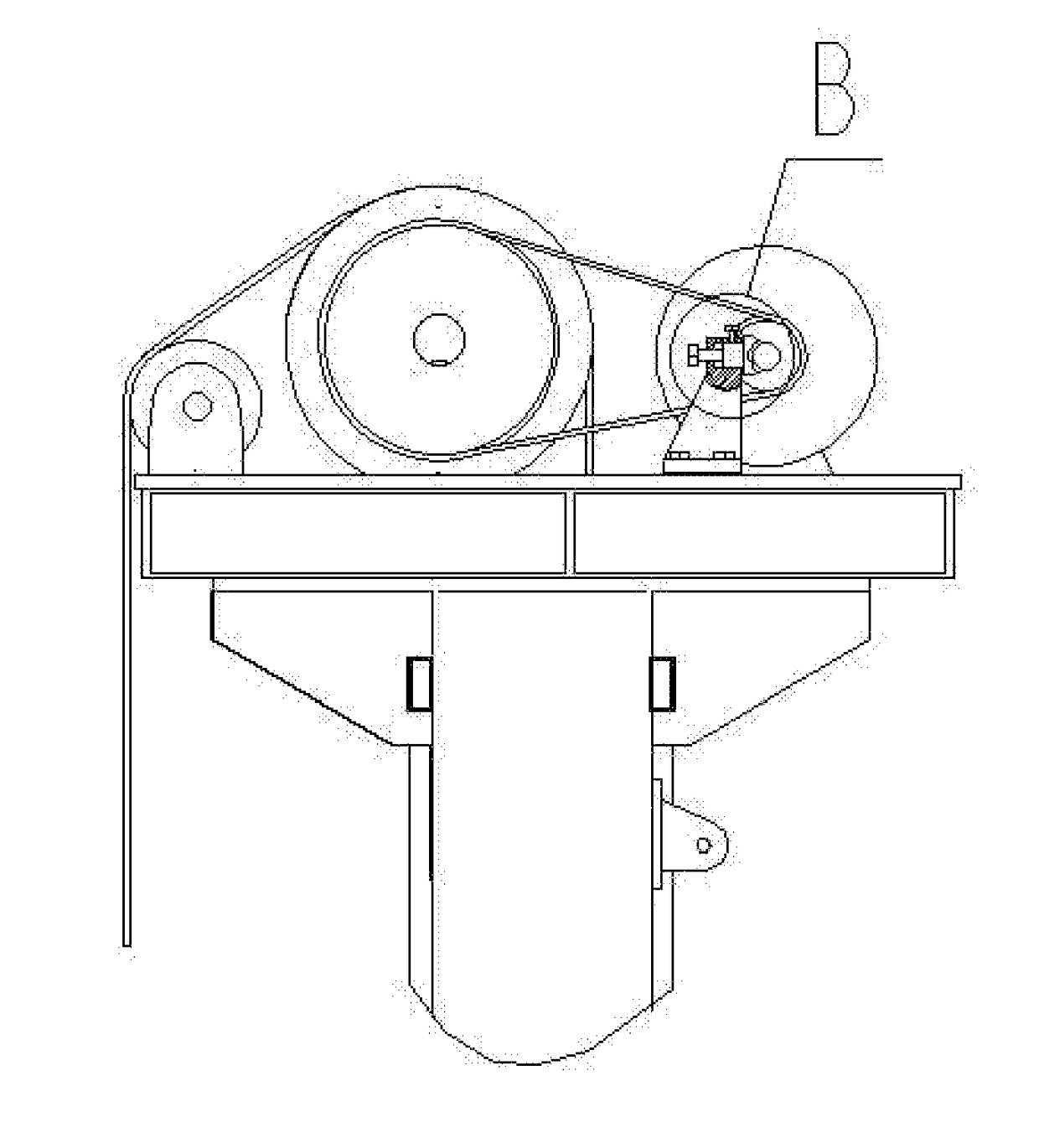

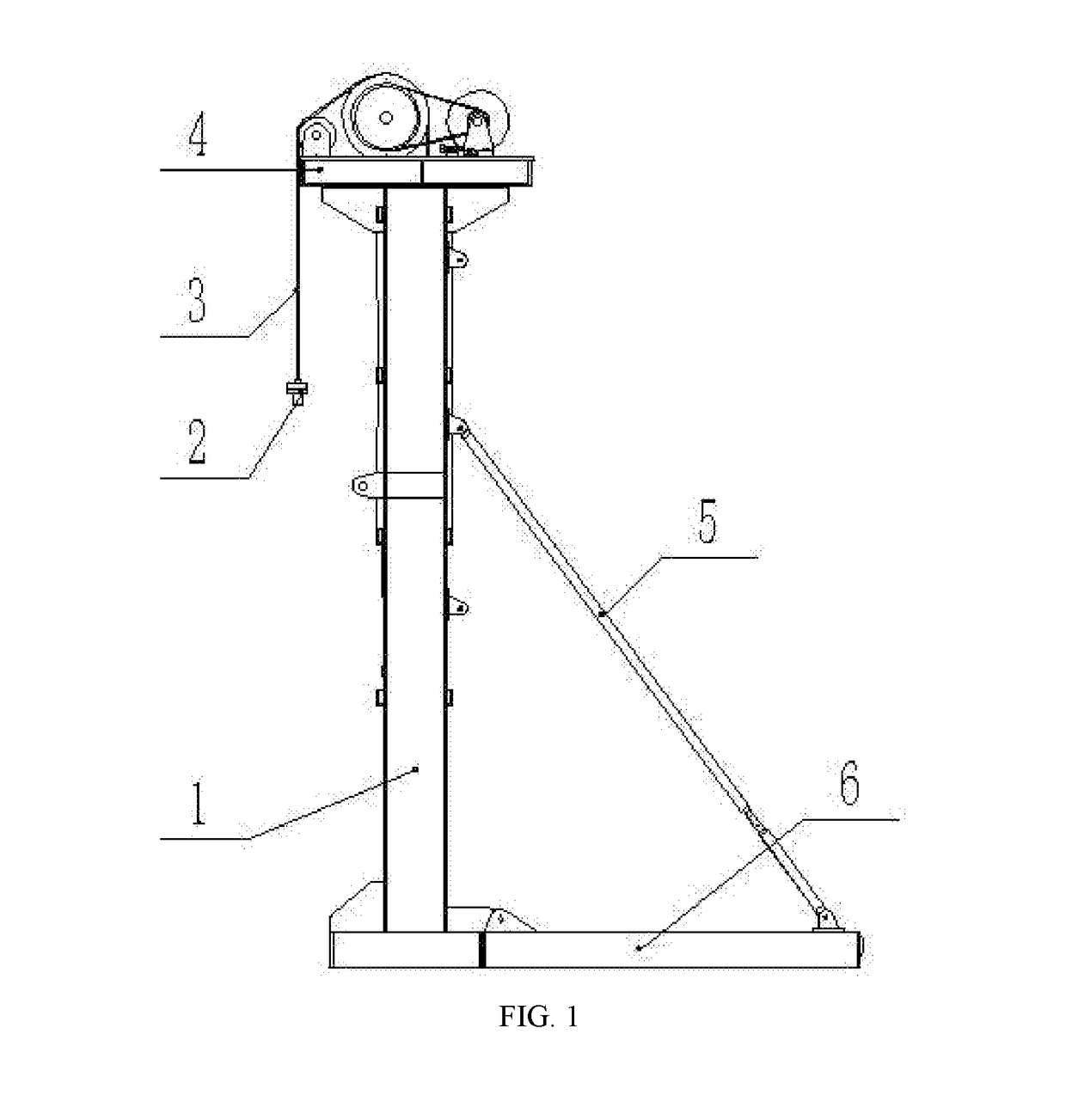

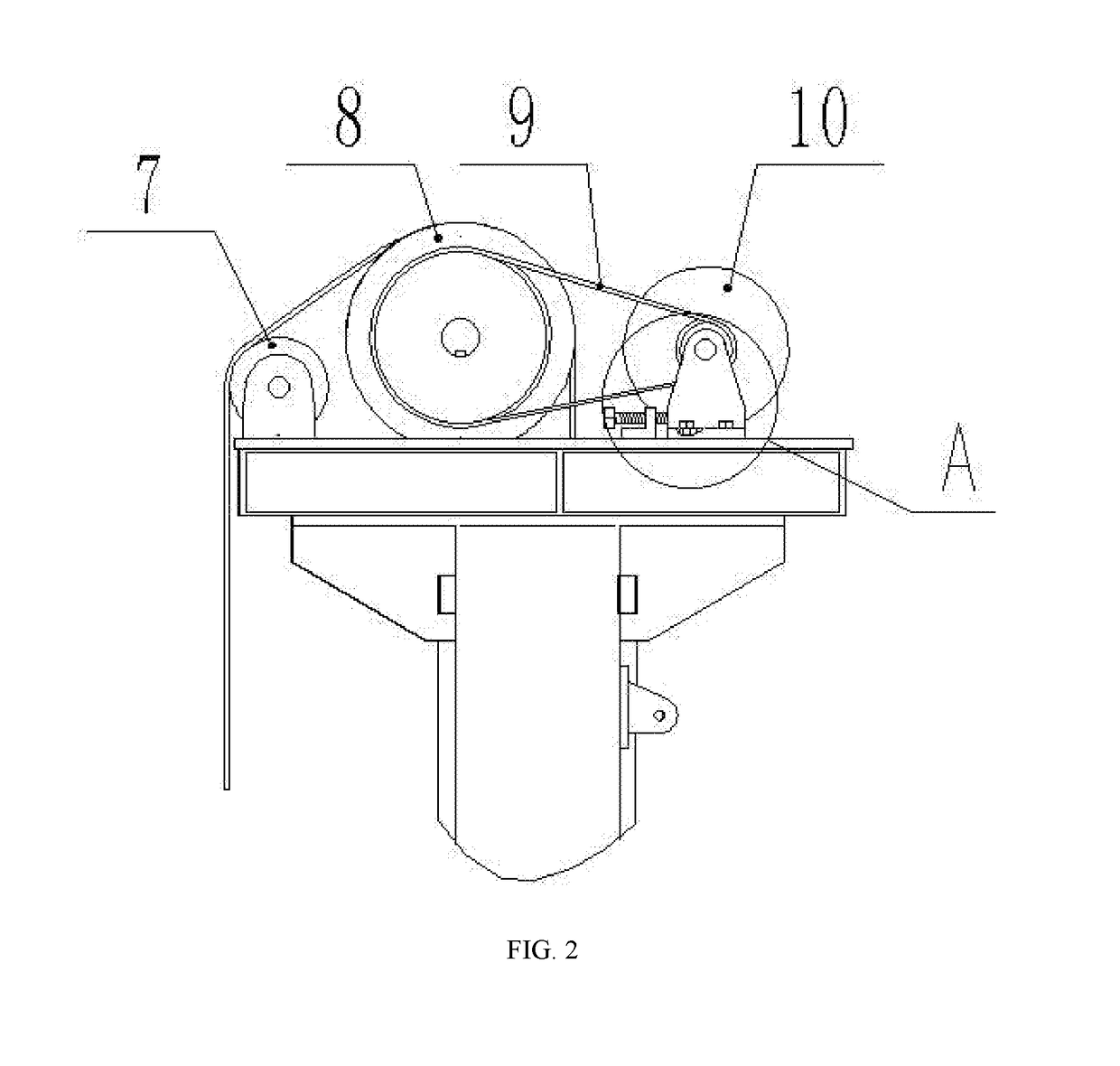

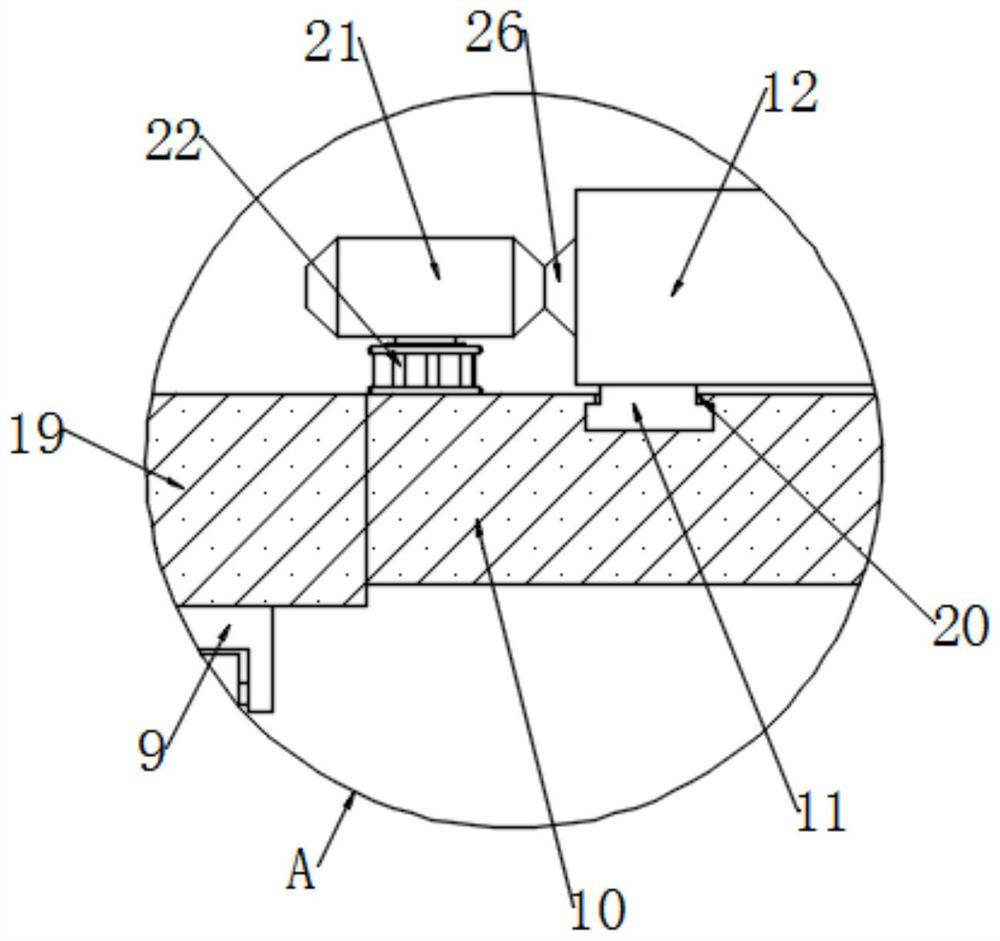

Non-beam Pumping Unit with a Motor Output Shaft Righting Device

InactiveUS20180156318A1Effectively eliminate bending tendencyImprove stabilityPositive displacement pump componentsGearingSprocketEngineering

The utility belongs to the field of the non-beam pumping unit, specifically relating to a non-beam pumping unit with a motor output shaft righting device. The non-beam pumping unit with a motor output shaft righting device comprises a base, a tower body and a drive mechanism. The base is fixedly mounted on the ground. The drive mechanism is mounted on the platform, comprising a motor, a large roller, a small roller, a belt and a counterweight device. The motor is connected with the large roller through a chain and sprockets, and one end of the belt is connected with a beam hanger and the other end hangs down after wrapping around the large roller and the small roller from the upper side and then connected with the counterweight device.

Owner:DAQING DANNUO PETROLEUM TECH DEV

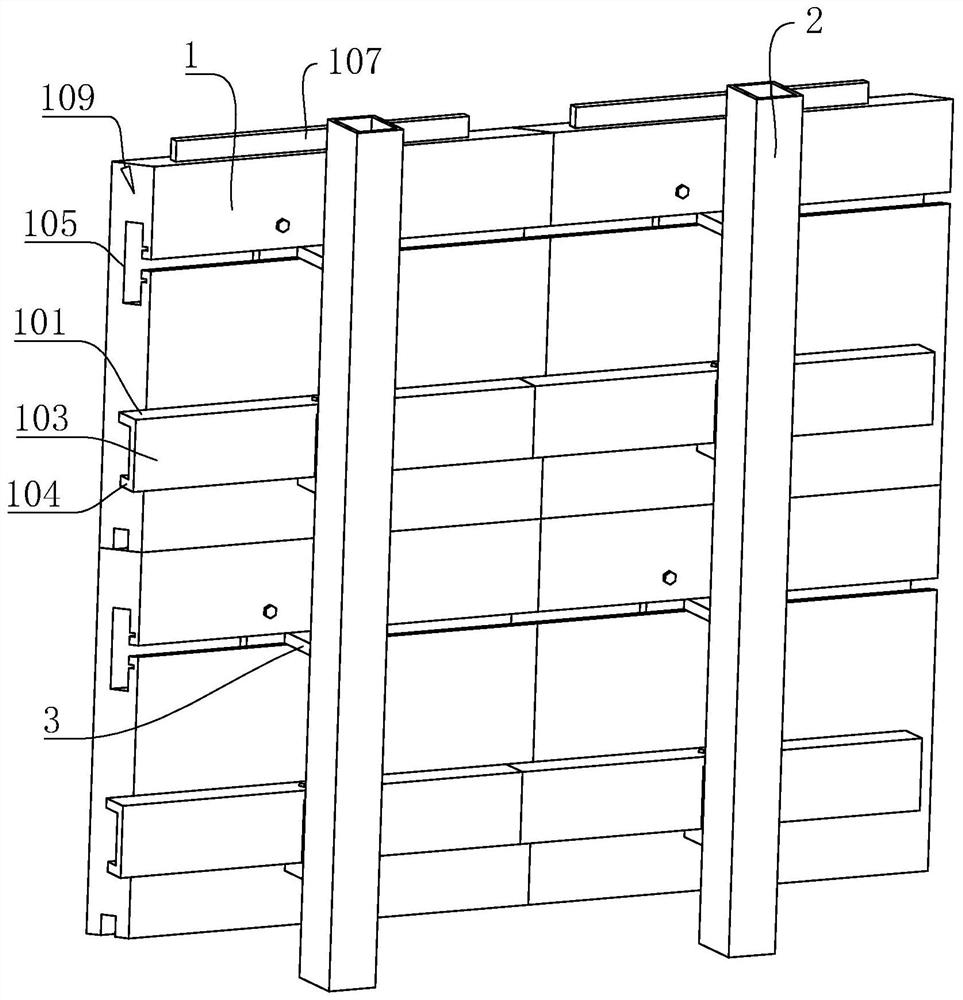

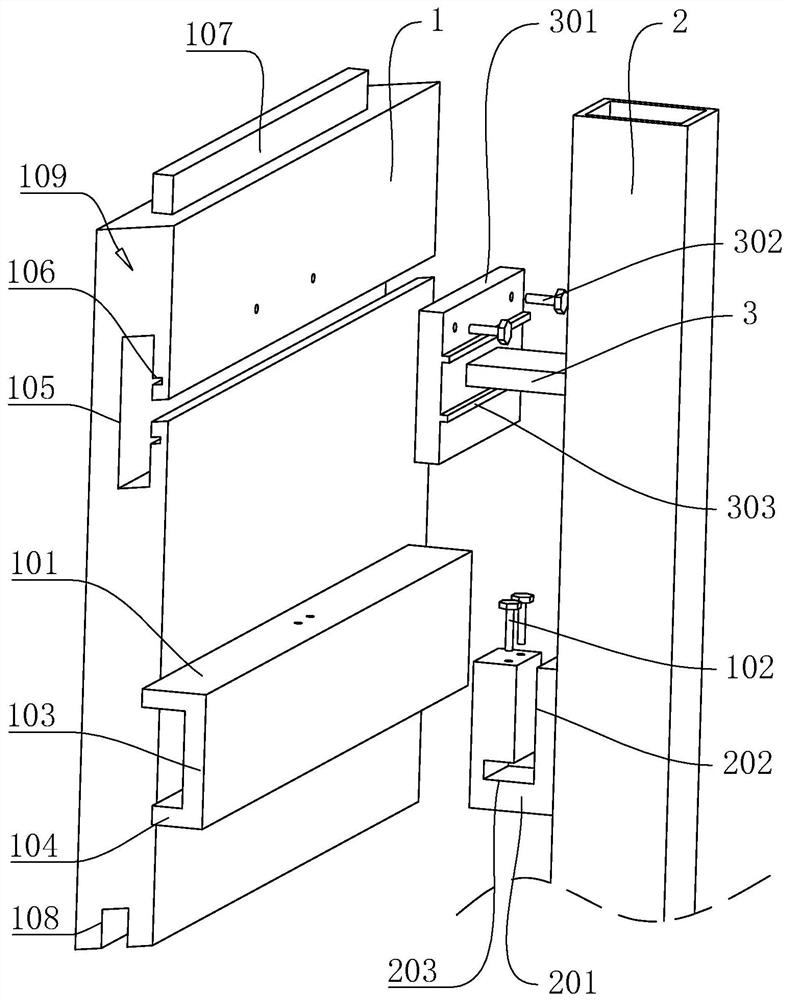

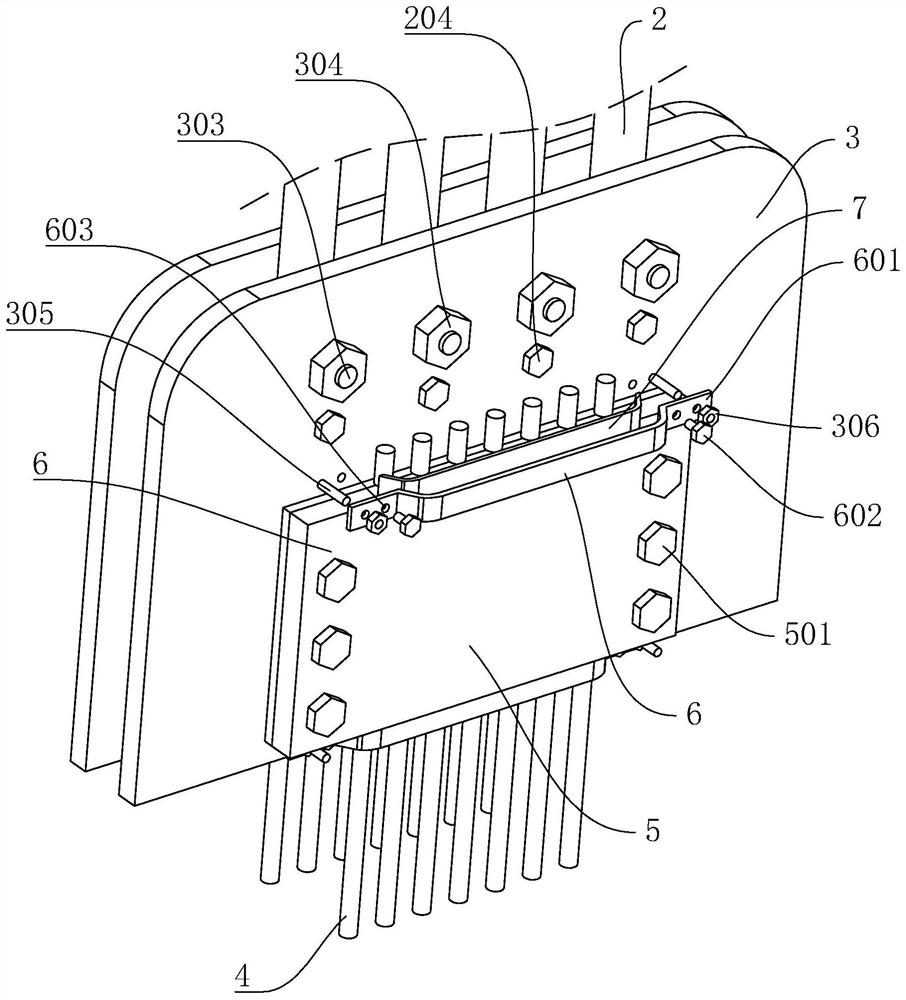

Stone curtain wall with high connection strength and construction process thereof

InactiveCN112252546ANot easy to looseNot easy to deflectWallsArchitectural engineeringUltimate tensile strength

The invention relates to a stone curtain wall with high connection strength and a construction process thereof. The stone curtain wall with the high connection strength comprises stone panels and stand columns, extension plates are arranged on the side walls, facing the stand columns, of the stone panels, abutting plates are arranged on the end walls, away from the stone panels, of the extension plates, fixing blocks are arranged on the side walls, facing the stone panels, of the stand columns, clamping grooves are formed in the top wall of the fixing block, and a plurality of first fixing pieces are arranged between the extension plates and the fixing blocks together; opposite-pull plates are arranged on the side walls, facing the stone panels, of the abutting plates, and limiting groovesfacilitating abutting of the opposite-pull plates are formed in the outer side walls of the fixing blocks; and abutting strips are arranged on the top walls of the stone panels, and embedded groovesare formed in the bottom walls of the stone panels. The construction method comprises the following construction steps of measuring and positioning, preparing and positioning raw materials, mounting the stone panels, caulking and sealing glue, and checking and accepting. The stone curtain wall has the effects that the connecting strength of the formed stone curtain wall is improved, and an operator can conveniently mount the stone panels.

Owner:飞帆集团有限公司

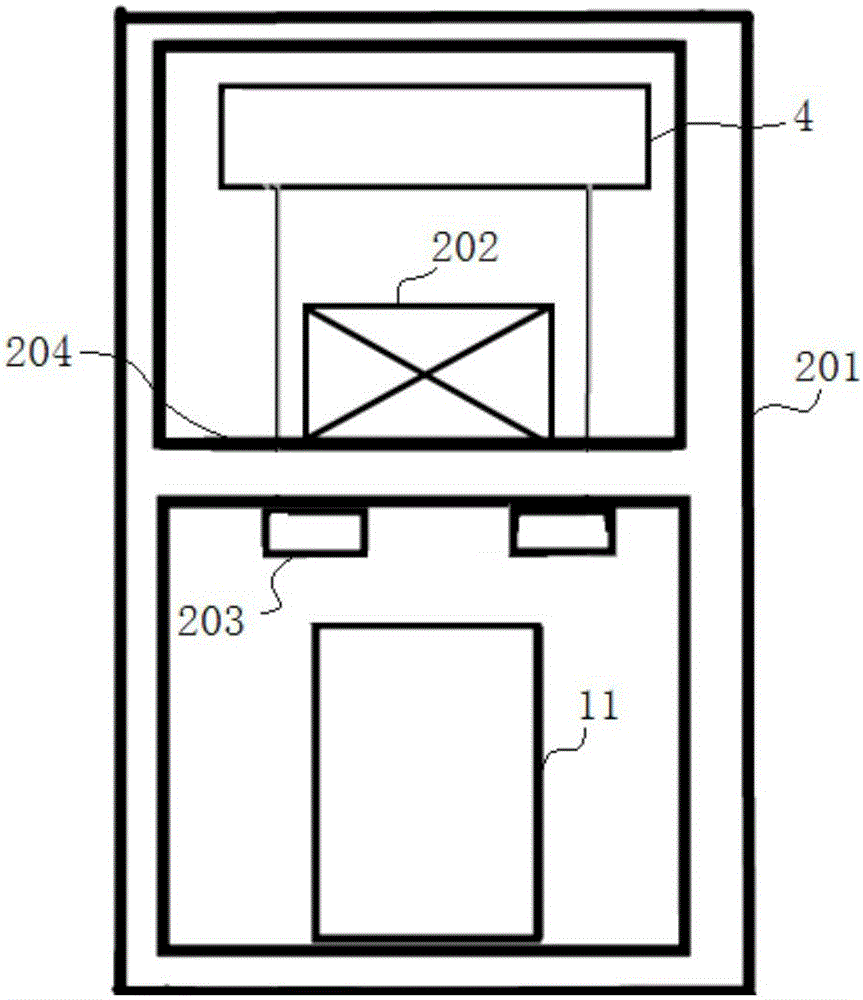

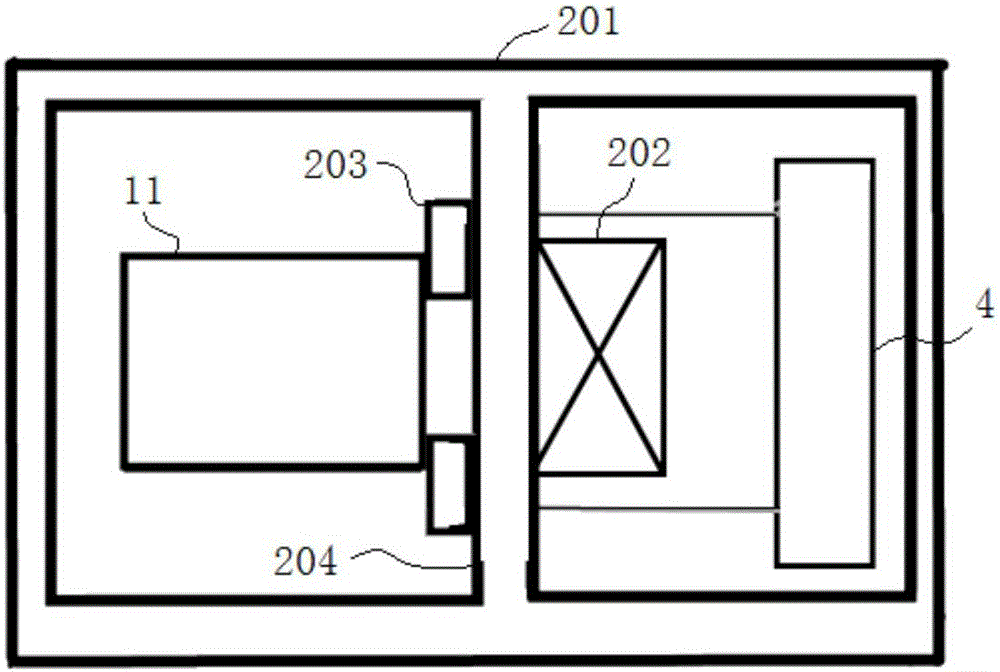

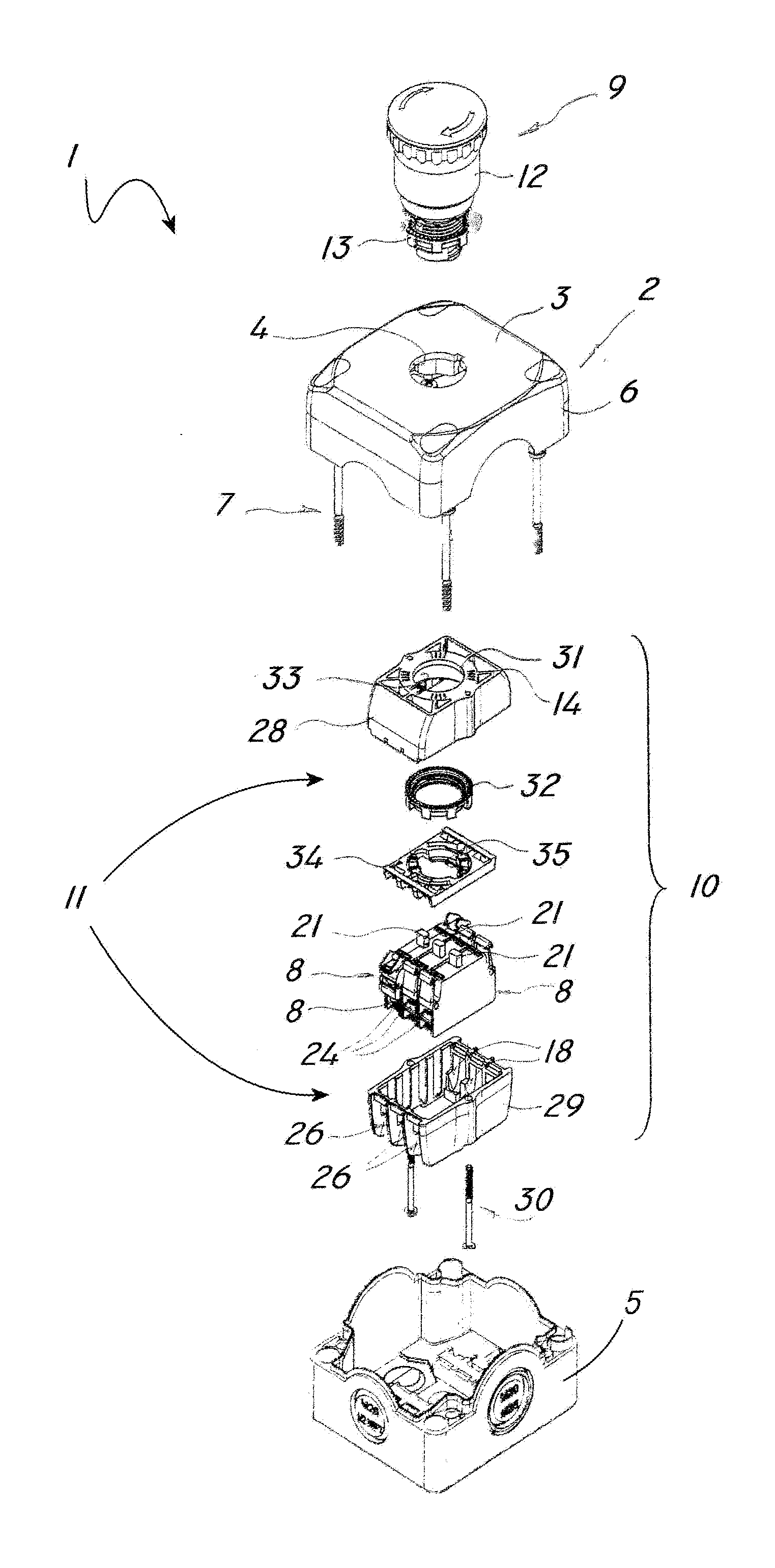

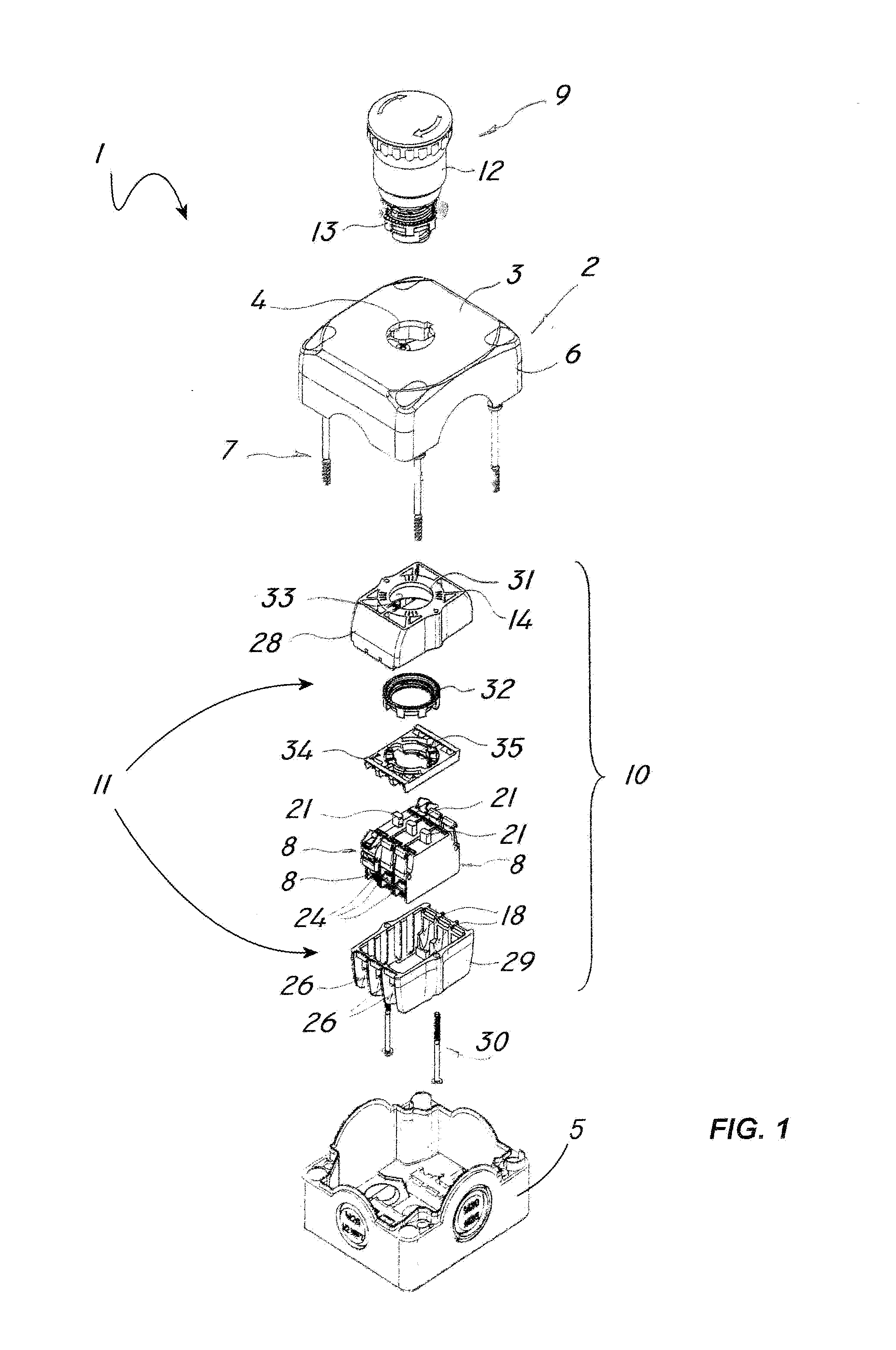

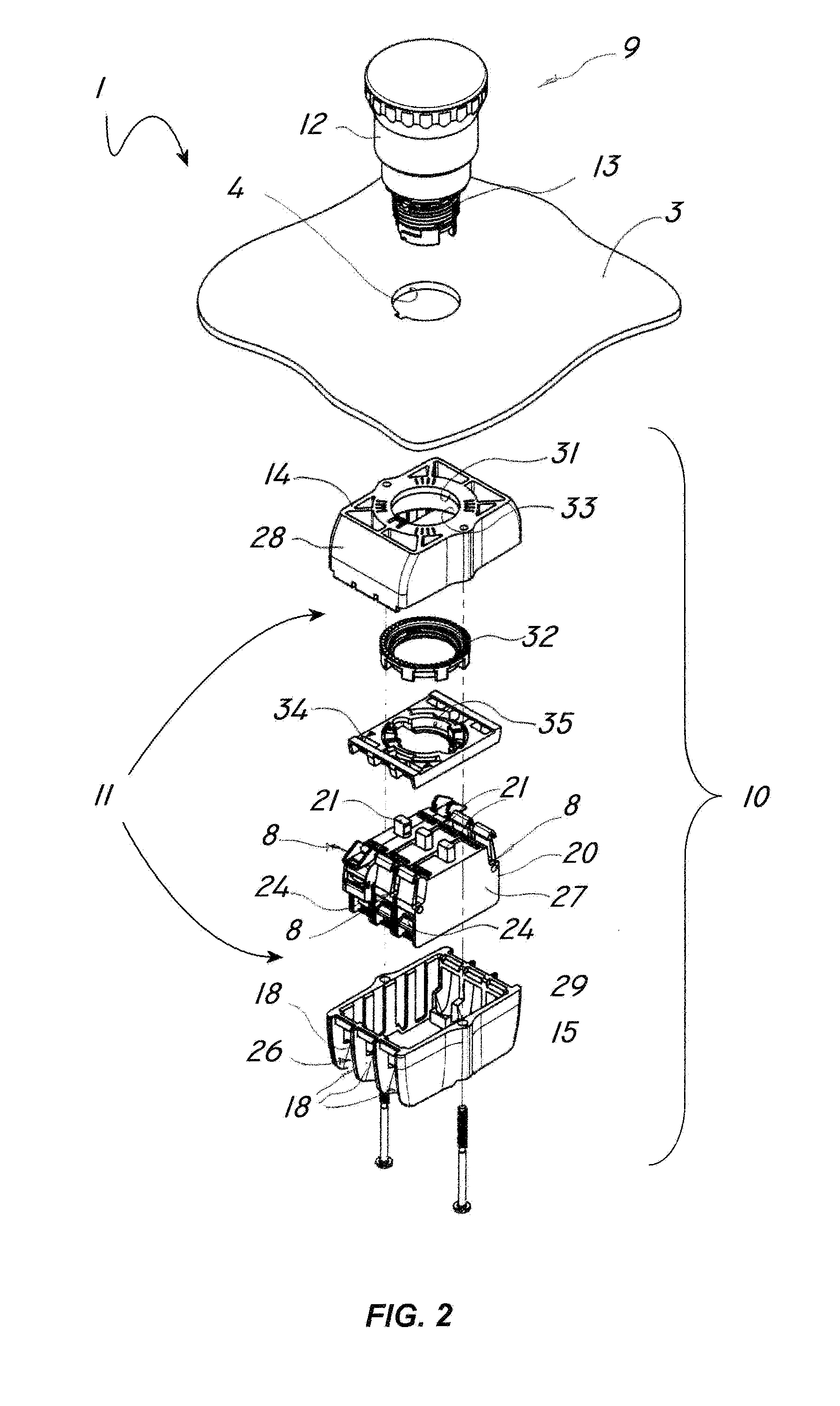

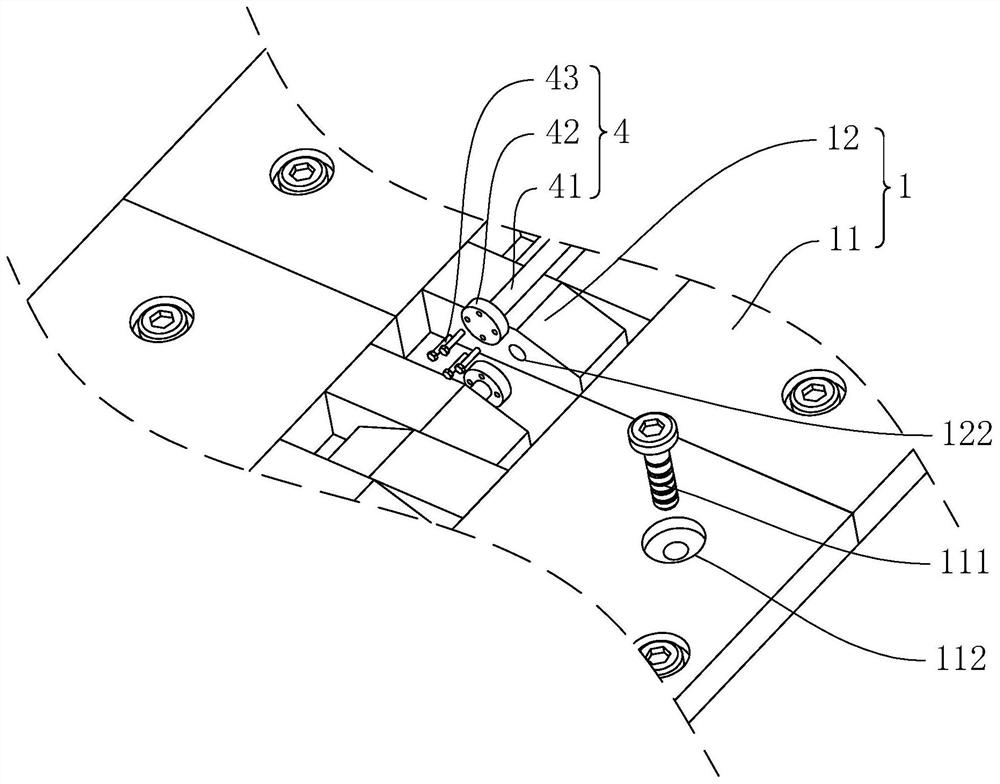

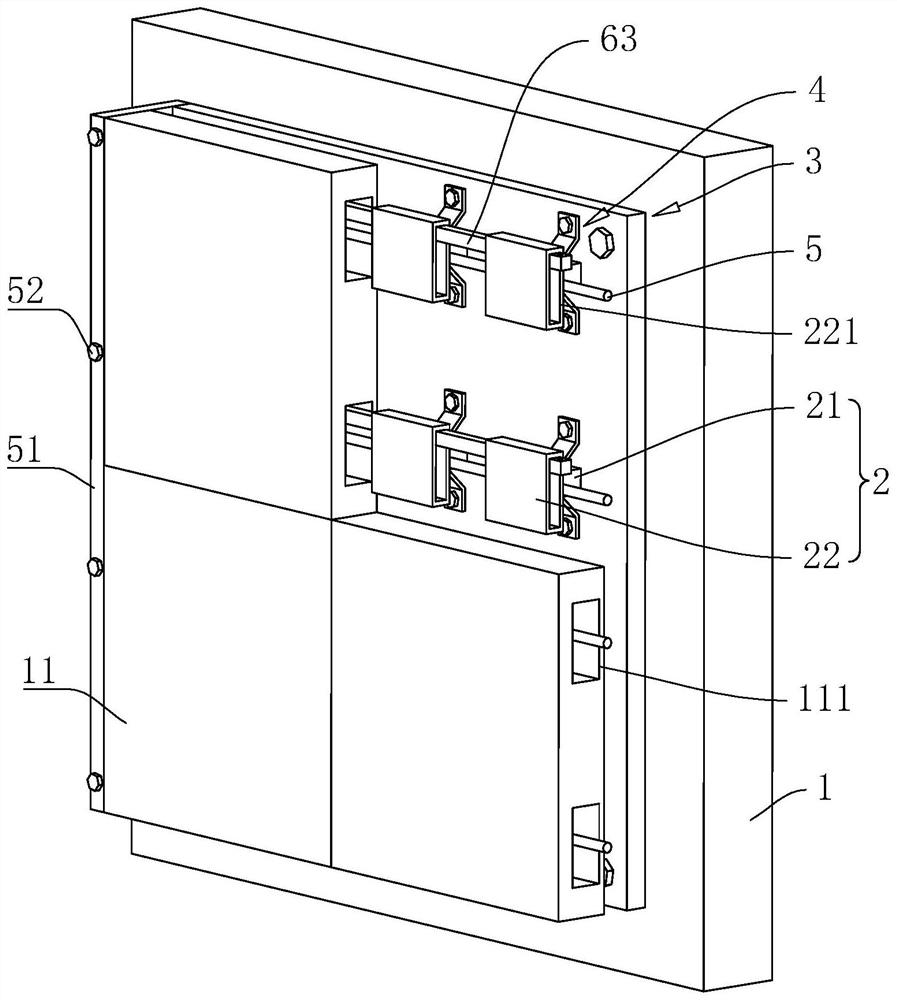

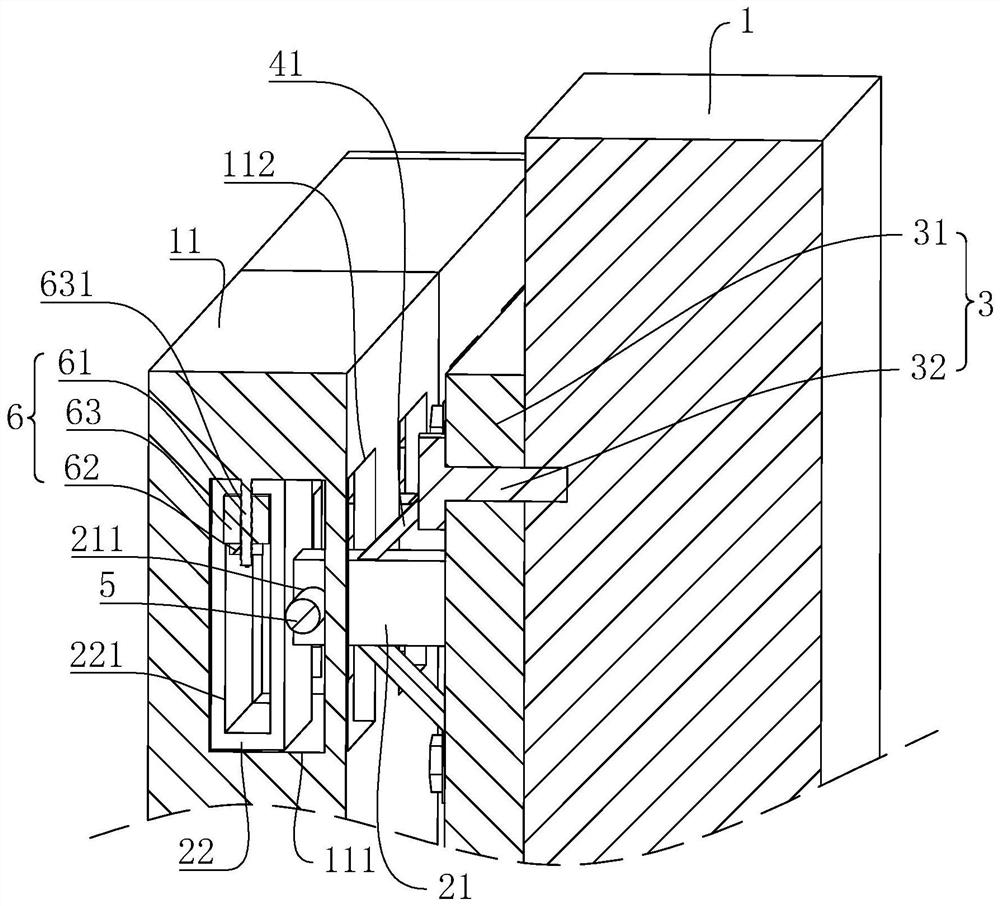

Switch control apparatus for electric plant

ActiveUS20160189889A1Improve efficiencyEnsure positional stabilityEmergency casingsContact vibration/shock dampingEngineeringActuator

A switch control apparatus for electric plants includes, a box-like body which is adapted to be anchored to a fixed o movable part of an electric plant and has a closing panel with at least one passage therethrough, at least one contact unit which is accommodated in the box-like body at the passage and is adapted to be electrically connected to at least one respective electric circuit of the plant for selective open / close control thereof, at least one actuator which is adapted to interact with the contact unit for the latter to ensure selective opening / closing of the respective circuits, an anchor system for anchoring the contact unit to the actuator. The anchor system includes a container member which is adapted to enclose and contain the contact unit and to be anchored to the closing panel in the box-like body for stably securing the contact unit on the actuator.

Owner:PIZZATO ELETTRICA

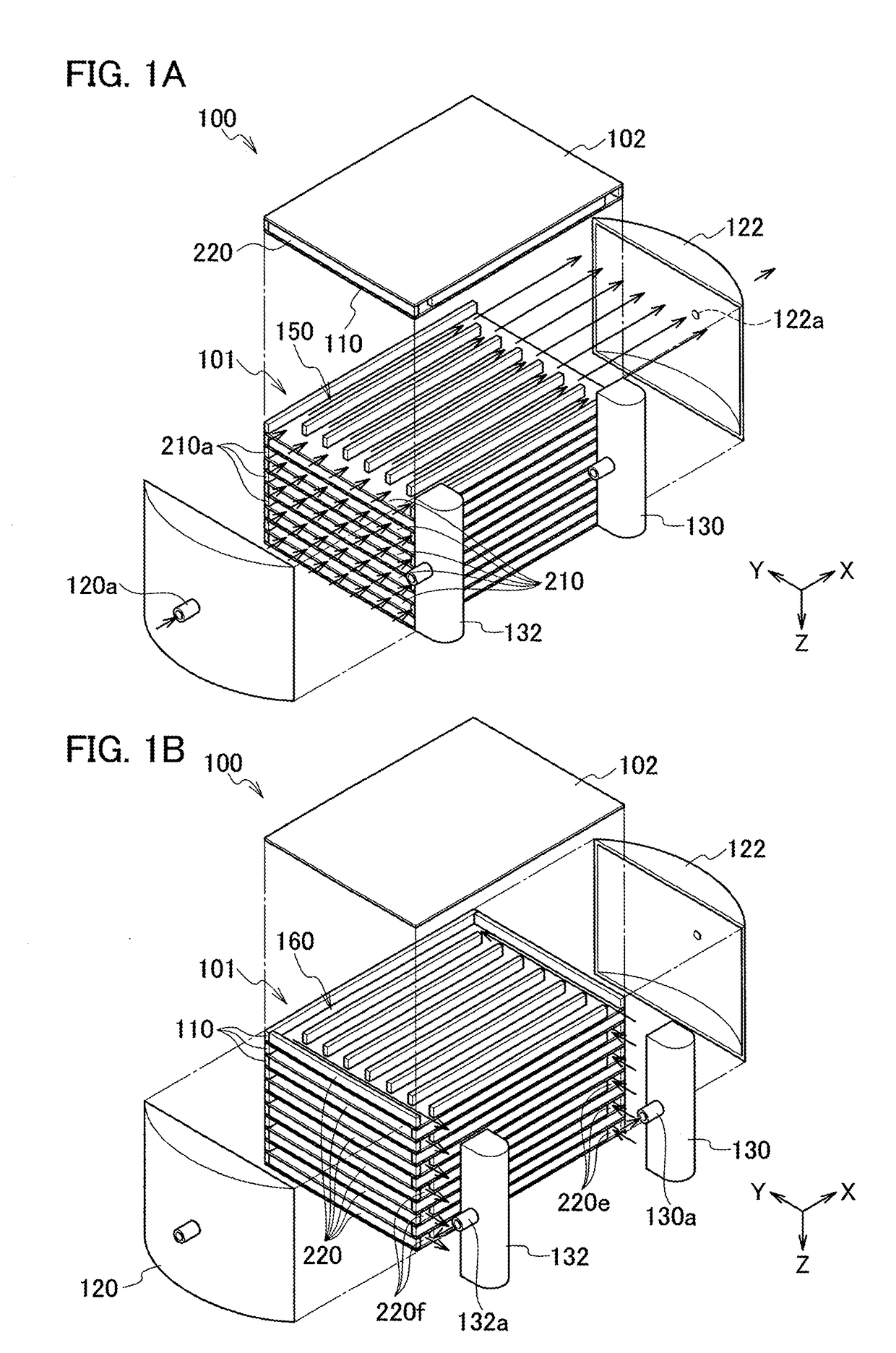

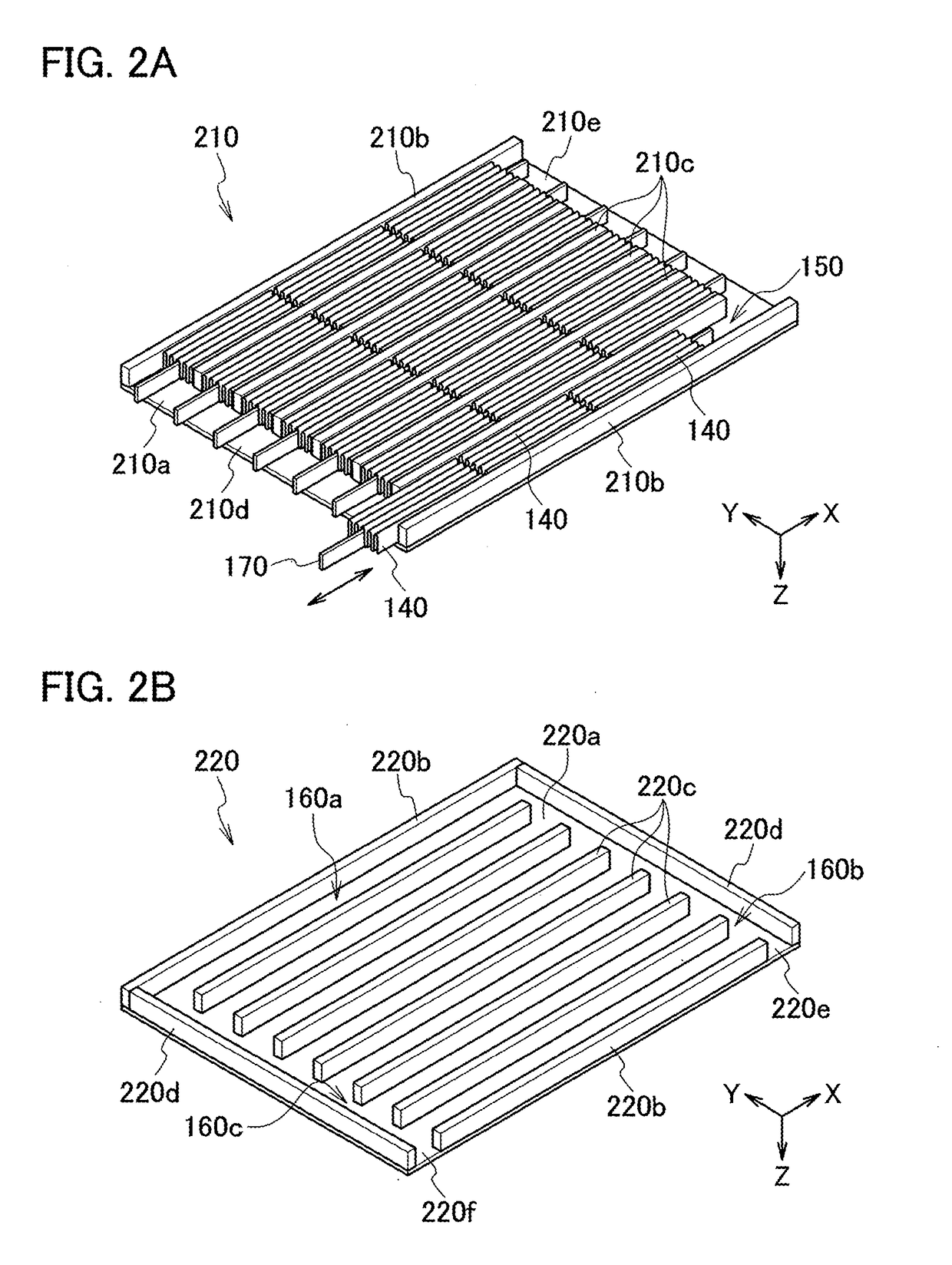

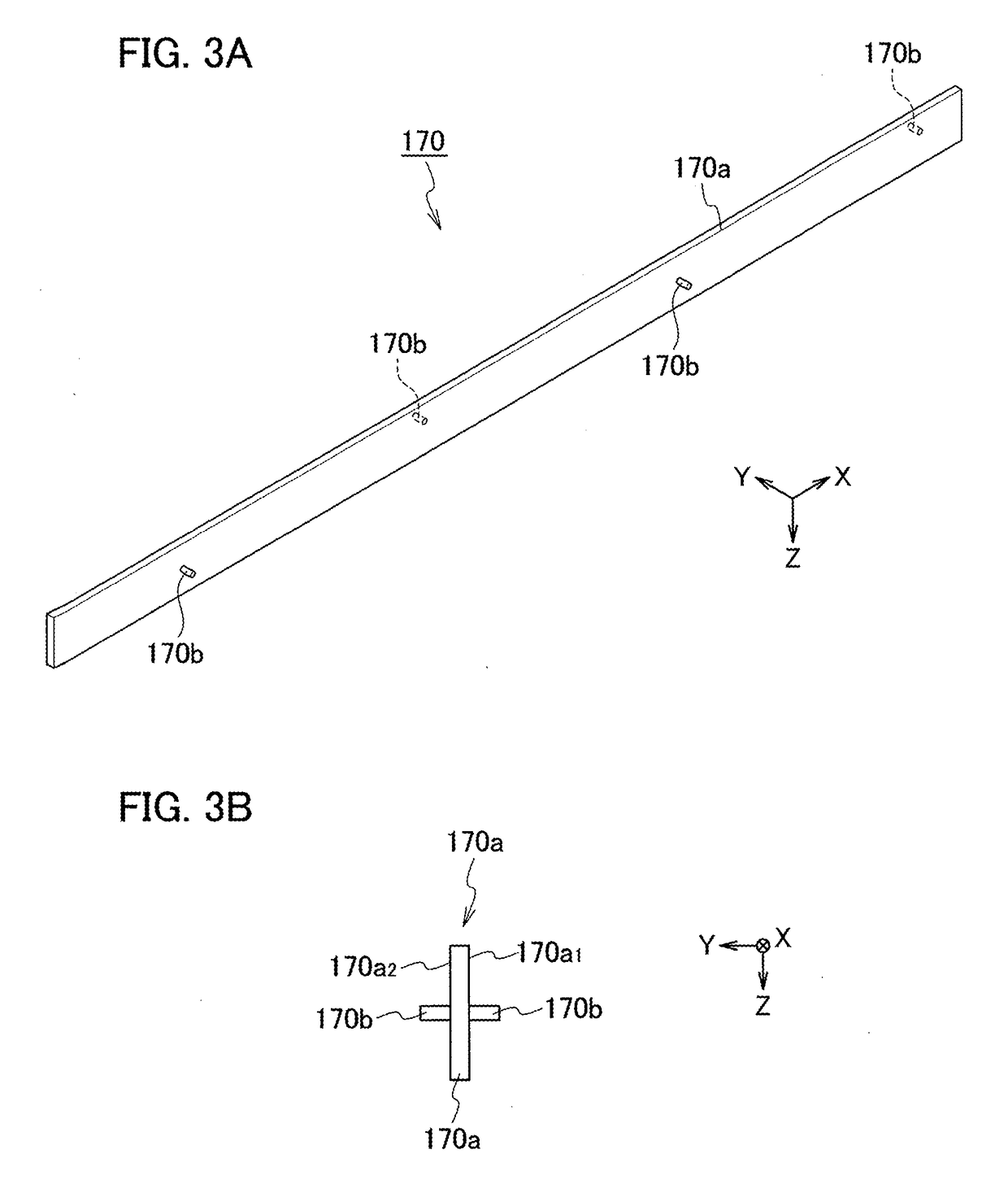

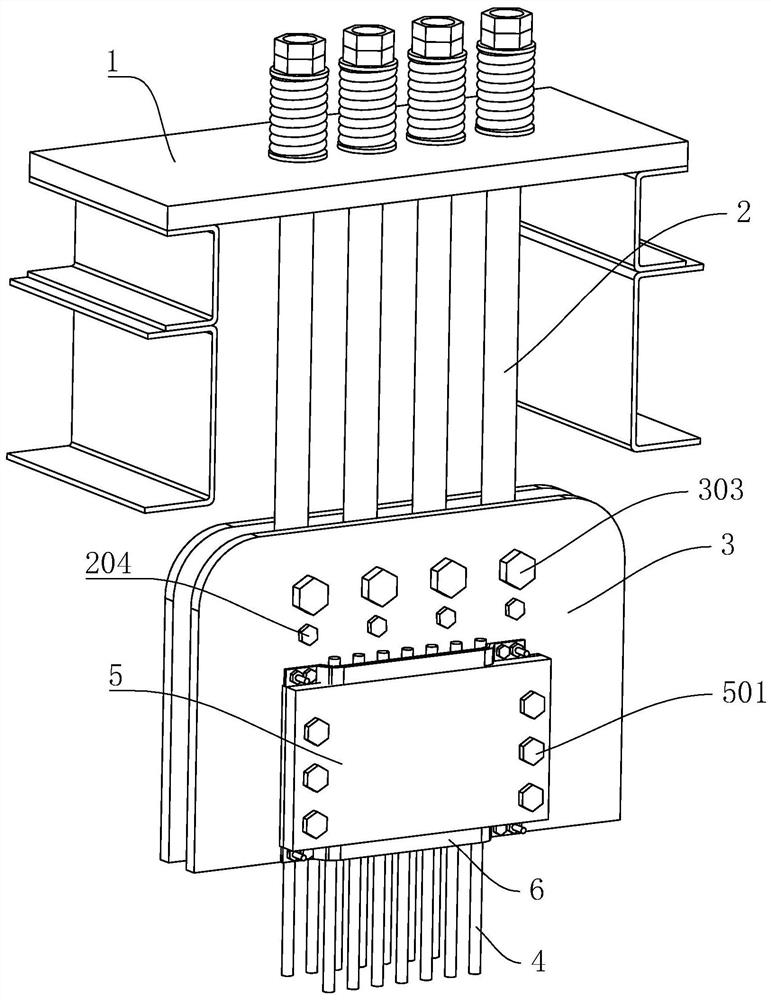

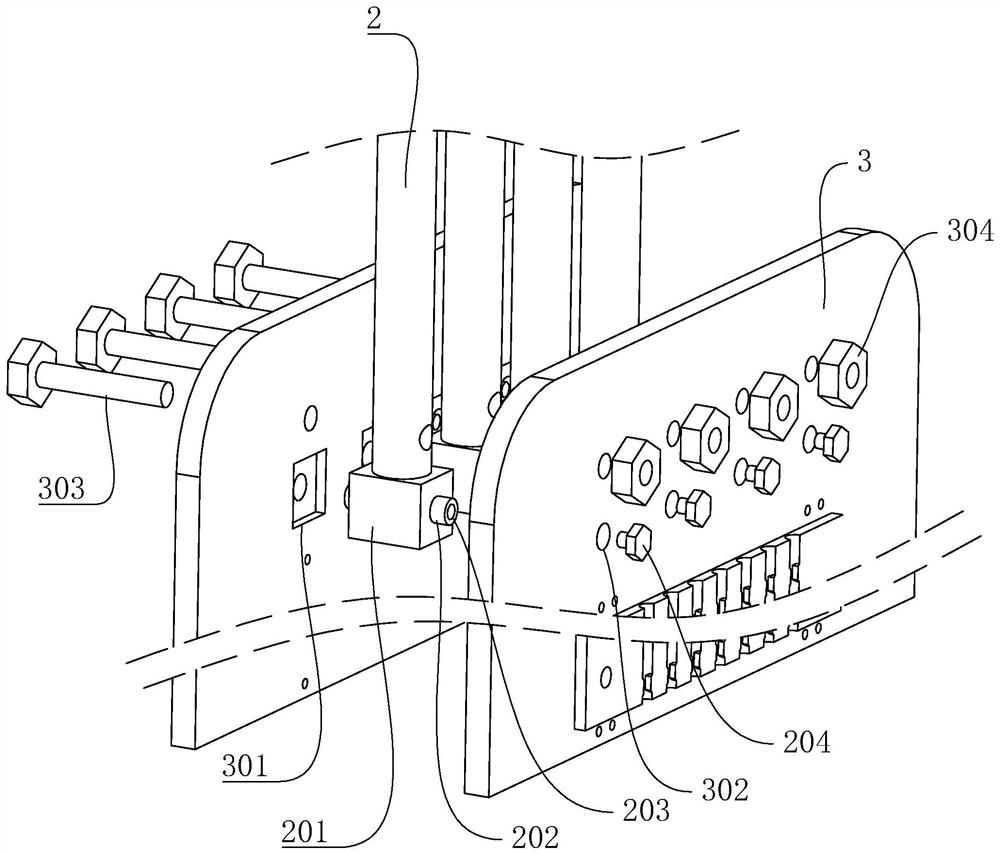

Reactor

ActiveUS20180372415A1Ensure positional stabilityEasy to installPhysical/chemical process catalystsOrganic chemistry methodsEngineeringMechanical engineering

Owner:IHI CORP

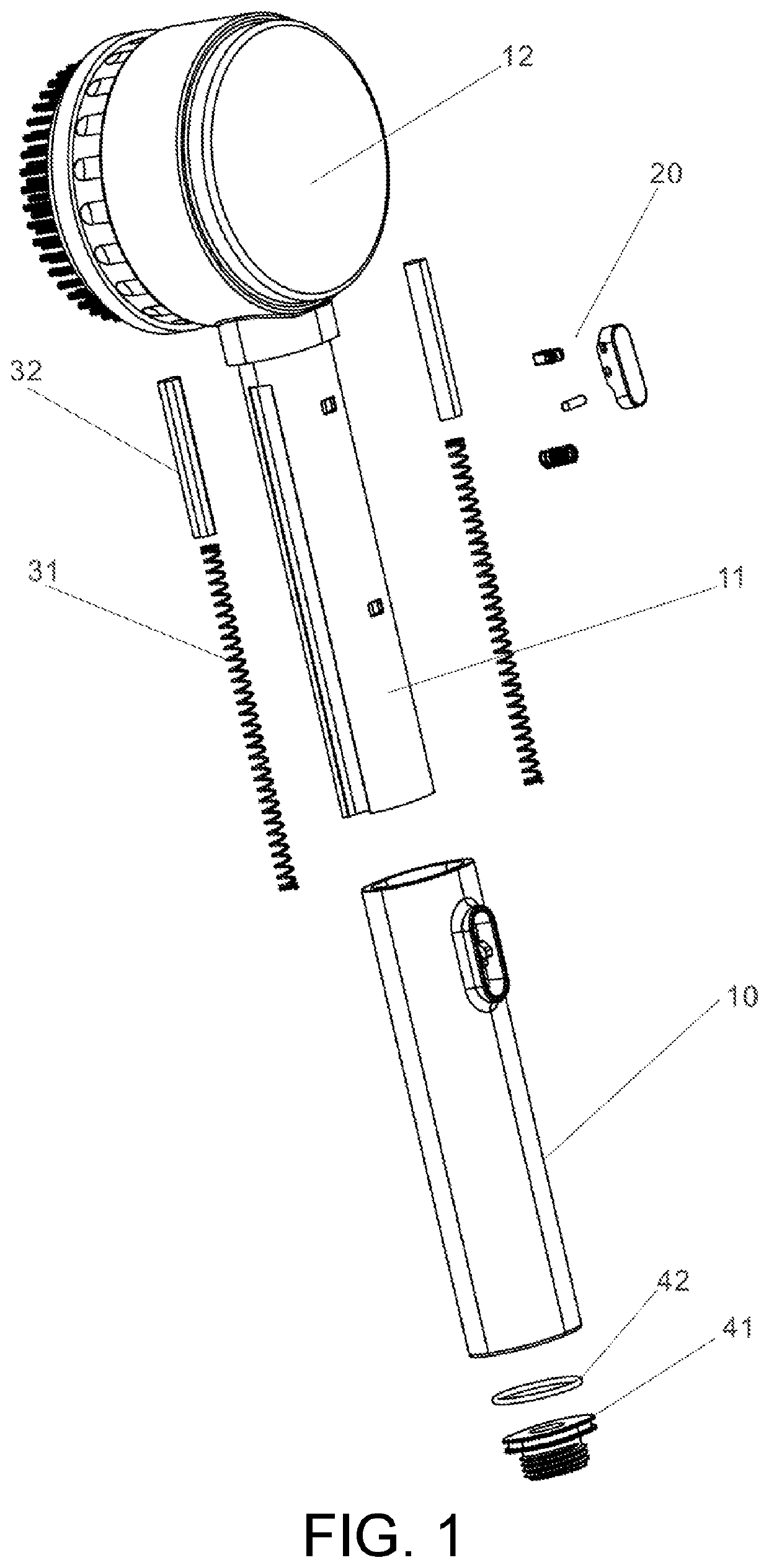

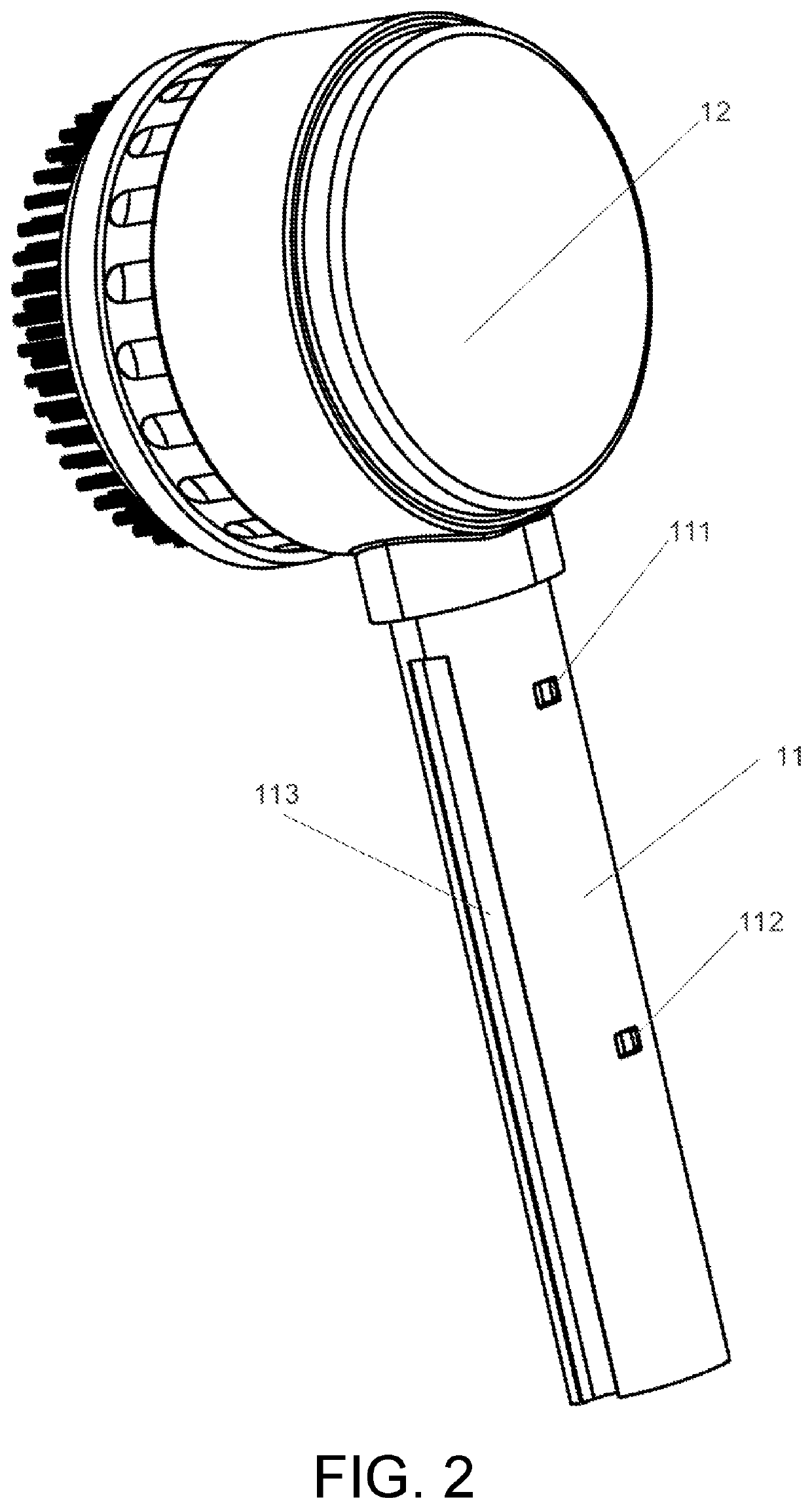

Telescopic shower

PendingUS20220120065A1Ensure positional stabilitySuppress inclinationBathsDouchesEngineeringMechanical engineering

A telescopic shower including a shower body, a telescopic sleeve, and a pressing assembly is provided. The shower body is provided with a first limiting groove and a second limiting groove in an extending direction of a water inlet pipe thereof. The telescopic sleeve and the shower body are slidably connected and form limitation and matching of rotation. A positioning block in the pressing assembly extends into the first limiting groove or the second limiting groove so as to position different positions of the shower body when the shower body extends and retracts relative to the telescopic sleeve.

Owner:FUJIAN XIHE SANITARY WARE TECH

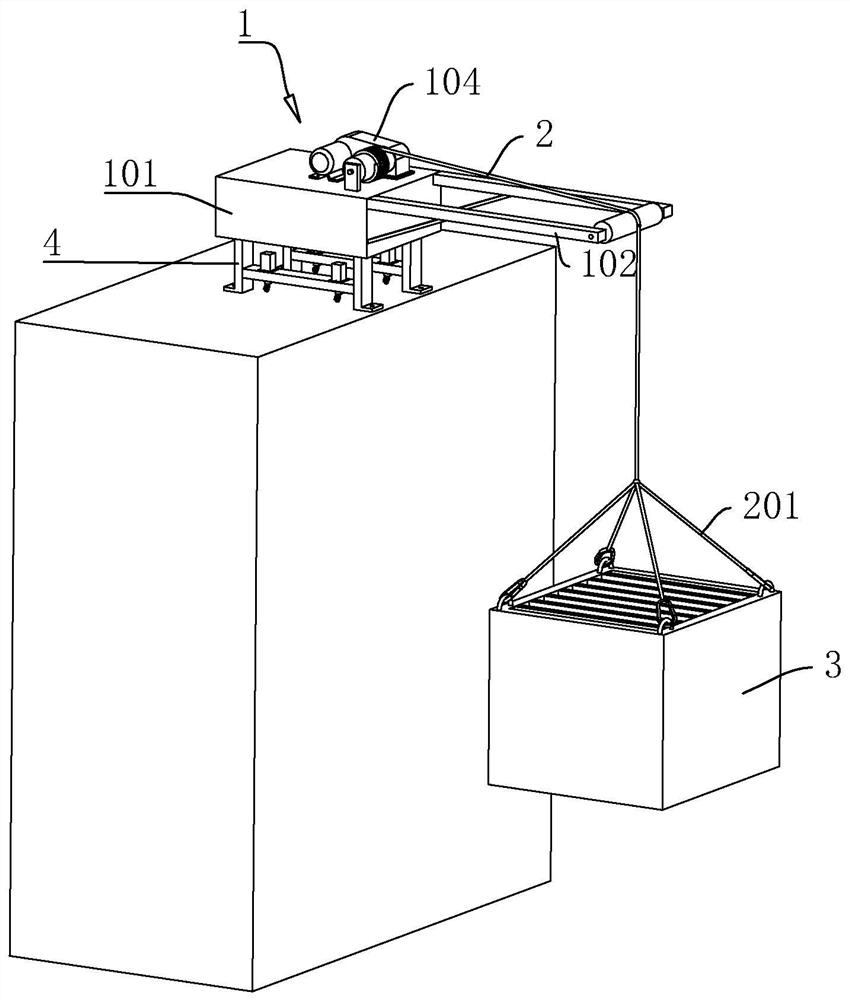

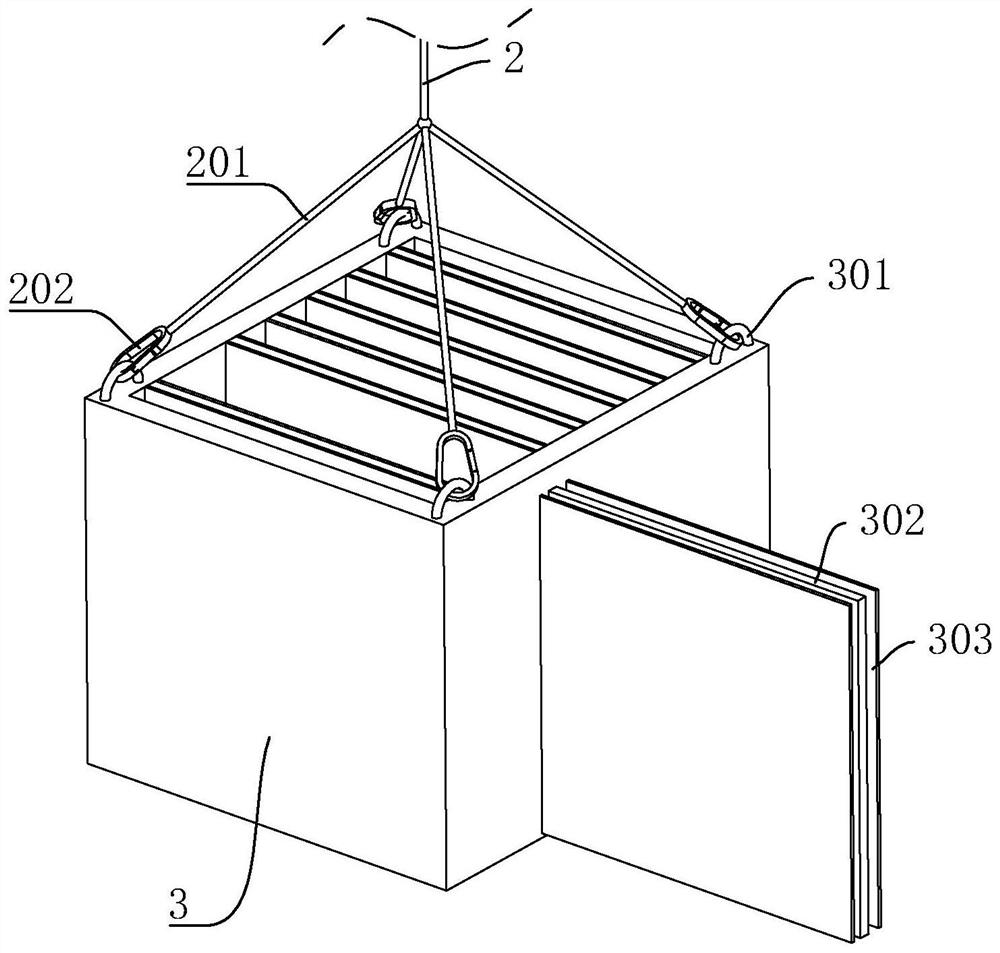

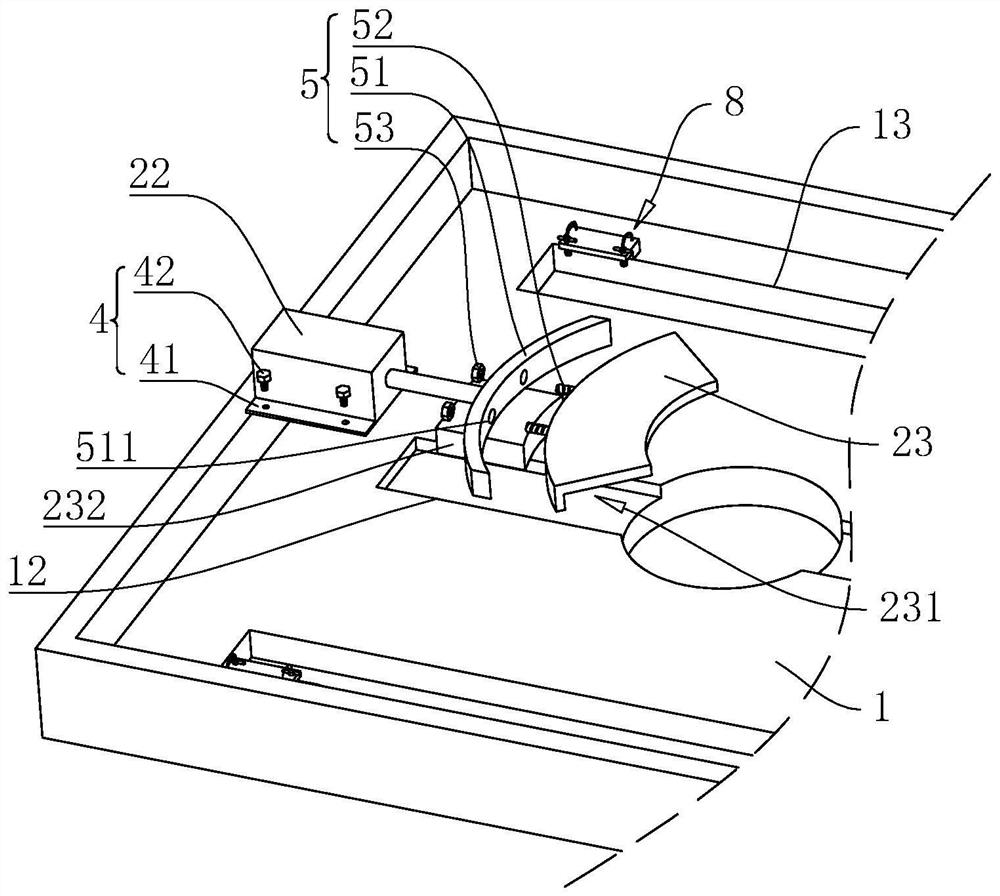

Transfer device for curtain wall hoisting

ActiveCN111689415AEnsure positional stabilityEnsure safetyWallsBase supporting structuresClassical mechanicsEngineering

The invention relates to a transfer device for curtain wall hoisting, which comprises a transfer frame, wherein the transfer frame comprises a counterweight rack and a winding device arranged at the top of the counterweight rack; a connecting cable is wound on a winding drum of the winding device; a receiving basket is arranged at one end, away from the direction of the winding device, of the connecting cable; two extension plates are arranged on the outer side wall of the counterweight rack; a guide roller used for receiving the connecting cable is jointly rotatably arranged between the two extension plates; a plurality of bottom supporting legs are arranged at the bottom of the counterweight rack; a supporting plate is jointly arranged between two adjacent bottom supporting legs; two supporting pieces are arranged on each supporting plate; connecting blocks are arranged at the bottoms of piston rods of the supporting pieces; and guide pulleys are arranged at the bottoms of the connecting blocks. The transfer device has the advantages that an operator can hoist a glass plate indoors conveniently, and the glass plate installation progress can be effectively guaranteed.

Owner:江苏中南建设装饰集团有限公司

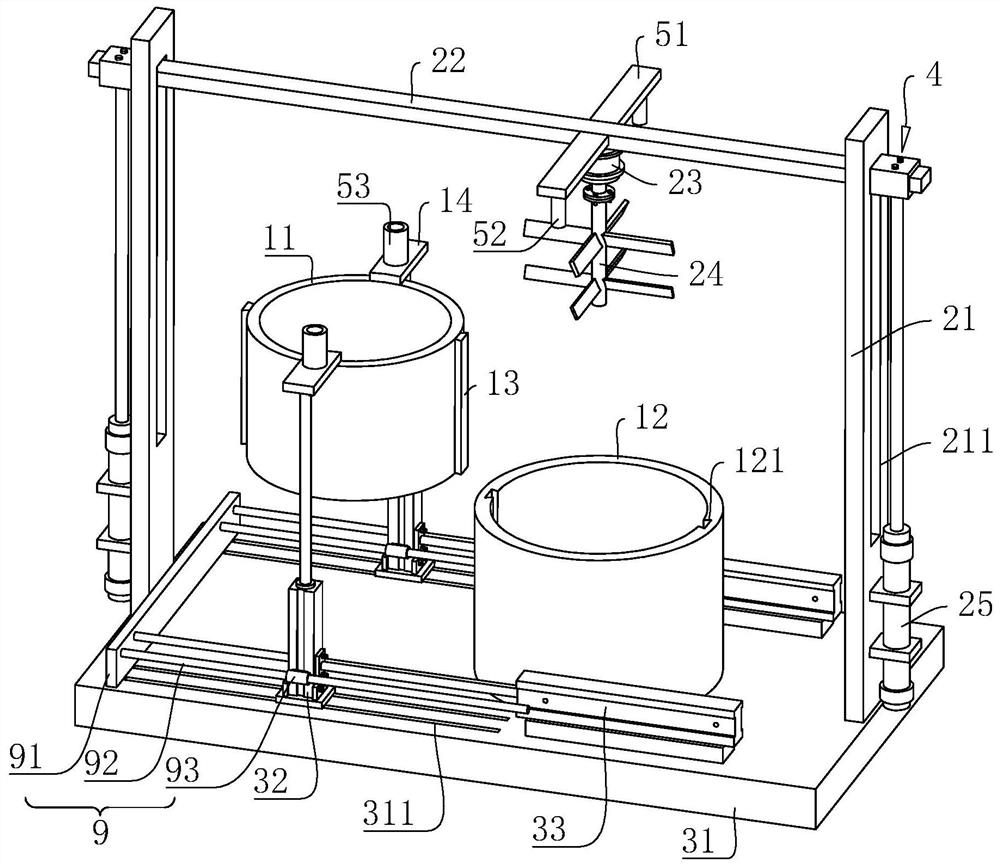

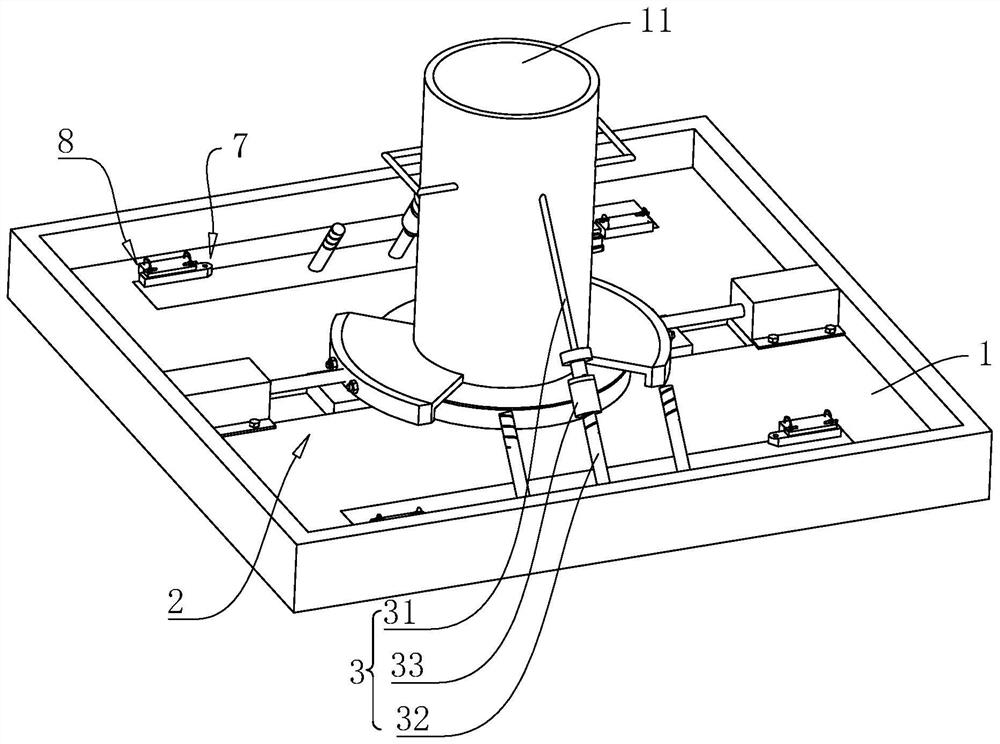

Stirrer for titanium dioxide production and processing technology

InactiveCN113244806AQuick releaseFor quick replacementTransportation and packagingMixing methodsElectric machineryEngineering

The invention relates to a stirrer for titanium dioxide production and a processing technology. The stirrer comprises a tank body, a stirring assembly and a transferring assembly. The tank body comprises an inner tank, an outer tank, a limiting strip and an extending plate, and the inner tank is arranged in an inner cavity of the outer tank. The transferring assembly comprises a bottom supporting plate, a bearing air cylinder and a pushing air cylinder, the bearing air cylinder is used for lifting the extending plate upwards, and a piston rod of the pushing air cylinder is fixedly connected with the bearing air cylinder. The stirring assembly comprises two sets of supporting frames, a connecting plate, a driving motor, a stirring shaft and jacking air cylinders. The connecting plate is arranged between the two sets of supporting frames in a sliding mode, and the jacking air cylinders are arranged on the outer side walls of the supporting frames. The driving motor is arranged on the side wall, facing the inner tank, of the connecting plate; the stirring shaft is arranged at one end of the output end of the driving motor. The processing technology comprises the steps of assembly separation, inner tank displacement and inner tank adjustment. The stirrer has the advantages that an operator can conveniently and quickly detach the inner tank to clean and replace the inner tank, and the use efficiency of the stirrer is guaranteed.

Owner:江苏沪申钛白科技有限公司

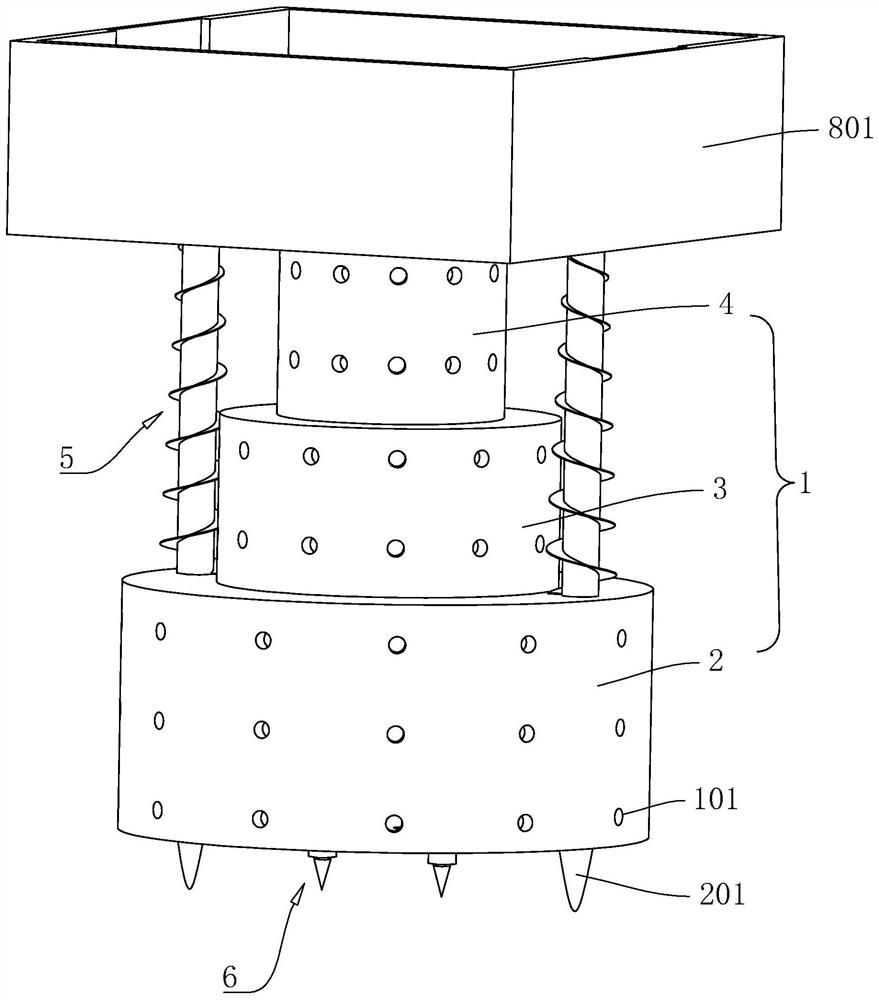

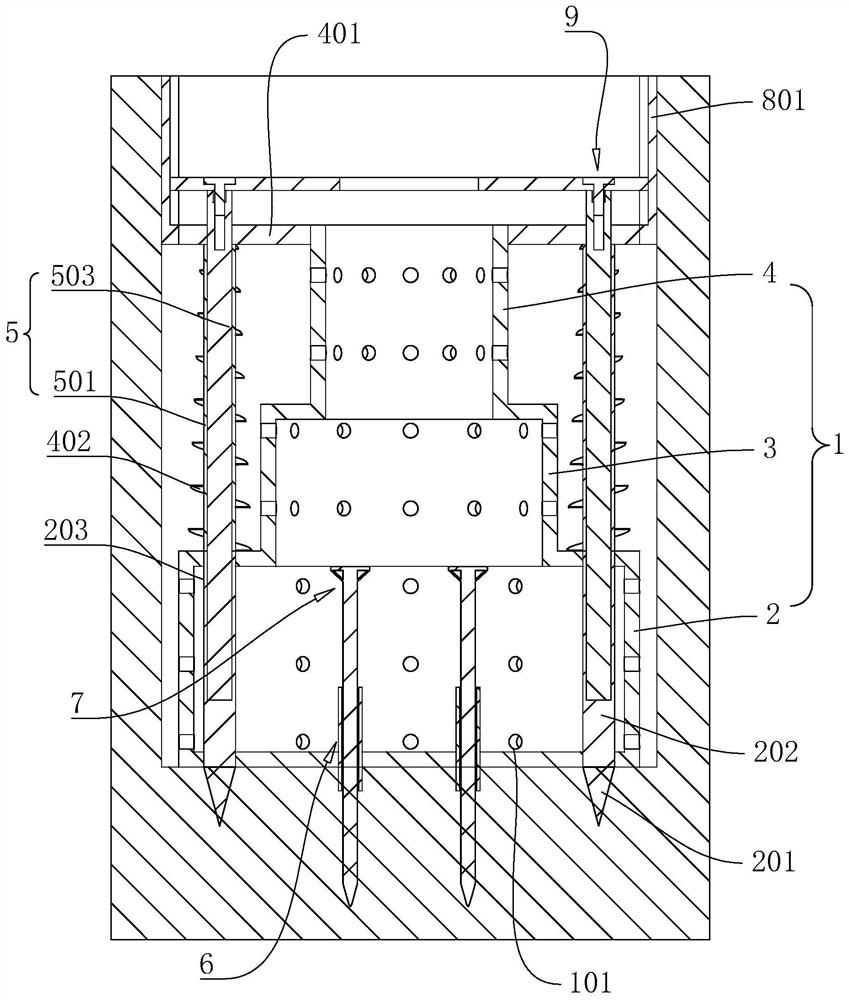

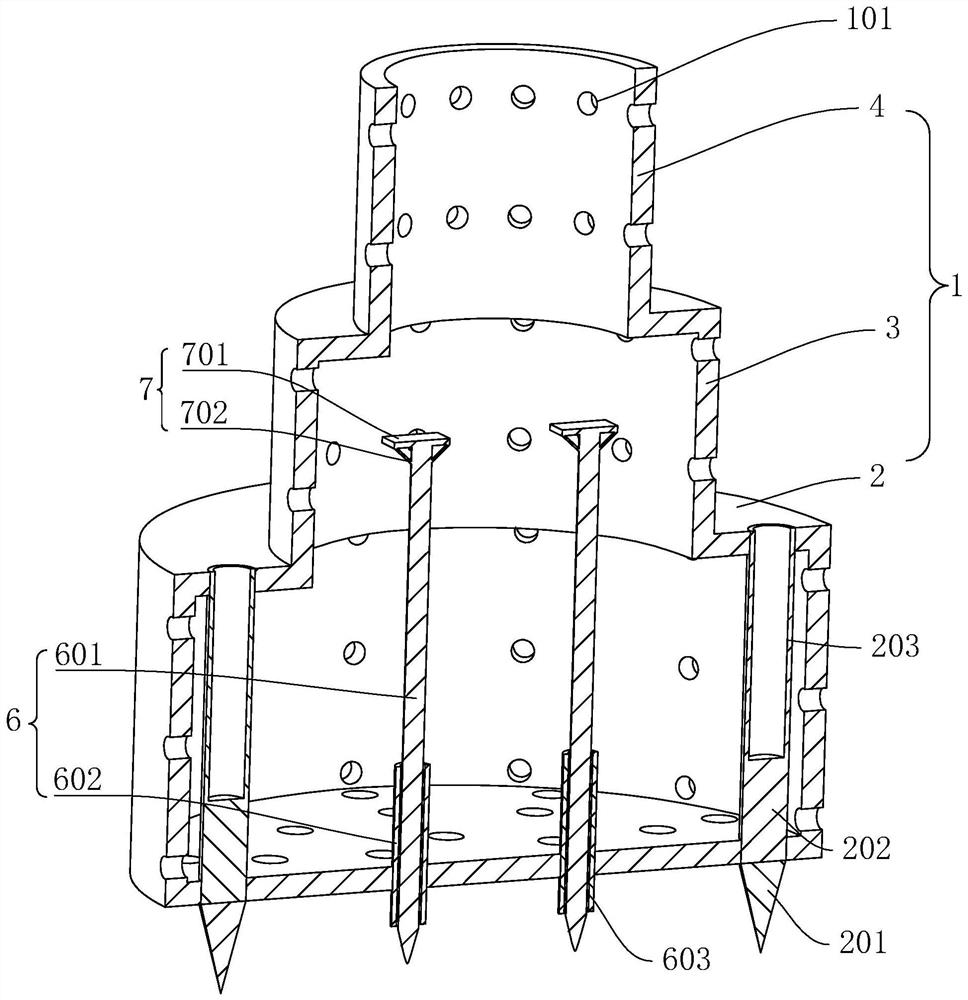

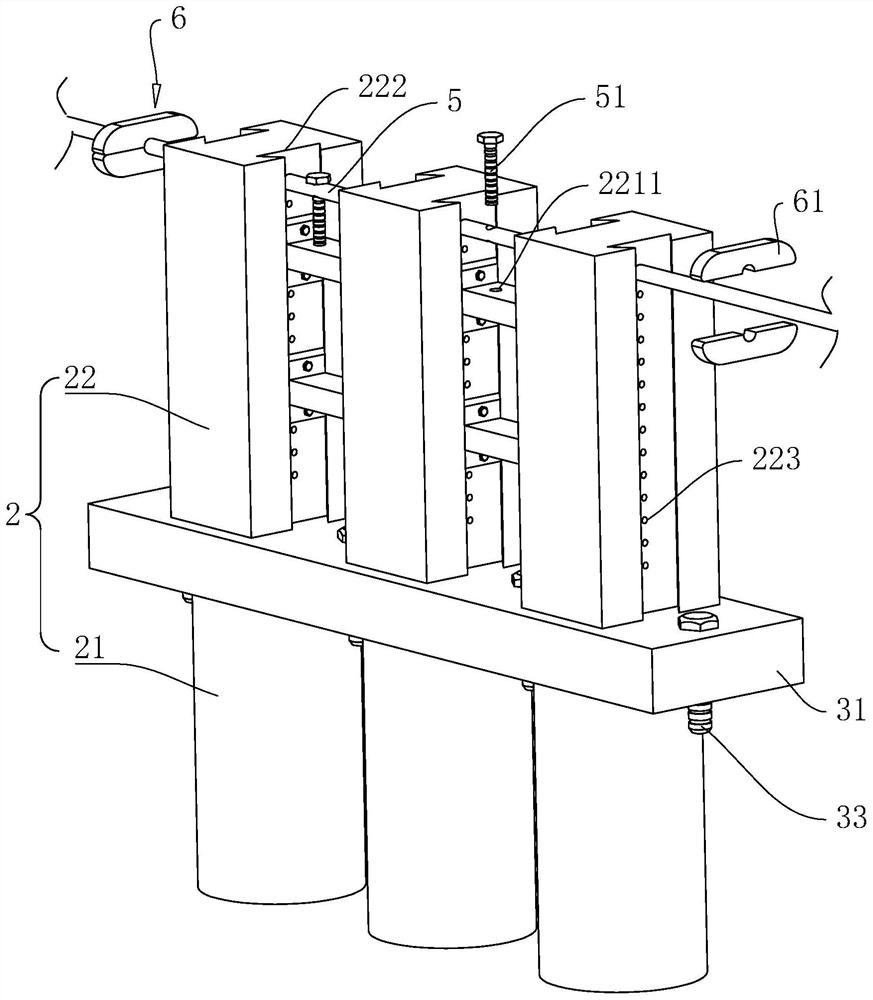

Foundation reinforcing device with high pulling strength for rotary jet grouting drilling machine

ActiveCN112227360AIncrease static frictional resistanceEnsure positional stabilityBulkheads/pilesStructural engineeringUltimate tensile strength

The invention relates to a foundation reinforcing device with high pulling strength for a rotary jet grouting drilling machine. The foundation reinforcing device with high pulling strength for the rotary jet grouting drilling machine comprises a limiting barrel, and a plurality of permeation holes are formed in the outer side wall of the limiting barrel; the limiting barrel comprises a positioningcavity, an isolation cavity and an end cavity, the positioning cavity and the end cavity are located at the two ends of the isolation cavity in the length direction correspondingly, the inner diameter of the positioning cavity is larger than that of the isolation cavity, and the inner diameter of the isolation cavity is larger than that of the end cavity; a plurality of bearing columns are arranged in an inner cavity of the positioning cavity, and a positioning cone is arranged on the outer side wall of the positioning cavity; a top connecting plate is arranged on the outer side wall of the end cavity, and a positioning assembly is arranged between the top connecting plate and the positioning cavity; and a connecting assembly for limiting the position of the positioning cavity is arrangedon the positioning cavity. The foundation reinforcing structure has the effects that the anti-pulling strength of a concrete block body and the limiting barrel in the foundation is improved, and theposition stability and the punning property after the foundation is reinforced are effectively guaranteed.

Owner:福建新华夏建工集团有限公司

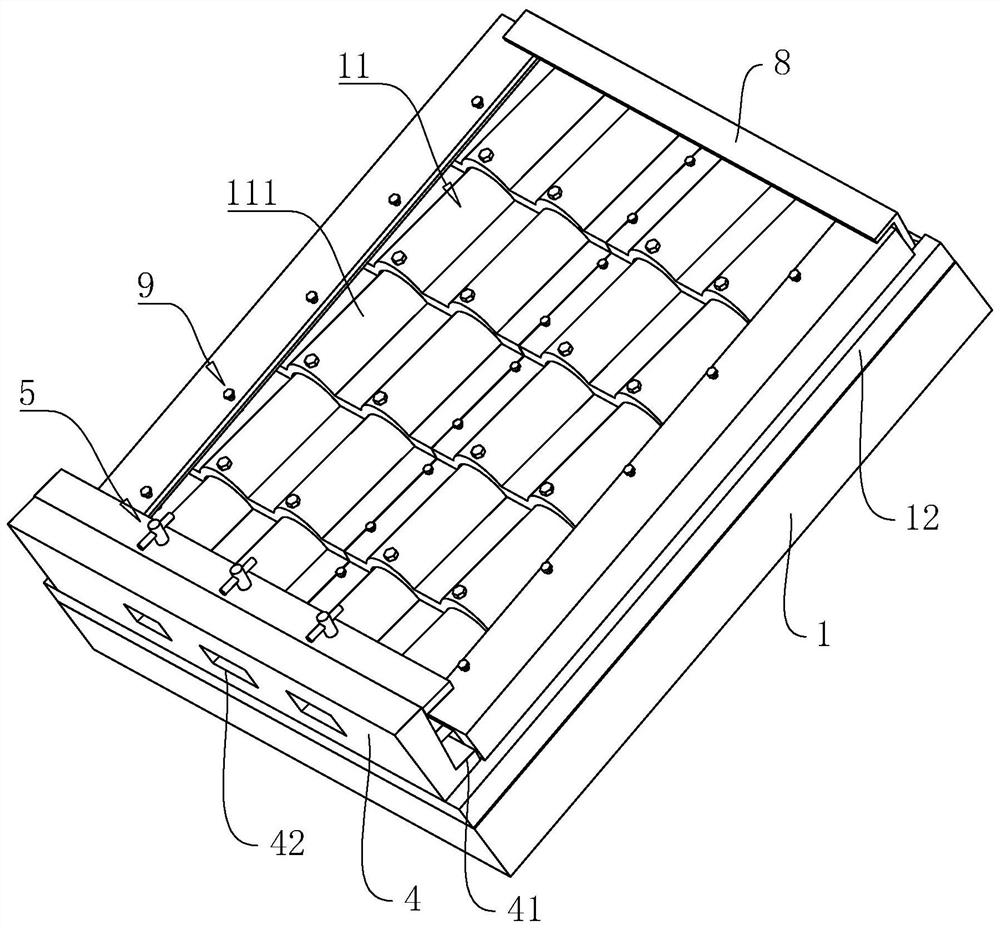

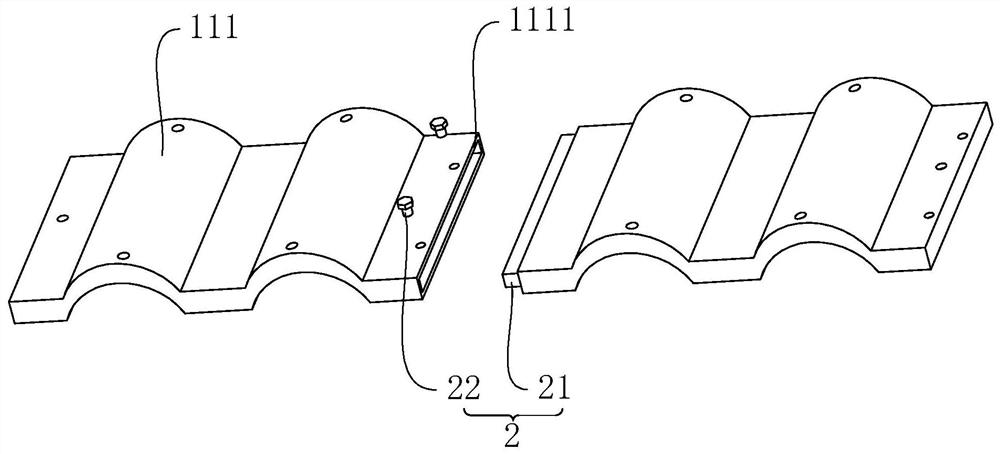

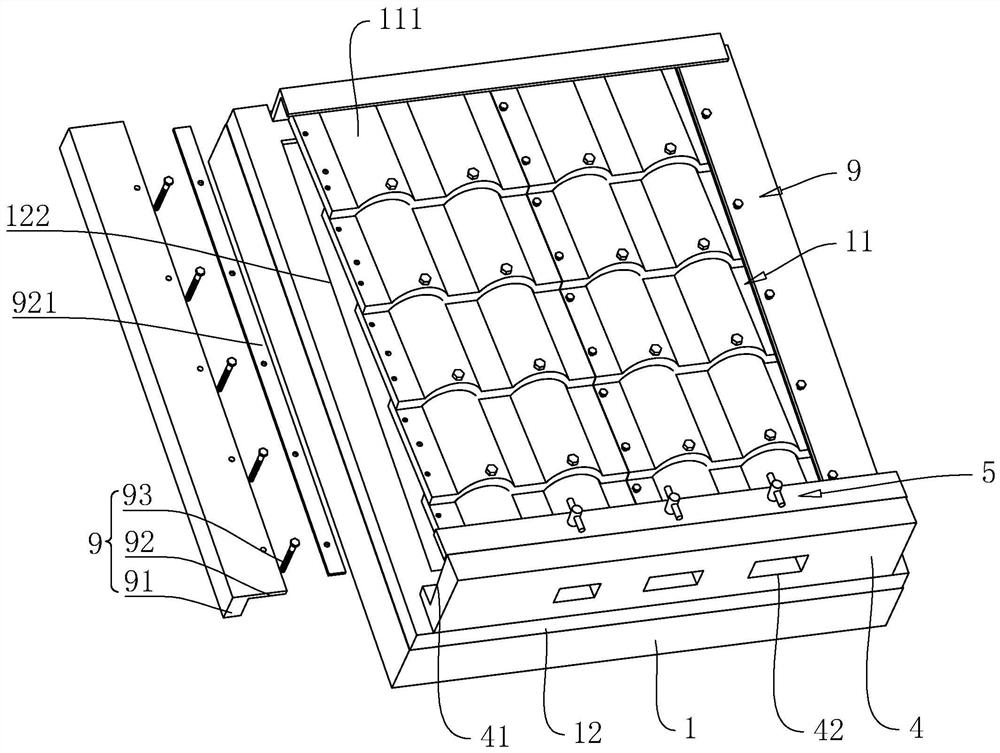

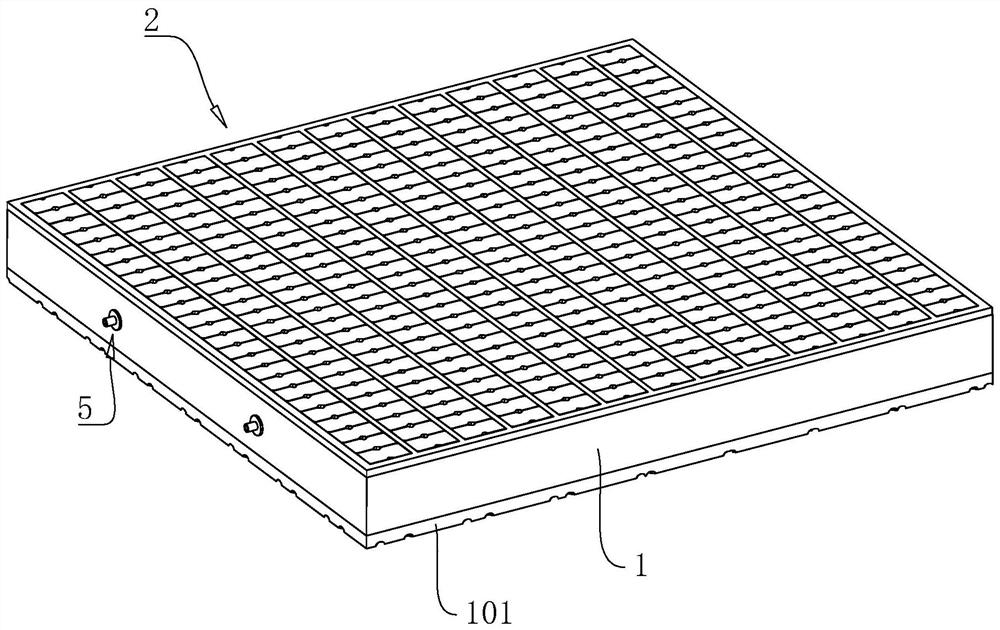

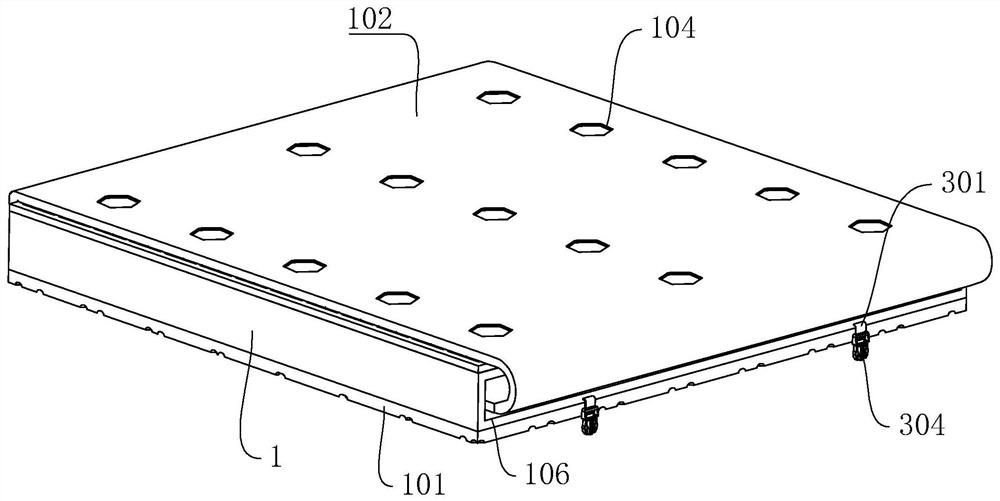

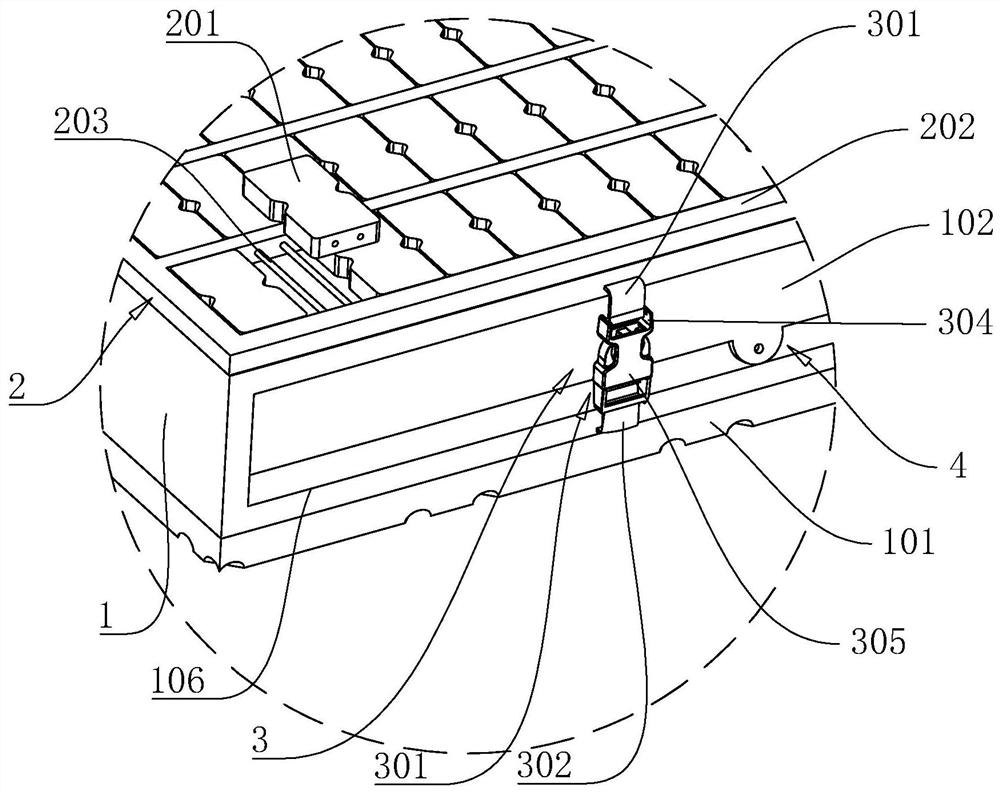

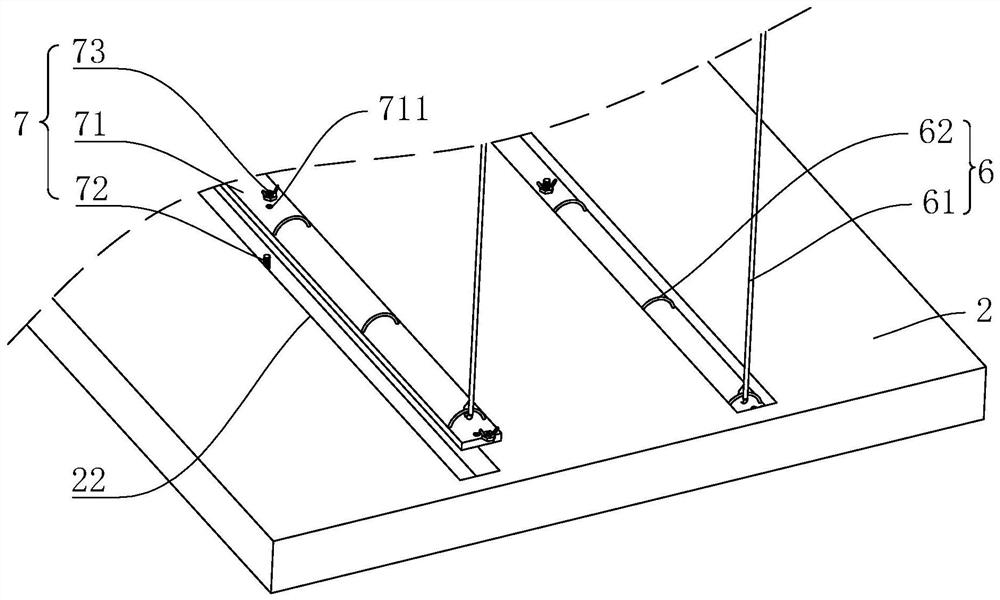

Large-gradient sloping roof tile fixing structure

ActiveCN113530095AImprove positional stabilityImprove stabilityRoof covering using tiles/slatesPhotovoltaic energy generationRoof tileSupport plane

The invention relates to a large-gradient sloping roof tile fixing structure. The large-gradient sloping roof tile fixing structure comprises a plurality of roof tiles; a mounting frame is arranged on the outer side wall of a roof used for mounting the roof tiles; all the roof tiles are arranged on the side wall, away from the roof, of the mounting frame; a bottom supporting strip and a top connecting strip which are used for limiting the positions of the roof tiles are arranged on the side wall, away from the roof, of the mounting frame; all the roof tiles are located between the bottom supporting strip and the top connecting strip; the roof tiles which are in lap joint up and down and a supporting frame are jointly provided with a connecting assembly; the connecting assembly comprises a through connecting rod and a locking piece.The through connecting rod is arranged on the side wall, away from the roof, of the mounting frame, the through connecting rod penetrates through the roof tiles which are in lap joint up and down at the same time, a preset groove is formed in the end wall, away from the mounting frame, of the through connecting rod, a rod body of the locking piece is arranged in the preset groove in a threaded fit mode, and the end of the locking piece abuts against the through connecting rod and the roof tiles at the same time.The method has the effect of effectively improving the stability of the paved roof tiles.

Owner:广东中城建设集团有限公司

Novel cushion capable of effectively improving cool degree

InactiveCN112089257AEnsure positional stabilityReduce loosenessStuffed mattressesSpring mattressesPhysicsCushion

The invention relates to a novel cushion capable of effectively improving the cool degree. The novel cushion comprises a cushion body, wherein a plurality of air dispersing holes are formed in the topwall of the cushion body in a penetrating manner; a first gel film layer is arranged on the surface of one end of the cushion body in the height direction; a cooling layer is arranged on the surface,far away from the first gel film layer, of the cushion body; a second gel film layer is arranged on one side of the cushion body; a storage assembly for limiting the position of the second gel film layer is arranged on the outer side wall of the cushion body; a connecting assembly is arranged at one end, far away from the cushion body, of the second gel film layer; and a clamping assembly which can be matched with the connecting assembly and fix the position of the second gel film layer is arranged on one side, far away from the second gel film layer, of the cushion body. The novel cushion has the effect of improving the cool feeling and the comfort level of a user sitting on the cushion for a long time.

Owner:南通馨宇诺家居用品有限公司

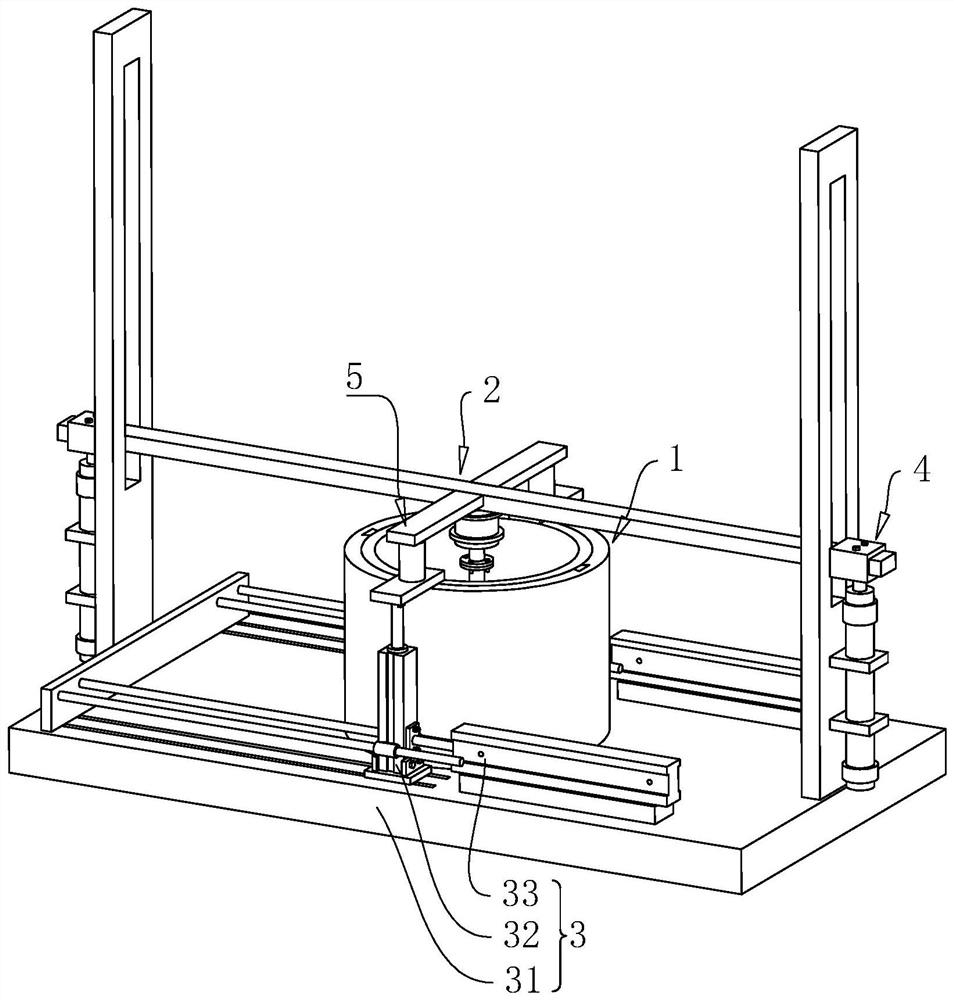

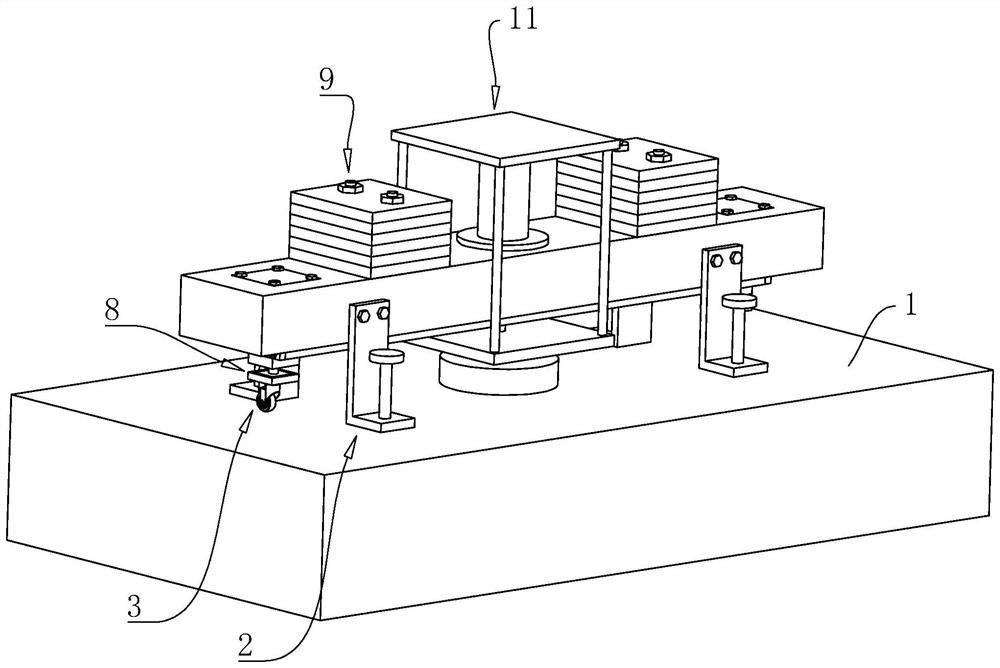

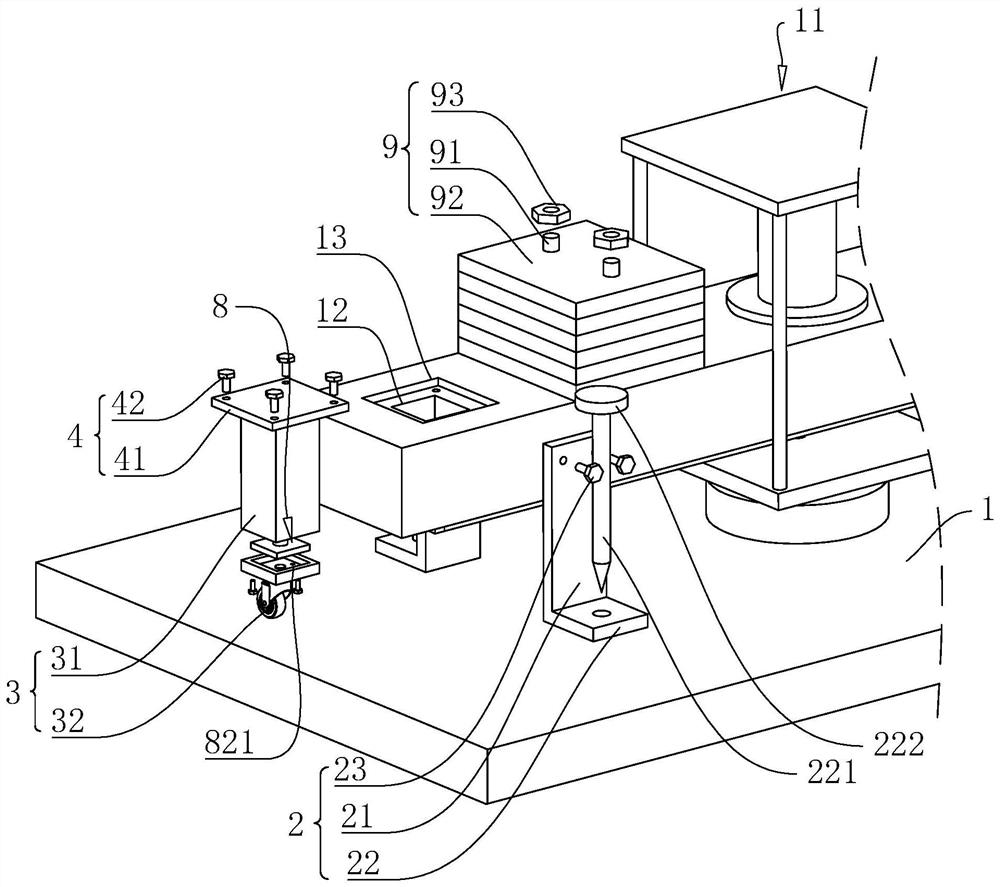

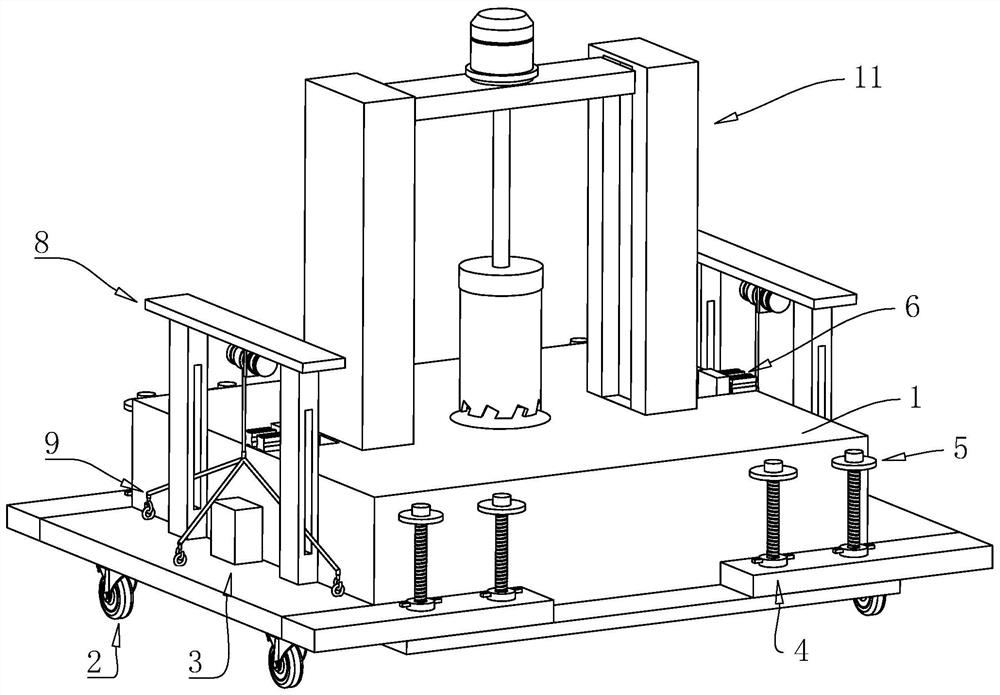

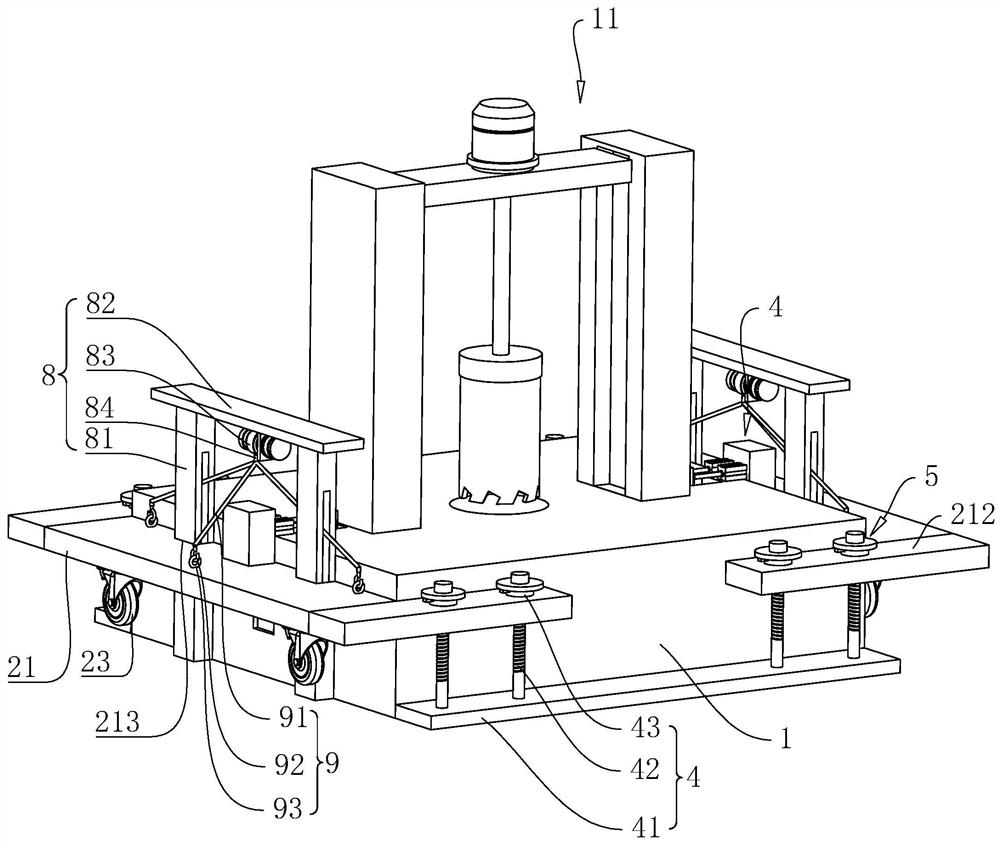

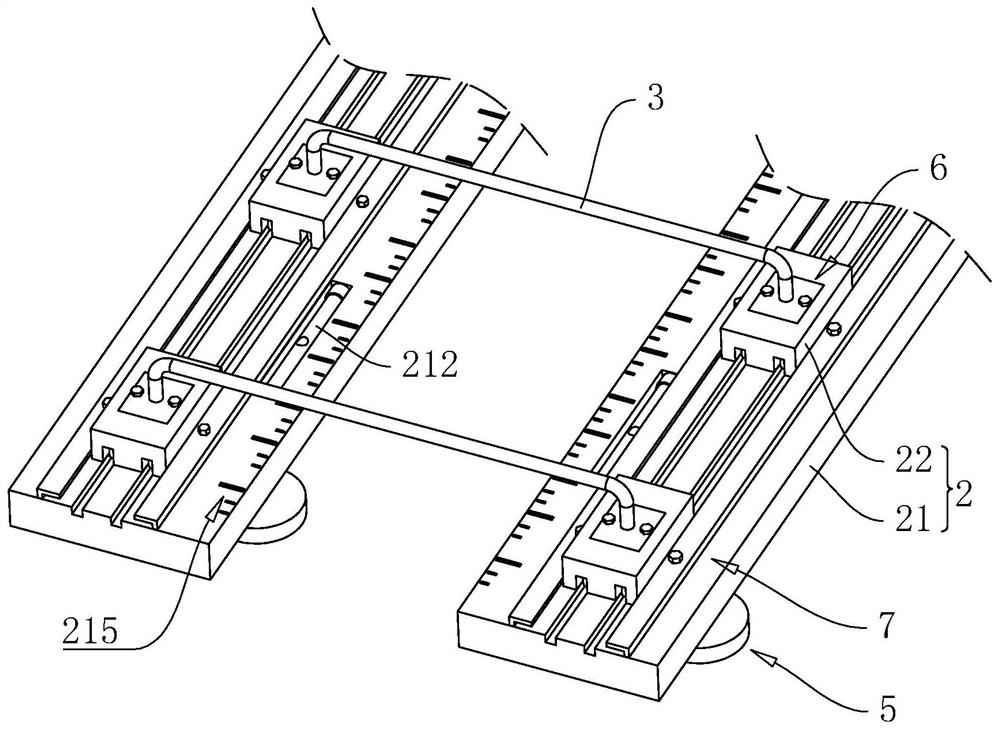

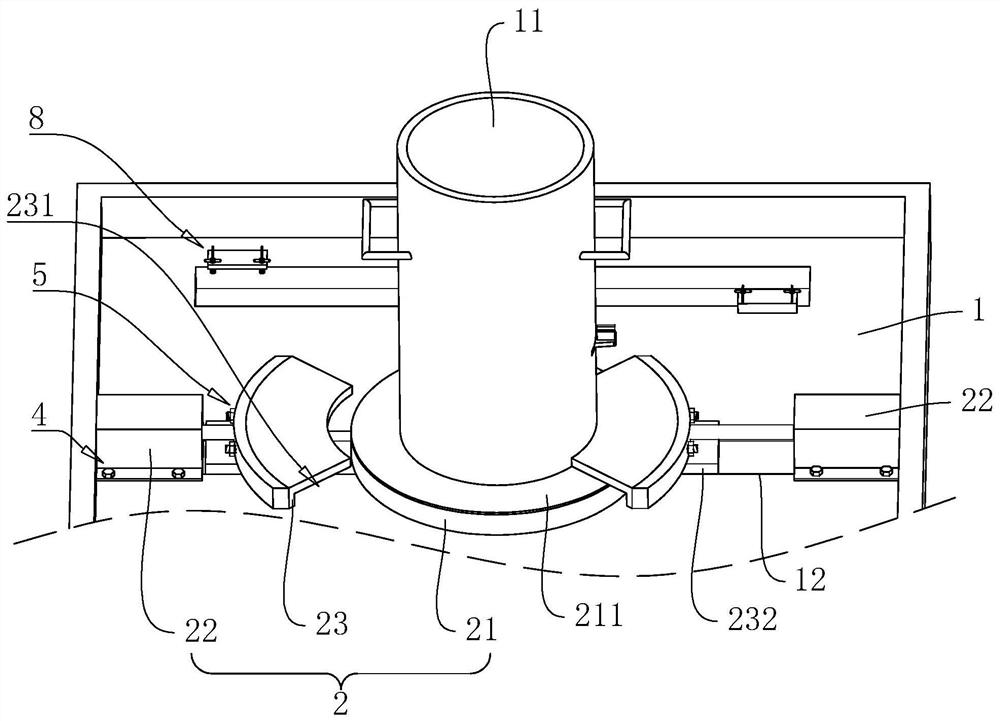

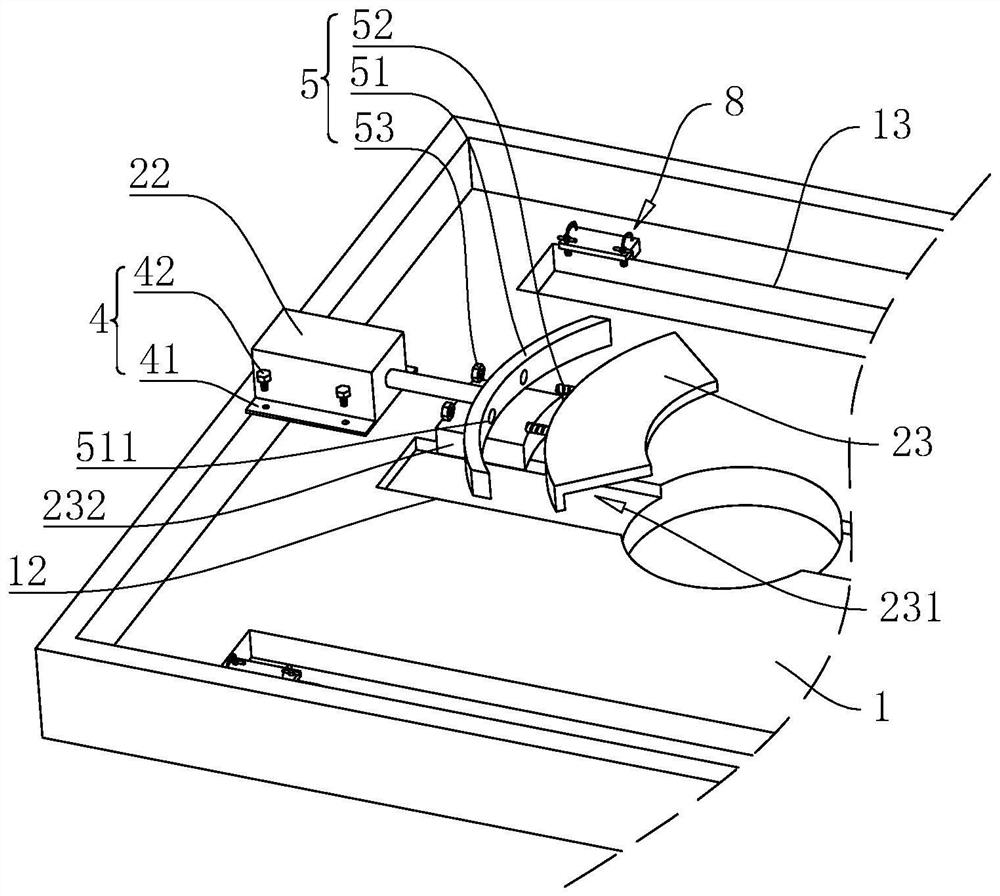

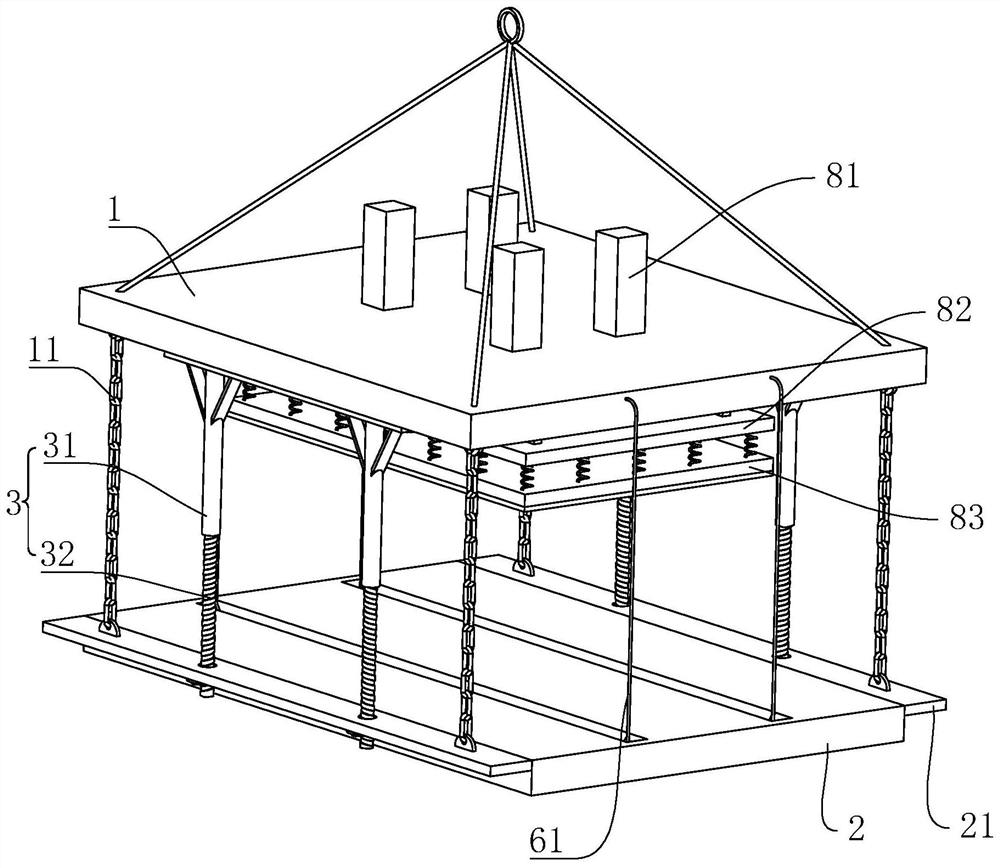

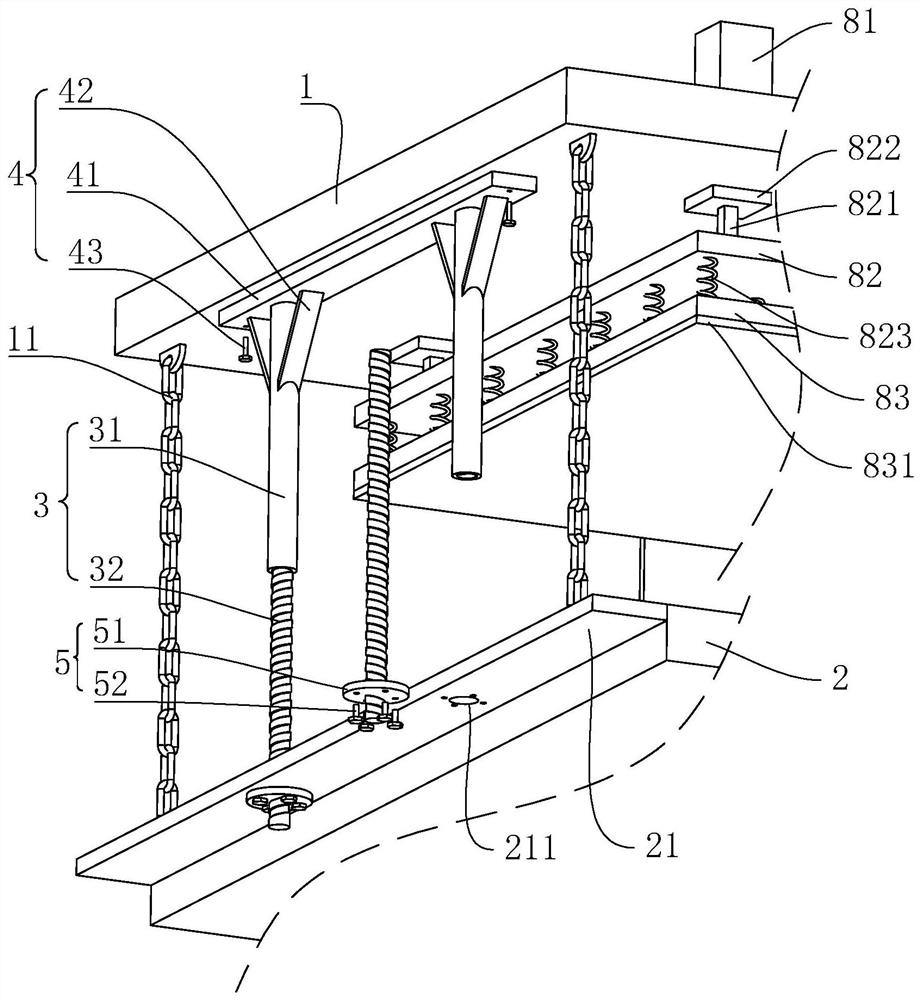

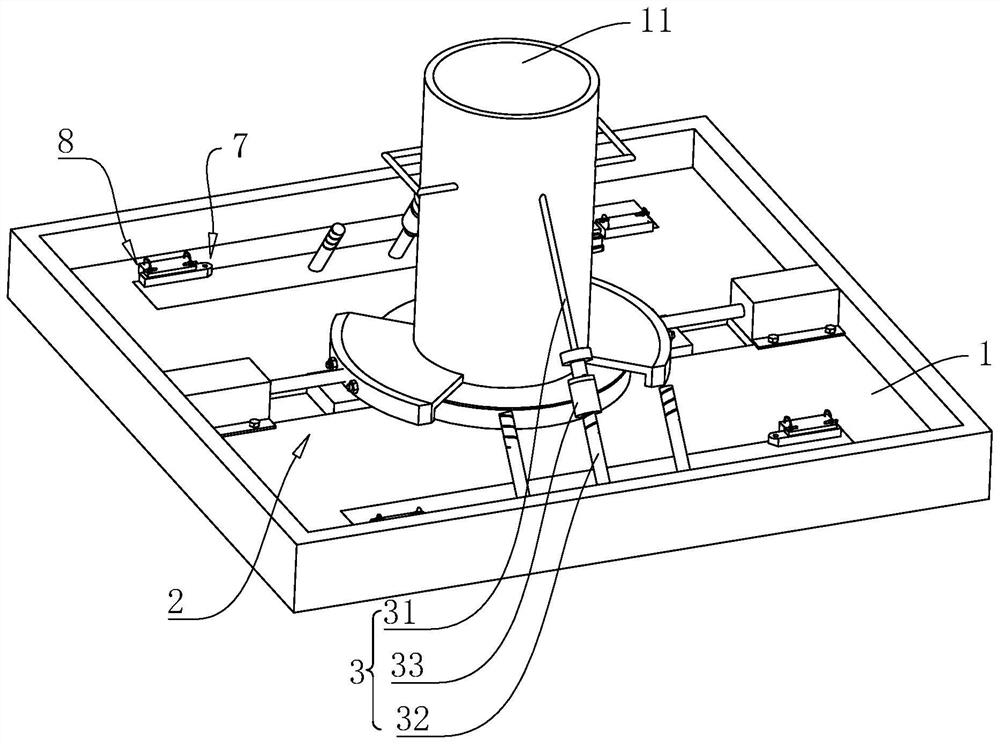

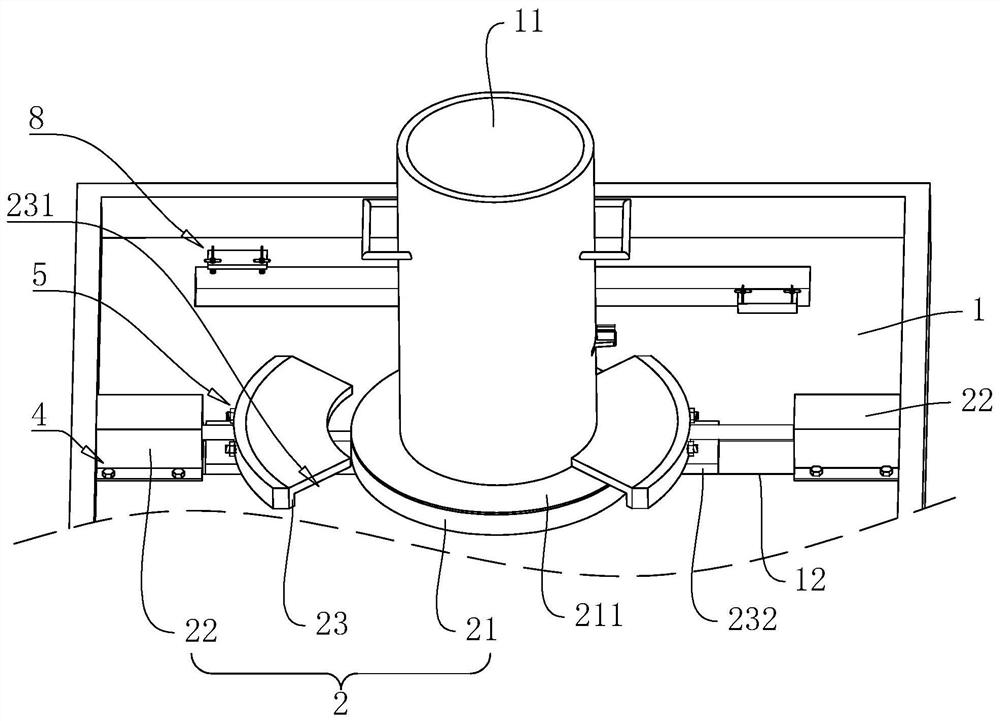

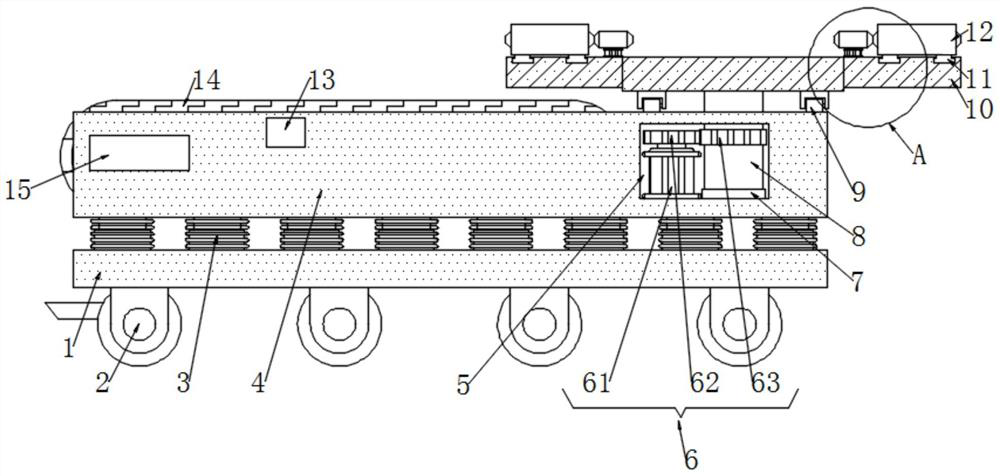

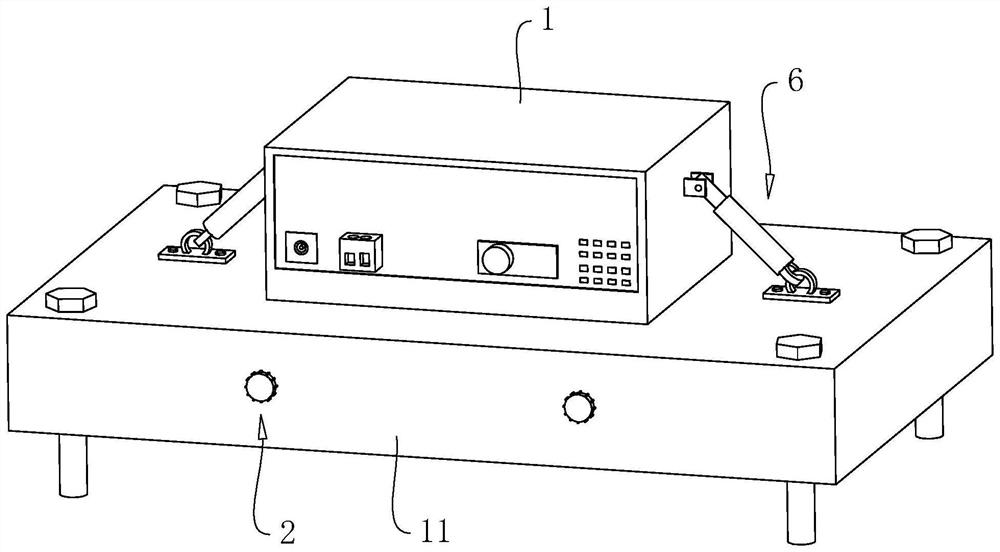

Pile foundation pulling resistance detection device

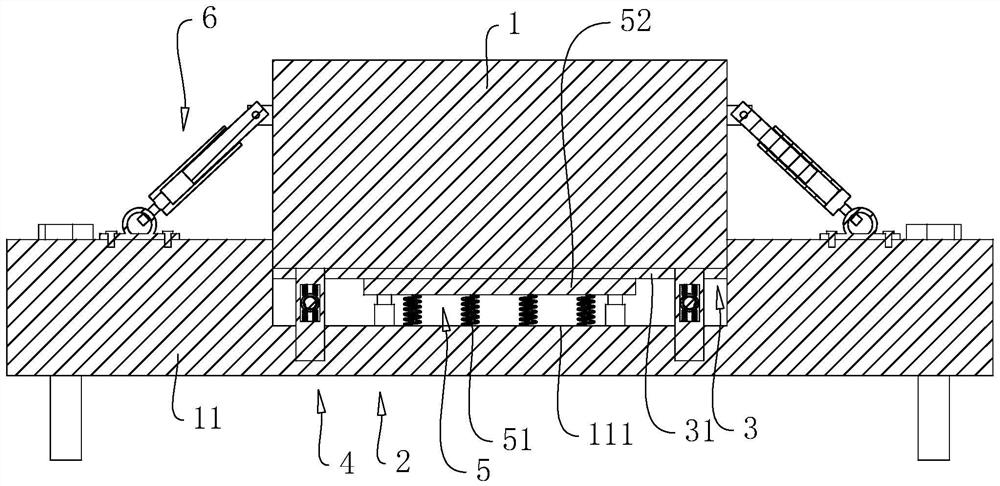

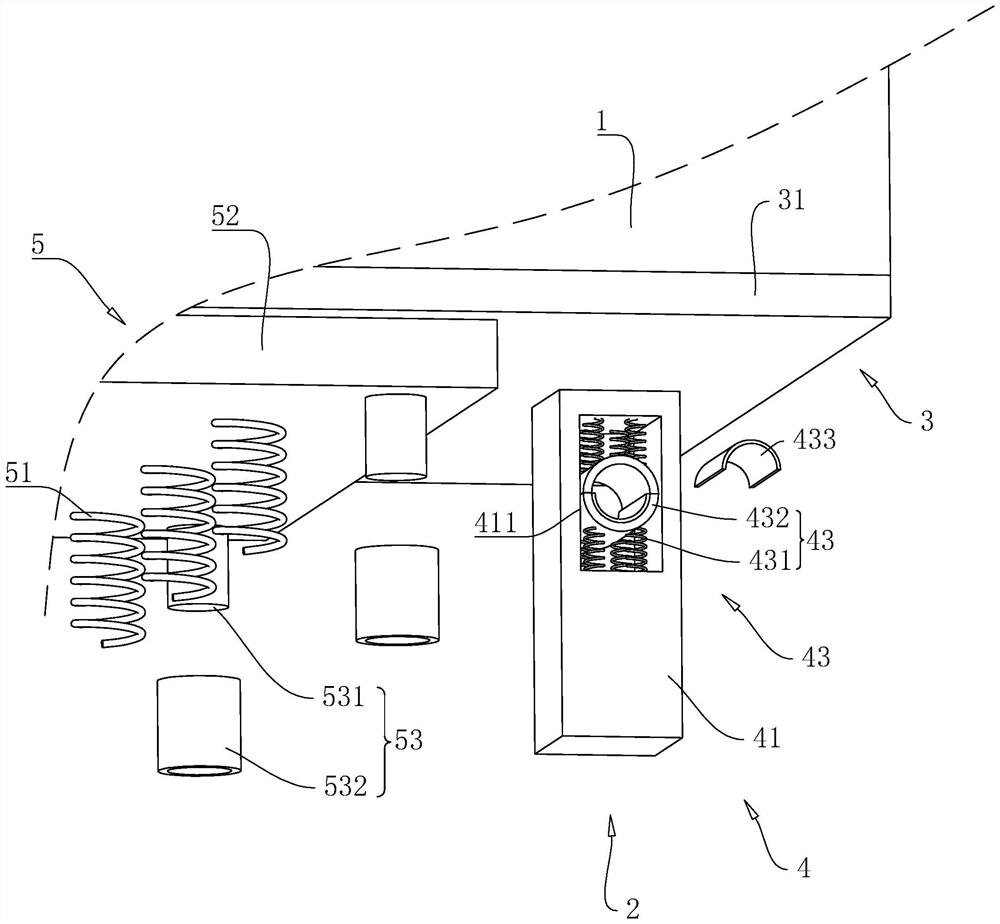

ActiveCN112814047AEnsure positional stabilityImprove positional stabilityFoundation testingPhotovoltaic energy generationStructural engineeringArchitectural engineering

The invention relates to a pile foundation pulling resistance detection device. The pile foundation pulling resistance detection device comprises a detection machine body and a bearing plate, wherein the detection machine body is located on the bearing plate, a plurality of bearing assemblies are arranged on the top wall of the bearing plate, and each bearing assembly comprises a driving part and a guide wheel; the driving parts are located on the bearing plate, piston rods of the driving parts are located below the bearing plate, and connecting assemblies are jointly arranged between the guide wheels and the piston rods of the driving parts; and a plurality of counterweight assemblies are arranged on the top wall of the bearing plate, and a plurality of side supporting assemblies are arranged on the outer side wall of the bearing plate. The pile foundation pulling resistance detection device has the effects that the detection machine body can be rapidly moved to a pile body to be detected and positioned, so that the detection precision of the detection machine body on the pile body is effectively guaranteed, and the detection efficiency of the detection machine body on the pile body is improved.

Owner:扬州市开元岩土工程检测有限公司

Vermicular graphite cast iron cylinder cover for automobile engine

PendingCN110439703AReduce the risk of oil spillsTo achieve a fixed connectionCylinder headsSealing arrangements for enginesInternal pressureButt joint

The invention relates to a vermicular graphite cast iron cylinder cover for an automobile engine. The vermicular graphite cast iron cylinder cover comprises a cylinder cover component and fastening components; when the vermicular graphite cast iron cylinder cover is used, the front side of the cylinder cover component faces downwards and is in butt joint with an engine oil cylinder; a plurality ofgroups of valve guide pipe holes A and valve guide pipe holes B are formed and correspondingly connected with different oil pipes; extension arms, a butt-joint groove A and a butt-joint groove B arearranged, so that the tight connection degree of the engine oil cylinder and an engine cover body is improved, and the oil leakage risk caused to the untight engine oil cylinder is reduced; when the vermicular graphite cast iron cylinder cover is used, outer sleeves are rotated by a hand, the outer sleeves rotate to drive sleeve walls to rotate, arc-shaped sliding grooves rotate along with the sleeve walls, spiral structures of the sliding grooves enable sliding blocks to spirally descend to drive top shafts to be extruded inwards, the bottom surfaces of the top shafts are tightly close to the engine oil cylinder, when the top shafts re extruded downwards, the engine cover body is driven by the counter-acting force to be separated from the engine oil cylinder, the condition that the cylinder cover body is adsorbed by the suction caused by the difference between the internal pressure and the external pressure generated when the oil cylinder is no-load is prevented, and the vermicular graphite cast iron cylinder cover is high in practicability.

Owner:湖北玛尔帕斯动力科技有限公司

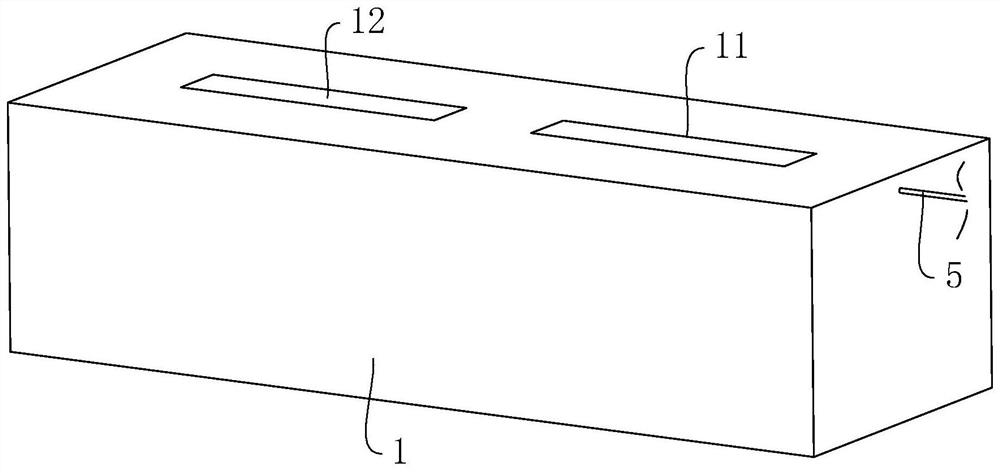

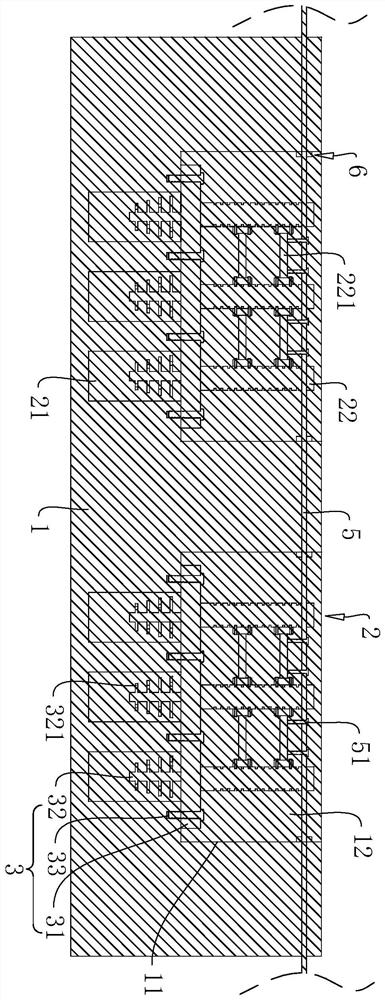

A kind of aluminum alloy door and window with fresh air system

ActiveCN112267806BEnsure cleanliness and freshnessReduce accumulationDispersed particle filtrationVentilation arrangementSash windowFresh air

The application relates to an aluminum alloy door and window with a fresh air system, which includes a window frame and a window sash. An air inlet is provided, and an air outlet is provided on the top wall of the air guide box; the inner cavity of the air guide box is provided with a dust isolation assembly, an air guide assembly and a filter assembly; the air guide assembly includes a receiving plate, a side support plate and a In the guide fan, the dust-proof assembly includes a bearing member and a dust-proof member, and the filter assembly includes a dust-proof cotton board and an adsorption board. The present application has the effect of effectively reducing the influx of dust into the room when the room is ventilated.

Owner:江苏锦恒幕墙装饰工程有限公司

Coastal city building foundation multilayer reinforcing structure

ActiveCN113668495AEnsure positional stabilityImprove structural stabilityExcavationsSoil preservationArchitectural engineeringStructural engineering

The invention relates to a coastal city building foundation multilayer reinforcing structure, and relates to the field of foundation reinforcing structures. The coastal city building foundation multilayer reinforcing structure comprises a foundation block, a plurality of groups of foundation pits are arranged at the top of the foundation block at intervals, and a plurality of insertion piles are arranged at each foundation pit of the foundation block at intervals; one end of each inserting pile is fixed in the foundation block, the other end of each inserting pile is located in the foundation pits, and all the inserting piles in the same foundation pit are fixedly connected through connecting pieces; and the foundation block is provided with a backfill block in each foundation pit. The coastal city building foundation multilayer reinforcing structure has the effect of effectively guaranteeing the structural stability of the foundation block after being applied for a long time.

Owner:DACHANG CONSTR GRP

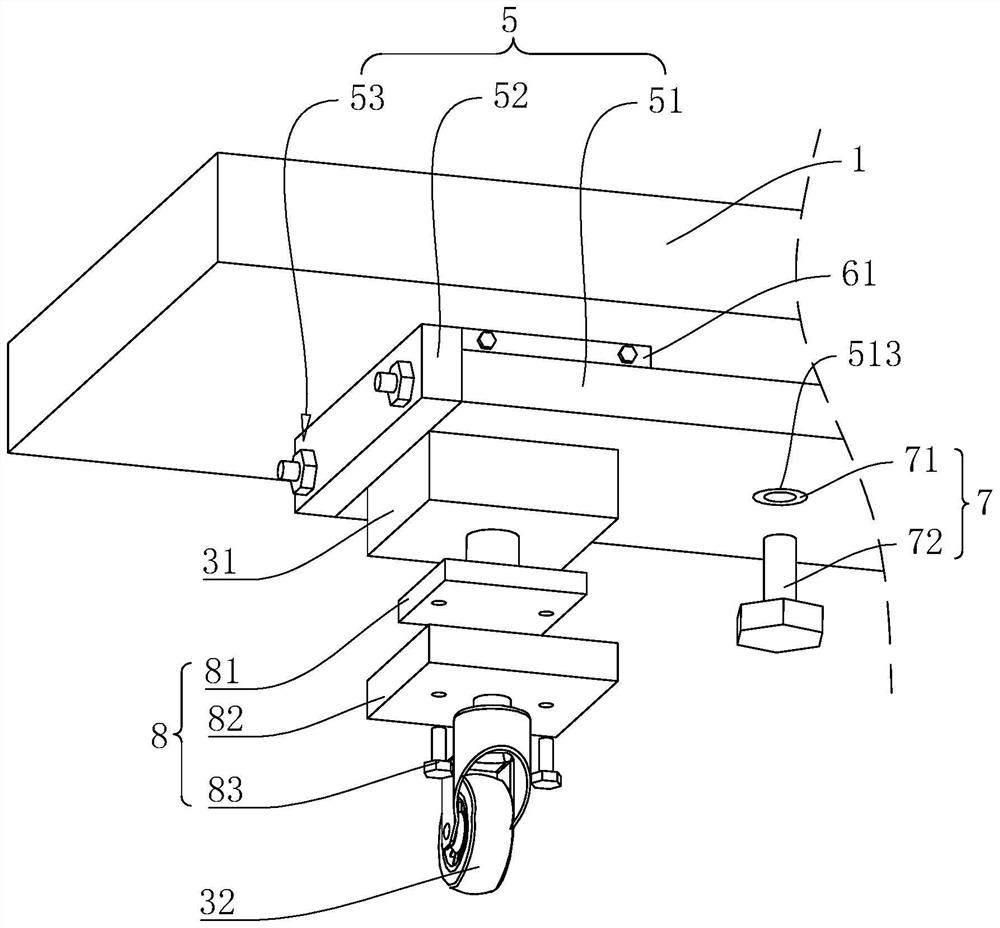

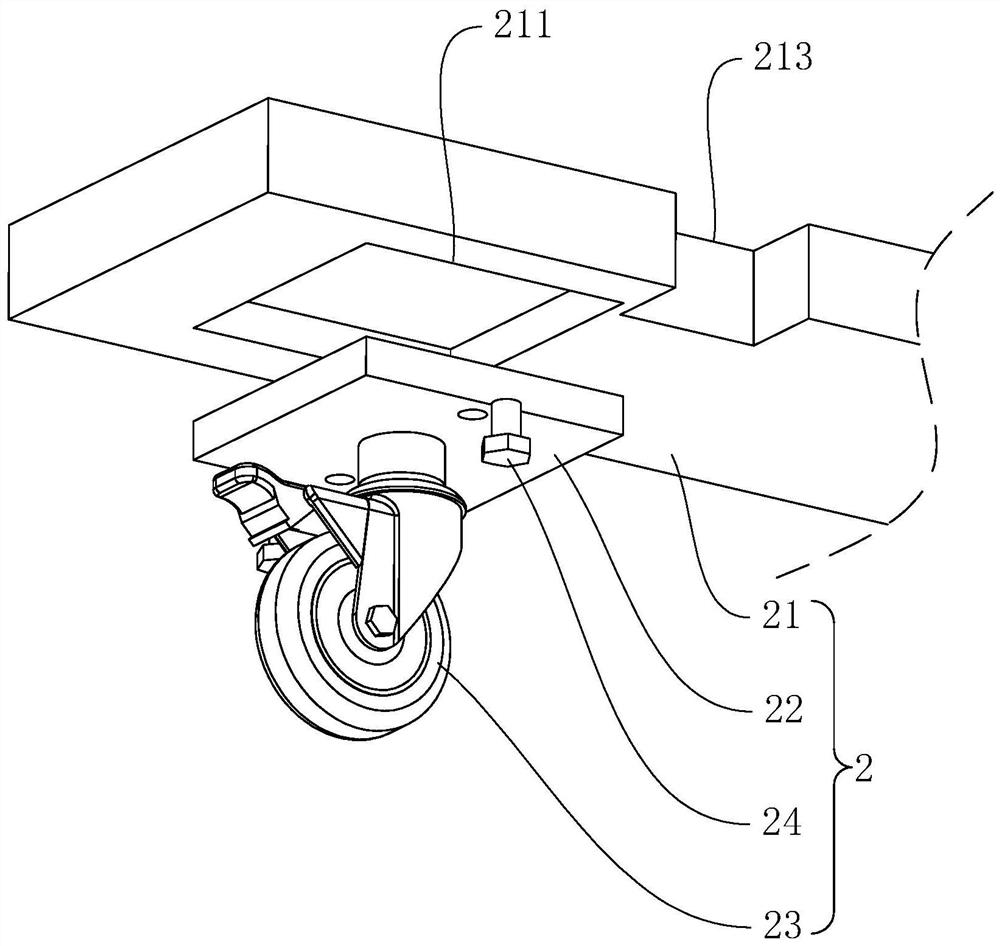

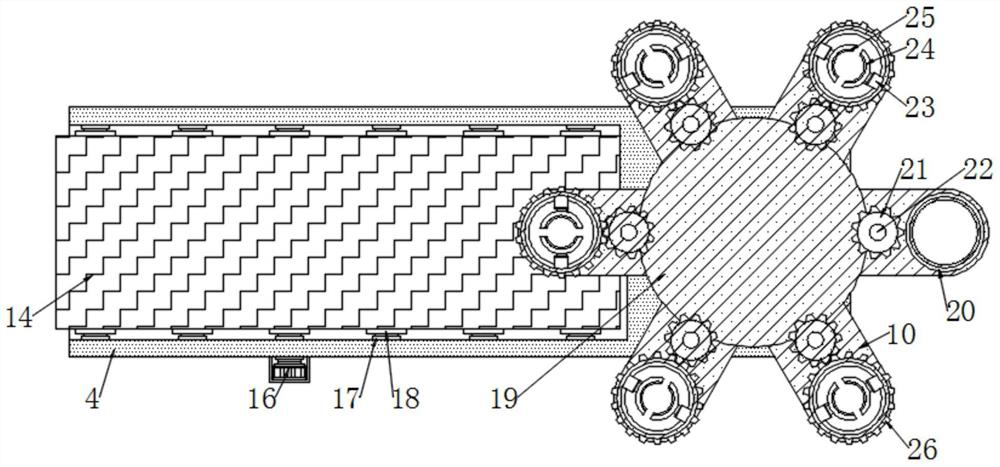

Soil sampling device for roadbed compactness detection and application method thereof

ActiveCN113373895AImprove work efficiencyImprove application efficiencyIn situ soil foundationAgricultural engineeringEngineering

The invention relates to a soil sampling device for roadbed compactness detection and an application method thereof, and relates to the field of soil sampling devices. The soil sampling device comprises a supporting plate and a soil sampling piece, wherein the soil sampling piece is arranged on the side wall, away from the ground, of the supporting plate, two groups of moving assemblies are oppositely arranged on the outer side wall of the supporting plate, and each group of moving assemblies comprises a bearing plate, a mounting plate, universal wheels and fixing bolts; the bearing plate is arranged on the outer side wall of the supporting plate, supporting plates are arranged at the two ends of the bearing plate in the length direction respectively, and each supporting plate and the bearing plate are jointly provided with a positioning assembly; and the universal wheels are arranged on the side wall, facing the ground, of the mounting plate, a preset groove used for limiting the position of the mounting plate is formed in the side wall, facing the ground, of the bearing plate, and the fixing bolts are used for fixing the mounting plate in an inner cavity of the preset groove. The application method comprises the steps of equipment moving, assembly separation and positioning soil sampling. The soil sampling device has the effect of being convenient to move to a designated place quickly for soil sampling tests.

Owner:南通东洲工程项目管理有限公司

Novel bridge deck pavement structure and construction method thereof

PendingCN113389140AGuarantee molding qualityGuarantee the flatness of the topBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention relates to a novel bridge deck pavement structure and a construction method thereof. The pavement structure comprises a U-shaped rib, a mounting frame and a plurality of groups of comb plates which are matched with one another, each group of comb plates comprises a fixed side plate and a plurality of extension strips, and a reserved groove is formed between every two adjacent extension strips; each fixing side plate and a foundation used for bearing the fixing side plate are jointly provided with a connecting bolt, and the upper surface of each fixing side plate is provided with an embedded groove used for containing the end of the corresponding connecting bolts. The mounting frame is located on the sides, away from each other, of the two symmetrical comb plates, and the mounting frame comprises two supporting plates and two positioning blocks. The positioning blocks and the supporting plates are jointly provided with locking assemblies used for limiting the position of the positioning blocks on the supporting plates. The construction method comprises the steps that the elevation belts are laid, the U-shaped ribs are installed, and concrete is poured; The novel bridge deck pavement structure has the effect of effectively improving the forming quality and flatness of the bridge deck pavement layer.

Owner:湖南宏振建设工程有限公司

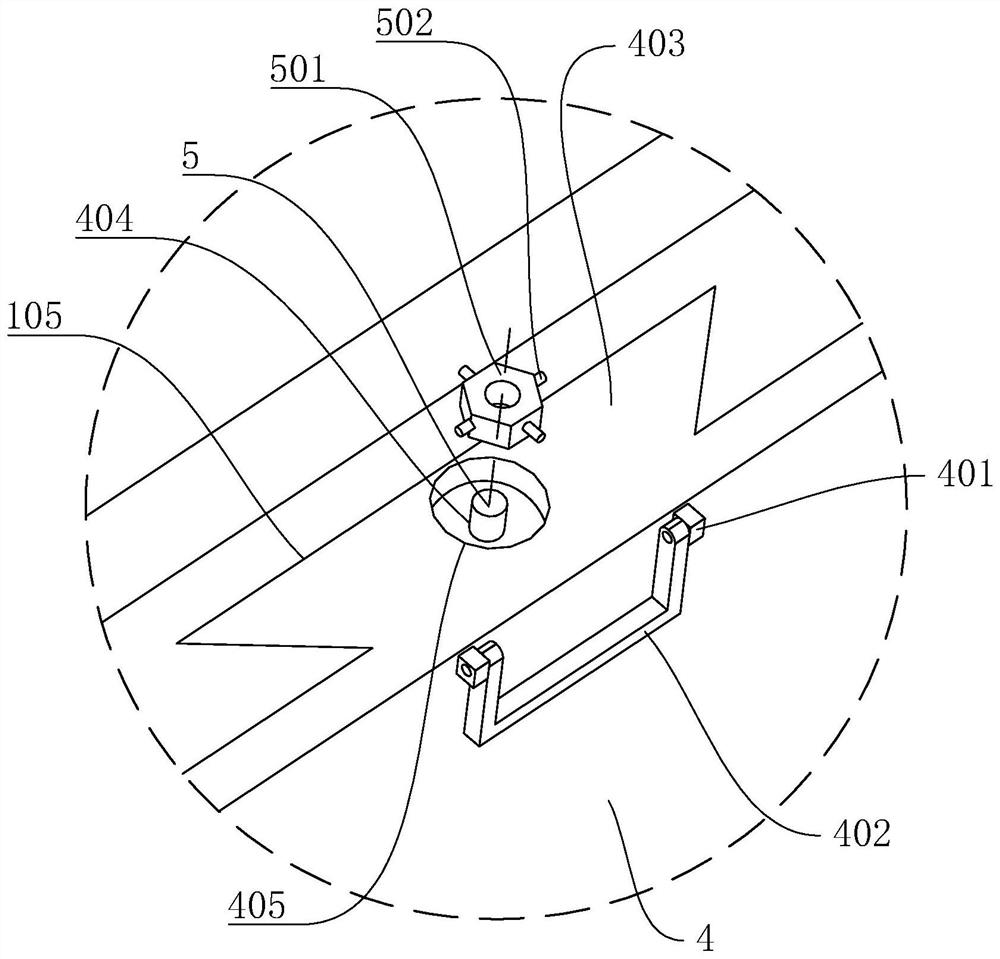

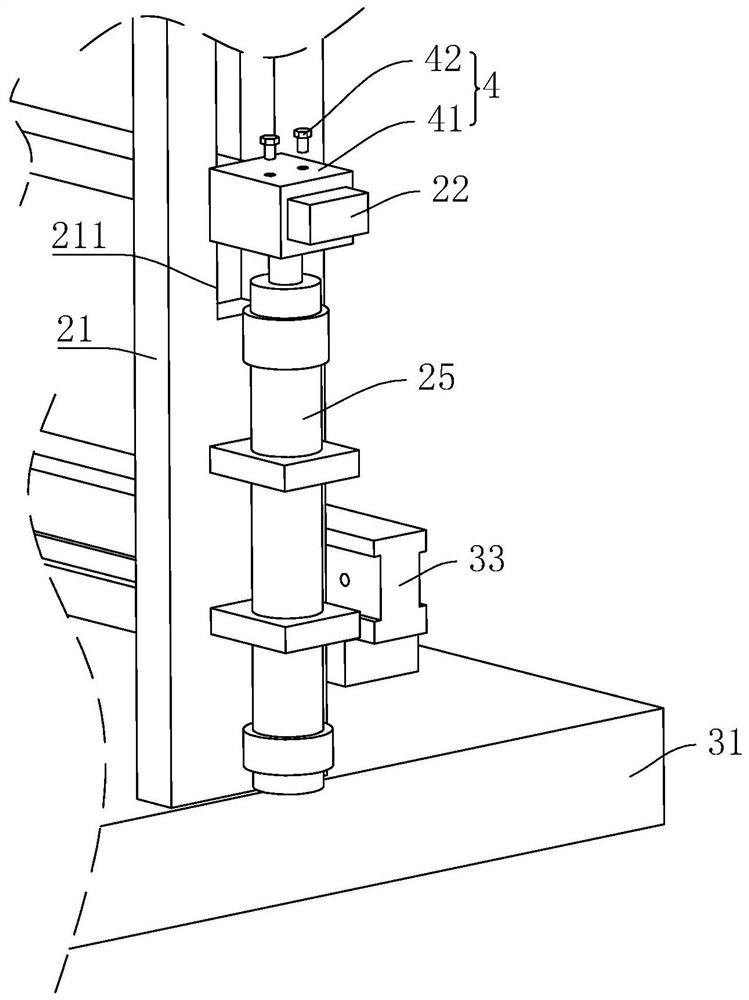

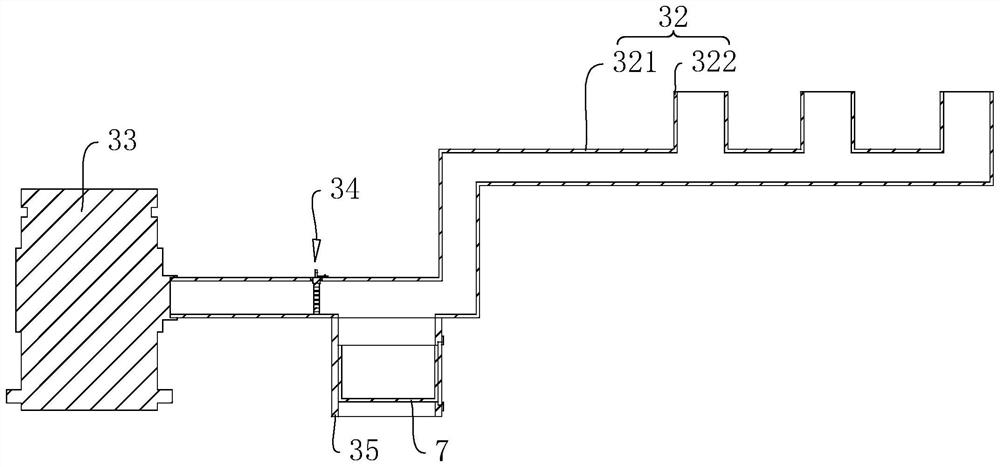

A sand filling instrument for detecting large-thickness and wide-width water stability layers and its construction method

ActiveCN113136855BIncrease contact areaEnsure positional stabilityIn situ soil foundationClassical mechanicsScrew thread

The present application relates to a sand filling instrument for detecting large-thickness and wide-width water stability layers and its construction method. The sand filling instrument includes a sand storage tank and a base plate. The base plate and the sand storage tank are jointly provided with a pressing component. The assembly includes a limit cylinder, an abutment plate and a bottom support ring plate; the bottom support ring plate is set on the outer edge of the sand storage cylinder, the limit cylinder is set on the upper surface of the base plate, and the lower surface of the abutment plate is provided with a card connection groove; the base plate and the sand storage cylinder are also jointly provided with an anti-bias assembly, the anti-deflection assembly includes a tie belt, a locking screw and a locking cylinder; the locking cylinder is rotatably arranged on the tie belt One end in the length direction, one end of the pair of pull ties is set on the outer wall of the sand storage cylinder, the clamping screw is set on the upper surface of the base plate, and the clamping screw is threaded into the inner cavity of the locking cylinder; the construction method includes : Datum positioning, cylinder reinforcement and detection experiment; this application has the effect of effectively ensuring the position stability of the sand storage cylinder on the base plate and improving the detection accuracy of the sand filling instrument.

Owner:福建省亿方建设工程有限公司

Rope head combination structure for indoor construction elevator

ActiveCN112173915AGuarantee the tightness of the glandImprove connection strengthElevatorsBuilding liftsStructural engineeringControl theory

The rope head combination structure for the indoor construction elevator comprises a connecting frame and connecting steel ropes, a plurality of lifting steel ropes are arranged on the bottom wall ofa top plate of the connecting frame at intervals, and two rope head bottom plates are arranged at the ends, away from the direction of the connecting frame, of the lifting steel ropes; one ends of allthe connecting steel ropes in the length direction are located on the sides, away from each other, of the two rope head bottom plates respectively; rope head cover plates used for pressing and covering the connecting steel ropes are arranged on the sides, away from each other, of the two rope head bottom plates respectively; and a plurality of locking pieces are arranged between the rope head cover plates and the rope head bottom plates which are close to each other. The rope head combination structure has the effect of effectively improving the connecting strength and the position stabilityafter the ends of the connecting steel ropes are fixed.

Owner:高企达电梯(江苏)有限公司

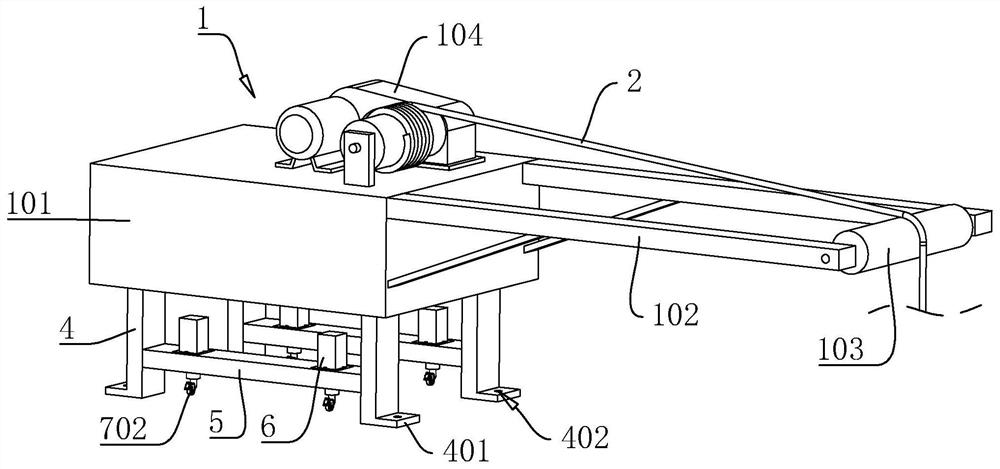

Efficient lifting appliance for PC component and lifting method thereof

ActiveCN113120747AReduce loosenessReduce deflectionLoad-engaging elementsClassical mechanicsEngineering

The invention relates to an efficient lifting appliance for a PC component and a lifting method thereof. The lifting appliance comprises a stabilizing frame, a connecting steel cable and a bearing frame, a positioning plate is arranged on the outer side wall of the bearing frame, the positioning plate and the stabilizing frame are jointly provided with an anti-deviation assembly, and the anti-deviation assembly comprises a limiting barrel and an anti-deviation lead screw; the anti-deviation lead screw is arranged on the positioning plate in a penetrating mode, the limiting barrel is arranged on the side wall, facing the positioning plate, of the stabilizing frame, and the anti-deviation lead screw is arranged in the limiting barrel in a threaded fit mode; the stabilizing frame and the bearing frame are jointly provided with a limiting assembly, and the limiting assembly comprises a tensioning tying belt and a plurality of clamping rings; a settling tank is arranged on the upper surface of the bearing frame, and all the clamping rings are arranged in the settling tank at intervals; one end, in the length direction, of the tensioning tying belt is arranged on the outer side wall of the stabilizing frame, and the other end of the tensioning tying belt is fixed to the outer edge of one clamping ring; and the lifting method comprises the steps of assembly limiting, component loading and hoisting limiting. The efficient lifting appliance and the lifting method have the effect of effectively improving the lifting stability of the PC component.

Owner:博尔建设集团有限公司

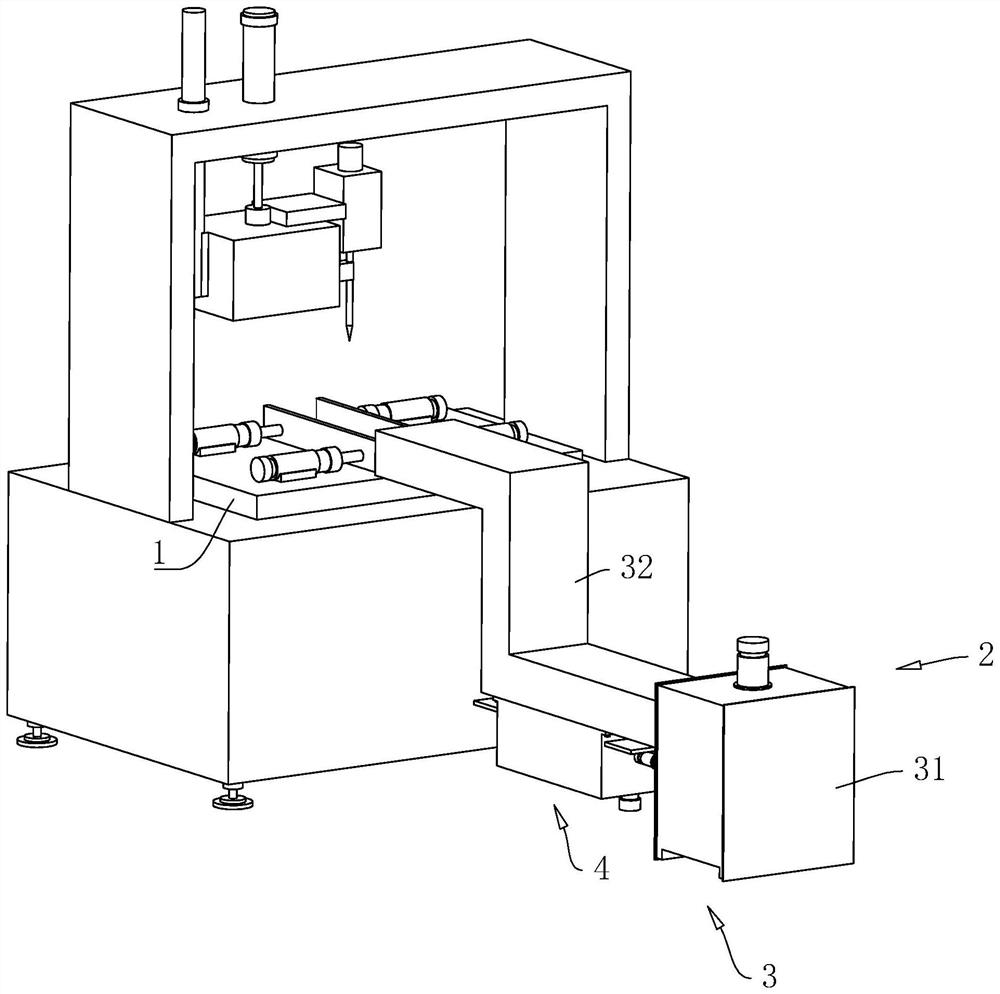

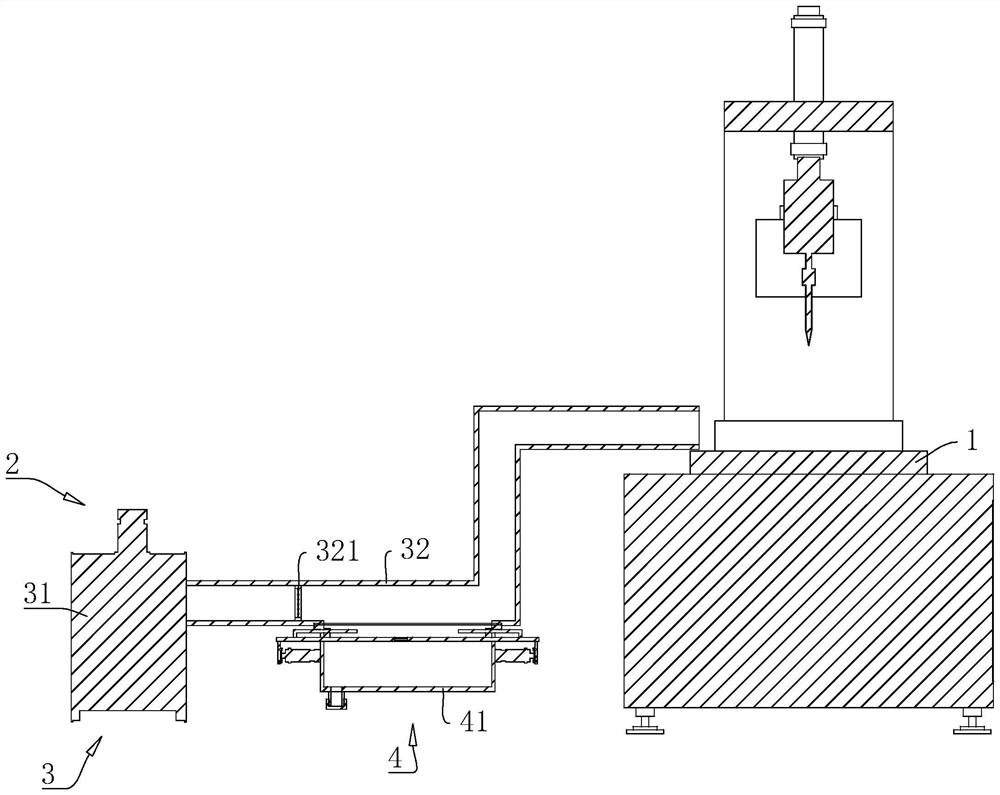

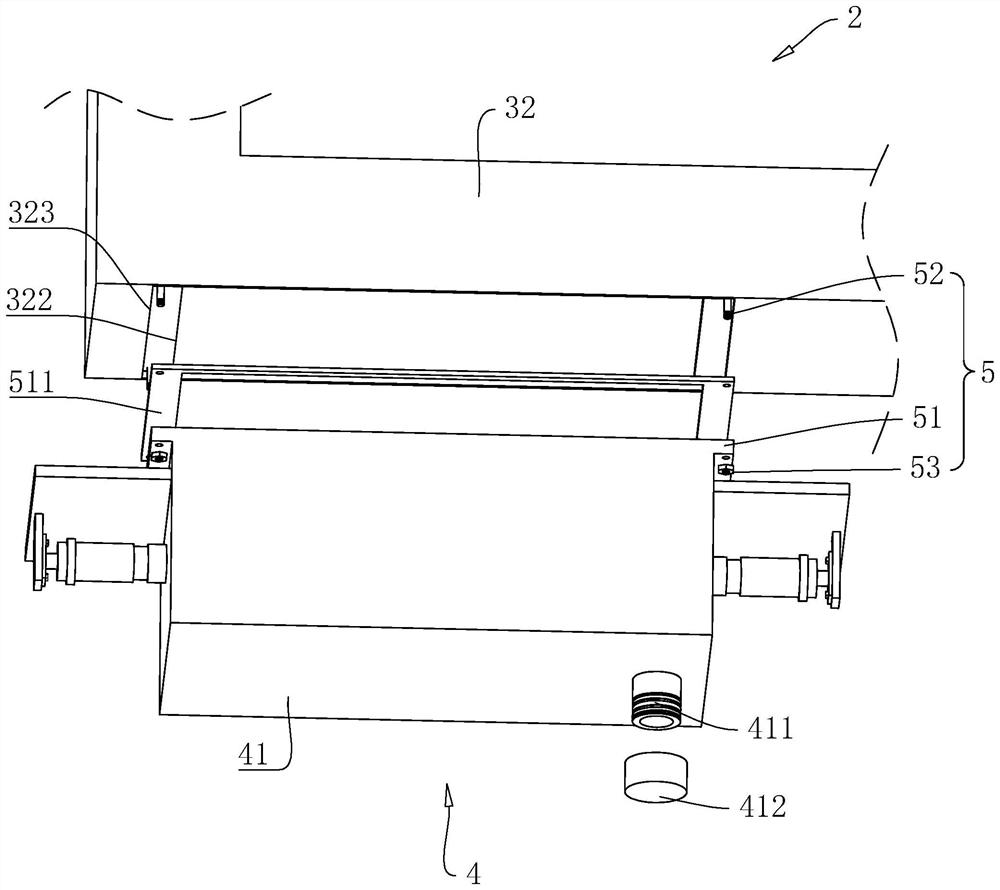

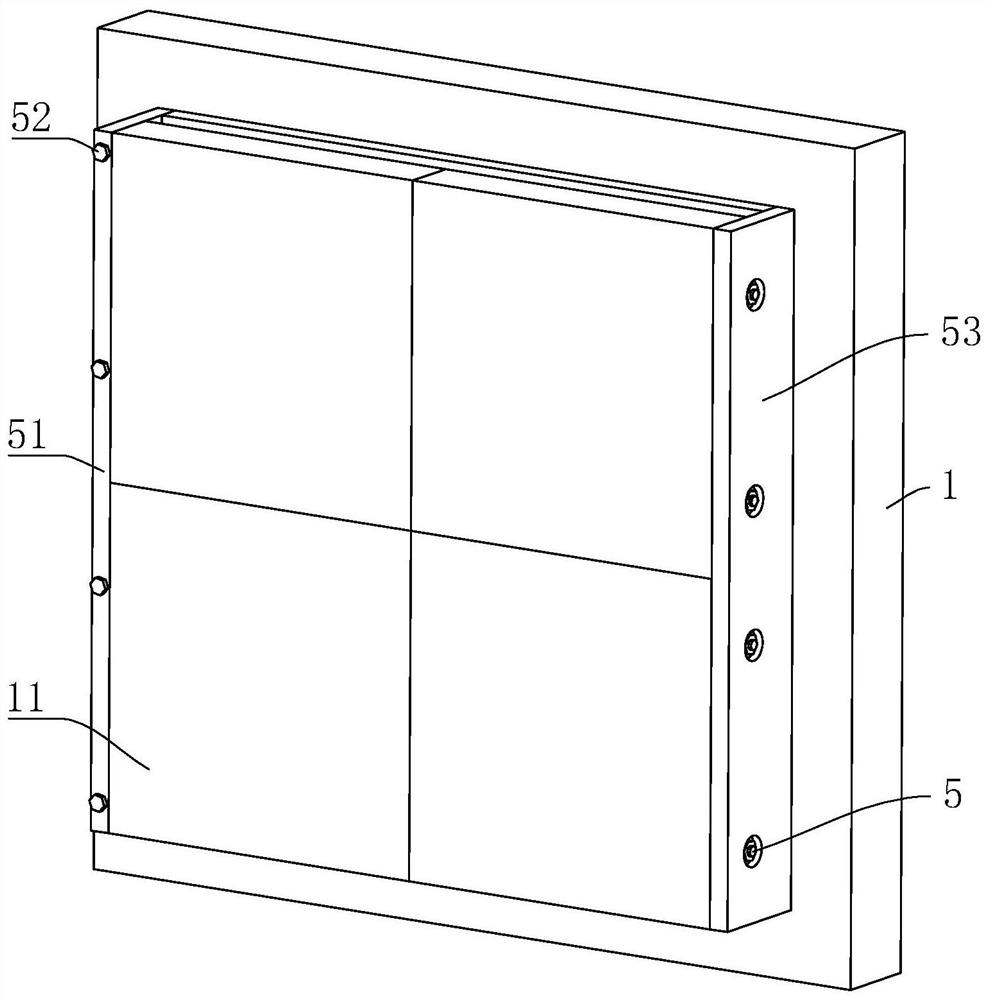

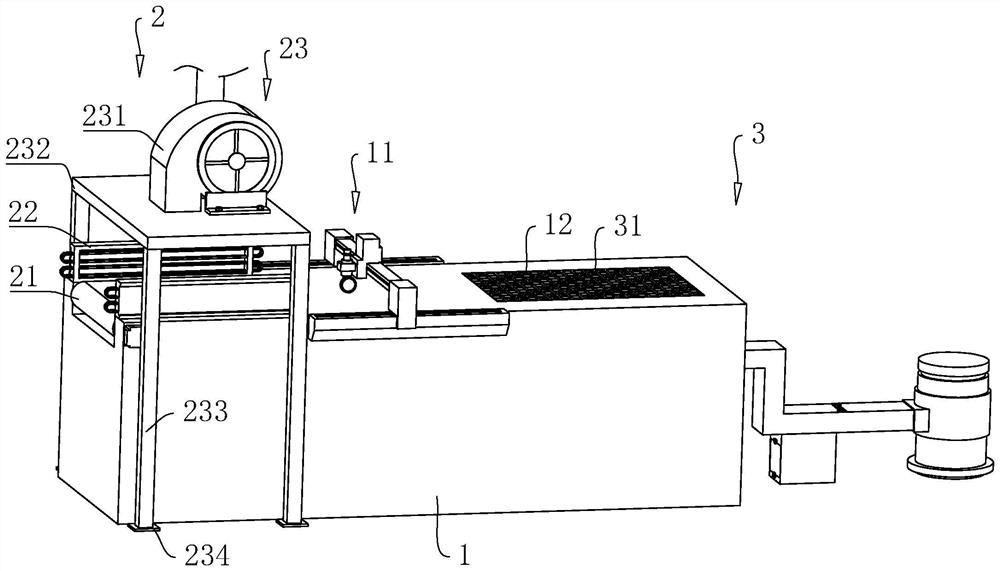

Type-c shell machining equipment capable of improving product production quality

PendingCN114193217AEnsure positional stabilityEnsure cutting accuracyMaintainance and safety accessoriesProcess engineeringMachining

The invention relates to type-c shell machining equipment capable of improving product production quality, and relates to the technical field of type-c shell machining equipment.The type-c shell machining equipment comprises a bearing base and further comprises a cleaning device, and the cleaning device comprises a scrap suction mechanism and a scrap storage mechanism; the scrap suction mechanism comprises an exhaust fan and a scrap guide air pipe; one end, in the length direction, of the scrap guide air pipe is connected to the air draft end of the exhaust fan, and the other end, in the length direction, of the scrap guide air pipe is arranged on the bearing base so as to absorb scraps on the bearing base; an isolation piece used for isolating chippings is further arranged in the side wall of the chipping guiding air pipe. The scrap storage mechanism comprises a scrap collecting box, the scrap collecting box is arranged on the scrap guide air pipe, the scrap collecting box is located at the end, away from the exhaust fan, of the isolation piece, and the scrap collecting box is used for collecting scraps entering the scrap guide air pipe. The device has the effect of improving the product quality of the workpiece.

Owner:SUZHOU WEIJU ELECTRONICS TECH

A connection structure and connection method of prefabricated exterior wall panels and prefabricated walls

ActiveCN113107156BEnsure positional stabilityImprove connection strengthCovering/liningsEngineeringSupport plane

This application relates to a connection structure and connection method between a prefabricated exterior wall panel and a prefabricated wall. The connection structure includes a positioning wall and a plurality of prefabricated panels. The support frame includes a circumscribed square column and a clamping plate; groove-shaped holes are provided through the outer side wall of each prefabricated panel, and the outer side wall of the prefabricated panel is provided with abutment holes, and all the circumscribed square columns at the same horizontal height A connecting rod is jointly arranged; one end of the length direction of all the connecting rods is jointly provided with a positioning plate, and the other end of the length direction of all the connecting rods is jointly provided with a cover plate, and the positioning plate and the cover plate are mutually arranged. The facing side walls are respectively opposed to the outer side walls of the prefabricated panels; the connection methods include: assembly of components, fixing of components and overall fixing. The application has the effects of effectively improving the connection strength of the prefabricated panels fixed on the outer side wall of the positioning wall, and facilitating the operators to quickly and efficiently install the prefabricated panels on the outer side wall of the positioning wall.

Owner:珠海市交通勘察设计院有限公司

Sand filling instrument for detecting large-thickness and wide-width water-stable layer and construction method of sand filling instrument

ActiveCN113136855AIncrease contact areaEnsure positional stabilityIn situ soil foundationClassical mechanicsEngineering

The invention relates to a sand filling instrument for detecting a large-thickness and wide-width water-stable layer and a construction method of the sand filling instrument. The sand filling instrument comprises a sand storage barrel and a base plate, wherein the base plate and the sand storage barrel are jointly provided with an abutting assembly, the abutting assembly comprises limiting air cylinders, abutting plates and a bottom supporting ring plate, the bottom supporting ring plate is arranged on the outer edge of the sand storage barrel, the limiting air cylinders are arranged on the upper surface of the base plate, clamping grooves are formed in the lower surfaces of the abutting plates, the base plate and the sand storage cylinder are further jointly provided with an anti-deviation assembly, the anti-deviation assembly comprises an opposite-pull tying belt, a clamping lead screw and a locking cylinder, the locking cylinder is rotationally arranged at one end of the opposite-pull tying belt in the length direction, one end of the opposite-pull tying belt is arranged on the outer side wall of the sand storage cylinder, the clamping lead screw is arranged on the upper surface of the base plate, and the clamping lead screw is in threaded fit with an inner cavity of the locking cylinder. The construction method comprises the steps of datum positioning, barrel reinforcing and detection experiment. The sand filling instrument has the advantages that the position stability of the sand storage cylinder on the base plate is effectively guaranteed, and the detection precision of the sand filling instrument is improved.

Owner:福建省亿方建设工程有限公司

Inductor machining positioning equipment

PendingCN114093646ARealize the clamping effectAchieve separationConveyorsNon-rotating vibration suppressionElectric machineGear wheel

The invention belongs to the technical field of inductor machining and positioning, and relates to inductor machining positioning equipment which comprises an operation table. A cavity is formed in the operation table, a first bearing is fixedly connected to the bottom of the inner wall of the cavity, and a first rotating shaft is arranged in the first bearing in a penetrating mode; and the surface of the first rotating shaft is fixedly connected with a driving assembly, and the driving assembly is fixedly connected to the bottom of the inner wall of the cavity. The positioning equipment has the beneficial effects that a third motor works to drive a third gear to rotate, a rotating disc can be driven to rotate by means of the meshing effect between the third gear and teeth, and then the purpose of driving an inductor to rotate for machining is achieved; and through the work of the electric push rod, the electric push rod extends and retracts, the clamping plates can be driven to stretch and retract, the purpose of clamping or separating the inductor is achieved, and the purpose of machining positioning or discharging conveying is achieved.

Owner:沅陵辰州磁电高科有限公司

Cutting equipment for TPO coiled material processing

PendingCN114274236AReduce the phenomenon of easily mixed impuritiesAccelerate evaporationDirt cleaningMetal working apparatusProcess engineeringMaterials processing

The invention relates to cutting equipment for TPO coiled material processing, and relates to the technical field of cutting equipment, the cutting equipment comprises a cutting table, the cutting equipment further comprises a pretreatment device, and the pretreatment device comprises a conveying belt, a hot drying machine and a guide suction mechanism; the conveying belt and the hot drying machines are both arranged on the cutting table, the conveying belt extends in the length direction of the cutting table so as to be used for conveying materials, and the hot drying machines are arranged on the two opposite sides of the conveying belt so as to be used for hot drying the materials on the conveying belt; the guide suction mechanism comprises an exhaust fan; and the exhaust fan is arranged above the conveying belt so as to suck impurities and volatile organic compounds on the conveying belt. The TPO coiled material packaging device has the advantages that the phenomenon that the TPO coiled material is doped with impurities during packaging is reduced, and the product quality is effectively improved.

Owner:SUZHOU RUIGAO NEW MATERIAL CO LTD

Receiver for aircraft communication

ActiveCN114671038AImprove application stabilityEnsure positional stabilityAircraft componentsTransmissionFlight vehicleStructural engineering

The invention relates to a receiver for aircraft communication, and relates to the technical field of receivers, the receiver comprises a machine body and a mounting plate used for mounting the machine body on an aircraft, the mounting plate is provided with a settling tank, a cushioning device is arranged between the machine body and the mounting plate, and the cushioning device comprises a cushioning mechanism and a docking mechanism; the cushioning mechanism comprises a cushioning piece, and the cushioning piece is arranged on the machine body; the butt joint mechanism comprises extension strips, a directional lead screw and a positioning piece, the extension strips are oppositely arranged on the machine body, and the extension strips are arranged on the cushioning piece in a penetrating mode; the directional lead screw is in threaded connection with the mounting plate and penetrates through the settling tank, and a movable channel allowing the directional lead screw to penetrate through and move is formed in the extension strip in a penetrating mode; the positioning pieces are oppositely arranged in the movable channels and used for controlling displacement of the directional lead screws in the movable channels. The application has the effect of improving the application stability of the receiver.

Owner:北京澳丰源科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com