Stirrer for titanium dioxide production and processing technology

A titanium dioxide and mixer technology, which is used in mixer accessories, mixers with rotating mixing devices, mixers, etc., can solve the problems of inconvenient disassembly, cleaning, replacement, etc., to ensure displacement stability, position stability, guarantee The effect of using efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

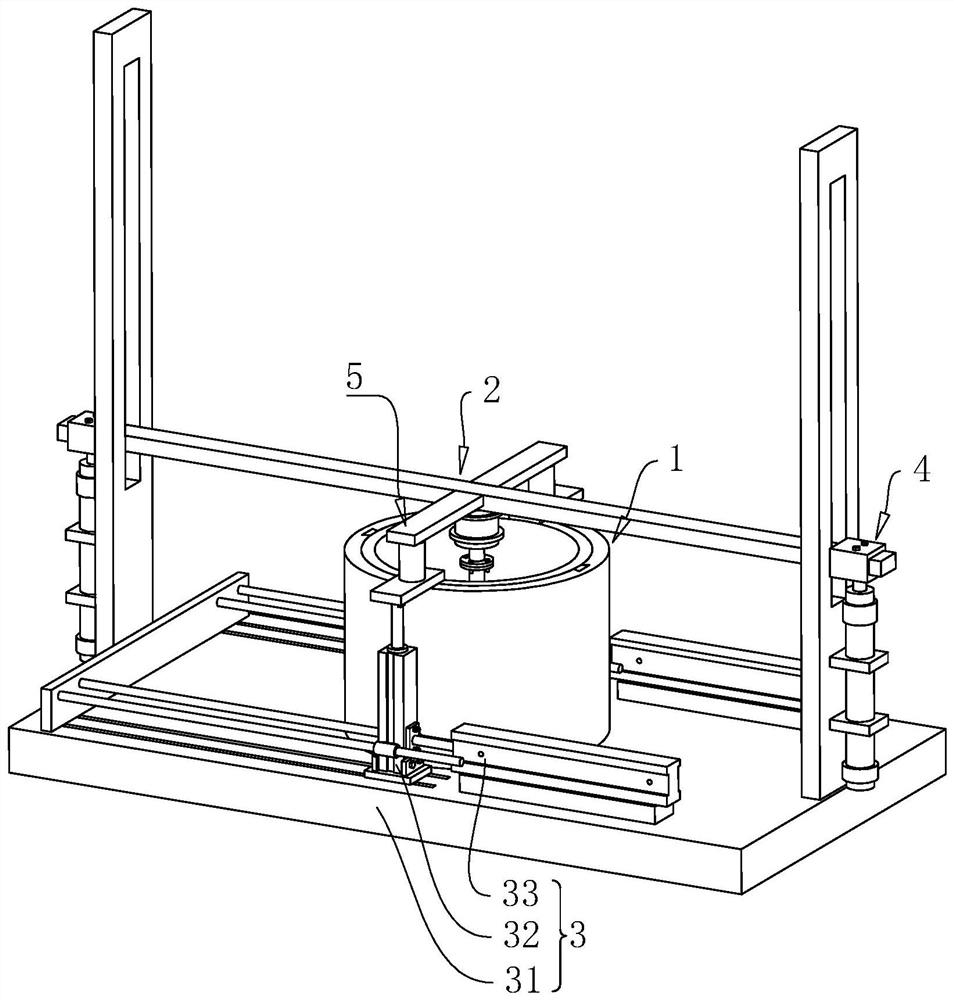

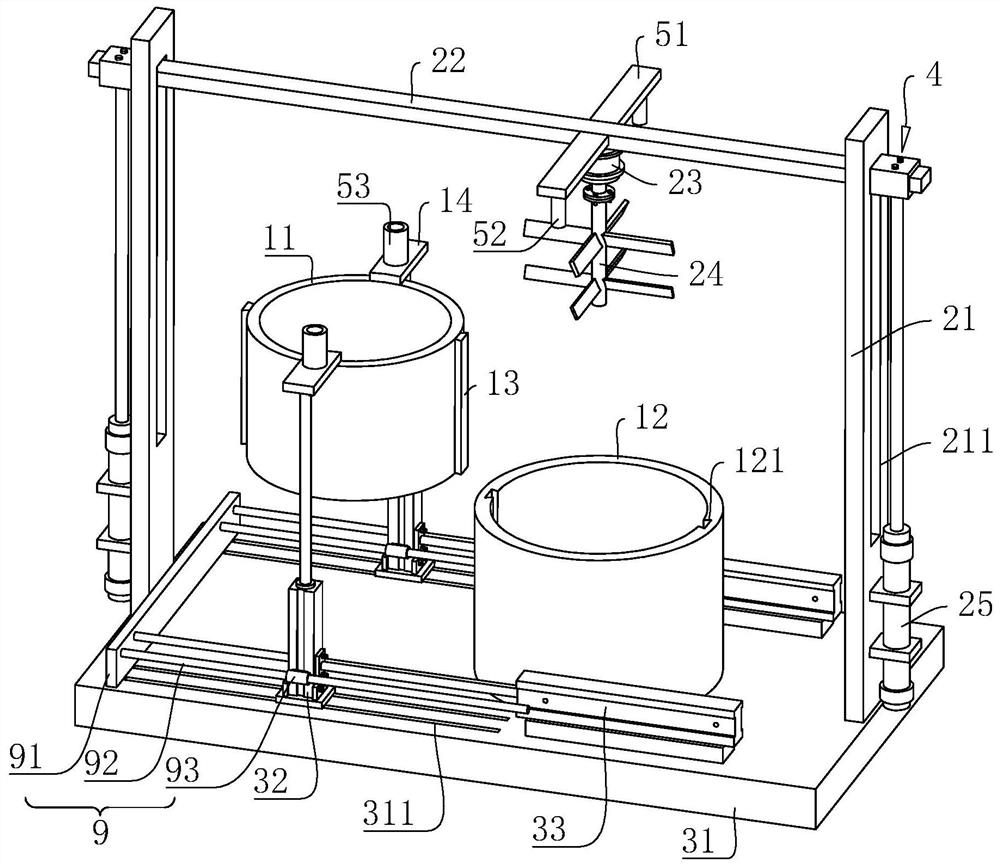

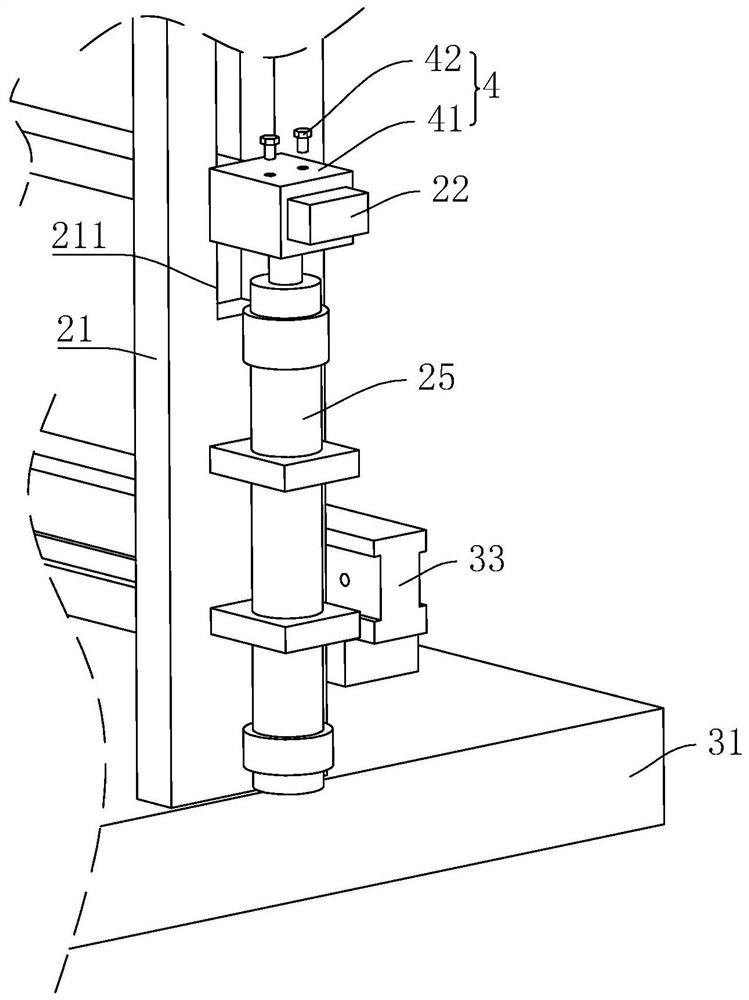

[0039] The following is attached Figure 1-7 The application is described in further detail.

[0040] The embodiment of the present application discloses a mixer for titanium dioxide production. refer to figure 1 and figure 2 , a mixer for titanium dioxide production includes a tank body 1 , a stirring component 2 and a transfer component 3 . The tank body 1 includes an inner tank 11 , an outer tank 12 , a limiting strip 13 and an extension plate 14 , and the inner tank 11 is arranged in the inner cavity of the outer tank 12 . Stirring assembly 2 includes two sets of support frames 21 , connecting plates 22 , drive motor 23 , stirring shaft 24 and jacking cylinder 25 , and transporting assembly 3 includes bottom brace 31 , supporting cylinder 32 and propulsion cylinder 33 . The connecting plate 22 is liftably arranged above the inner tank 11 through the support frame 21 and the jacking cylinder 25 , and the stirring shaft 24 is arranged on the side wall of the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com