Patents

Literature

135results about How to "Reduce the risk of oil spills" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

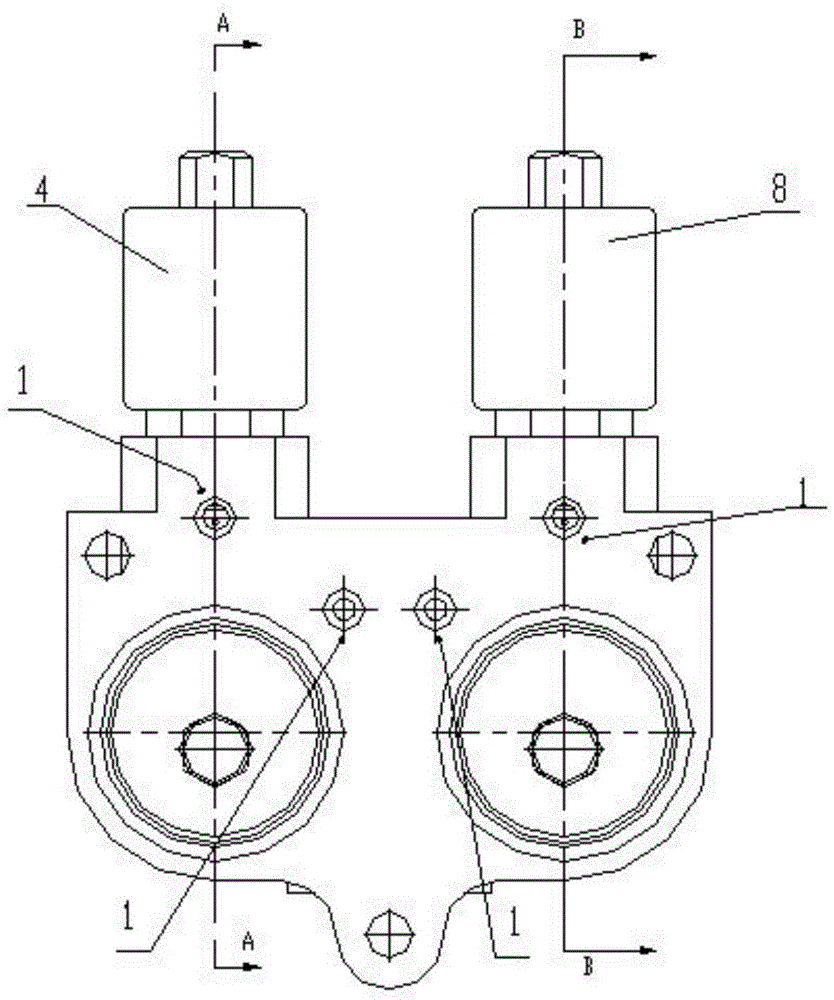

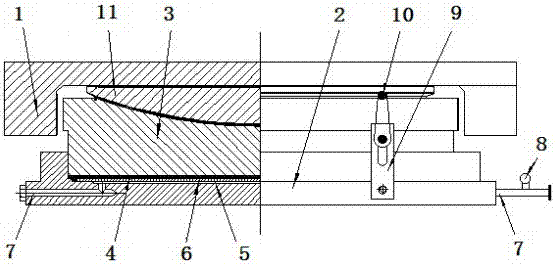

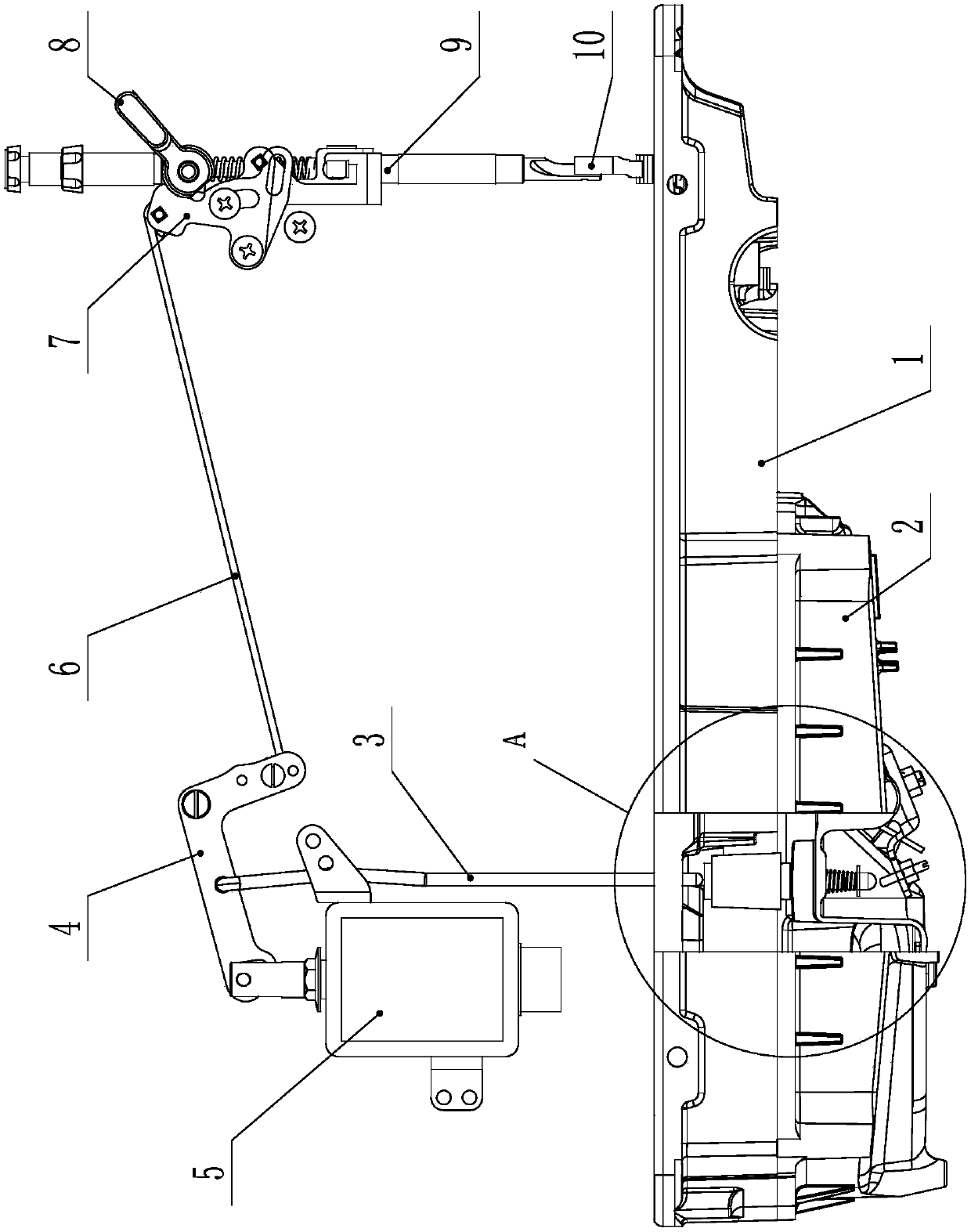

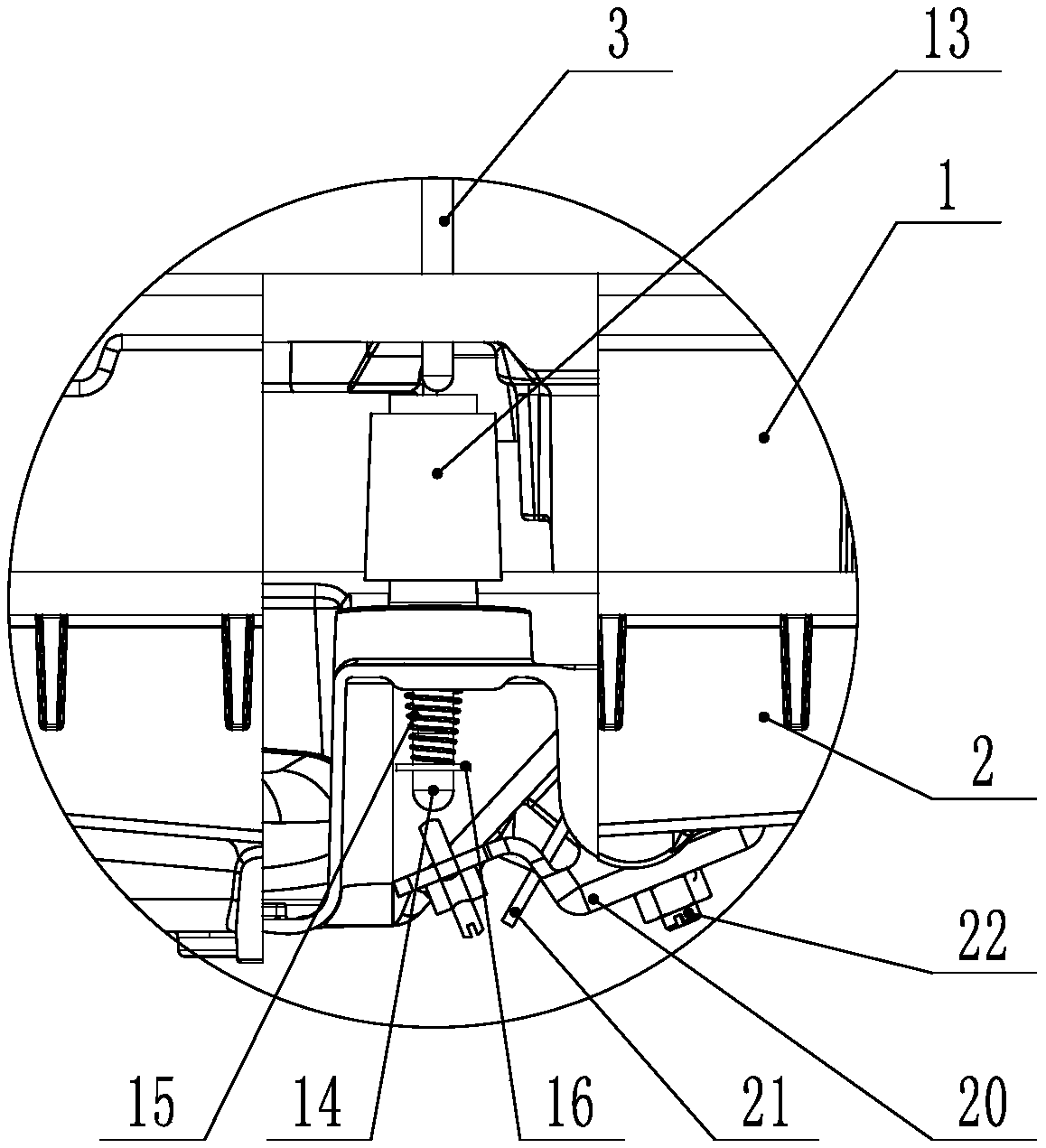

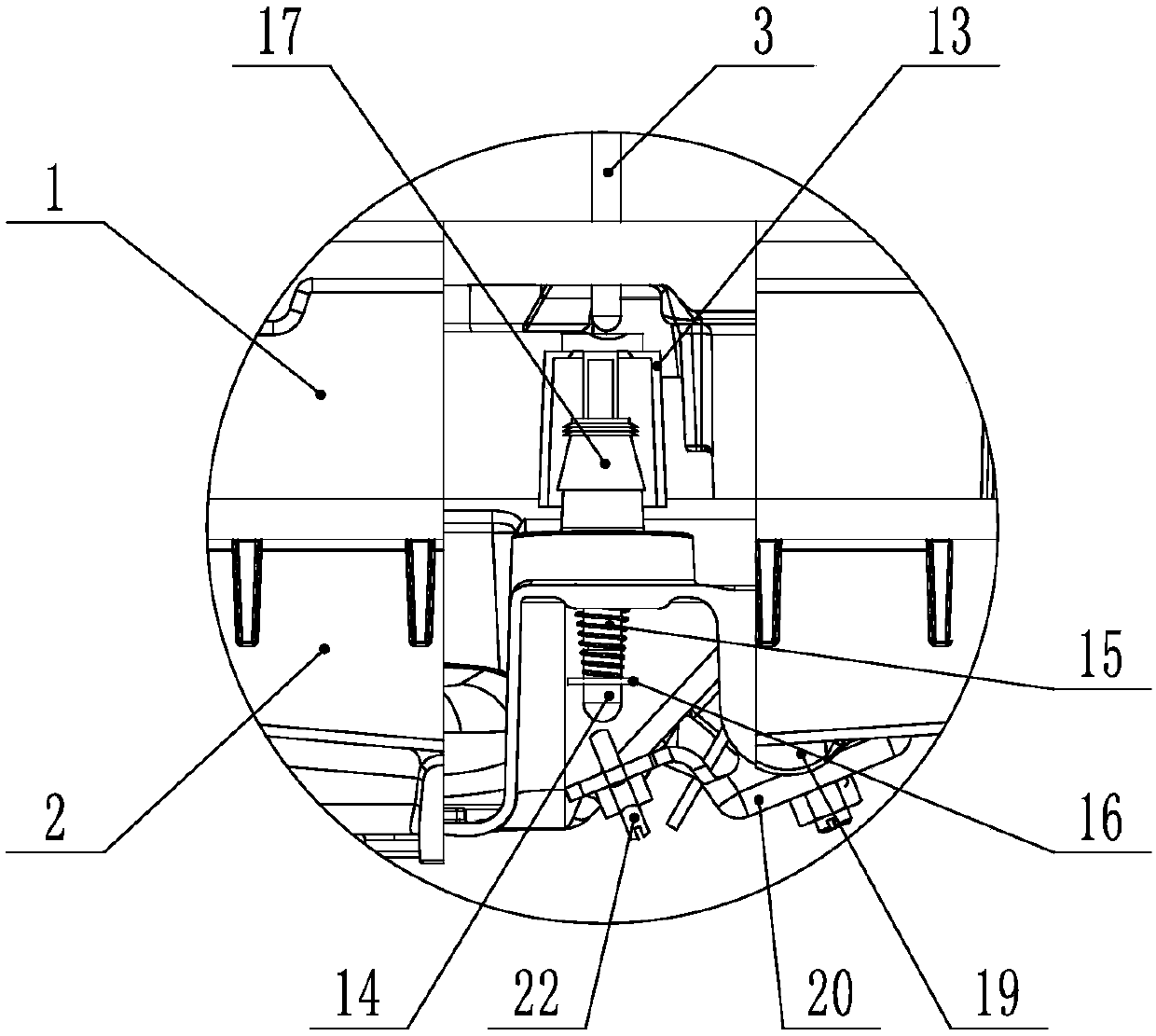

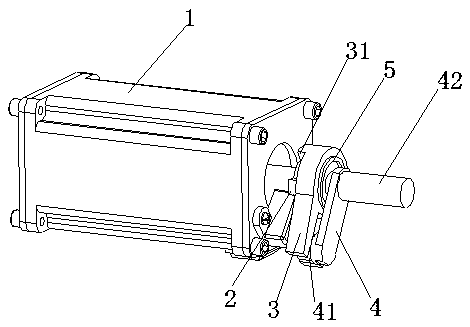

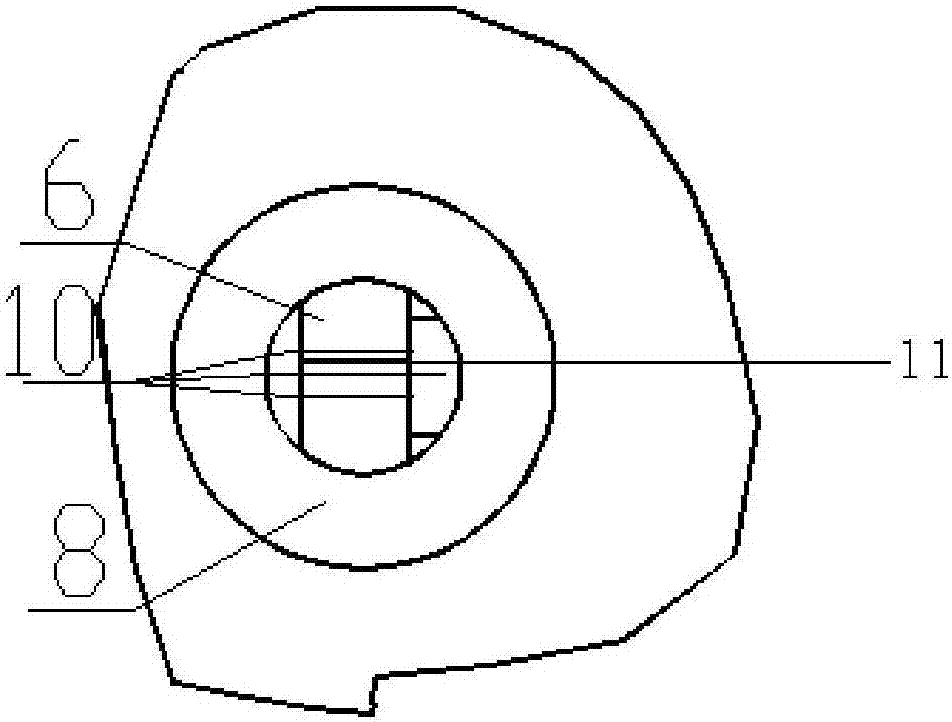

Thread cutting and presser foot lifting device of sewing machine and sewing machine

ActiveCN106948096ASimple structureSmall footprintNeedle severing devicesPressersElectric machineryEngineering

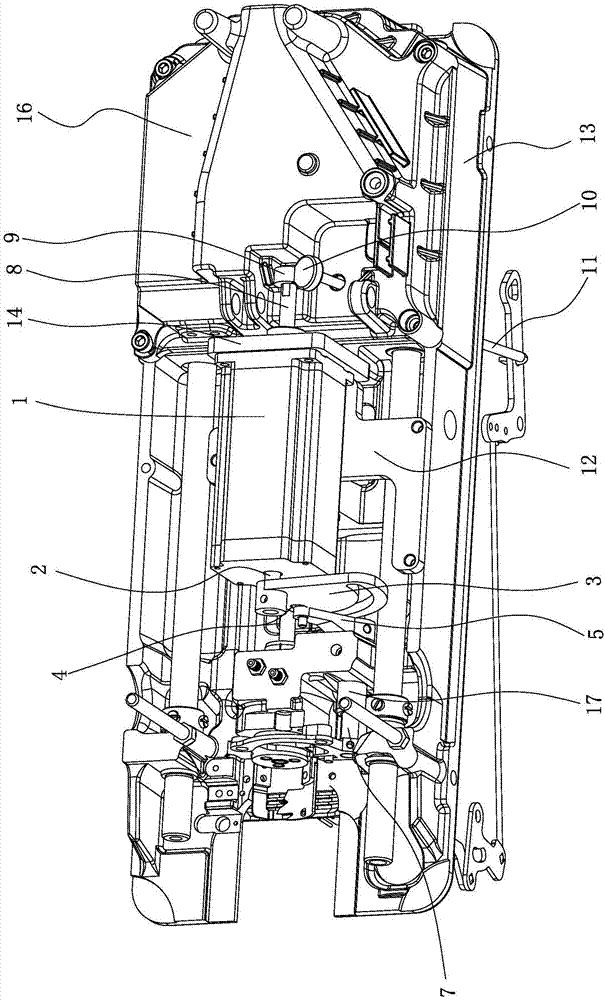

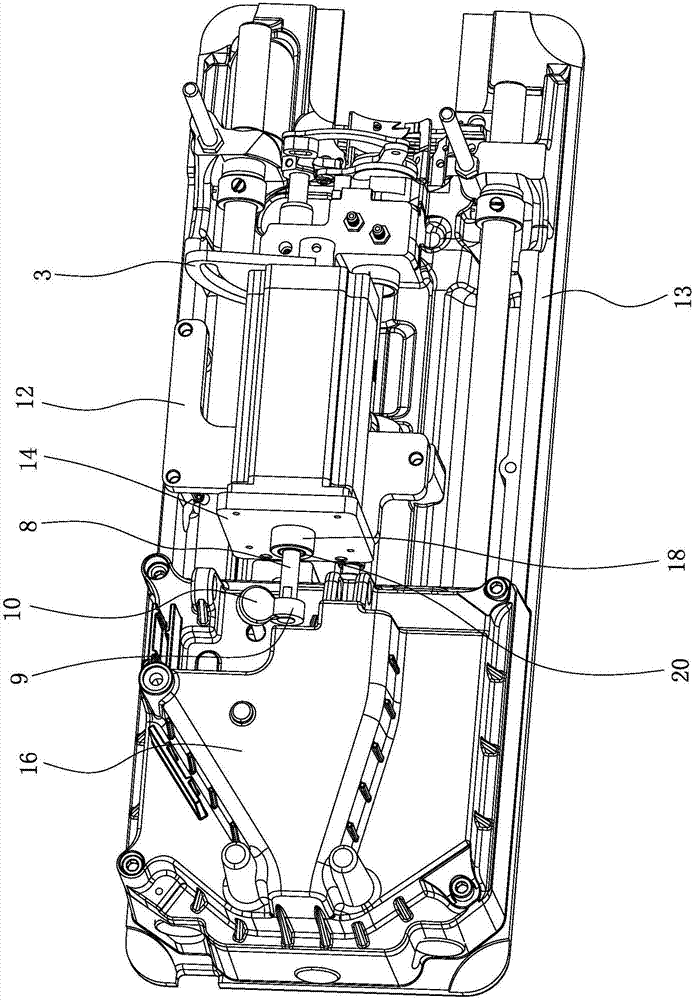

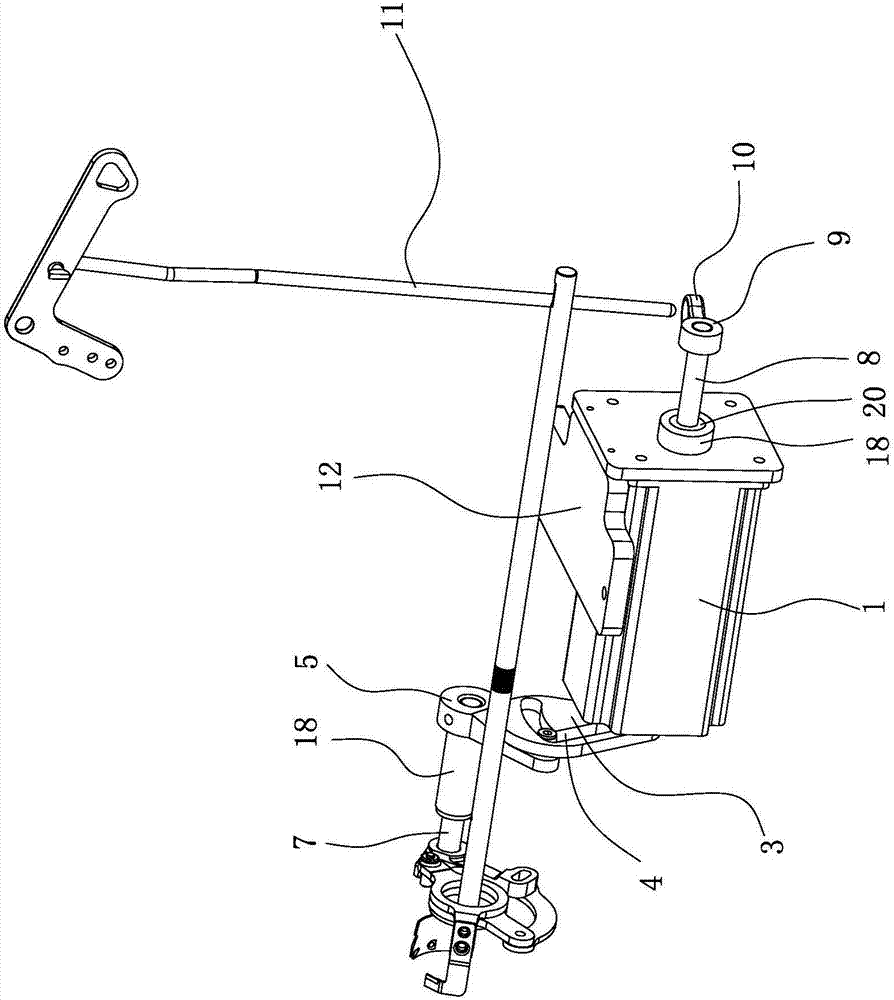

The invention belongs to the technical field of sewing machines and relates to a thread cutting and presser foot lifting device of a sewing machine and the sewing machine. The thread cutting and presser foot lifting device of the sewing machine comprises a double-end motor, a thread cutting cam assembly and a presser foot lifting crank assembly, wherein the thread cutting cam assembly comprises a thread cutting cam arranged on a motor shaft at one end of the double-end motor; a movement groove is formed in the thread cutting cam; one end of a thread cutting crank is connected with the thread cutting cam through a connecting pin; the connecting pin is arranged in the movement groove of the thread cutting cam; the other end of the thread cutting crank is connected with a thread cutting shaft; the thread cutting shaft is connected with a thread cutting mechanism; the presser foot lifting crank assembly comprises a presser foot lifting crank arranged on a motor shaft at the other end of the double-end motor; an abutting part is arranged on the presser foot lifting crank; the abutting part abuts against an ejection rod of a presser foot lifting mechanism. According to the thread cutting and presser foot lifting device of the sewing machine, one driving source is used for controlling movement of the thread cutting mechanism and the presser foot lifting mechanism; the driving source is reduced so that the structure is simpler and an occupied space is simple; the thread cutting and presser foot lifting device is convenient to mount and the cost is reduced.

Owner:JACK SEWING MASCH CO LTD

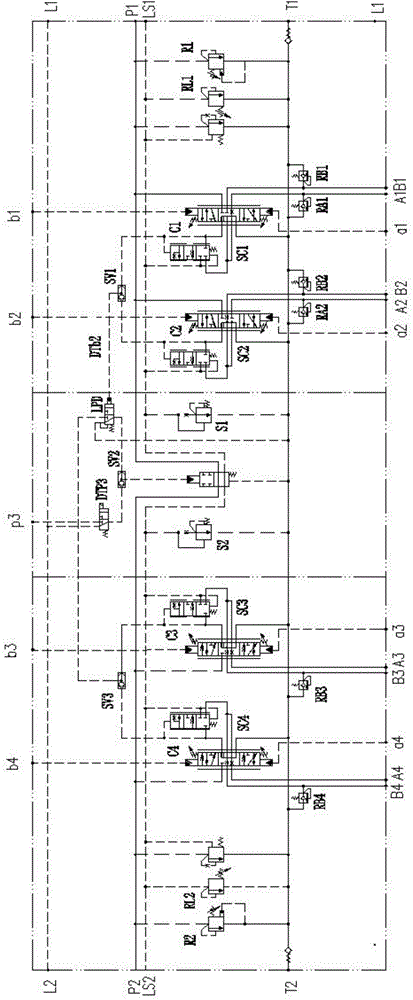

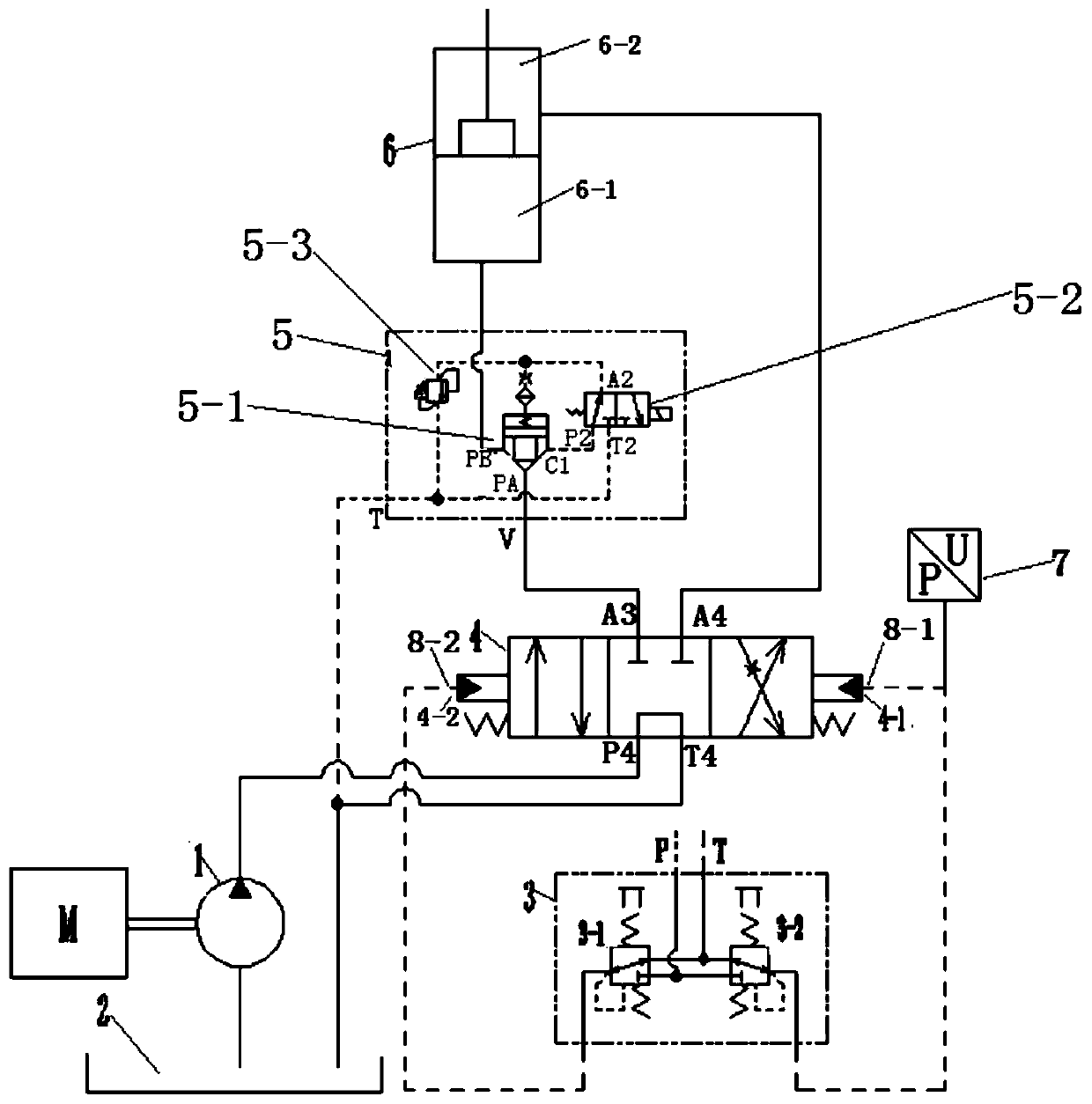

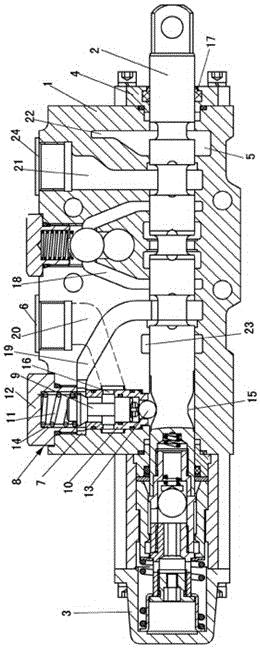

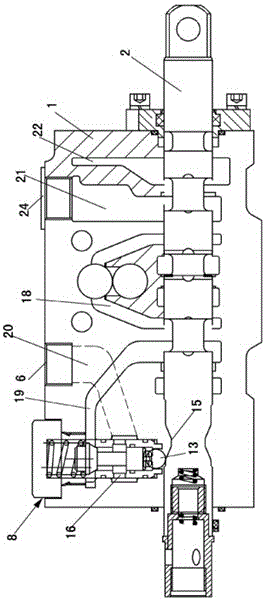

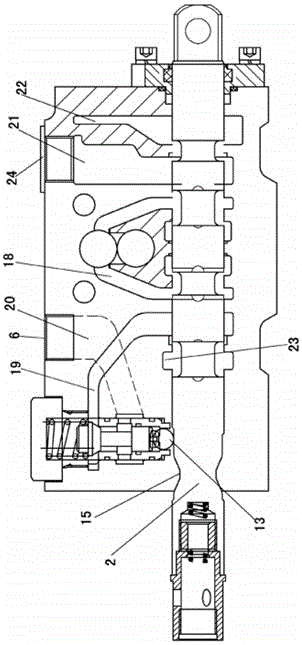

Valve back compensation type load-sensitive multitandem valve with bidirectional confluence function

ActiveCN104879336ARaise priorityLow priorityServomotor componentsServometer circuitsElectro hydraulicHigh load

The invention discloses a valve back compensation type load-sensitive multitandem valve with a bidirectional confluence function. The valve back compensation type load-sensitive multitandem valve comprises a confluence tandem and two oil inlet operation tandems arranged at two ends of the confluence tandem. The confluence tandem is provided with a confluence valve with the bidirectional confluence function and comprises an electromagnetic valve, a hydraulic control valve, a shuttle valve II and an electro-hydraulic joint control confluence switching valve, an oil inlet tandem and two operation tandems are integrated in each oil inlet operation tandem and each operation tandem comprises a reversing speed-regulation valve and a pressure compensation valve arranged at an outlet of the reversing speed-regulation valve. The confluence tandem is detachably connected with the oil inlet operation tandems on two sides. The output end of the electro-hydraulic joint control confluence switching valve in the confluence tandem is communicated with the operation tandems. The confluence tandem allows oil to flow bidirectionally from p1 to p2 or vice versa, flow speed range of the tandems is broadened, and the executing mechanisms can act more quickly. By the pressure compensation technology, the problem that high-load executing mechanisms have little flow or even no flow when the executing mechanisms act at the same is solved, and action stability is improved.

Owner:XCMG HYDRAULICS CO LTD

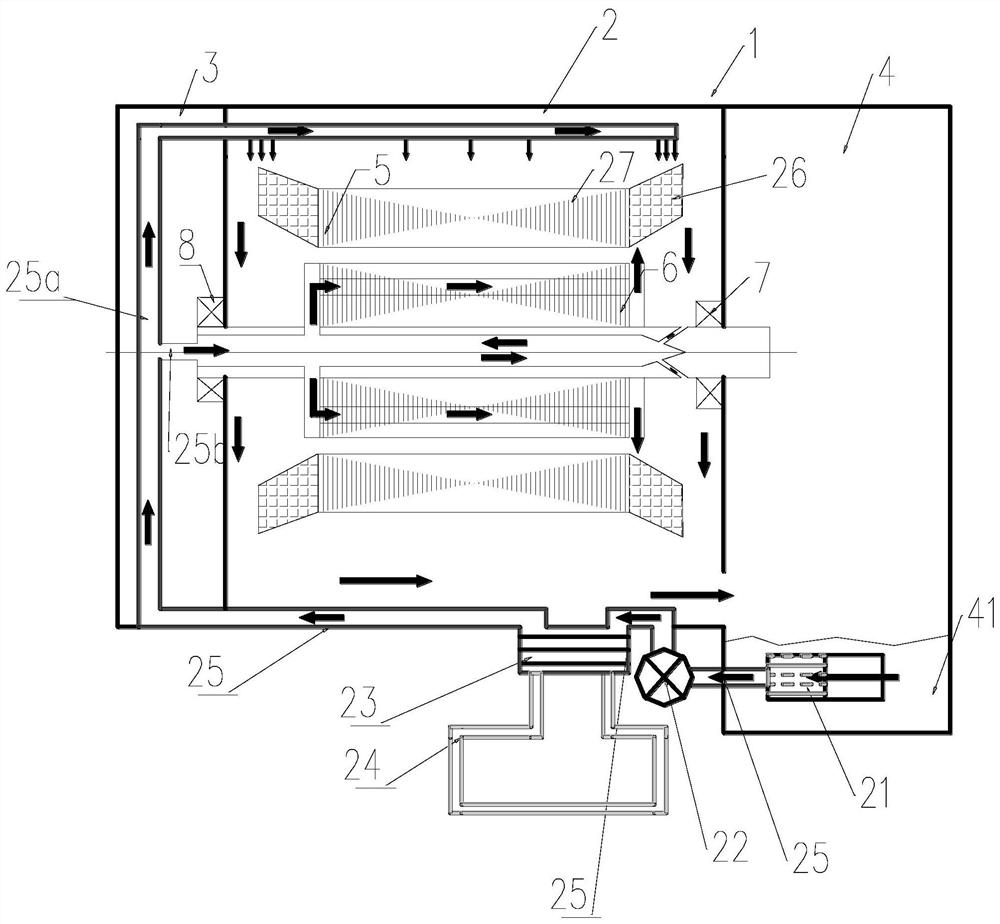

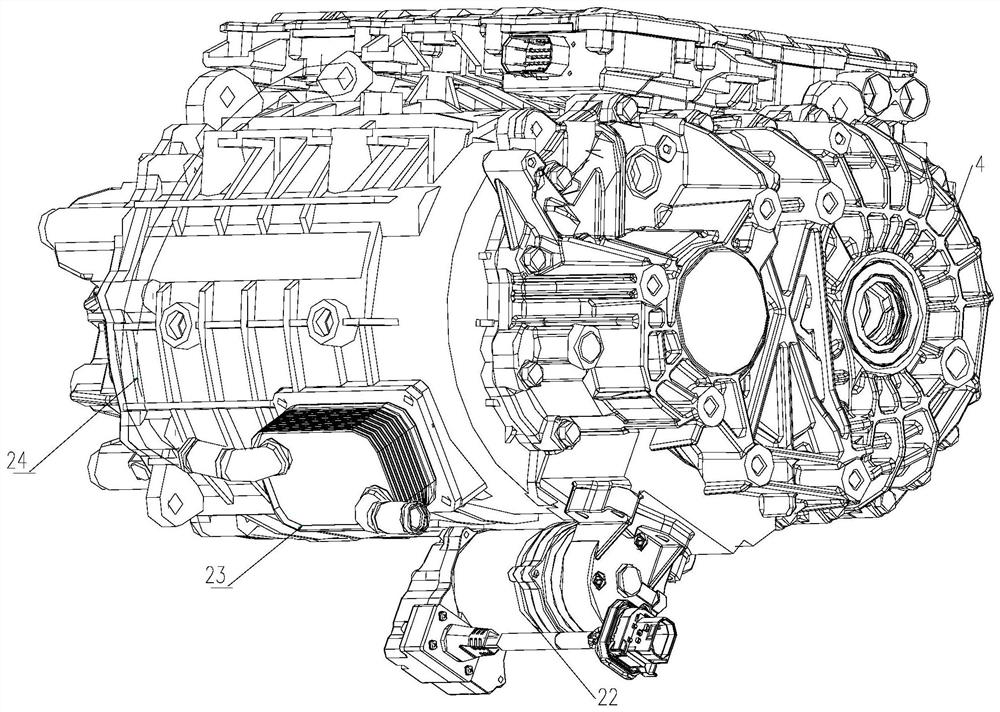

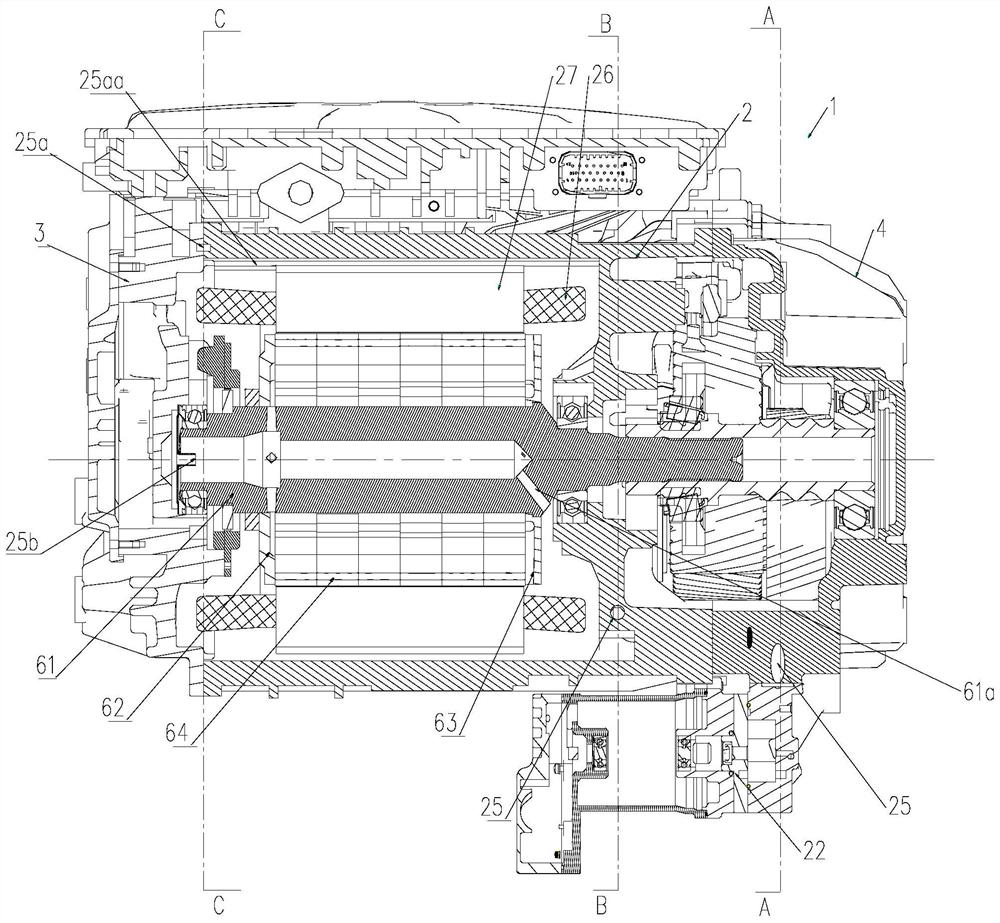

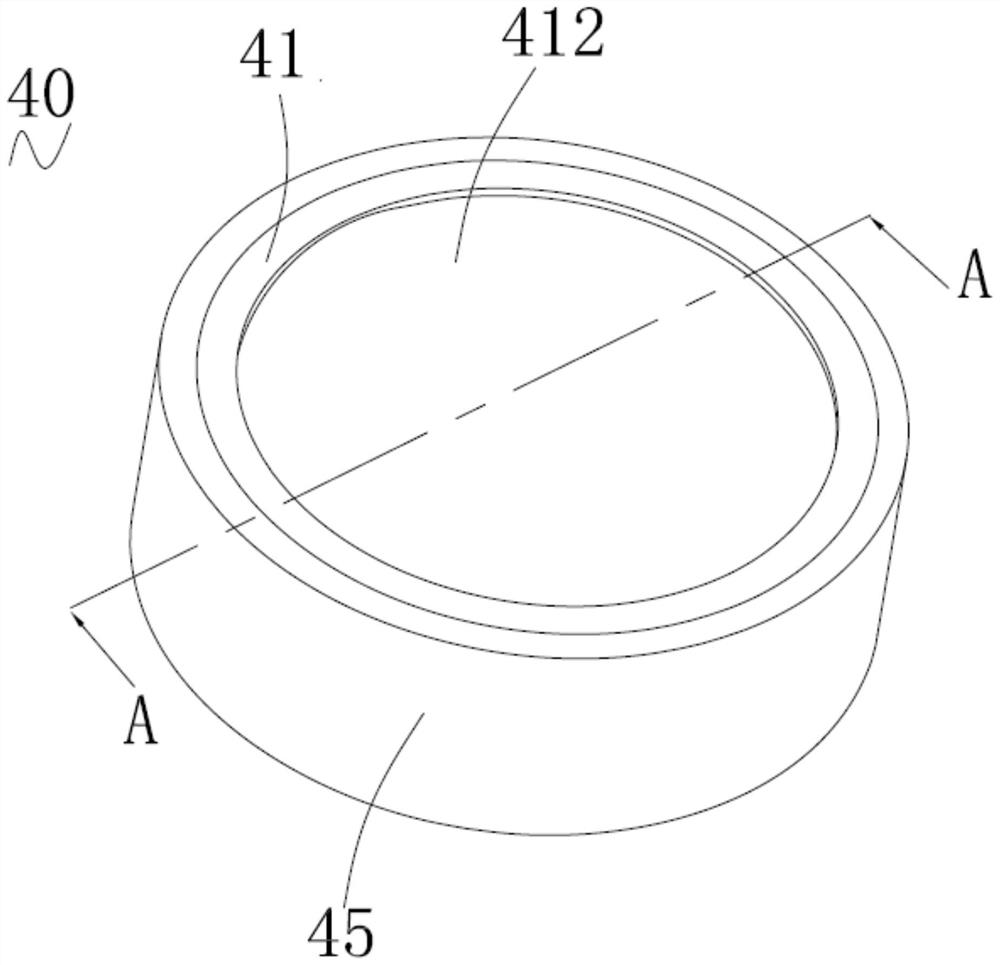

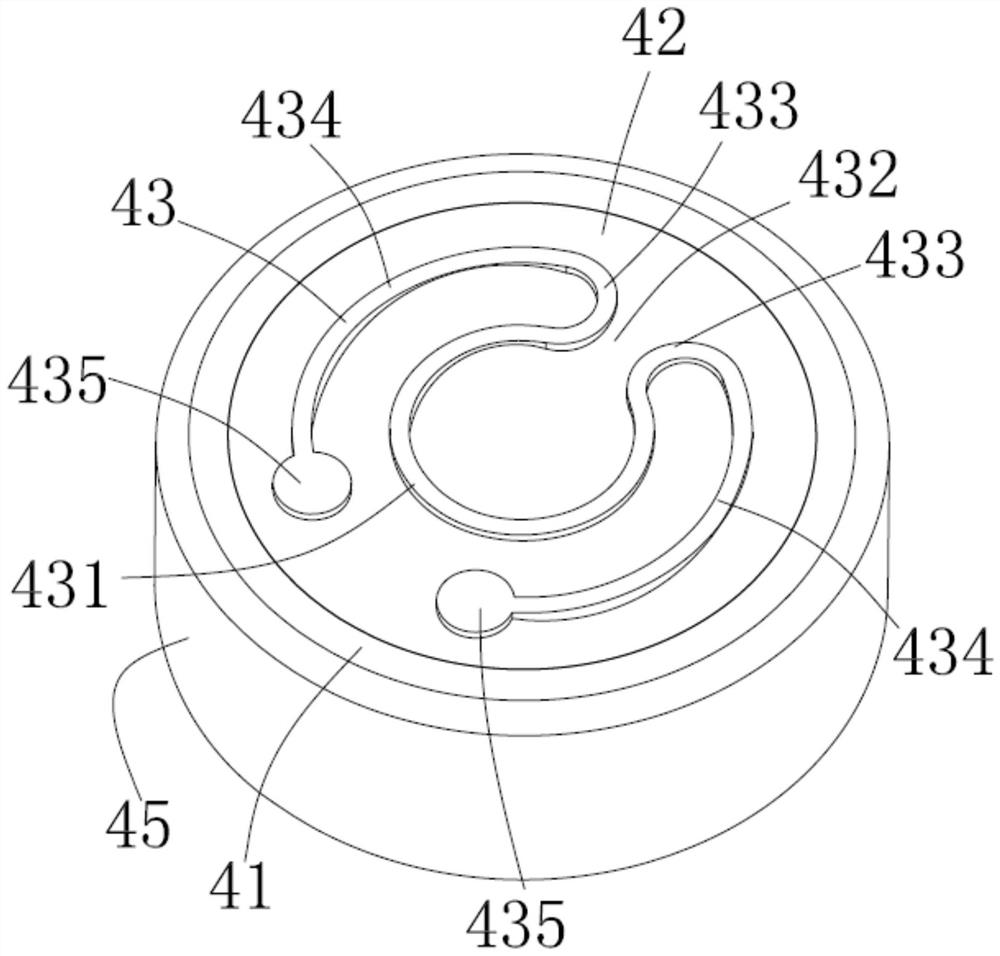

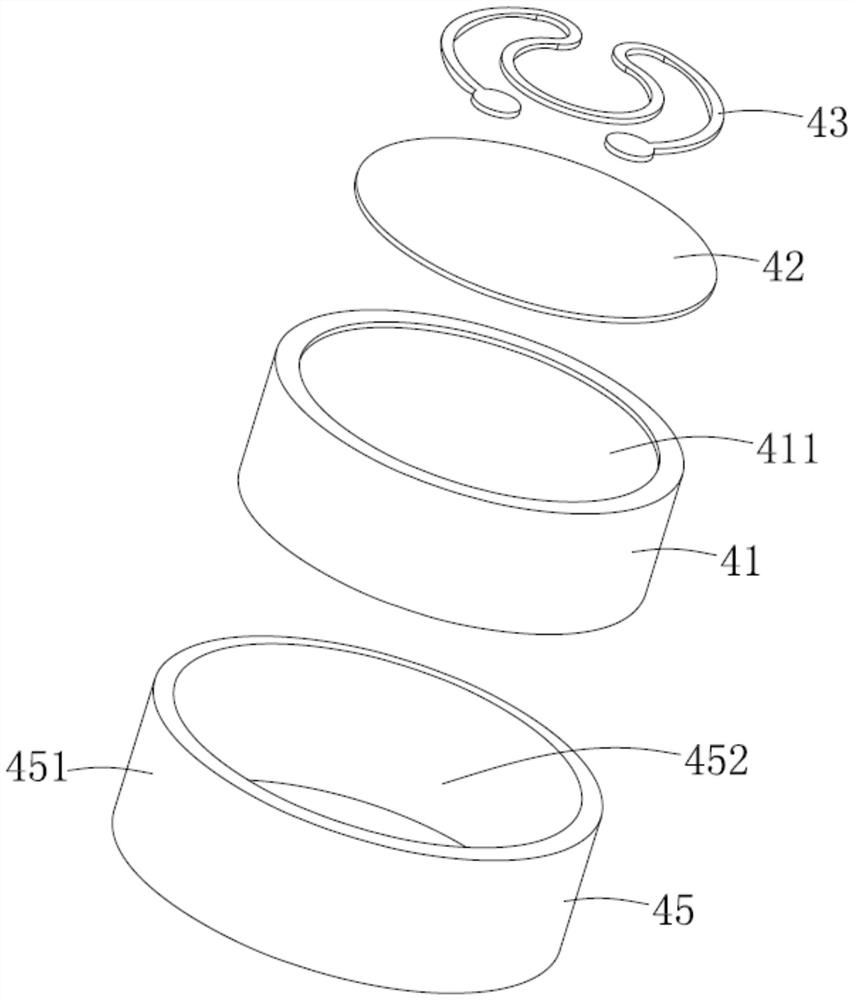

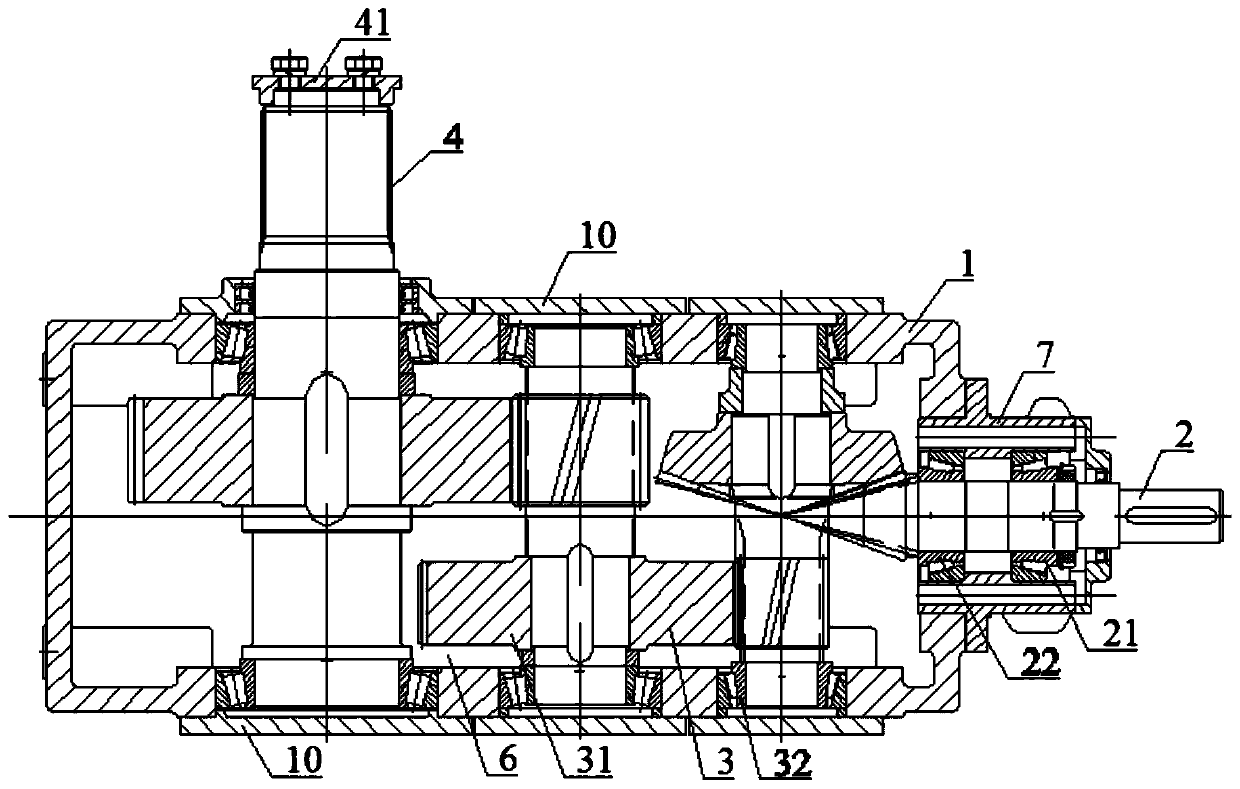

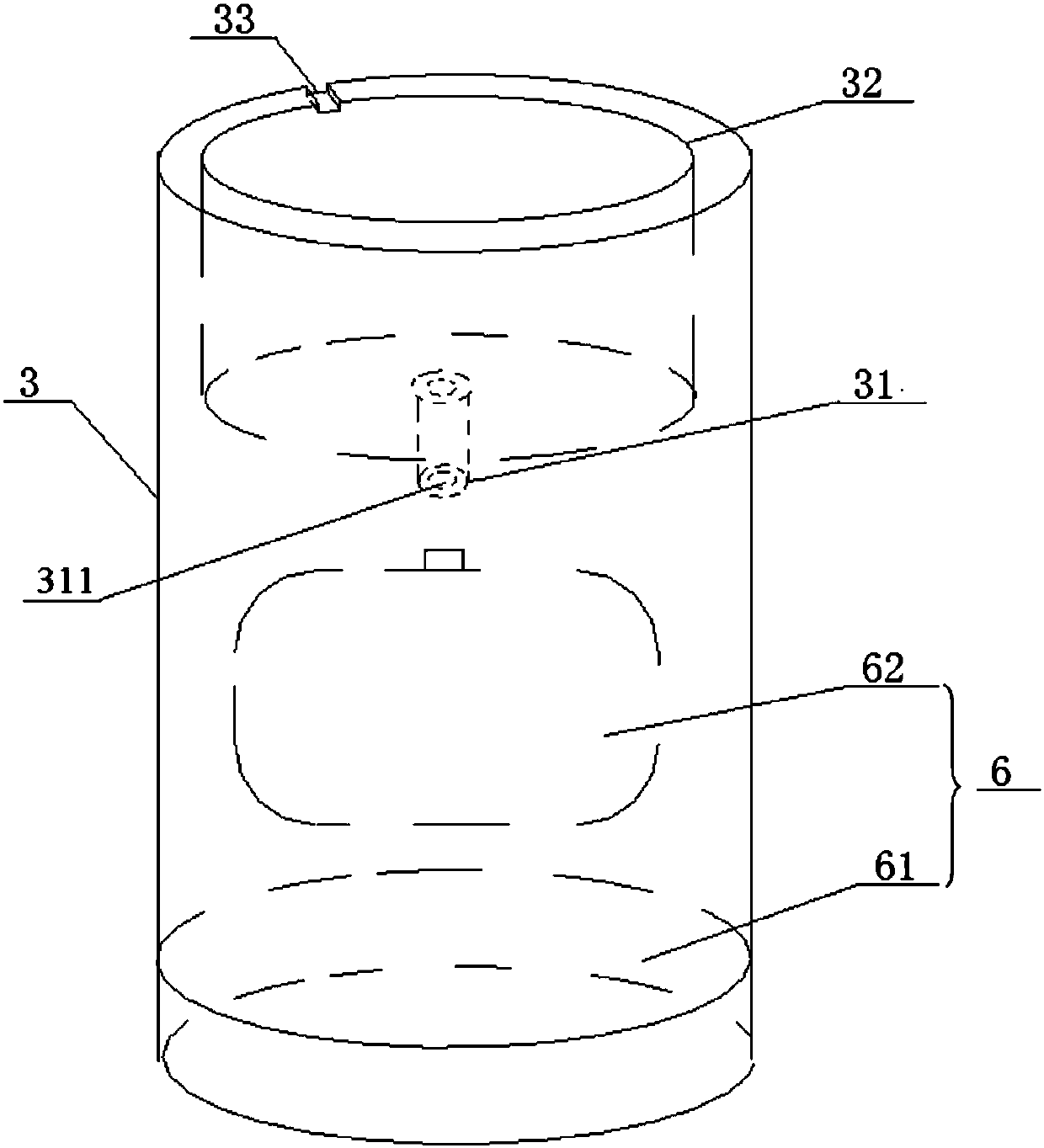

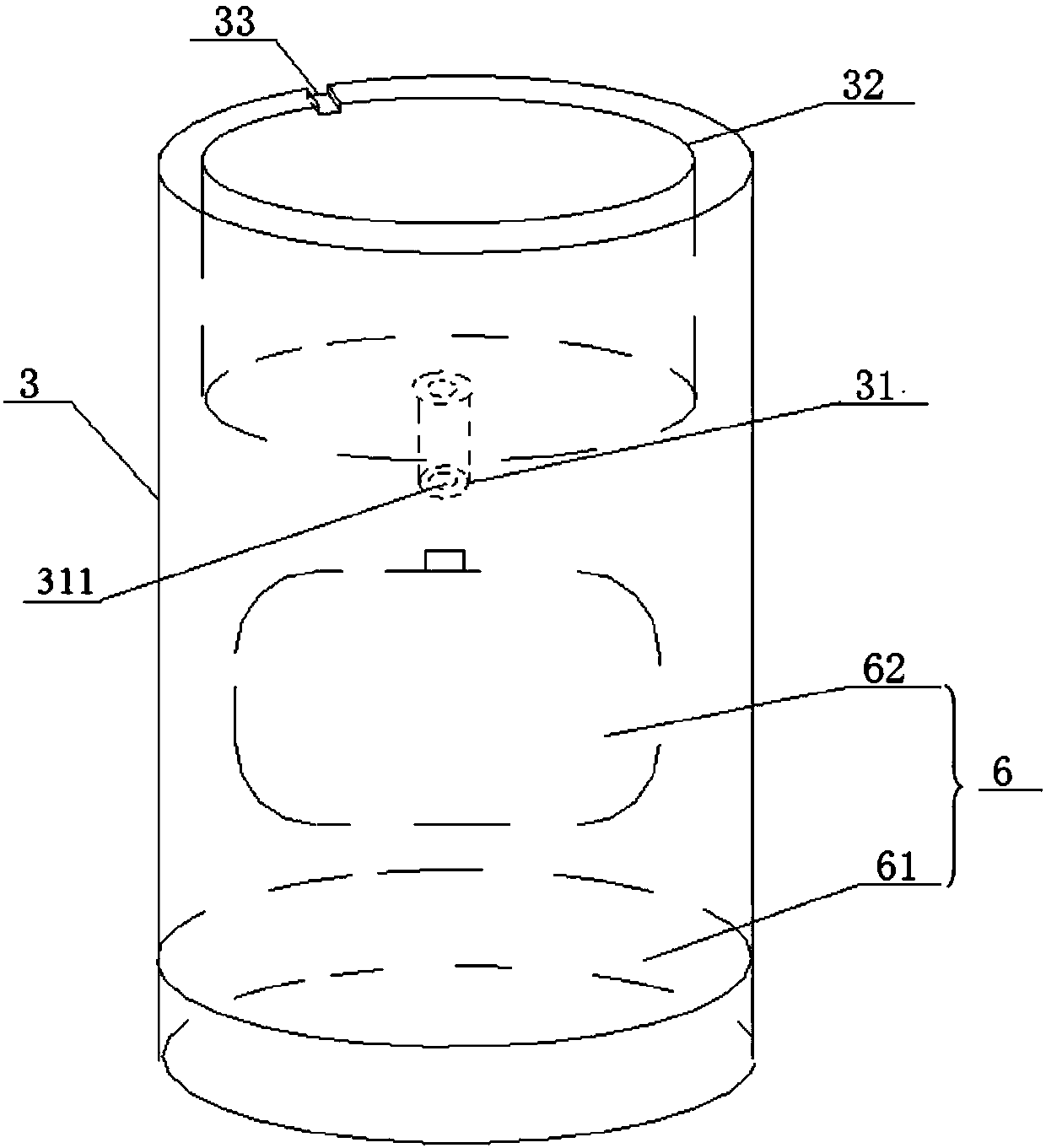

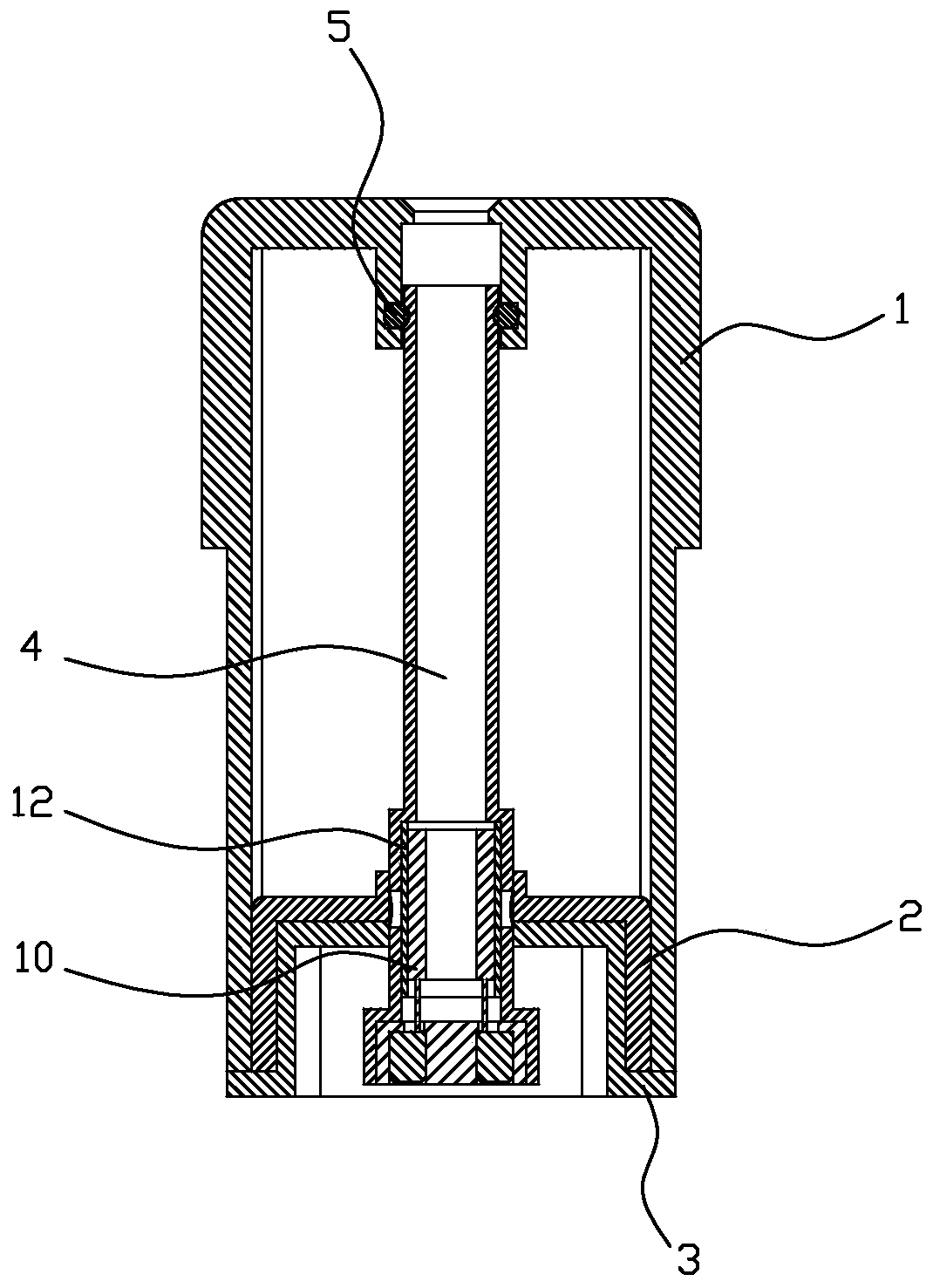

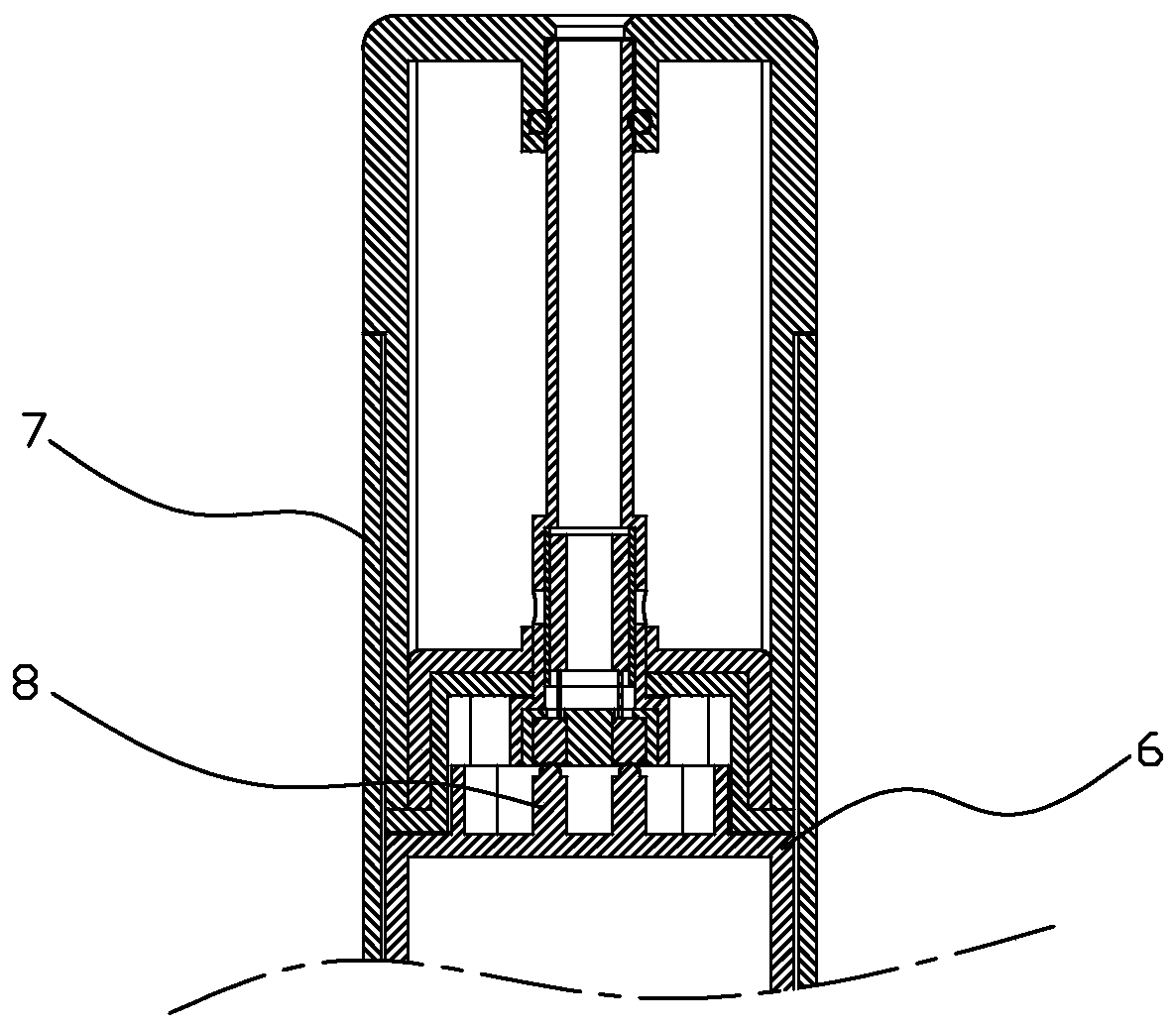

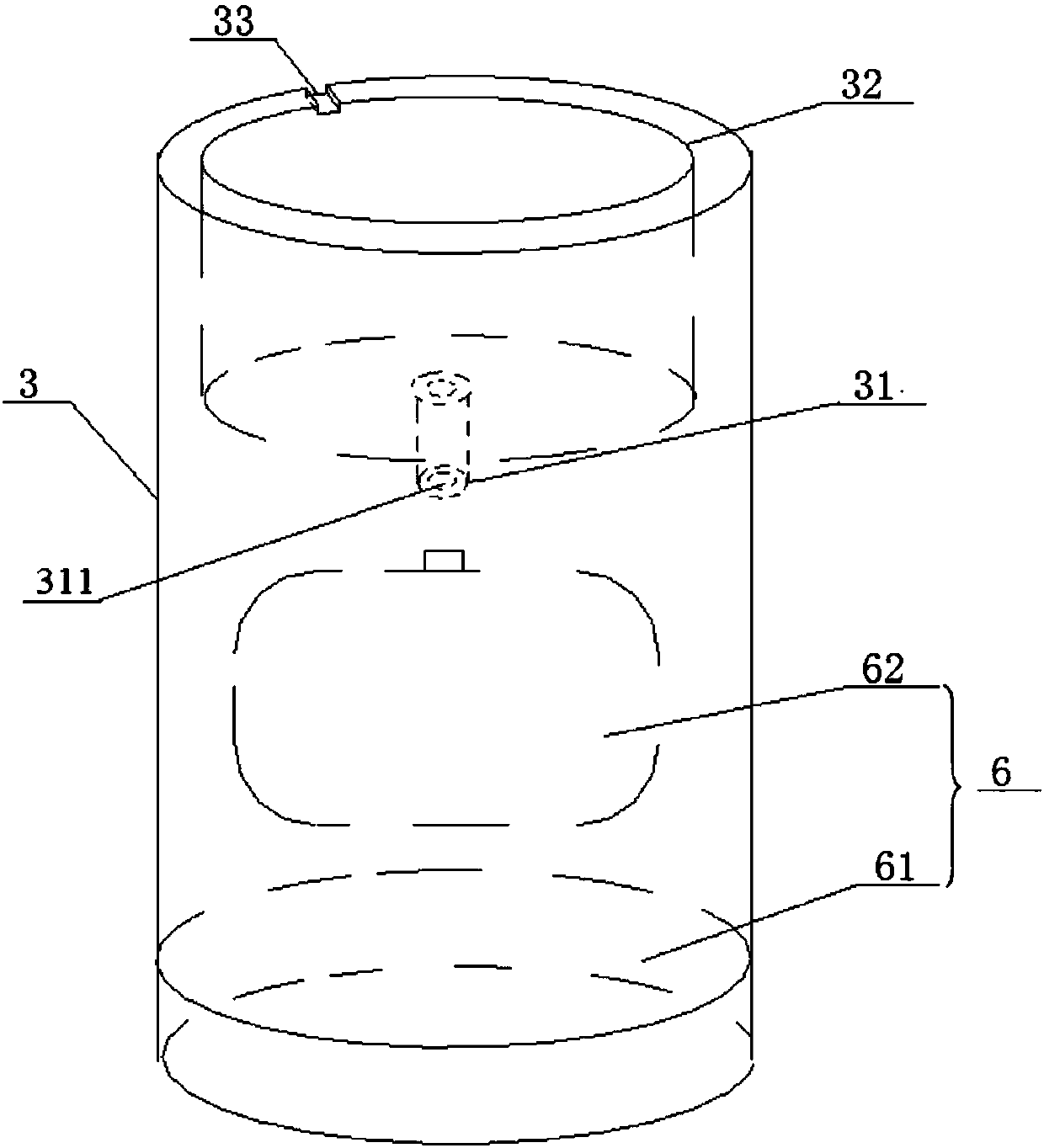

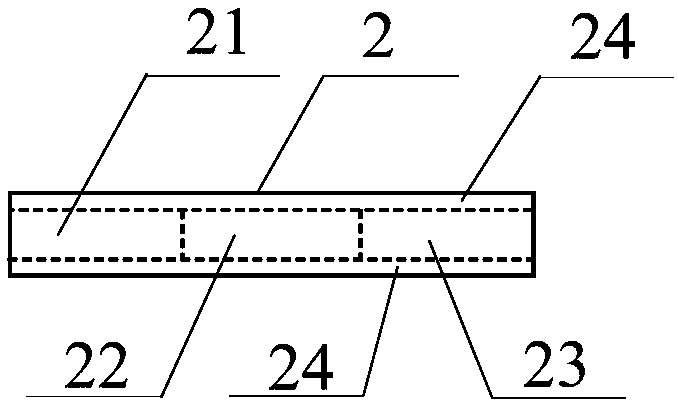

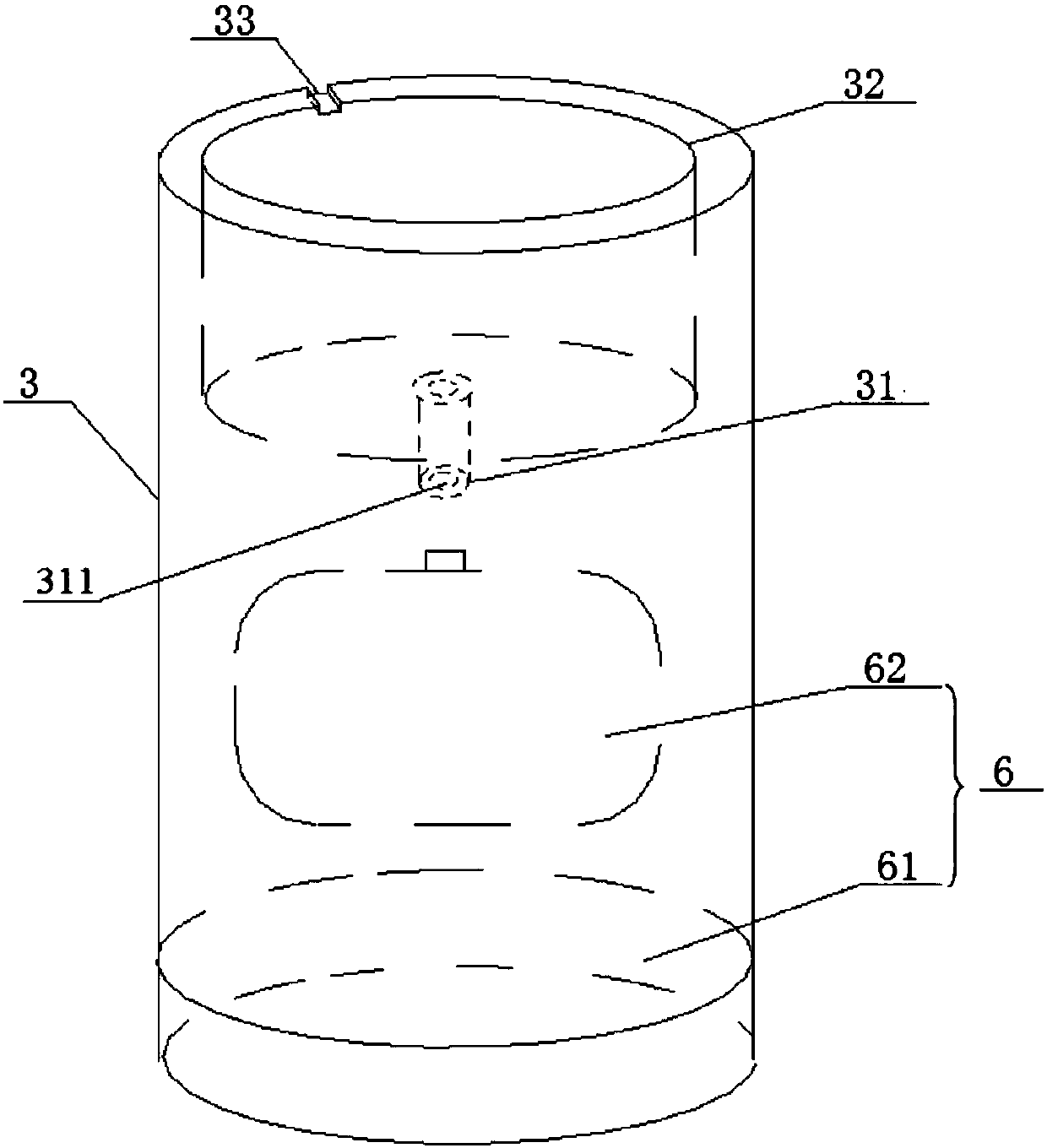

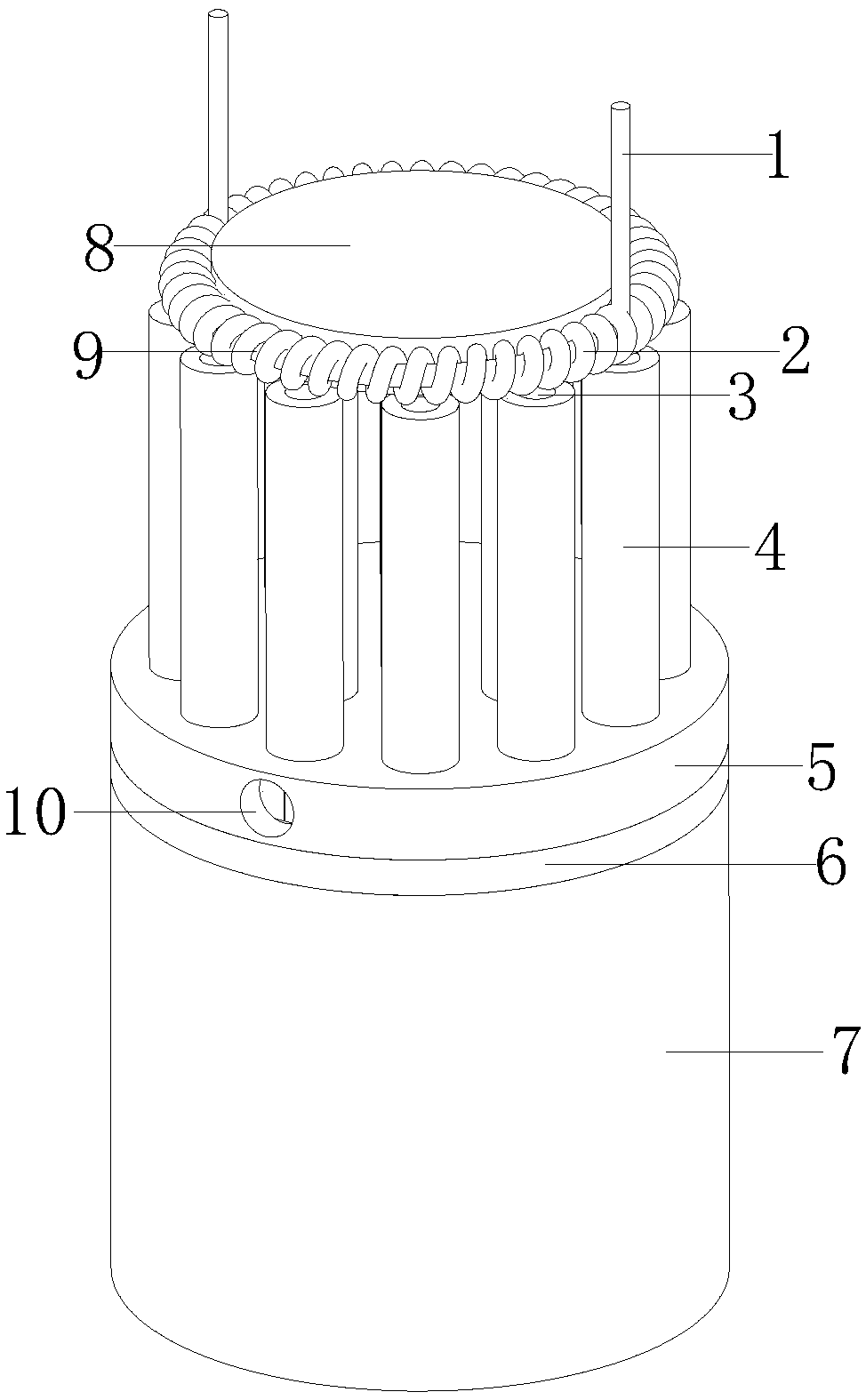

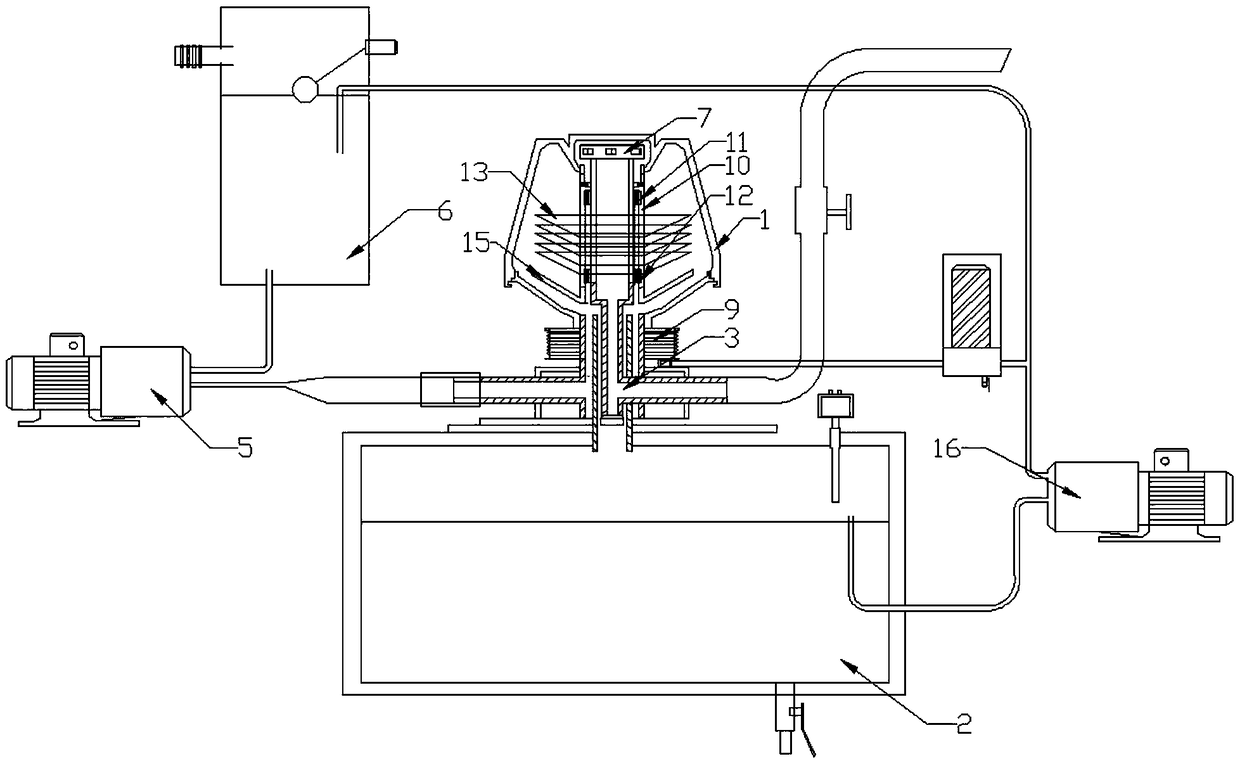

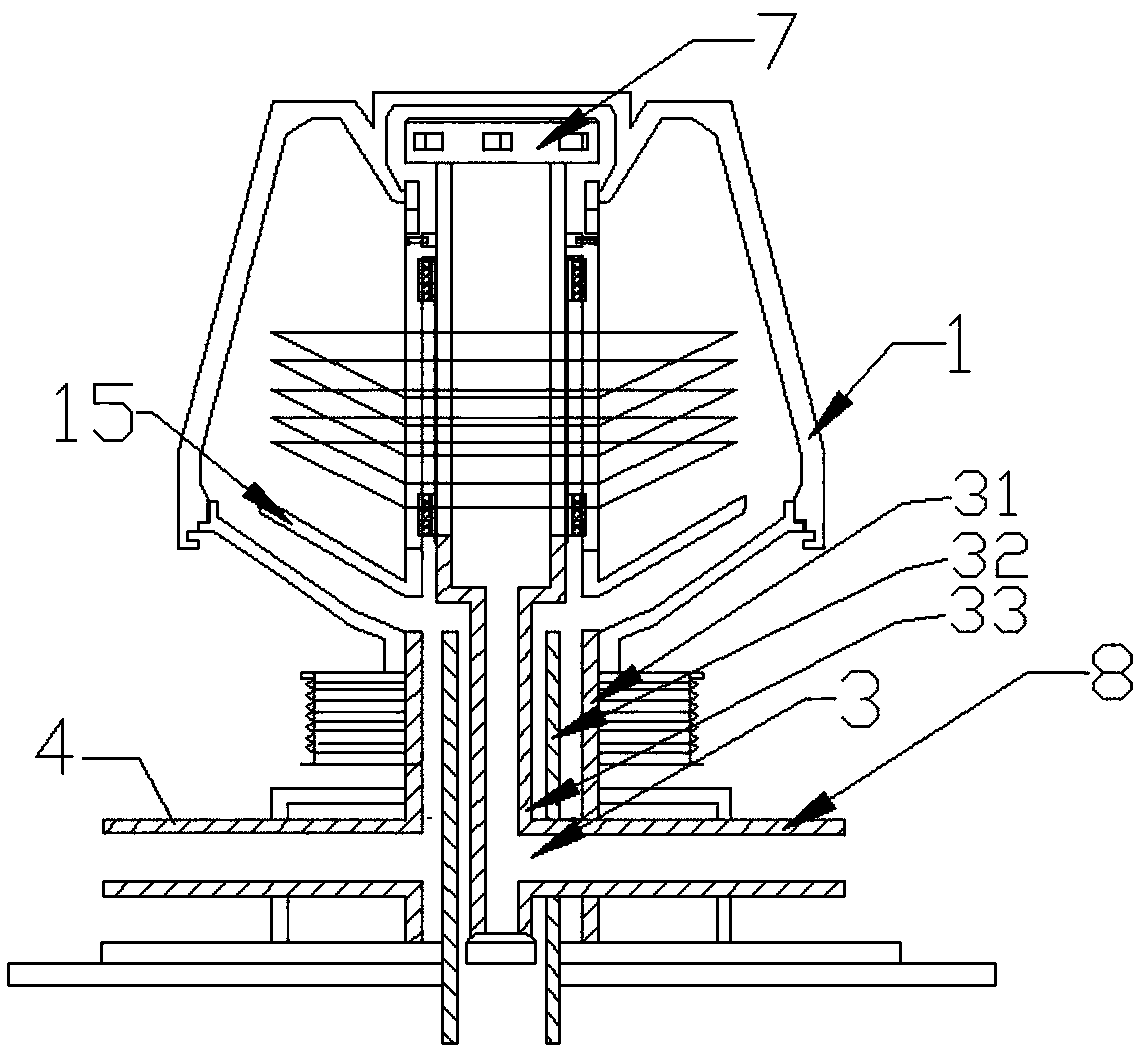

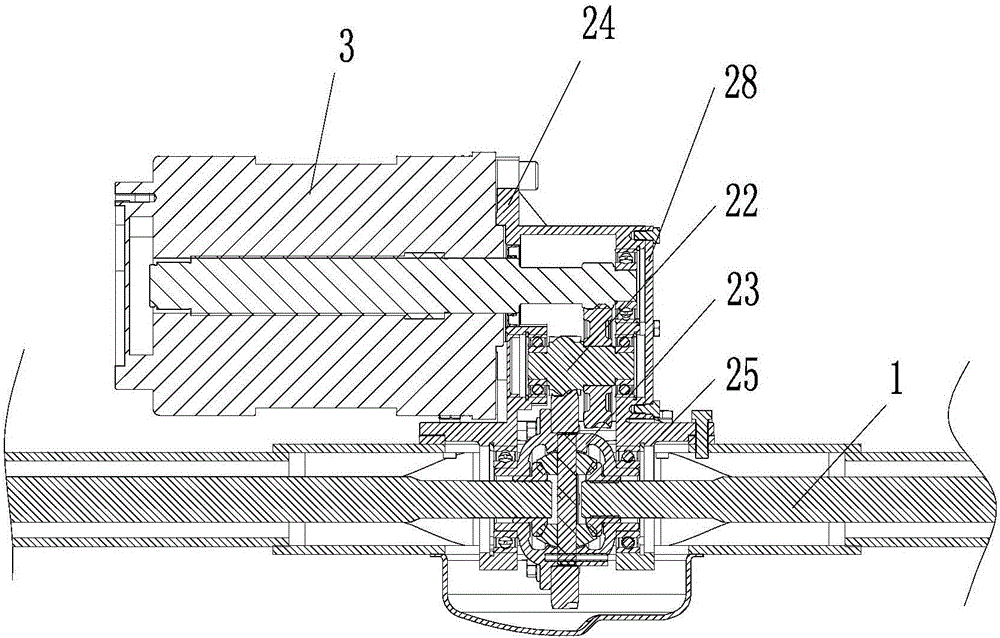

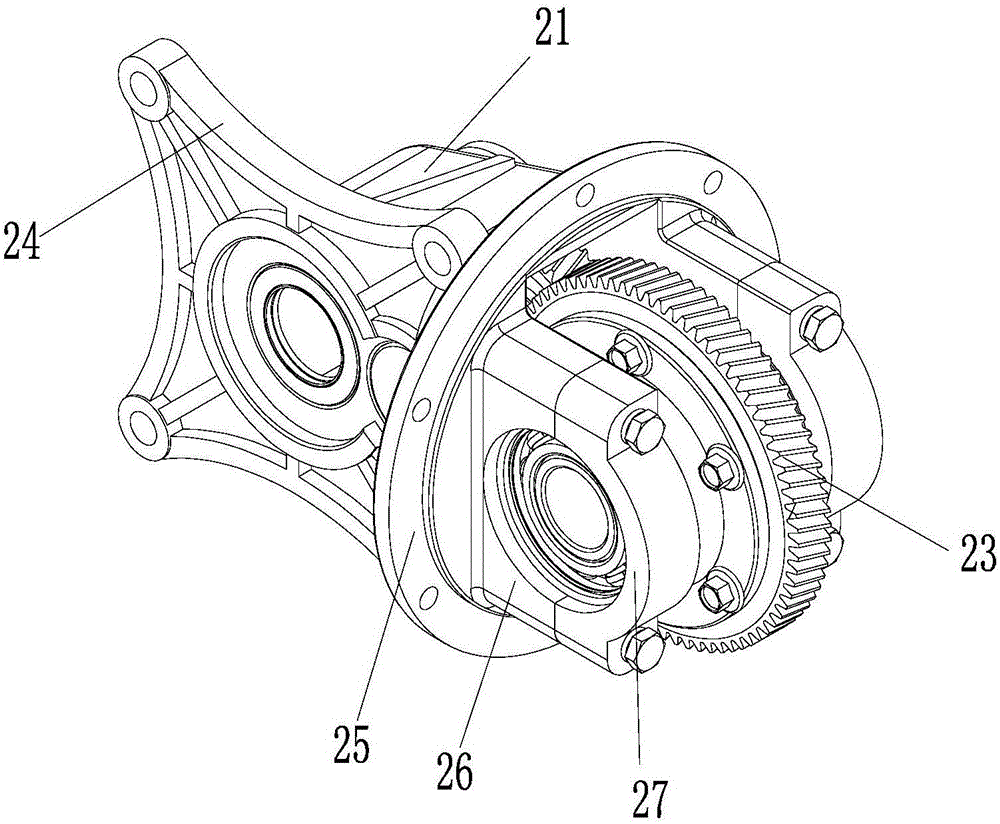

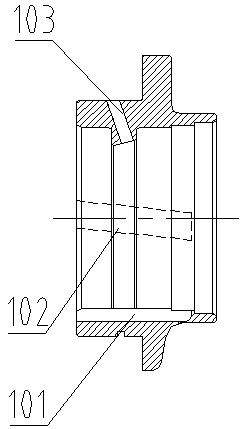

Three-in-one oil cooling electric driving structure

ActiveCN112421889AReduce the risk of oil spillsGuaranteed cooling effectMagnetic circuit rotating partsElectric machinesElectric machineReduction drive

The invention discloses a three-in-one oil cooling electric drive structure which comprises a speed reducer-to-motor rear end oil cooling structure integrated with an electric drive shell, a rotor cooling structure and a stator cooling structure. The speed reducer-to-motor rear end oil cooling structure conveys cooling oil in a speed reducer shell into a main oil way of the motor shell, the main oil way is divided into a first oil way and a second oil way on a rear end cover, the first oil way is communicated with the stator cooling structure, and the second oil way is communicated with the rotor cooling structure. The stator cooling structure is used for introducing cooling oil into the upper part of the electric drive, and directionally cooling the stator through an oil spraying hole ina stator oil distribution channel in the motor shell; the rotor cooling structure is used for rotating and throwing cooling oil through a rotor to achieve cooling. A circulating oil way is connected through the structural design of the shell, the oil way is shunted on the shell, cooling of the stator and the rotor is guaranteed, an additional oil distributing structure and an additional copper pipe are not needed, the integration degree of oil cooling electric drive is improved, the cost is reduced, and the risk of oil leakage of an oil pipe is reduced.

Owner:HEFEI JUYI POWER SYST CO LTD

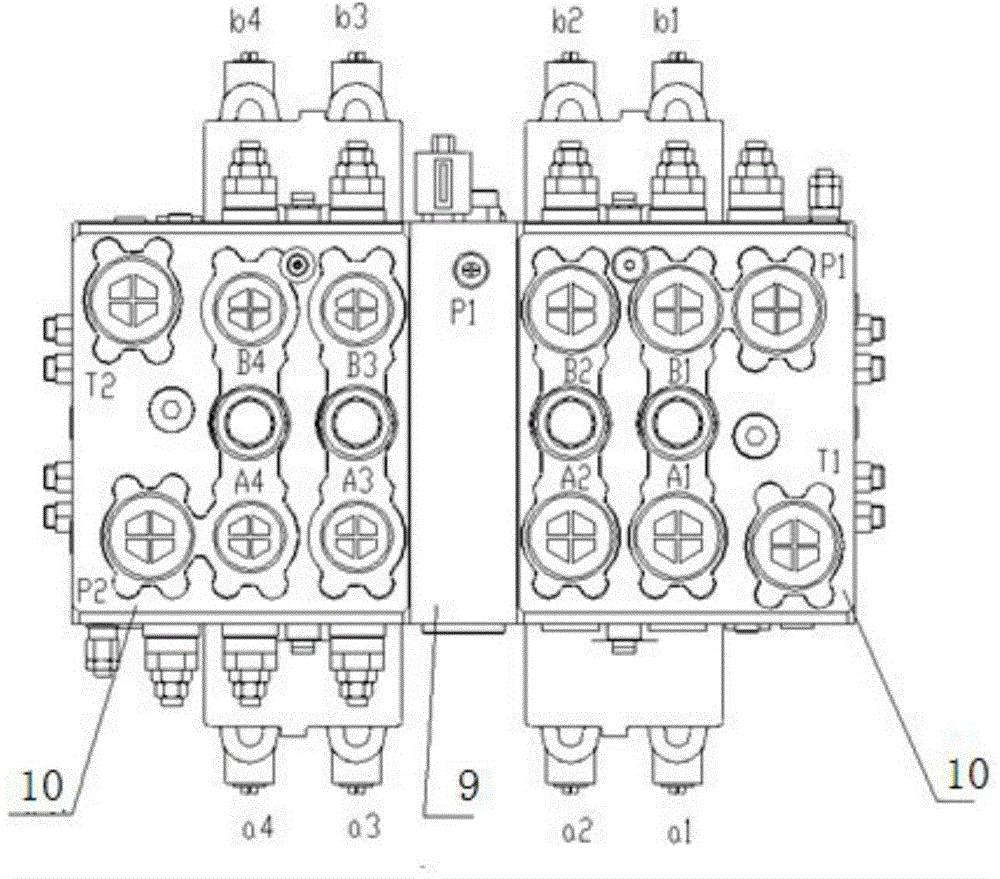

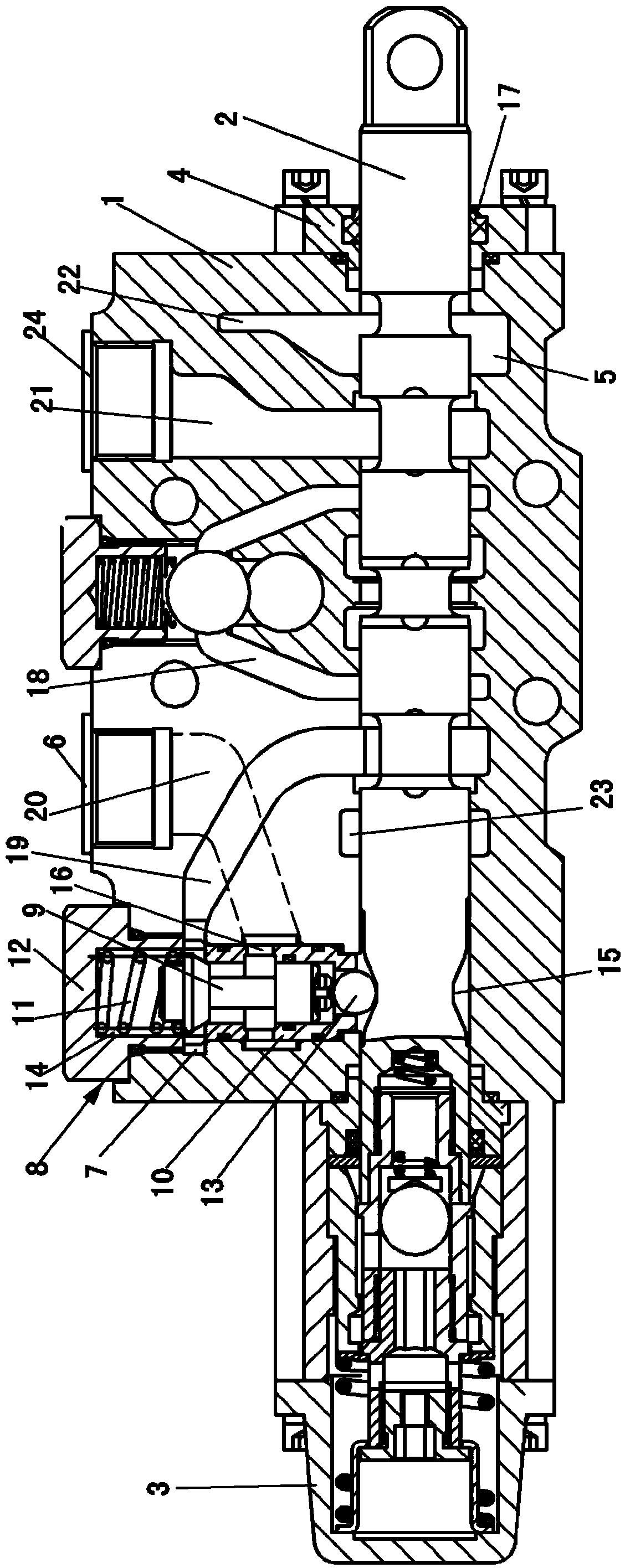

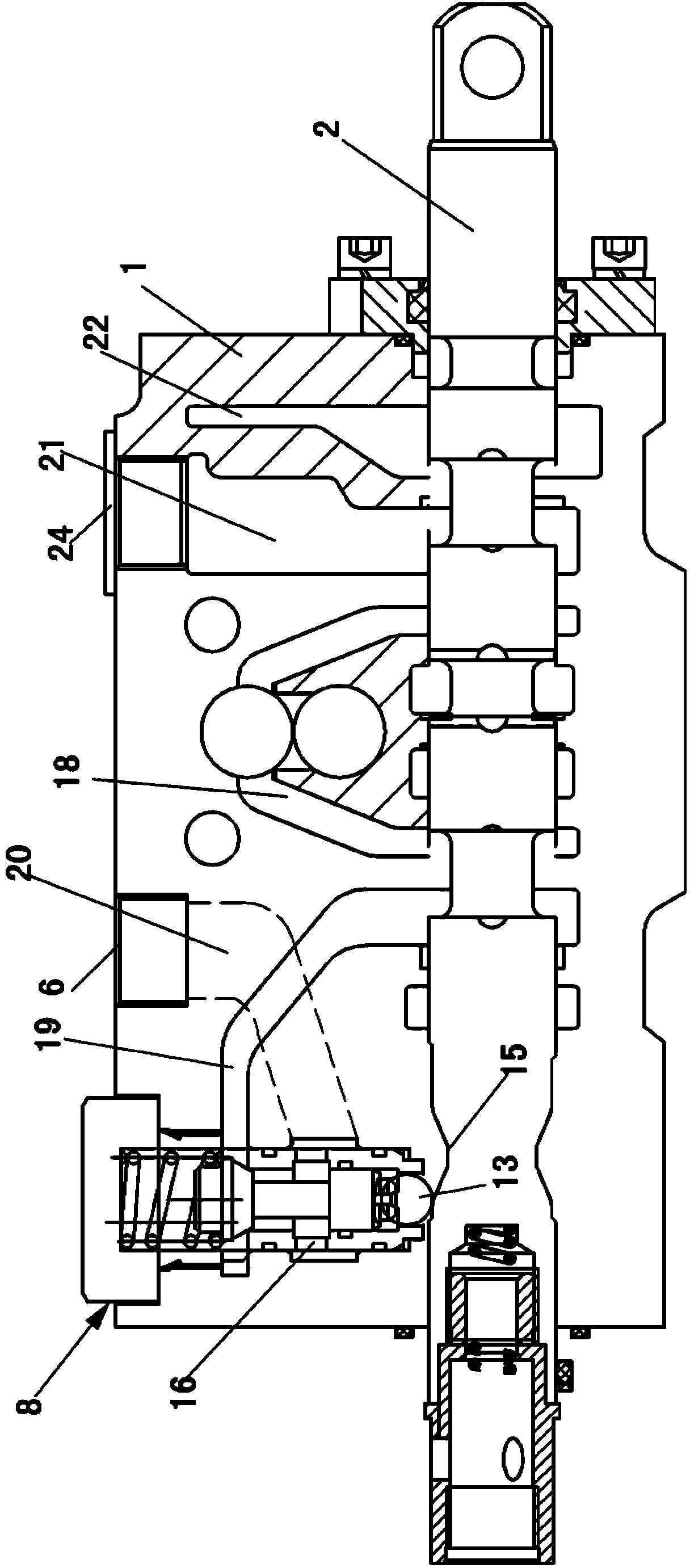

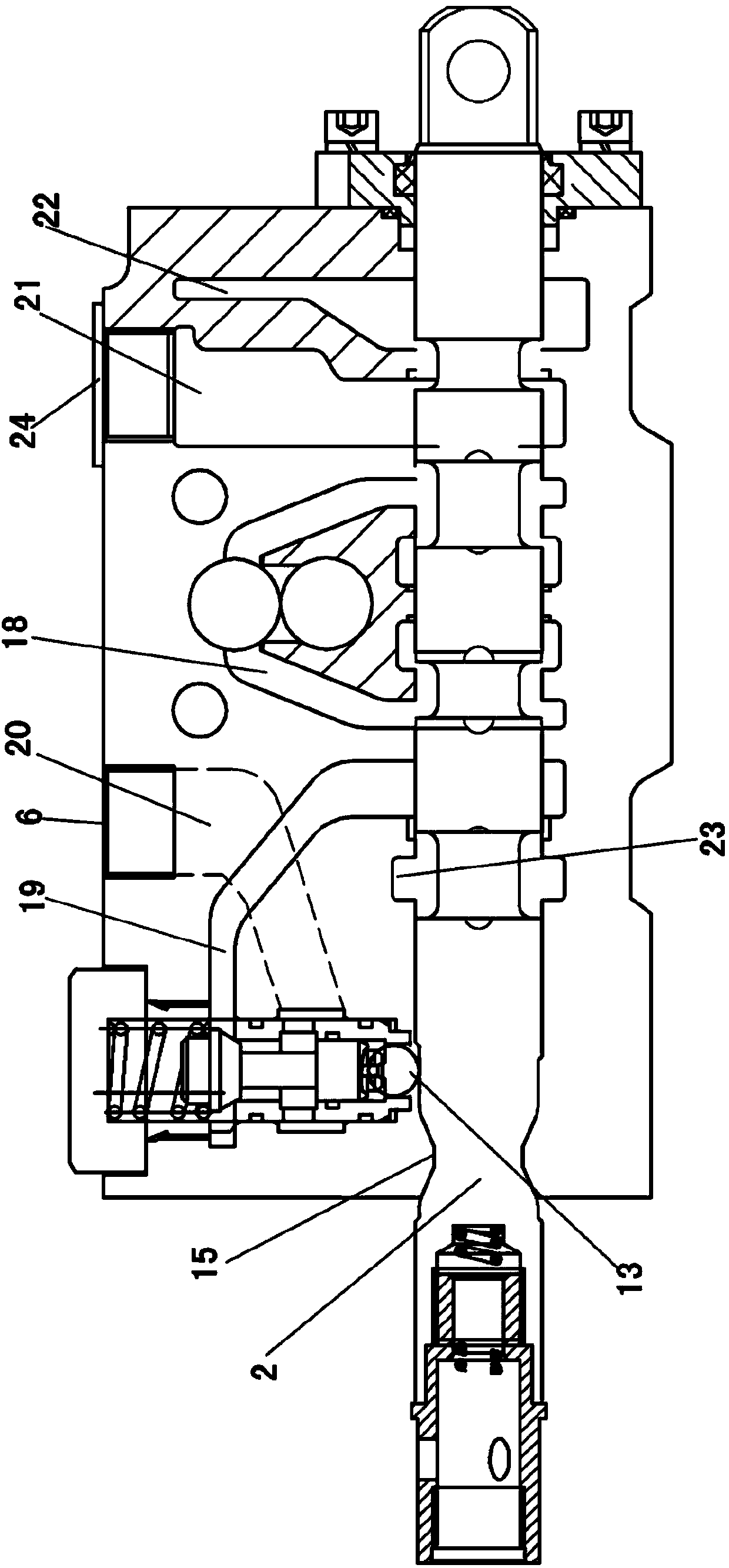

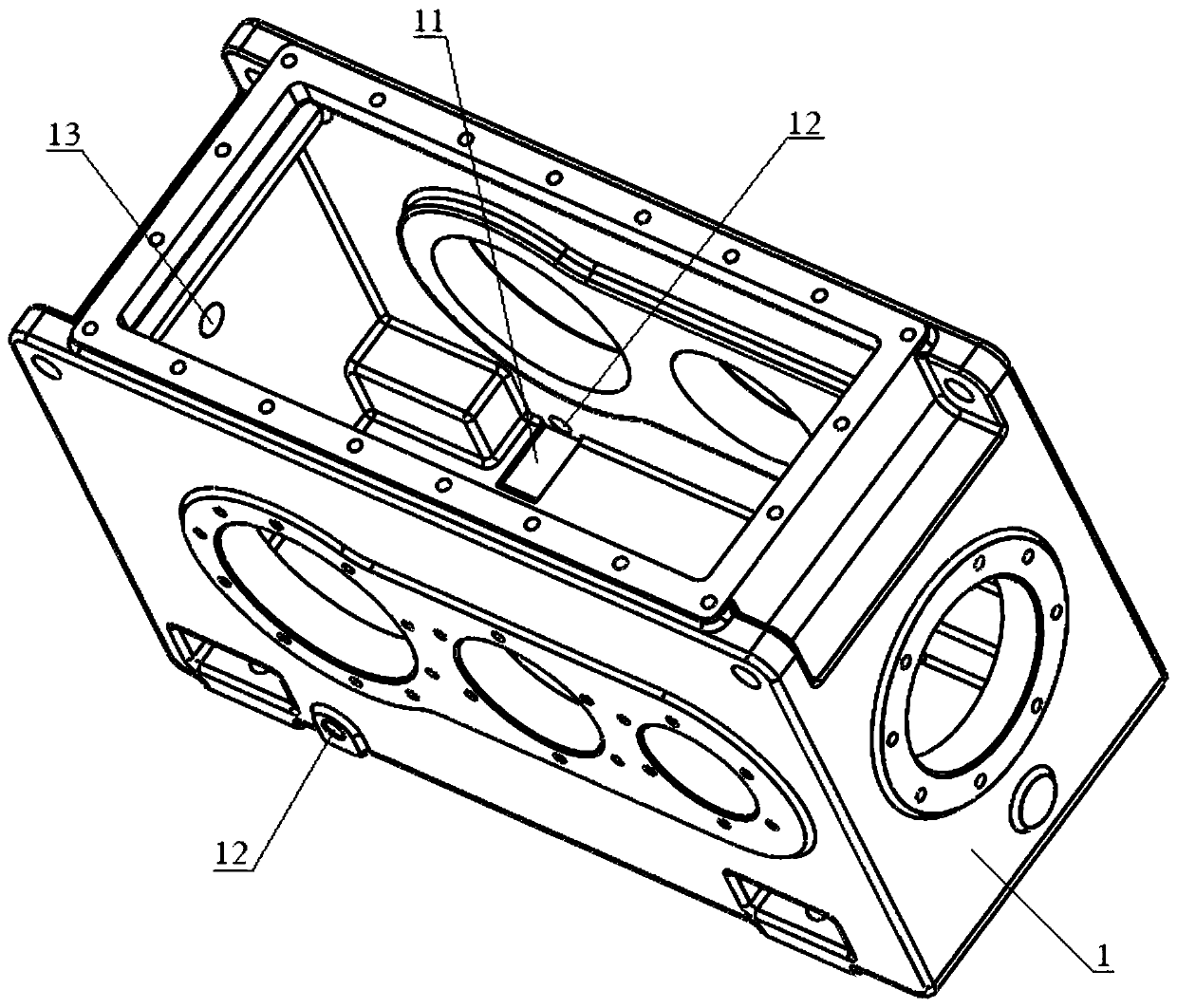

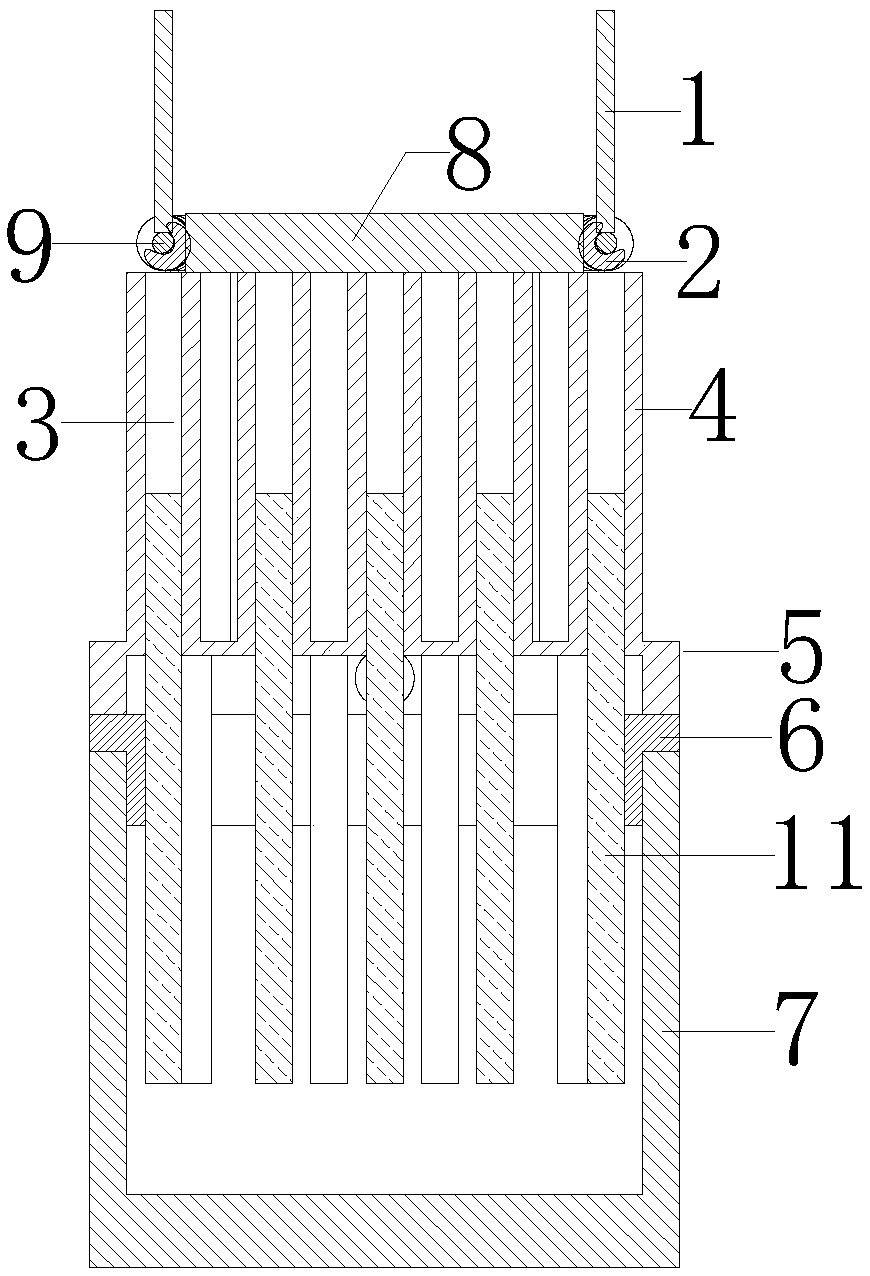

Hydraulic multi-channel valve for agricultural machine

ActiveCN104179749AIncrease floating functionSolve the problem of not being able to streamServomotor componentsSteel ballCheck valve

The invention discloses a hydraulic multi-channel valve for an agricultural machine. The hydraulic multi-channel valve comprises a valve body, a valve stem, a rear bonnet and a support. A valve cavity is arranged in the valve body, the valve stem is inserted into the valve cavity, the right end of the valve stem extends out of the valve body, and the support sleeves the valve stem and is positioned on the right end surface of the valve body; the rear bonnet is positioned at the left end of the valve body; a working oil port A and a hydraulic lock cavity are arranged on the valve body; the hydraulic lock cavity is connected with the valve cavity by a second oil duct. A hydraulic lock is arranged on the hydraulic lock cavity; the hydraulic lock comprises a check valve element, a check valve sleeve, a spring, a screw plug and a steel ball; an arc-shaped groove which is bent towards the axis of the valve stem is formed in the valve stem. The hydraulic multi-channel valve for the agricultural machine has the advantages that oil leakage risks can be reduced, the work reliability of the valve can be improved, forward locking and floating can be effectively combined with each other, oil leakage and dust can be prevented, and the like.

Owner:HEFEI CHANGYUAN HYDRAULICS

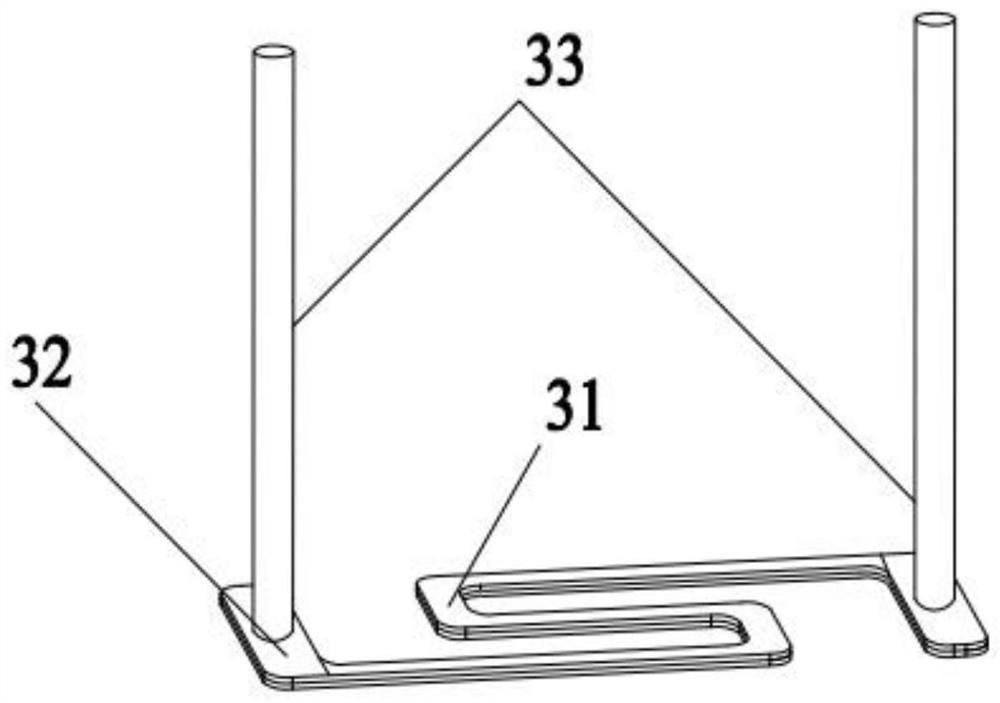

Bridge health monitoring supporting base and monitoring method thereof

PendingCN107059606AAvoid the problem of inaccurate force measurementImprove yield rateForce measurementBridge structural detailsArchitectural engineeringMechanical engineering

The invention discloses a bridge health monitoring supporting base. The bridge health monitoring supporting base comprises an upper supporting base plate and a lower supporting base plate, a middle liner plate is arranged between the upper supporting base plate and the lower supporting base plate, a basin cavity is formed in the top face of the lower supporting base plate, an oil cavity is formed in the basin cavity, an elastic layer is arranged at the top of the oil cavity, at least two oil ways communicated with the oil cavity are formed in the side face of the lower supporting base plate, any oil way is provided with a pressure sensor, a travel switch is arranged on the lower supporting base plate and provided with a contact, and the contact selectively makes contact with the upper supporting base plate. The bridge health monitoring supporting base is capable of overcoming defects in the prior art, reduces construction complexity of bridge health monitoring and improves bridge monitoring accuracy.

Owner:CHINA RAILWAY DESIGN GRP CO LTD +1

Sewing machine

InactiveCN107858790AReduce frequent exerciseNot easy to aging and damageLubrication/cooling devicesPressersElectromagnetSewing machine

The invention relates to the technical field of sewing equipment, in particular to a sewing machine. The upper end of a top rod is hinged to a lifting presser foot rear lever, the middle of the lifting presser foot rear lever is hinged to a machine shell, the back end of the lifting pressing pedal back lever is connected with an electromagnet, and the front end of the lifting pressing pedal back lever is connected with a lifting pressing pedal front lever through a pull rod; the lifting pressing pedal front lever is connected with a press rod, a boss is arranged in an oil sealing disc, and a through hole which runs through the oil sealing disc is formed in the boss; an oil sealing cap is arranged on the boss, the sealing cap comprises a cap body and a rod part, the lower end of the rod part extends out of the oil sealing disc through the through hole in the boss, and a spring and a limit part are arranged at the lower end of the rod part; one end of the spring abuts against the limit part, the other end of the spring abuts against the bottom plane of the oil sealing disc, and the cap body is connected with a sealing part which is used for preventing the through hole in the boss from leaking oil; the lower end of the top rod penetrates through a baseplate and is located above the oil sealing cap, and the oil sealing cap is driven by a jacking device to move up and down to drivethe top rod to up and down move. According to the sewing machine, frequent movement of the oil sealing cap is reduced, so that the oil sealing cap is not easily aged and damaged, and the risk of oil leakage is reduced.

Owner:JACK SEWING MASCH CO LTD

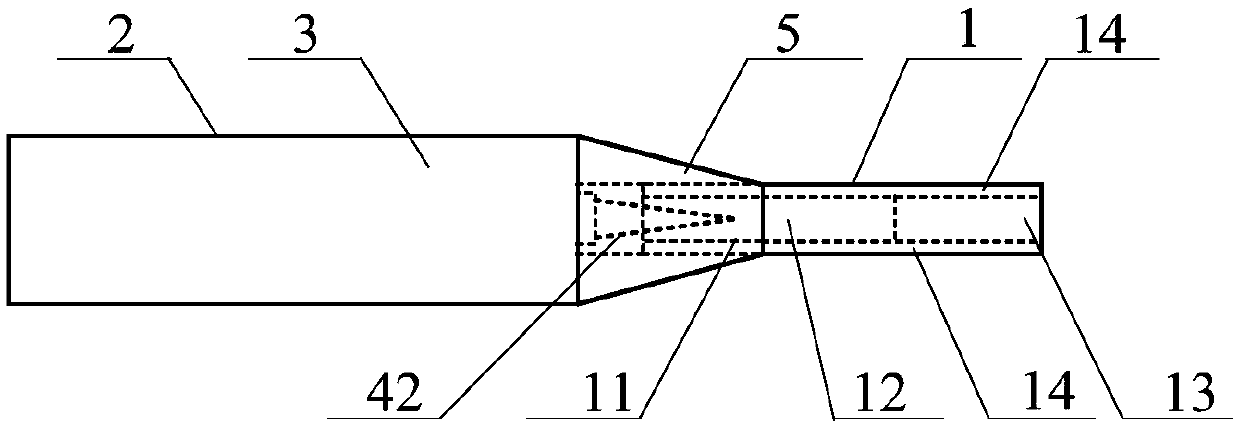

Atomizing core and smoke cartridge

An atomizing core comprises a shell provided with a vertically-through containing cavity, a porous body wrapped in the containing cavity of the shell and a heating element arranged on the bottom face of the porous body, the porous body comprises a first surface making contact with atomized liquid and a second surface opposite to the first surface, the first surface is a liquid absorbing surface, the second surface is an atomizing surface, the heating element is arranged on the atomizing surface, the atomized liquid permeates to the atomizing surface from the liquid absorbing surface, the heating element on the atomizing surface is used for heating, and heat is conducted into the porous body to atomize the atomized liquid. The invention further discloses a smoke cartridge.

Owner:DONGGUAN ALPHA ELECTRONICS TECH CO LED

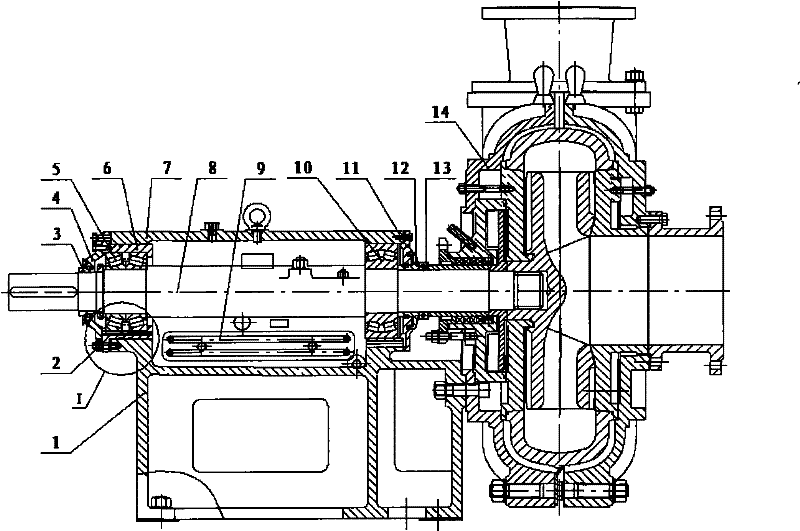

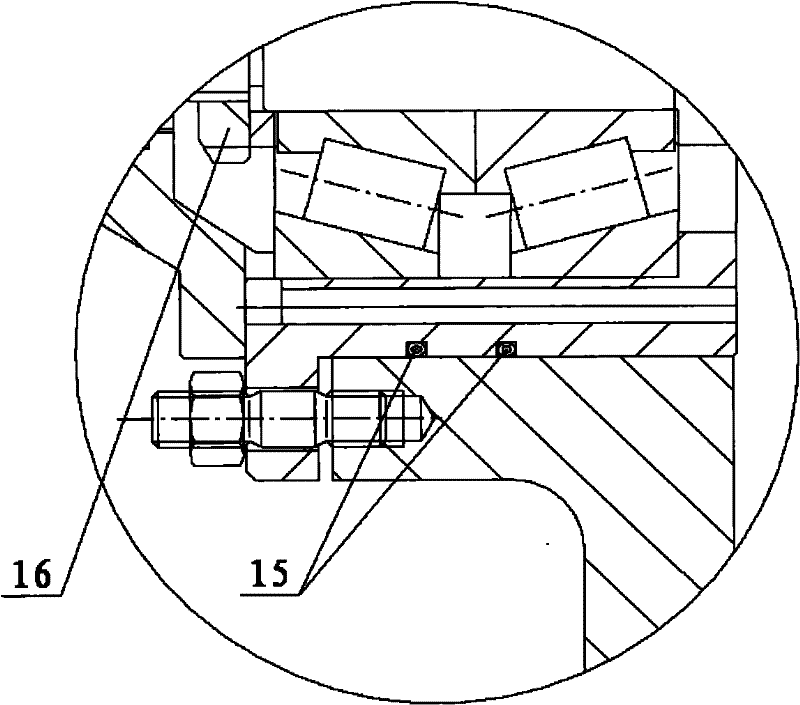

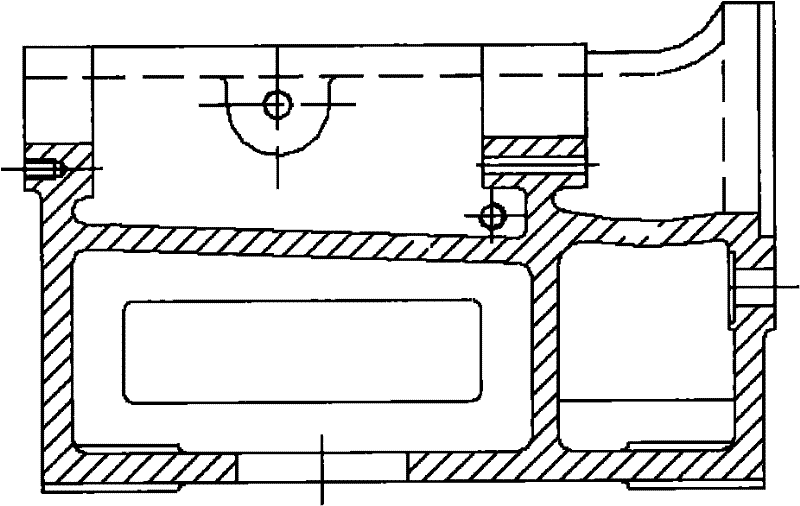

Bearing box of heavy slurry pump and shafting transmission structure thereof

ActiveCN102242727AGuaranteed coaxialityReduce the amount of processingSpecific fluid pumpsPump componentsImpellerEngineering

The invention discloses a bearing box of a heavy slurry pump and a shafting transmission structure thereof and particularly relates to an integral bearing box of a horizontal abrasion-resistant slurry pump and a shafting transmission structure thereof, which belongs to the field of a mechanical transmission technique. The shafting transmission structure disclosed by the invention comprises a pumpshaft, a cooler, a front bearing gland, a rear bearing gland, a front dustproof disk, a rear dustproof disk, a carrier, a bearing box, a second regulating bolt, rear locking stud nuts and a compression ring. In order to reduce the machining area and matching area among a carrier body, a bearing bush and a carrier cover, the bearing bush and the carrier cover are cast into an integral; in order toconveniently regulate the gap between an impeller and an flow passage component, the arrangement of the second regulating bolt is optimized; and a second shaft regulating bolt is changed to be arranged between the rear lower end of the bearing box and the rear rib plate of the carrier, and the regulating space is enlarged, therefore thicker and longer bolts, studs and nuts can be adopted, therebyenlarging the regulating space. In the invention, the machining load can be reduced; the machining cost is lowered; the machining and finishing accuracy is improved; the oil leakage risk is reduced; and the coaxially of the bearing box and the carrier can be better guaranteed.

Owner:XIANGYANG WU ER WU PUMP IND

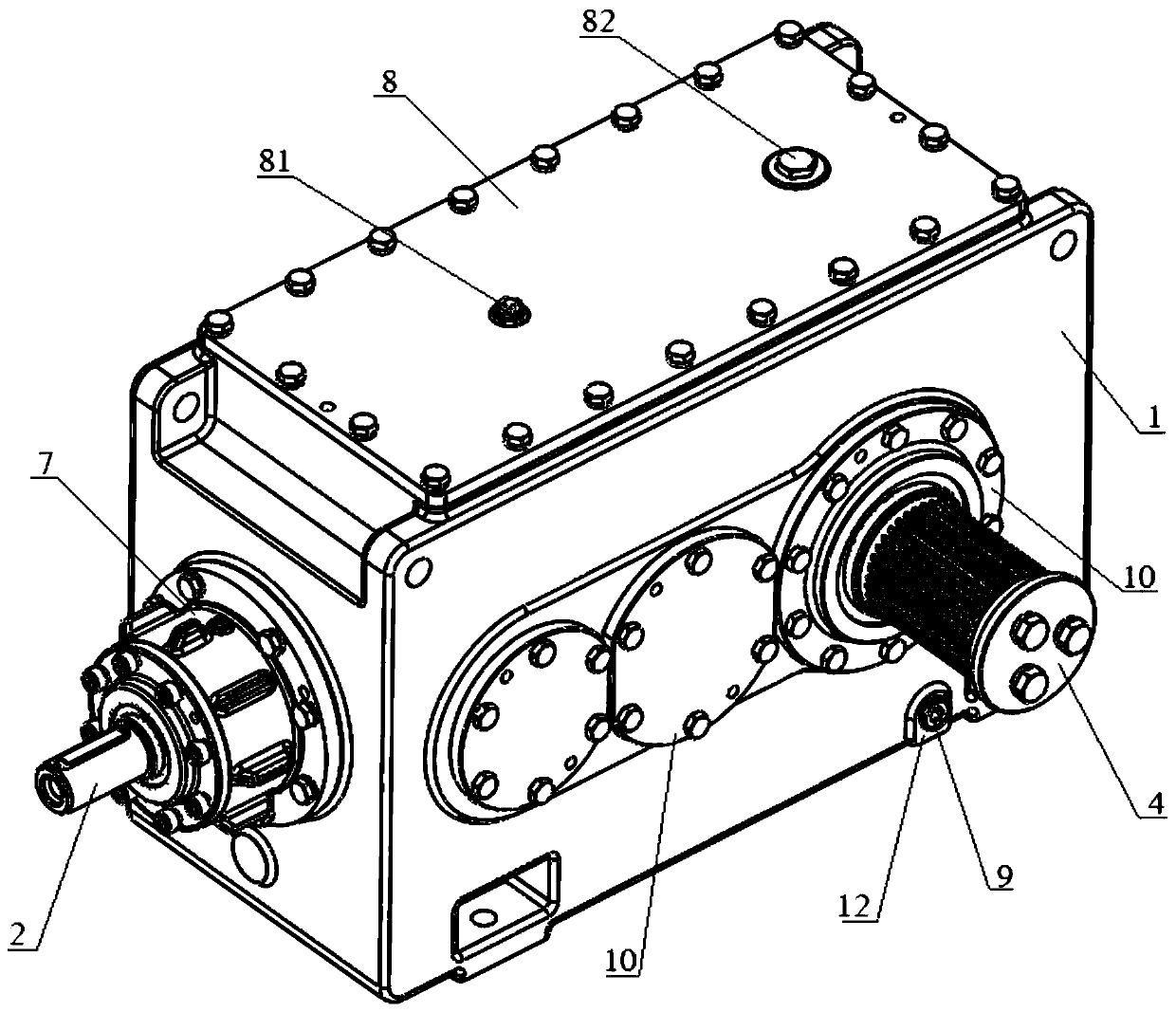

Efficient lightweight speed reducer for tower crane

PendingCN110065896AReduce weightReduce joint surfaceGear lubrication/coolingWinding mechanismsReduction driveReducer

The invention discloses an efficient lightweight speed reducer for a tower crane. The speed reducer comprises a whole box body, an input shaft, a transmission assembly and an output shaft, wherein theinput shaft, the transmission assembly and the output shaft are sequentially engaged for transmission, the end, extending out of the box body, of the output shaft is of a spline structure, a first convex stop opening is preset on a cover plate of the output shaft and is matched with a first concave stop opening of a winding cylinder spline sleeve, and a second convex stop opening is preset on anouter circle shaft of the end, extending out of the box body, of the output shaft, and is matched with a second concave stop opening of the winding cylinder spline sleeve; an oil tank is formed in thebox body, the inner wall of the oil tank forms a first oil collection groove and a first oil way, the first oil way passes through the transmission assembly and / or a bearing of the output shaft, oneend of the first oil way communicates with the first oil collection groove, the other end of the first oil way communicates with an oil tank inner cavity, the box body is connected with a high-speed end bearing pedestal, a second oil collection groove and a second oil way are formed on the high-speed end bearing pedestal, the second oil way passes through an inner cavity of the high-speed end bearing pedestal, one end of the second oil way communicates with the second oil collection groove, and the other end of the second oil way communicates with the oil tank inner cavity.

Owner:CHENGDU JIUHE CONSTR EQUIP

Electronic cigarette

ActiveCN107772536AQuick changePrevent oxidative deteriorationTobacco devicesElectronic cigaretteEngineering

The invention discloses an electronic cigarette which comprises a device and a cigarette. The device comprises a shell, a power part, a heating part and a clamping part. The heating part is detachablyconnected with the shell, and the clamping part is detachably connected with the heating part or the shell. The heating part and the clamping part are matched when the heating part is inserted in theclamping part. The cigarette comprises a liquid storage part, a cigarette holder part and a cigarette package part, wherein the liquid storage part and the cigarette holder part are communicated witheach other. The liquid storage part comprises a medium capable of adsorbing cigarette liquid and the cigarette liquid capable of being adsorbed by the medium. The cigarette is contained and supportedby the clamping part. The device and the cigarette are matched when the heating part is inserted in the liquid storage part. During sucking, the liquid storage part is inserted in the device, and smoke is generated through heating and allowed to be felt by a smoker; when smoking ends, the next round of sucking can be conducted by replacing the cigarette. The electronic cigarette is simple in structure, sanitary in sucking, good in imitation feeling, convenient to use, environmentally friendly and rapid in cigarette replacing and has wide application prospects, and the cigarette liquid oxidative deterioration and liquid leakage risks are greatly reduced.

Owner:CHINA TOBACCO HUNAN INDAL CORP

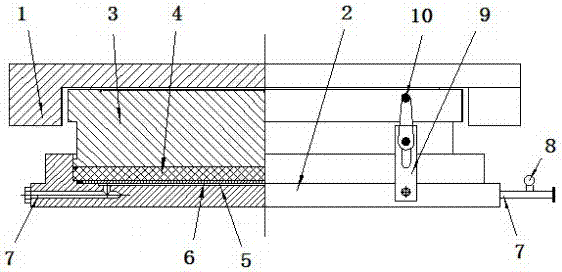

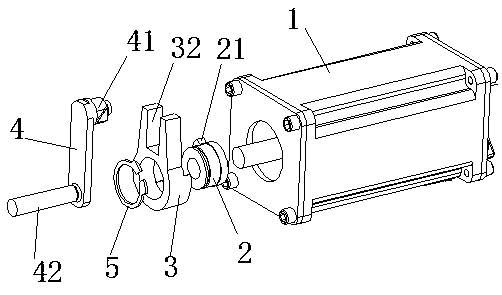

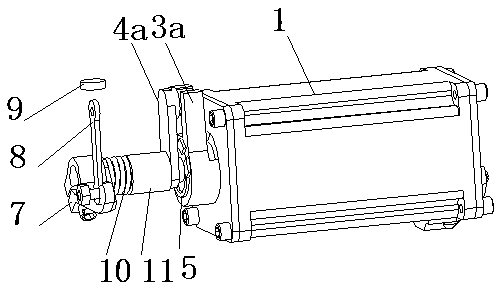

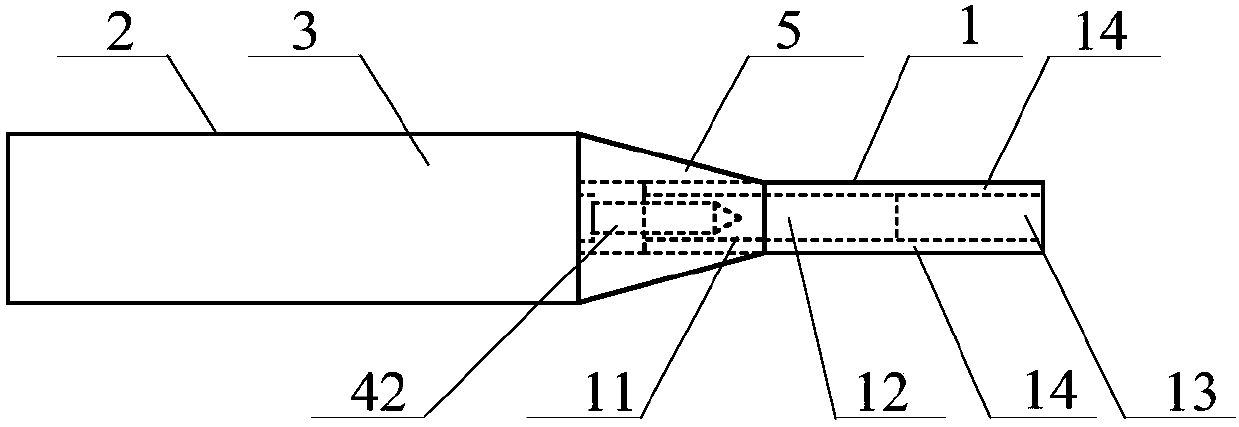

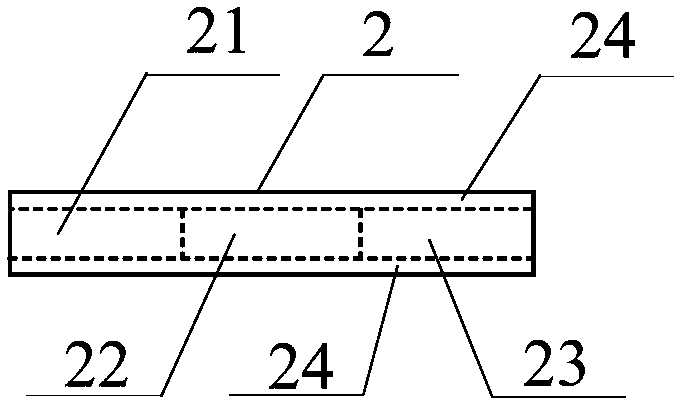

Thread shearing or presser foot lifting drive mechanism of sewing machine and thread shearing or presser foot lifting device

PendingCN111074441AImprove stabilityReduce shakingNeedle severing devicesSewing-machine control devicesCrankElectric machinery

The invention discloses a thread shearing or presser foot lifting drive mechanism of a sewing machine. The drive mechanism comprises a motor, a clutch mandrel, a clutch yoke and a drive crank. A motordrive mode replaces a high-power electromagnet, the clutch mandrel with a short force arm is adopted and the clutch yoke is driven to rotate by output of a motor shaft, so that the effect of the large torque on the motor shaft due to a long moment arm of a cam or the crank is reduced, and the overall transmission stability and reliability are high. In addition, the invention discloses a thread shearing or presser foot lifting device. The actions of a thread shearing mechanism and a presser foot lifting mechanism are controlled through a double-end motor, and compared with the prior art, drivesources are reduced, the structure is simpler, the occupied space is small, installation is convenient, and the cost is reduced; moreover, compared with an electromagnet, motor drive has the advantages that the noise is reduced; and further, by combination with an anti-vibration pad, the stability of the whole device is improved, and shake and noise are reduced.

Owner:台州市福崎缝纫机有限公司

Sheet-shaped heating-type electronic cigarette

The invention discloses a sheet-shaped heating-type electronic cigarette. The electronic cigarette comprises an appliance and a cigarette body. The appliance comprises a shell, a power supply part, aheating part and a clamping part; the heating part comprises a sheet-shaped insertion supporting part and heating elements; the cigarette body comprises a liquid storage part, a suction nozzle part and a cigarette body packaging part; the liquid storage part comprises a medium which can adsorb tobacco tar and the tobacco tar which is adsorbed by the medium; the clamping part can contain and support the cigarette body, and the appliance is matched with the cigarette body in the mode that the insertion supporting part is inserted into the liquid storage part. During suction, the liquid storage part which contains the tobacco tar is inserted into the appliance and is heated, so that smoke is generate and sensed by a smoker; after suction, a next round of suction can be conducted by replacingthe cigarette body. The heating elements can be arranged on a single surface or double surfaces of the insertion supporting part, so that the atomizing capacity of the sheet-shaped heating-type electronic cigarette for the tobacco tar is greatly improved. The sheet-shaped heating-type electronic cigarette is simple in structure, is sucked hygienically, and is good in simulation sense, convenient to use and environmentally friendly, the cigarette body is replaced rapidly, the risks of oxidative deterioration and tar leakage of the tobacco tar are greatly lowered, and the sheet-shaped heating-type electronic cigarette has broad application prospects.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Fuse with sleeve structure and mounting method

ActiveCN103268847AAchieve protectionAchieve electrical connectionElectric component structural associationEmergency protective devicesElectricityPower cable

The invention provides a fuse with a sleeve structure and a mounting method, aims to overcome the defects that a transformer leaks oil and is easily subjected to hot-line work, caused by installation manners of a sleeve and a fuse of a transformer in the prior art, and provides the fuse with the sleeve structure. The sleeve comprises an inner sleeve, an outer sleeve and a sleeve inner protection cover, wherein the inner sleeve is internally provided with a fuse inserting hole; the fuse is inserted into the fuse inserting hole; the sleeve inner protection cover covers outside the inner sleeve and tightly presses the fuse; the outer sleeve covers the inner sleeve and the sleeve inner protection cover; and the outer sleeve is fixedly connected with the inner sleeve. The invention further provides a mounting method of the fuse. The mounting method comprises the following steps: A, inserting the fuse into the inner sleeve; B, fastening the fuse into the inner sleeve; C, fixedly mounting the fuse with the sleeve structure on a box body of the transformer; D, electrically connecting a power cable and the fuse; and E, electrically connecting a high-voltage side winding with the fuse. According to the fuse with the sleeve structure and the mounting method disclosed by the invention, the volume of the transformer is reduced and the risk of leaking oil is reduced; and the fuse is applicable to the circumstance using the transformer.

Owner:深圳市罗庚电气有限公司

Tar leakage preventing structure and method for electronic cigarette

The invention discloses a tar leakage preventing structure for an electronic cigarette. The structure comprises a cigarette cartridge, wherein an atomizing assembly is arranged in a central axis, an tar tank is arranged on an outer ring of the atomizing assembly in a sleeving manner, sealing silica gel is arranged in the middle of the tar tank, and a base is arranged on the outer side of the sealing silica gel; a battery case is a tubular case, and the top end of the battery case is contacted with the tar tank; a battery holder is arranged in the battery case; a spring pin is arranged at the top end of the battery holder; the atomizing assembly is arranged in the middle of the cigarette cartridge and slides in the axis direction; the atomizing assembly comprises a gas tube, tar inlet holesdistributed in the circumferential ring of the gas tube and a conductive pin arranged at the end part of the gas tube; tar guide cotton is arranged in the position, closely adjacent to the tar inletholes, of the circumferential ring of the inner wall of the gas tube. According to the technical characteristic that the atomizing assembly arranged in the middle of the cigarette cartridge can slidein the axial direction, the atomizing assembly moves to the corresponding positions in different use states and has the advantage that the tar outlet condition is flexibly controlled according to usage scenes; tobacco tar is sealed by the sealing silica gel, so that the tobacco tar can be prevented from leaking before use by a consumer, and tar leakage risk of a product is greatly reduced.

Owner:SHENZHEN YIYOU INT TECH

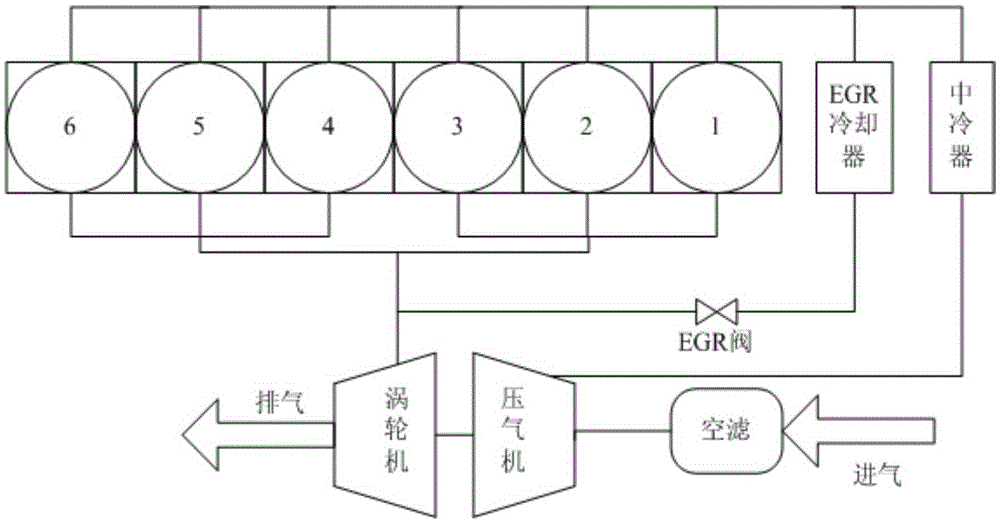

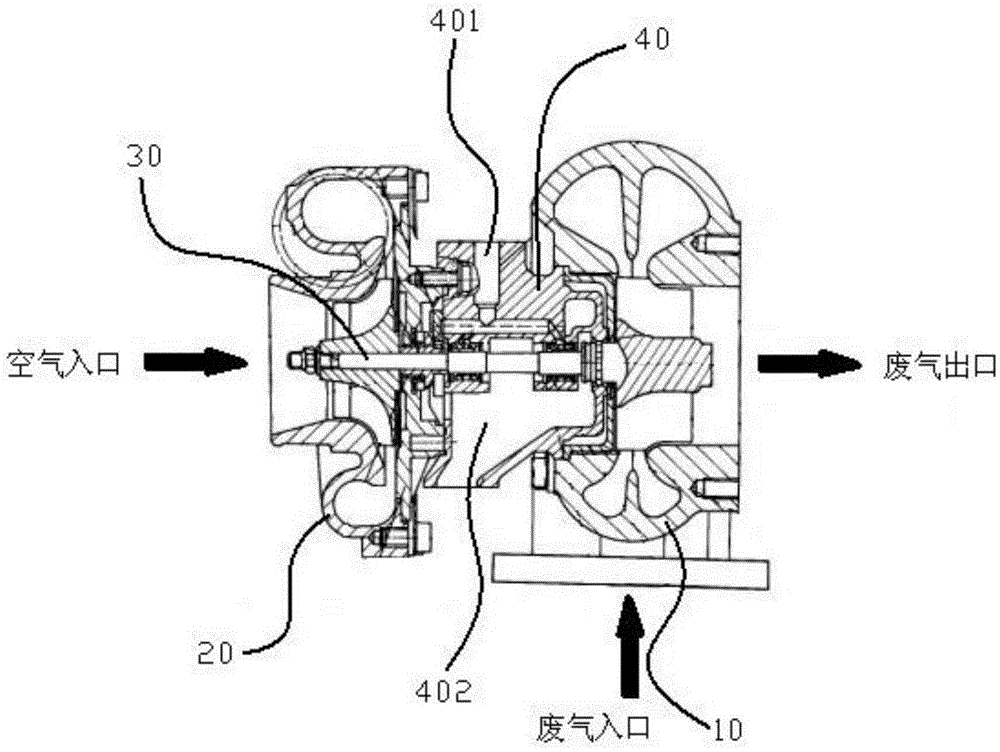

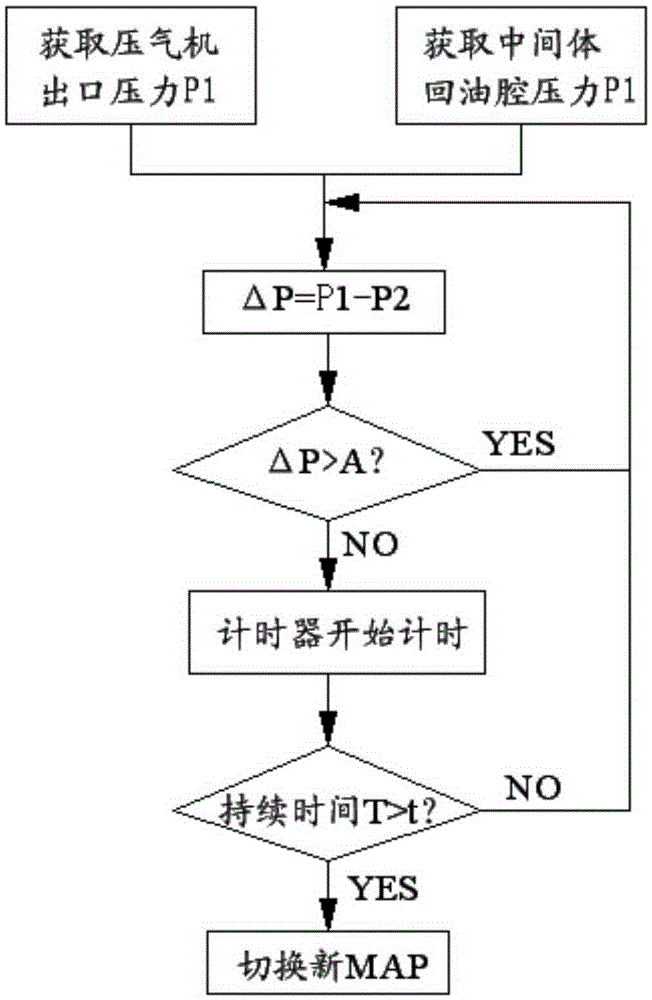

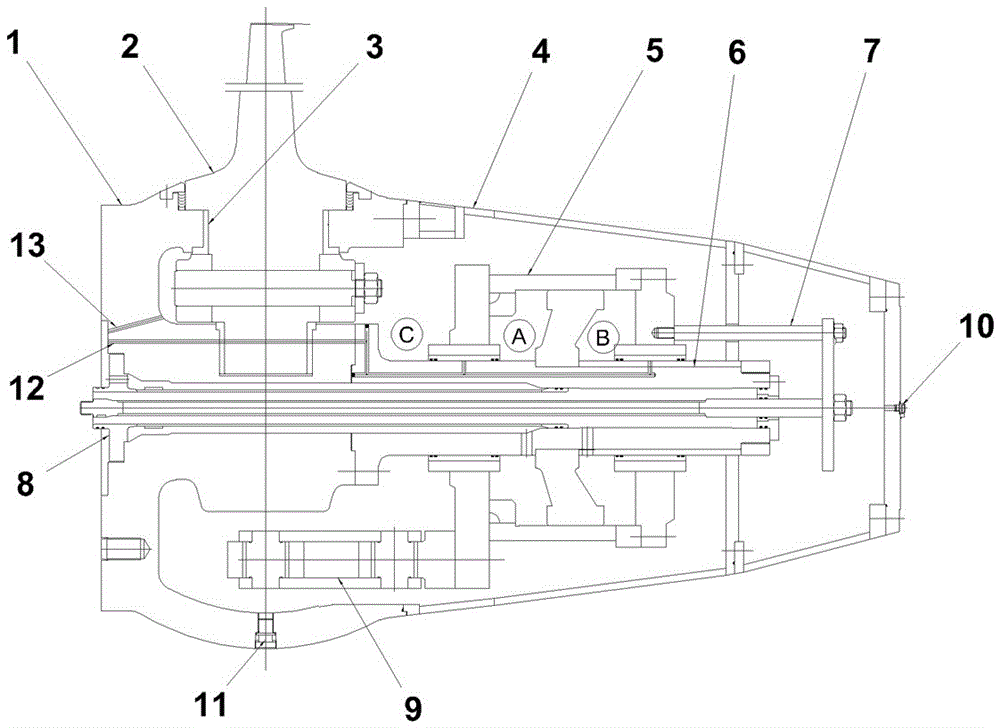

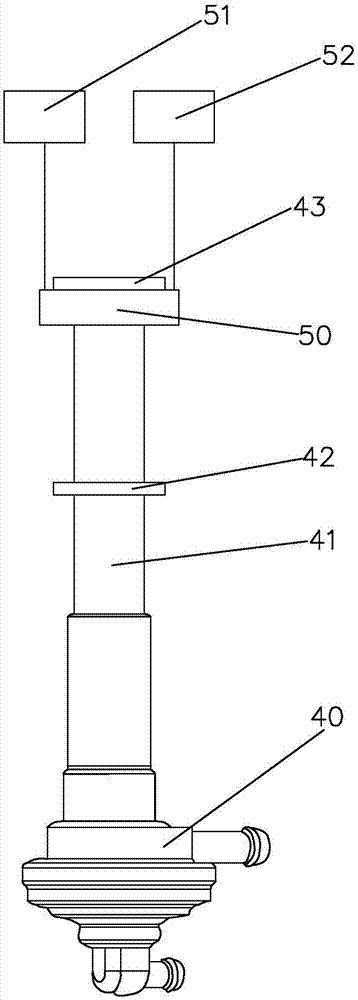

Turbocharger device and control method for reducing oil leakage risk of turbocharger

InactiveCN105332792AIncrease speedReduce the risk of oil spillsMachines/enginesEngine componentsImpellerTurbocharger

The invention discloses a turbocharger device and a control method for reducing the oil leakage risk of a turbocharger. The method comprises the following steps that the back pressure of an impeller of a compressor and pressure of an oil returning cavity of an intermediate body are obtained; and the back pressure of the impeller and the pressure of the oil returning cavity of the intermediate body are compared, and when the back pressure of the impeller is not larger than the pressure of the oil returning cavity, the rotating speed of the compressor is increased. According to the turbocharger device and the control method for reducing the oil leakage risk of the turbocharger, the pressure difference between the back pressure of the impeller and the pressure of the oil returning cavity of the intermediate body can be obtained in real time by obtaining the back pressure of the impeller and the pressure of the oil returning cavity of the intermediate body. According to the pressure difference, whether the turbocharger is in a risk area where oil leakage will happen or not is judged in real time, and before oil leakage happens, the measure that the rotating speed of the compressor is increased to increase the back pressure of the impeller is taken so as to improve the pressure difference, and oil leakage is prevented. Compared with the prior art, the oil leakage risk can be obviously reduced, and driving safety is improved.

Owner:WEICHAI POWER CO LTD

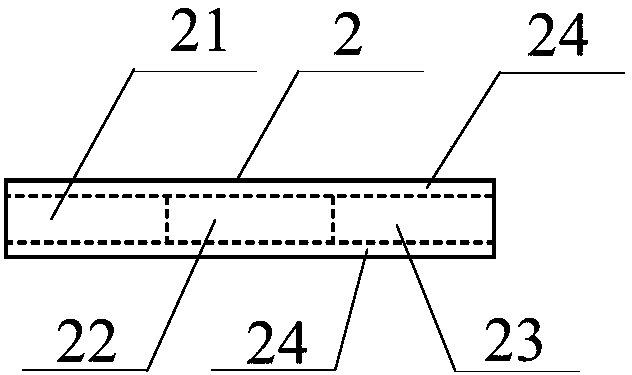

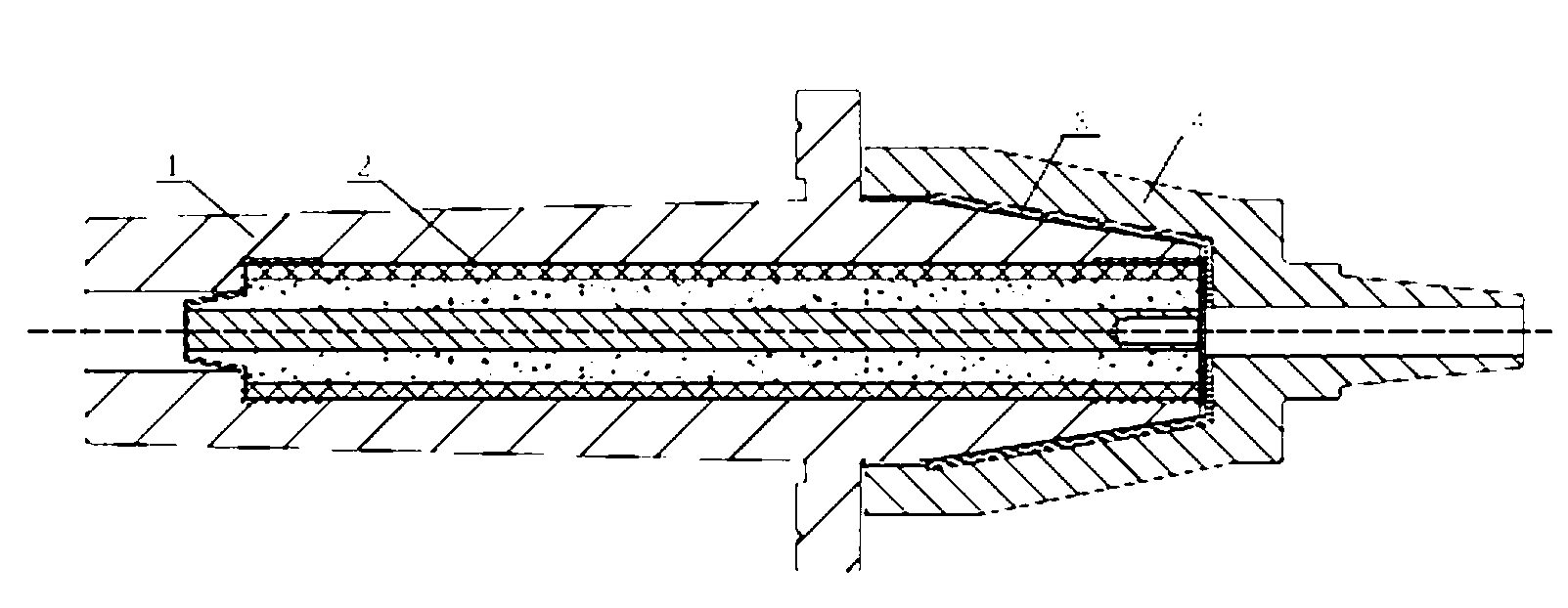

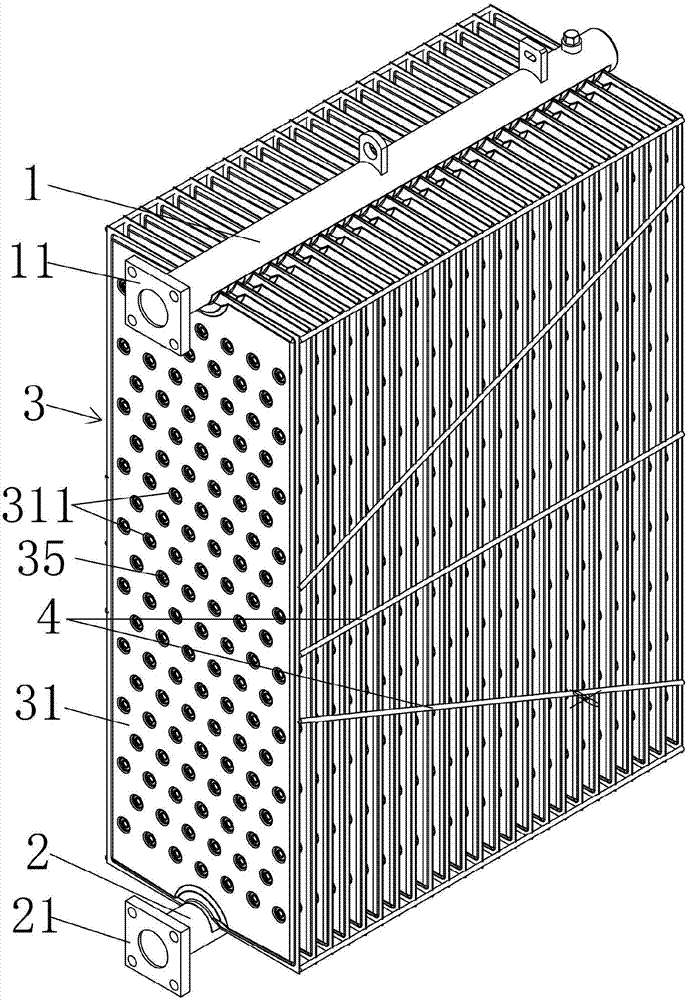

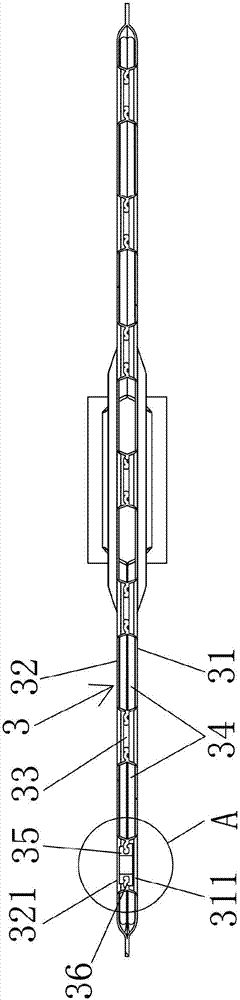

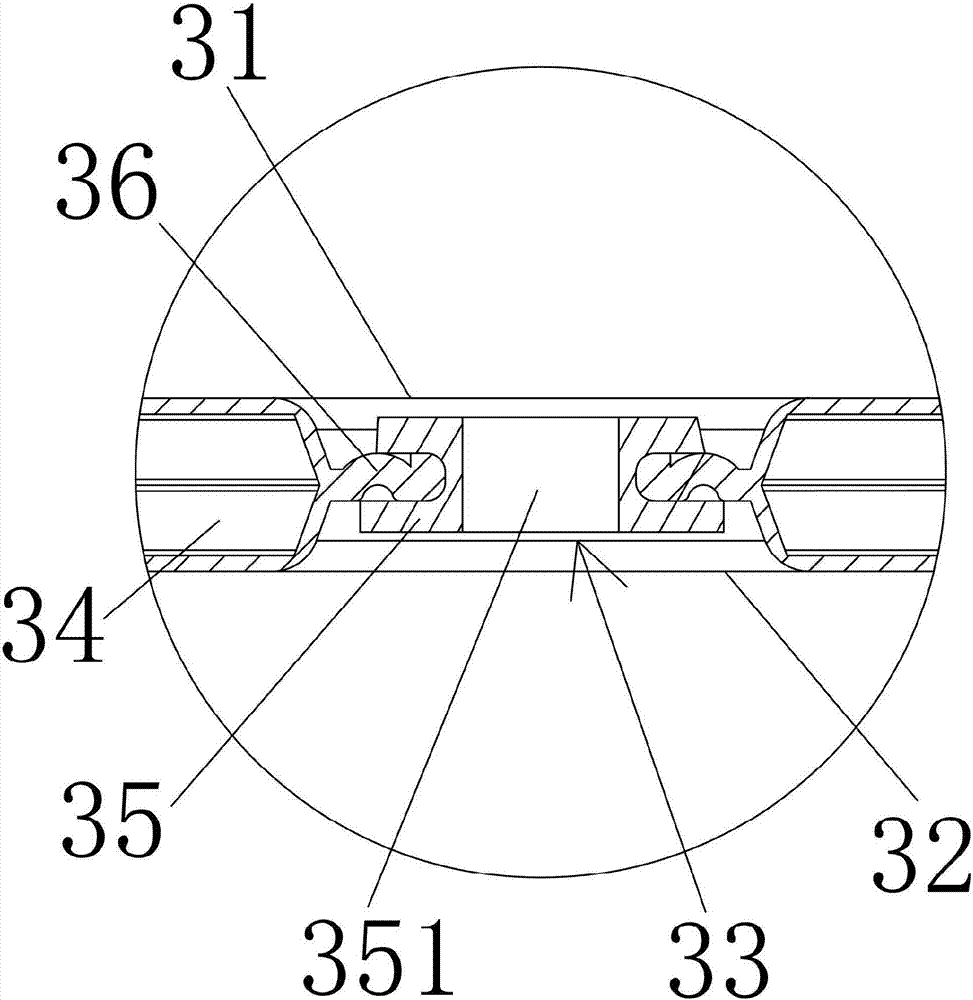

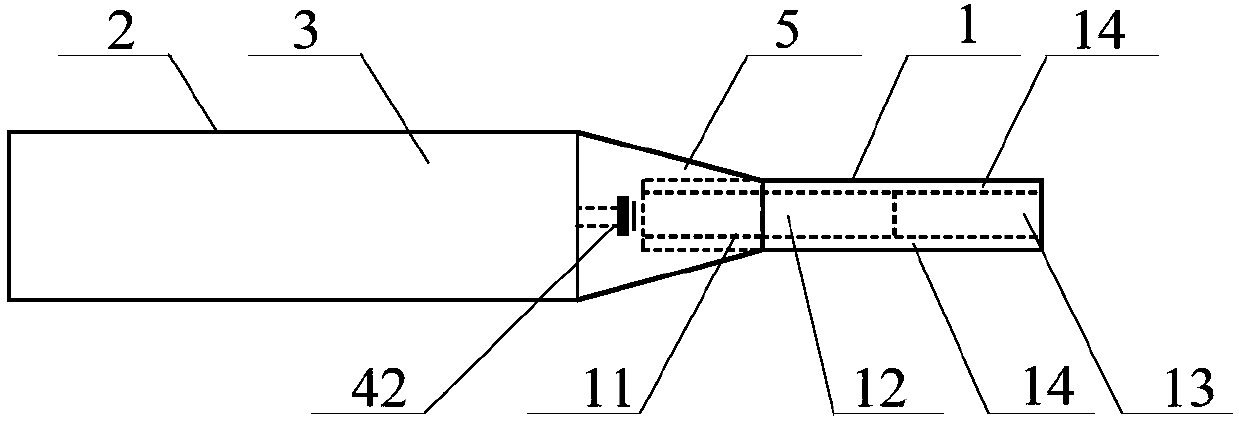

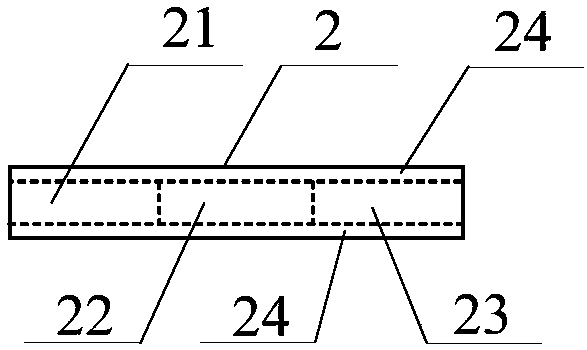

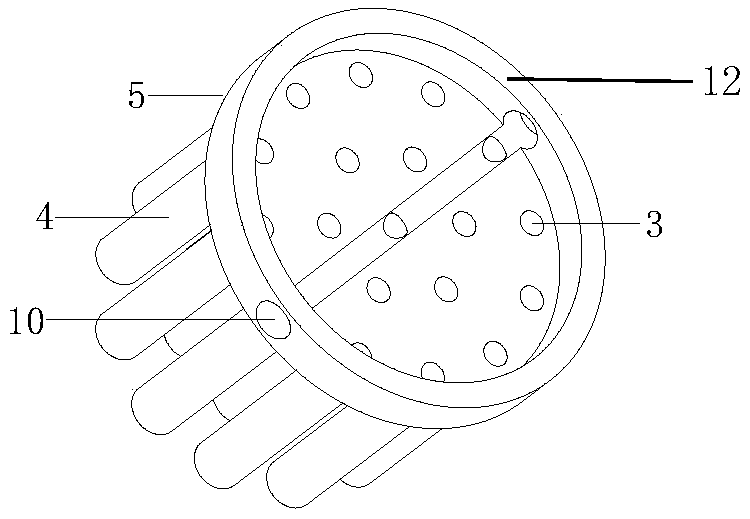

Sheet-shaped heat sink capable of high-efficiency heat dissipation

ActiveCN107103979AHigh compressive strengthReduce the risk of oil spillsTransformers/inductances coolingCooling effectEngineering

A sheet-shaped heat sink capable of high-efficiency heat dissipation comprises an oil inlet pipe, an oil outlet pipe and a group of cooling fins, wherein the cooling fins comprise a front cooling fin and a rear cooling fin, the sheet-shaped heat sink is characterized in that front flanging holes and rear flanging holes are formed in the front cooling fin and the rear cooling fin, a plurality of front flanging holes in horizontal lines are arranged at intervals from top to bottom, the front flanging holes in each horizontal line are isolated from one another, the positions of the front flanging holes on an upper horizontal line and a lower horizontal line which are adjacent to each other are staggered, the numbers of the front flanging holes and the rear flanging holes are same, the positions of the front flanging holes and the rear flanging holes are in correspondence, edges of the front flanging holes and the rear flanging holes which are in correspondence in positions are punched and integrated to a whole, a rivet hole is formed between the edges, a rivet is arranged in the rivet hole, and a heat dissipation oil duct between the front cooling fin and the rear cooling fin is partitioned to from staggered runners by the edges, which are punched and integrated, of the front flanging holes and the rear flanging holes. Secondary flow will be generated when transformer oil passes through the staggered runners, a hot oil boundary layer is broken, and the cooling effect is achieved; and the risk of oil leakage from the edges of the flanging holes is reduced, the pressure resistant strength of the cooling fins is improved, and the convective heat exchange coefficient is improved.

Owner:CHANGSHU YOUBANG RADIATOR

Heating element attached type electronic cigarette

The invention discloses a heating element attached type electronic cigarette which comprises a device and a cigarette body. The device comprises a shell, a power part, a heating part and a clamping part. The cigarette body comprises a liquid storage part, a cigarette holder part and a cigarette package part. The liquid storage part comprises a medium capable of adsorbing cigarette liquid and the cigarette liquid capable of being adsorbed by the medium. The cigarette body is contained and supported by the clamping part. The heating part comprises a horizontal heating element. The device and thecigarette body are matched when the cigarette body is inserted in the device. The liquid storage part makes contact with the heating element after the cigarette body is inserted in the device. Duringsucking, the liquid storage part is inserted in the device, and smoke is generated through heating and allowed to be felt by a smoker; when smoking ends, the next round of sucking can be conducted byreplacing the cigarette body. The heating element makes contact with the liquid storage part and can conduct heating through sucking and does not need to be inserted in the liquid storage part, and cigarette deformation can be prevented. The electronic cigarette is simple in structure, sanitary in sucking, good in imitation feeling, convenient to use, environmentally friendly and rapid in cigarette replacing and has wide application prospects, and the cigarette liquid oxidative deterioration and liquid leakage risks are greatly reduced.

Owner:CHINA TOBACCO HUNAN INDAL CORP

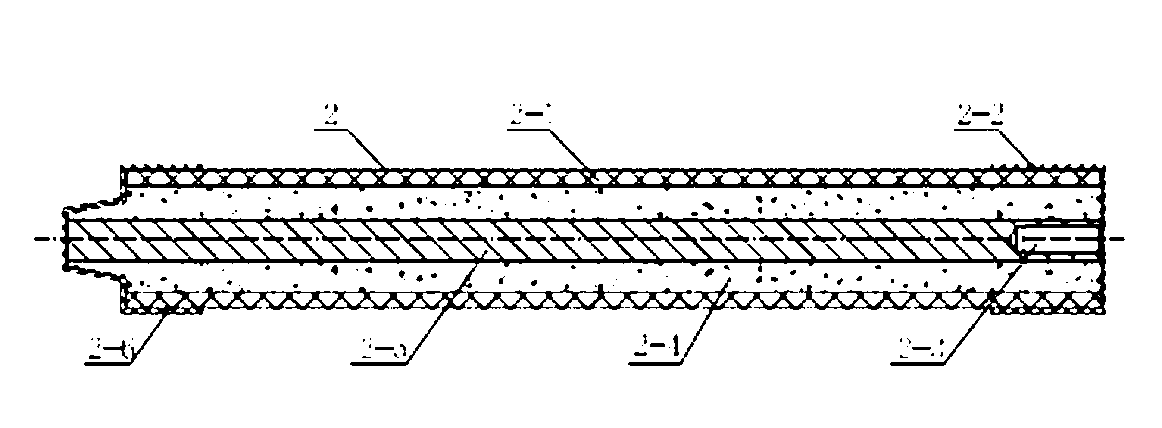

Oil-free lubrication Kaplan turbine runner

ActiveCN105545567AMonitor seal operationGuaranteed uptimeEngine fuctionsHydro energy generationOil freeEngineering

The invention discloses an oil-free lubrication Kaplan turbine runner. The oil-free lubrication Kaplan turbine runner comprises a hub body, a blade and a blade servomotor; a water injecting hole is formed in one side of the hub body for injecting clear water or other environment-friendly liquid in a hub before an unit is operated; a drain hole is formed in the bottom of the hub body for draining water in maintenance; the blade servomotor includes a cylinder body, a cylinder cover, a cavity and a piston rod; the cylinder body or the piston rod is connected with the blade through a blade connecting rod mechanism; a blade inner and outer shaft sleeve is arranged between the blade and the hub body; and shaft sleeves on the blade inner and outer shaft sleeve, the blade servomotor and the blade connecting rod mechanism are all self-lubricating bearings. The oil-free lubrication Kaplan turbine runner can adopt the water to replace lubricating oil in a conventional runner hub body, adopts the self-lubricating bearings suitable for the runner operation environment as bearings of a runner motion pair and a friction pair to enable the runner to smoothly operate without polluting rivers, adopts an anti-leaking measure to reduce the risk of the runner leaking oil to the rivers, and can be widely applied to axial flow type and cross flow type Kaplan turbines.

Owner:浙江富春江水电设备有限公司

Needle-like heating electronic cigarette

The invention discloses a needle-like heating electronic cigarette. The cigarette includes a device and a cigarette body, and the device includes a shell, a power source part, a heating part and a clamping part; the heating part includes a needle-like insertion supporting part and a heating element; the cigarette body comprises a liquid storage part, a nozzle part and a cigarette packing part, andthe liquid storage part includes a soft structure, tobacco tar and a medium capable of adsorbing the tobacco tar; the device and the cigarette body are matched with each other by inserting the insertion supporting part into the liquid storage part. During smoking, the liquid storage part containing the tobacco tar is inserted into the device and heated to generate smoke for a user to enjoy; aftersmoking, the cigarette body is replaced, and then the electronic cigarette can be used for smoking at the next time. The insertion supporting part with a needle-like top end can be more easily inserted into the liquid storage part, the problem that the tobacco tar leaks to the cigarette packing part and the nozzle part is solved, and the heating efficiency is much higher. The needle-like heatingelectronic cigarette is simple in structure, sanitary during smoking, great in simulation performance, convenient to use and environmentally friendly, the cigarette body is fast to replace, and the oxidative deterioration risk of the tobacco tar and the tar leakage risk are substantially reduced, so that the needle-like heating electronic cigarette has a wide application prospect.

Owner:CHINA TOBACCO HUNAN INDAL CORP

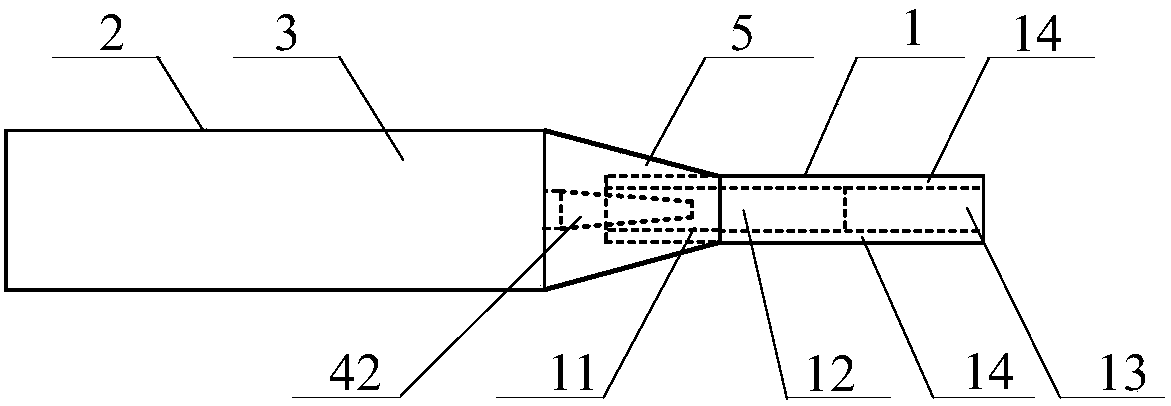

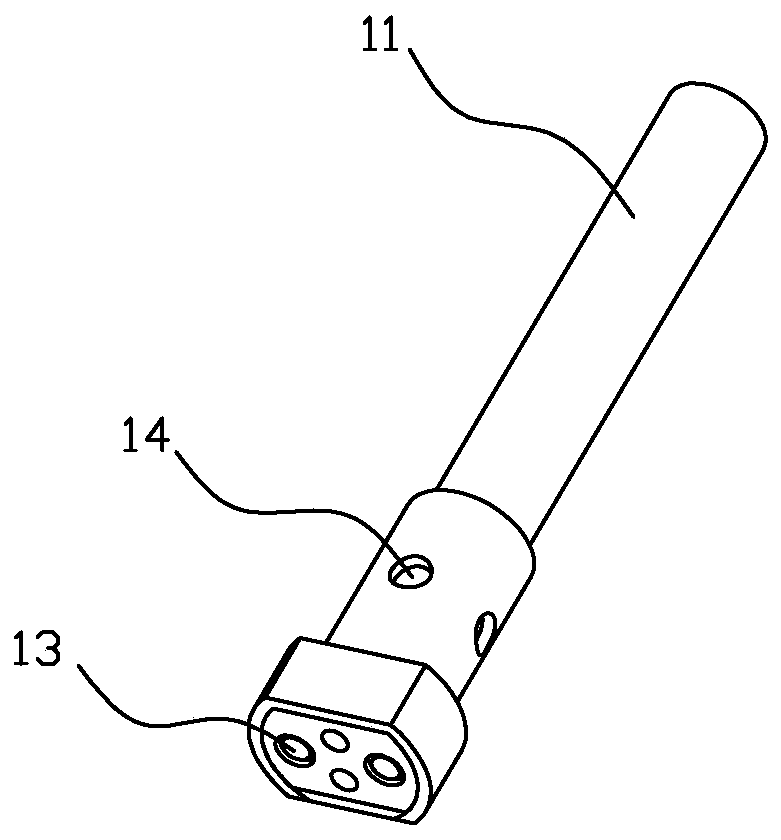

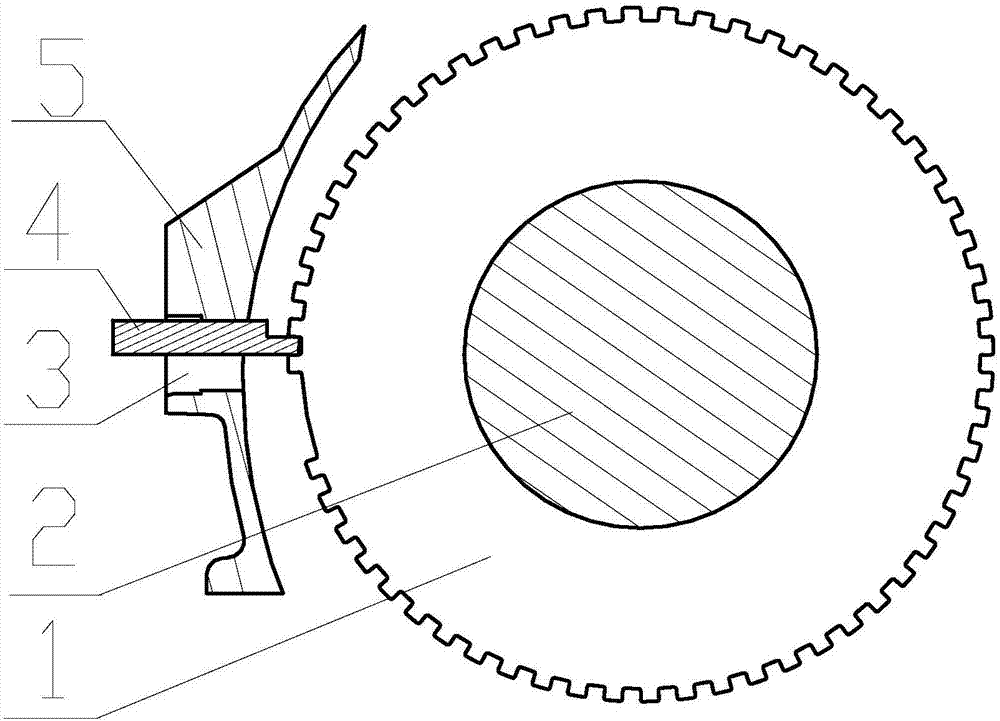

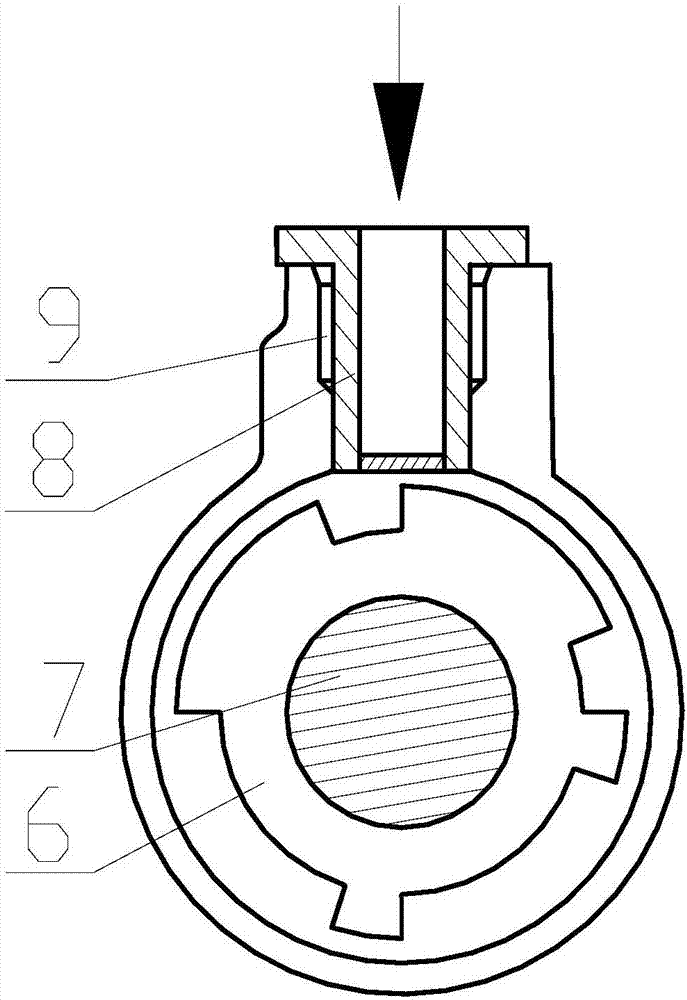

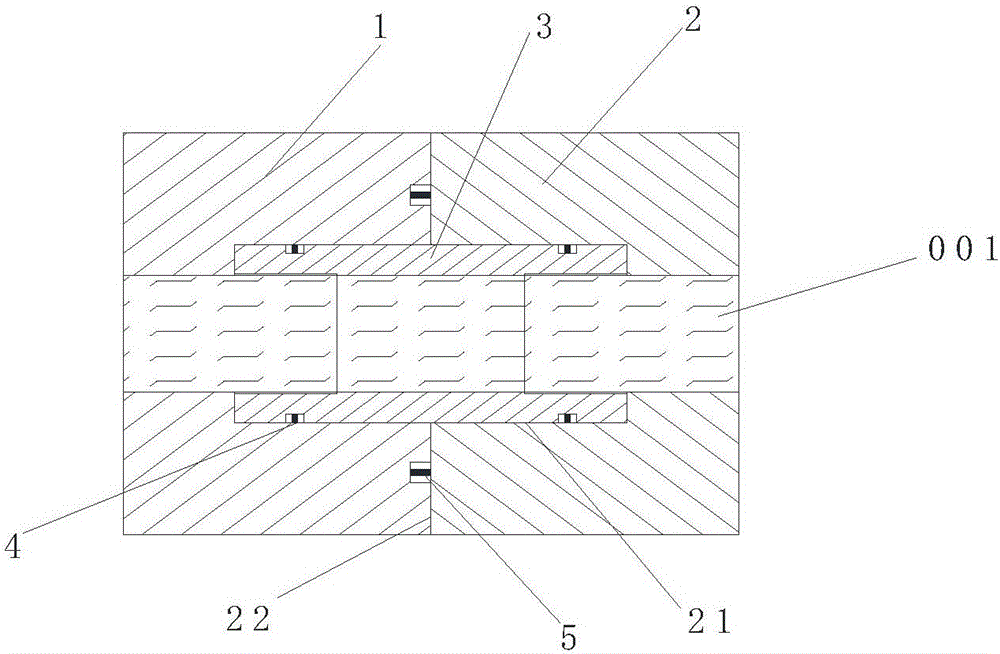

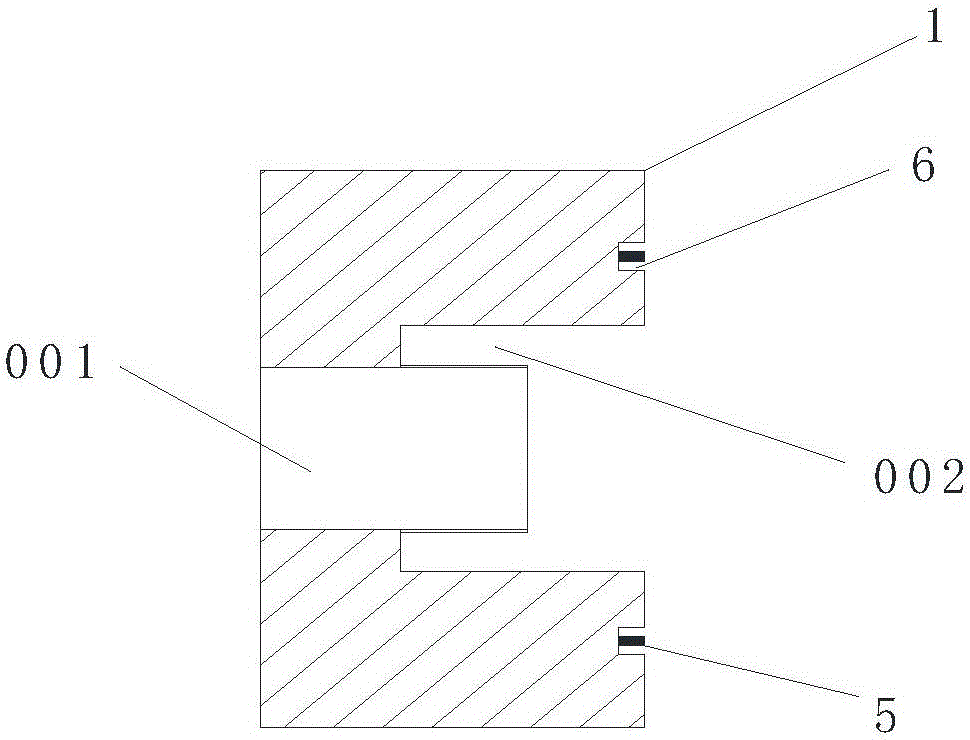

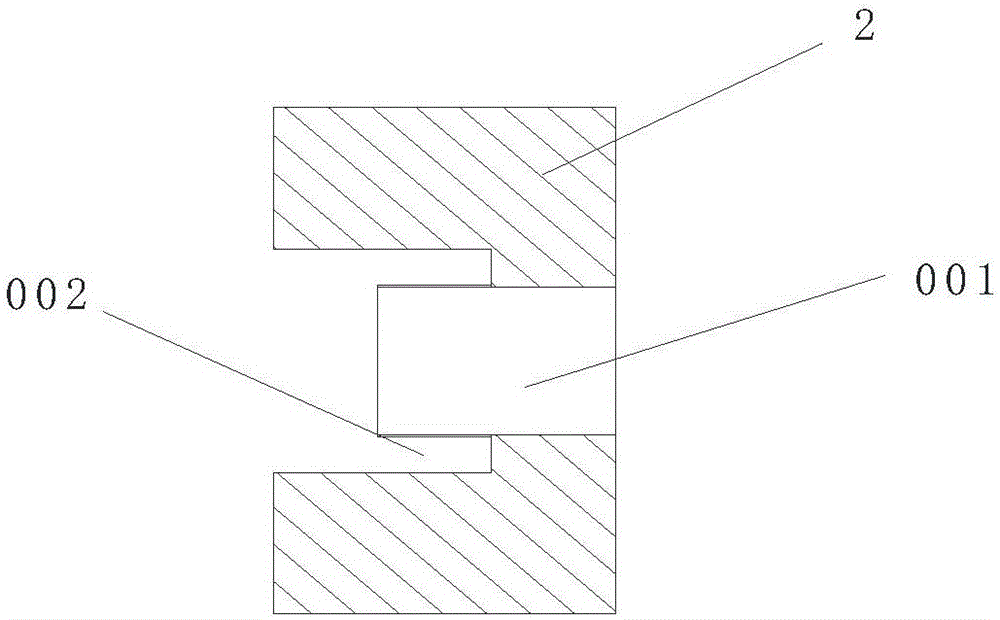

Engine correct timing system inspection tool and method thereof

InactiveCN106885699AReduce the risk of oil spillsReduce workloadInternal-combustion engine testingEngineeringTiming system

The invention discloses an engine correct timing system inspection tool. The inspection tool comprises a crankshaft position fixing component and a camshaft phase inspection component. The crankshaft position fixing component comprises a crankshaft position fixing body. One end of the crankshaft position fixing body is provided with a boss which is cooperated with a gap on a signal disc edge. A top surface of the crankshaft position fixing body is provided with a bump used for fixing a crankshaft position. The camshaft phase inspection component is a cylinder body whose bottom end is sealed. A top end of the cylinder body is provided with a step. A bottom of the cylinder body is made of a transparent material. The bottom of the cylinder body is marked with scales used for detecting a camshaft position. The invention also discloses an engine correct timing system inspection method. By using the tool and the method of the invention, a oil leakage risk of a correct time system is reduced and work efficiency is increased.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Explosion-proof valve, hydraulic control system, hydraulic control method and excavator

ActiveCN110499798AReduce layoutFirmly connectedSoil-shifting machines/dredgersControl systemEngineering

The invention provides an explosion-proof valve, a hydraulic control system, a hydraulic control method and an excavator. The explosion-proof valve is arranged between an oil supply device and a hydraulic actuating element, and comprises a logic check valve and a hydraulically controlled oil pipeline. An electromagnetic reversing valve and a pressure control valve are arranged in series on the hydraulically controlled oil pipeline. The electromagnetic reversing valve is used for controlling the logic check valve to be opened and closed. The pressure control valve is used for controlling the pressure of hydraulically controlled oil on the hydraulically controlled oil pipeline. By adopting an electronically controlled explosion-proof valve as the explosion-proof valve and arranging the explosion-proof valve in the hydraulic control system, the back pressure value of the explosion-proof valve when the hydraulic actuating element is lowered can be effectively reduced, corresponding pipeline arrangement is reduced, the pipeline connection is simple, the cost is greatly reduced, the oil leakage risk points are reduced, by arranging the explosion-proof valve in the hydraulic control system of a movable arm of the excavator, the movement speed of the movable arm is increased, and the lowering speed of the movable arm and the coordination of composite movement are not affected by mounting the explosion-proof valve additionally.

Owner:QINGDAO LOVOL EXCAVATOR

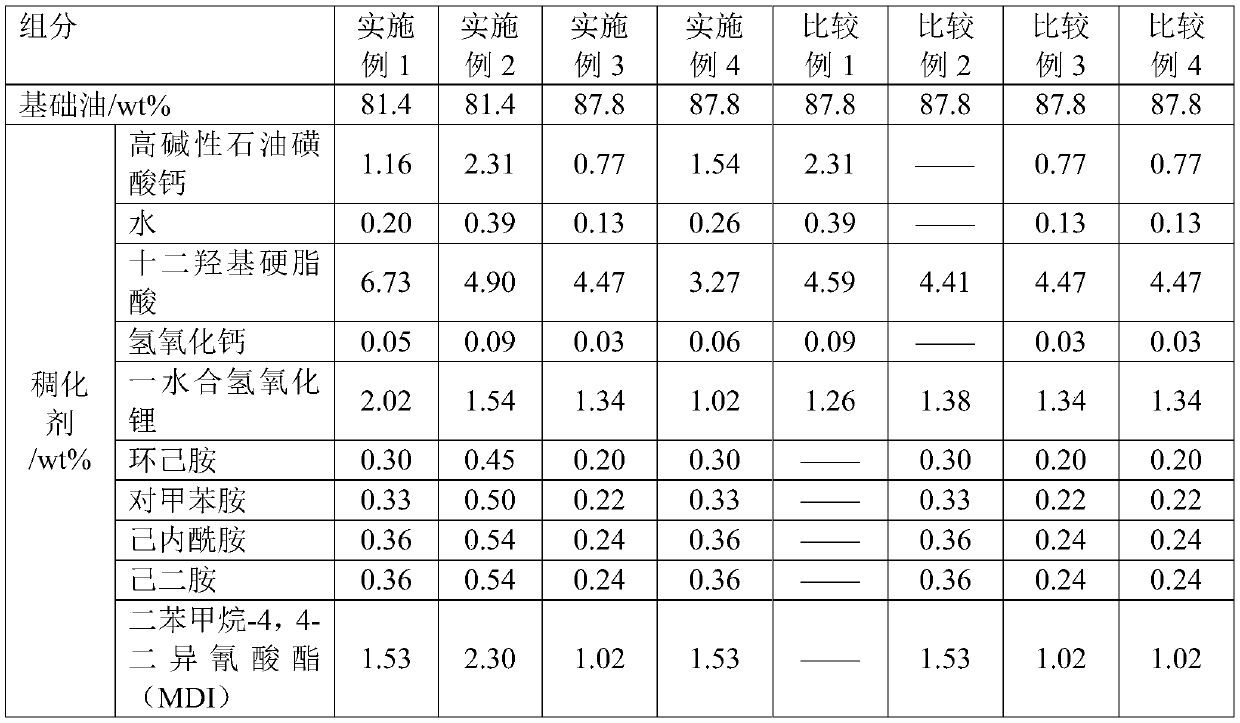

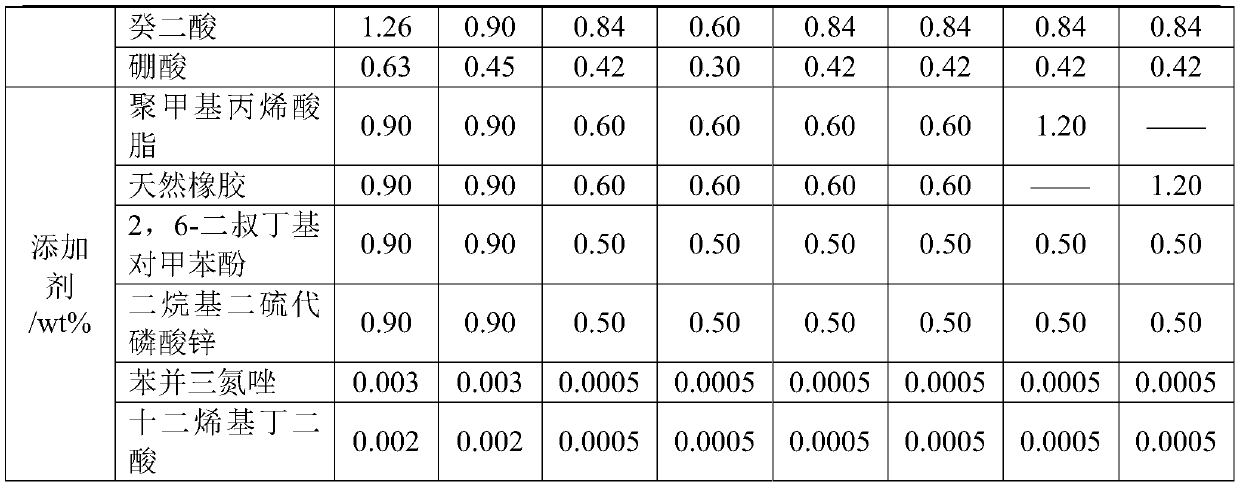

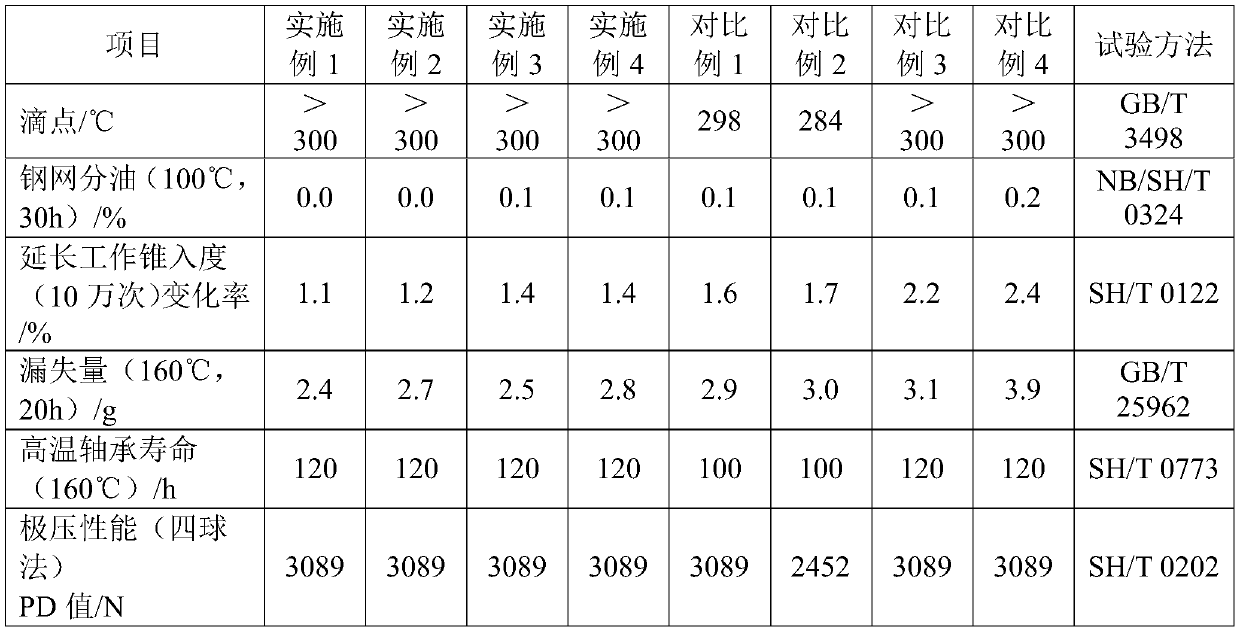

Commercial vehicle hub bearing lubricating grease and preparation method thereof

ActiveCN110616103APlay a synergistic roleImprove shear stabilityThickenersRolling resistance optimizationLithiumSynthesis methods

The invention discloses commercial vehicle hub bearing lubricating grease and a preparation method thereof. The invention belongs to the technical field of commercial vehicle hub bearing lubricating grease. The invention aims to improve the high-temperature stability and colloid stability of the lubricating grease, to reduce the grease separation amount of the lubricating grease, to improve the extreme pressure property and the shearing resistance of the lubricating grease, and to reduce consistence changes and grease-water separation of the lubricating grease. A composite polyurea thickeningagent, a composite calcium sulfonate thickening agent and a composite lithium thickening agent are compounded through an integrated synthesis method, so that the high-temperature stability and colloidstability of the lubricating grease are obviously improved, the oil separation amount of the lubricating grease is reduced, the service lifetime of a high-temperature bearing is prolonged, the oil leakage risk of the lubricating grease is reduced, the extreme pressure property and shearing resistance of the lubricating grease are improved, the consistency change of the lubricating grease is reduced and the grease-water separation risk is reduced. A composition of a synthetic adhesive and a natural adhesive has a synergistic effect, the shear stability of the lubricating grease is obviously improved, the consistency change of the lubricating grease is reduced, the lubricating grease is well adhered to the surface of a friction pair, and the grease-water separation risk of the lubricating grease is reduced.

Owner:FAW JIEFANG AUTOMOTIVE CO

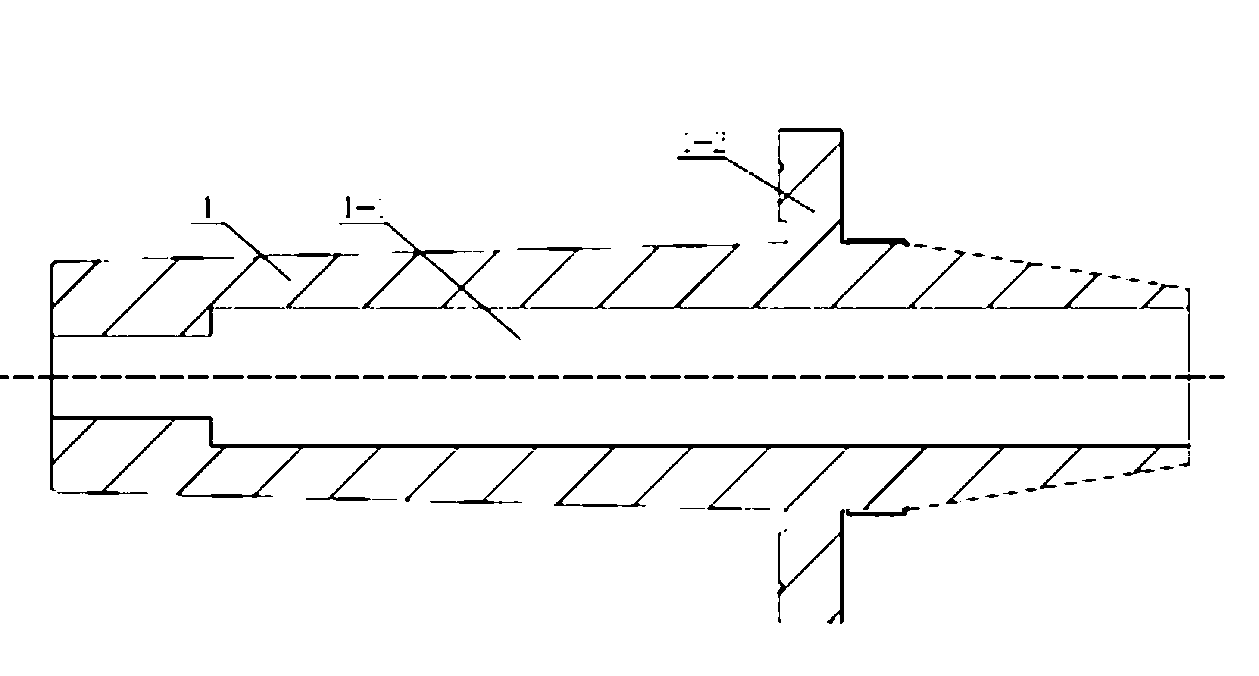

Oil port sealing structure used for wind power gear box

InactiveCN106122457ACompensate for small gapsReduce the risk of oil spillsGearing detailsEngineeringWind power

The invention relates to an oil port sealing structure used for a wind power gear box. The structure comprises a part I, a part II and a sealing sleeve; an oil port of the part I and an oil port of the part II are connected through the sealing sleeve; O-shaped sealing rings II are symmetrically arranged between the shaft diameter circumference outer wall face of the sealing sleeve and the contact face of the part I and the part II; an O-shaped sealing ring II is arranged between combination faces of the part I and the part II; a three-sealing structure is achieved, radial sealing, end face sealing and gap sealing can effectively compensate for a micro clearance caused by torsion and other factors of the gear box; the risk of oil leaking of the combination faces of the parts is reduced to the maximum degree, and the oil leaking risk generated in the repairing and maintaining process of the wind power gear box in air can be effectively reduced; and if oil leakage of the combination faces of the parts happens, direct aerial replacement can be carried out, and the maintaining cost is greatly reduced.

Owner:NANJING AVIS TRANSMISSION TECH

Capillary- conduit electronic cigarette atomizer

The invention discloses a capillary-conduit electronic cigarette atomizer. The capillary-conduit electronic cigarette atomizer comprises an oil storage bottle (7), an oil guide screen (5), and a heating wire (2), wherein the oil guide screen (5) comprises a sieve plate (12), a capillary conduit (4) penetrating through the sieve plate (12) and extending away from the oil storage bottle (7) is arranged on the sieve plate (12), third oil guide cotton (11) is accommodated in the capillary conduit (4), one end of the oil guide cotton (11) is in contact with tobacco tar in the oil storage bottle (7), and an oil injection hole (10) is formed in the side wall of the sieve plate (12); the heating wire (2) is fixed at one end, away from the sieve plate (12), of the capillary conduit (4) in a spiralstructure, and second oil guide cotton (9) is accommodated in a spiral cavity of the heating wire (2); and the oil guide screen (5) is in sealing connection with the oil storage bottle (7) through a silicone sealing plug (6). The electronic cigarette atomizer disclosed by the invention not only can reduce the risk of oil leakage, but also can prevent dry burning of the internal heating wire.

Owner:CHINA TOBACCO YUNNAN IND

Anti-leakage hydraulic valve for agricultural machine

InactiveCN105065712AHigh working reliabilityReduce the risk of oil spillsMultiple way valvesEngineeringMechanical engineering

The invention provides an anti-leakage hydraulic valve for an agricultural machine. The valve comprises a valve body, a valve rod, a rear cover and a support. A valve cavity is formed in the valve body. The valve rod is inserted into the valve cavity, and the right end of the valve rod extends out of the valve body. The valve rod is sleeved with the support, and the support is located on the right end face of the valve body. The rear cover is located at the left end of the valve body. The valve body is provided with a work oil port A and a hydraulic lock cavity. The hydraulic lock cavity and the work oil port A are connected through a third oil channel. The hydraulic lock cavity and the valve cavity are connected through a second oil channel. A hydraulic lock is arranged in the hydraulic lock cavity. The problem that lateral force of a one-way valve acts on a valve rod is solved through the anti-leakage hydraulic valve. The portion between the valve rod and the support is sealed through a dustproof ring. The design of dynamic seals and dustproof rings is adopted to the two ends of the valve rod. The problem that oil leaks from the dynamic seals of the valve rod is solved and dust can be prevented through the hydraulic valve.

Owner:LIUZHOU YIJIAN TECH

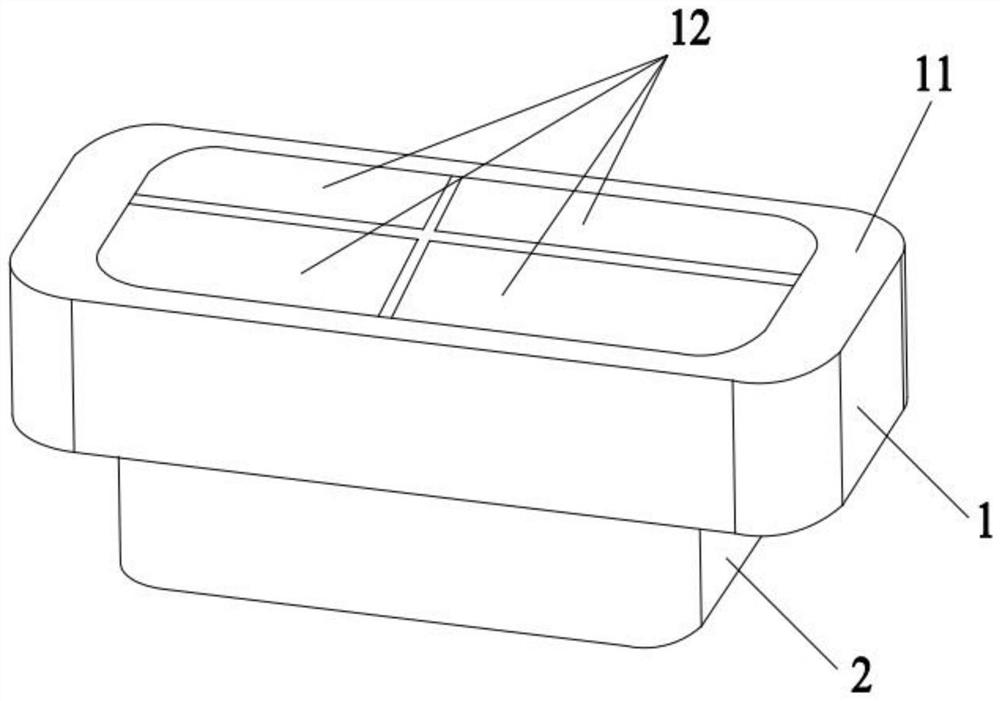

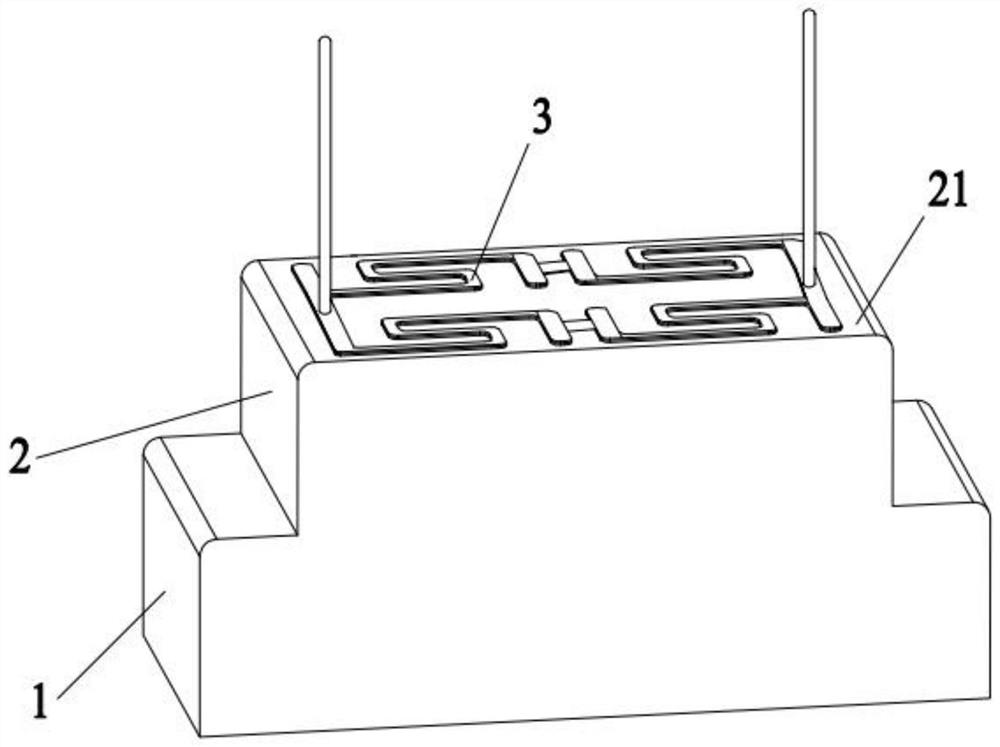

Porous ceramic heating body and atomizer

PendingCN114041628AImprove high temperature resistanceExtended service lifeTobaccoPorous ceramicsComposite material

The invention relates to the technical field of atomizers, in particular to a porous ceramic heating element and an atomizer, the porous ceramic heating element comprises a porous ceramic base body, the porous ceramic base body comprises an oil storage base body and an atomizing base body, the oil storage base body is arranged on the upper surface of the atomizing base body, the upper surface of the oil storage base body is an oil guide surface, and an oil storage tank is concavely formed in the oil guide surface; and the lower surface of the atomizing base body is an atomizing face, a heating assembly is printed or embedded in the atomizing face, and the heating assembly is arranged corresponding to the position of the oil storage tank. The porous ceramic base body is divided into the upper portion and the lower portion which are integrally formed, the amount of tobacco tar permeating into the atomizing base body from the oil storage base body in the unit area is increased, and the oil storage amount and the contact area between the tobacco tar and the oil storage base body can be increased by concavely arranging the oil storage tank in the oil guide face of the oil storage base body. The arrangement that the heating assembly is printed or embedded into the atomizing surface can effectively solve the problems that the bonding strength between the porous ceramic matrix and the heating assembly is poor, and the heating assembly is prone to falling off and cracking in the high-temperature atomizing application process in the past.

Owner:SHENZHEN HANQINGDA TECH CO LTD

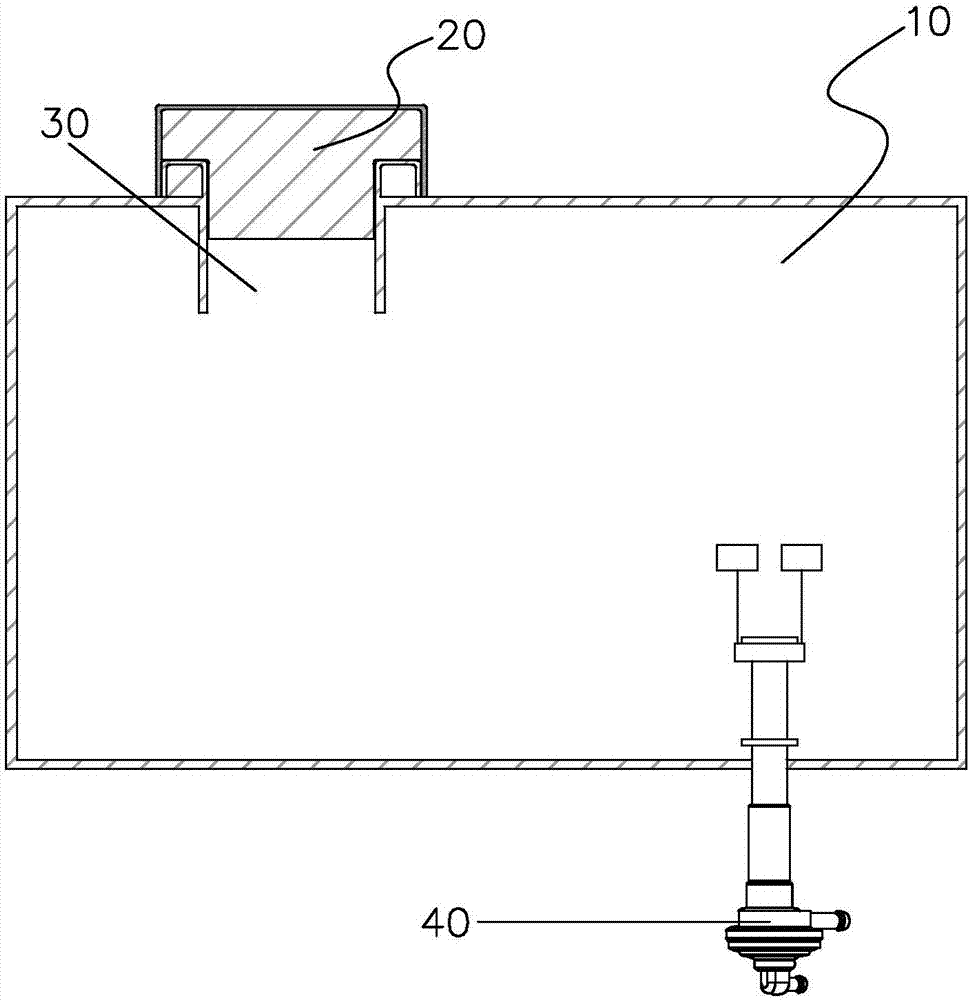

Full-speed oil purifying device

PendingCN108744609AEasy to separateImprove structural stabilityLiquid separationFatty substance recoverySlagPetroleum engineering

The invention discloses a full-speed oil purifying device. The full-speed oil purifying device comprises a rotary drum having an inner chamber of the rotary drum and a dirt containing tank arranged below the rotary drum, an oil pipe system is arranged between the rotary drum and the dirt containing tank, the oil pipe system comprises an oil-inlet vertical pipe, a slag outlet pipe and a cleansing oil vertical outlet pipe which sleeve in order from outer to inner, a rotation shaft sleeved at an outer wall of the cleansing oil vertical outlet pipe is arranged in the inner chamber of the rotary drum, an upper end of the rotation shaft is connected with an inner wall of the rotary drum, the rotation shaft and the cleansing oil vertical outlet pipe are connected through an upper rotation bearingand a lower rotation bearing, several dirt containing dishes sleeve the rotation shaft. The full-speed oil purifying device has the advantages of compact structure, high purifying efficiency, and fast speed.

Owner:镇江市长江机电设备厂有限公司

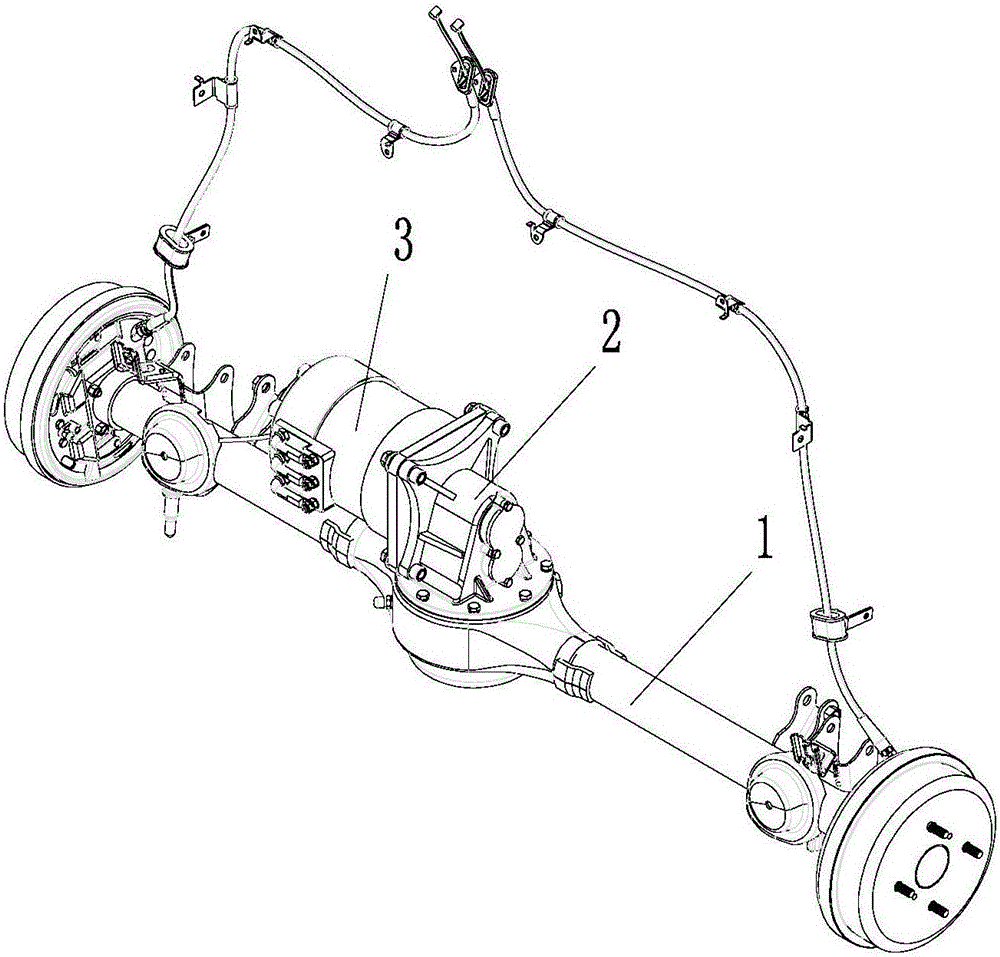

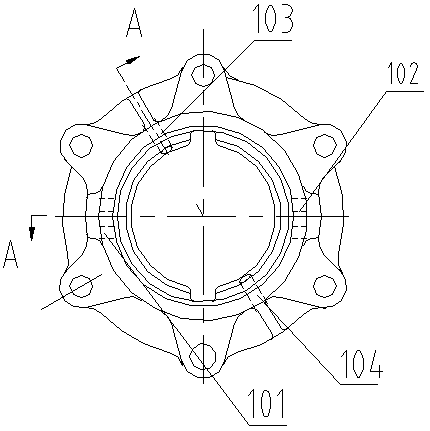

Automobile rear axle assembly

The invention discloses an automobile rear axle assembly, which includes a rear axle, a reducer and a drive motor. The reducer includes a reducer casing, an intermediate shaft and a differential gear. The reducer casing is formed by integral casting, and the motor shaft of the drive motor It extends into the reducer housing from the left or right, and meshes with the intermediate gear on the intermediate shaft through the driving gear on the motor shaft. The drive motor is installed on the motor mounting flange of the reducer housing. The left half shaft is inserted into the left side of the differential, and the bevel gear on the left half shaft is driven by the bevel gear of the differential to rotate, and the right half shaft of the rear axle is inserted into the right side of the differential, driven by the bevel gear of the differential The bevel gear on the right half shaft rotates, and the reducer is connected to the rear axle through the rear axle mounting flange at the bottom of the reducer housing. Small size, convenient installation and low cost, the motor shaft of the drive motor is used as the input shaft; the gears of the transmission are all wrapped in the casing, with low noise, reducing the risk of oil leakage and saving lubricating oil.

Owner:重庆利川变速器有限公司

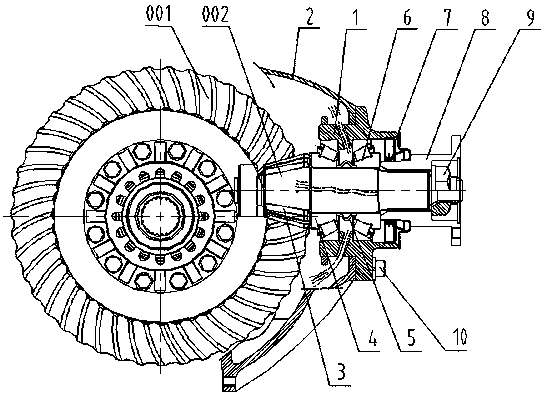

A main reducer for the rear drive axle of a new energy vehicle

ActiveCN106402342BImprove the hidden danger of insufficient low-speed pump oil capacityImprove the lubrication effectGear lubrication/coolingLow speedNew energy

The invention discloses a main speed reducer of a new energy automobile rear drive axle. The main speed reducer comprises a shell, a differential mechanism assembly and a drive gear assembly. The drive gear assembly is fixedly arranged on the shell and comprises a bearing block, a drive gear, an inner bearing, a spacer bush, an outer bearing, an oil seal, a flange and a flange nut. With the axis of the bearing block as the standard, a pair of horizontally-arranged oil passing grooves are symmetrically formed in the inner wall of the bearing block and are tilt angle groove holes. A pair of oblique oil holes formed in the radial direction are symmetrically formed in the inner wall of the part, in the circumferential direction deviating from the oil passing grooves by 45 degrees, of the bearing block, a pair of oil passing ways are symmetrically formed in the inner wall of the shell, and the oil passing ways communicate with and correspond to the oblique oil holes in a one-to-one manner. According to the main speed reducer, the hidden danger that the low-speed oil pumping capability of a traditional main speed reducer is insufficient is avoided, the lubricating performance of the main speed reducer under various work conditions is improved, the oil seal oil leakage risk is reduced, the main speed reducer can replace a traditional rear drive axle main speed reducer and achieve multiple purposes, the management cost is reduced, and the production efficiency is improved.

Owner:郑州江东汽车零部件有限公司

Motorcycle oil tank capable of preventing false alarm

The invention relates to a motorcycle oil tank capable of preventing false alarm, comprising an oil tank body, an oil filling port formed in the upper end of the oil tank body, an oil tank cover mounted at the oil filling port, as well as an oil switch, an oil level sensing device and an alarm circuit which are mounted at a mounting hole in the lower end of the oil tank body, wherein a push pipe positioned in the oil tank body is also arranged at the top of the oil switch; the oil level sensing device comprises a reed pipe, a lantern ring, a first floater and a second floater; the reed pipe is electrically connected with the alarm circuit and forms a switch of the alarm circuit; the reed pipe is mounted in the push pipe, the lantern ring is movably sleeved on the push pipe, and the first floater and the second floater are connected and fixed with the lantern ring respectively through strings; and the lantern ring is provided with a magnetic ring. According to the invention, by reasonably arranging the structure of the oil level sensing device, false trigger alarm of the oil level sensing device can be prevented when the oil tank shakes, and the risk of oil leakage of the oil tank body can be reduced, thereby improving the reliability of the oil tank.

Owner:张彩银

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com