A main reducer for the rear drive axle of a new energy vehicle

A technology for new energy vehicles and rear drive axles, which is applied to transmission parts, gear lubrication/cooling, belts/chains/gears, etc. It can solve problems such as weakening the lubrication performance of the main reducer, and improve low-speed pumping capacity. The effect of reducing the risk of oil seal leakage and reducing management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

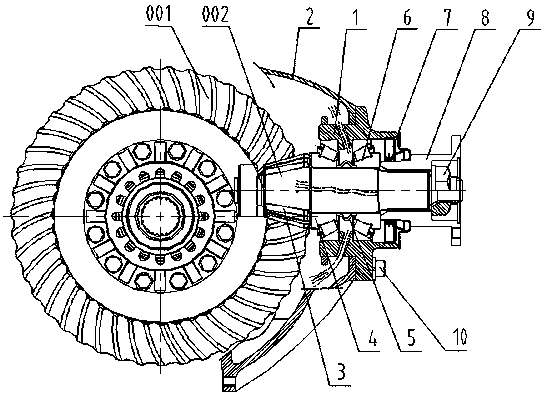

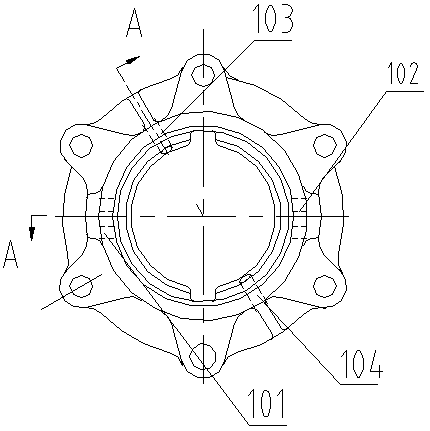

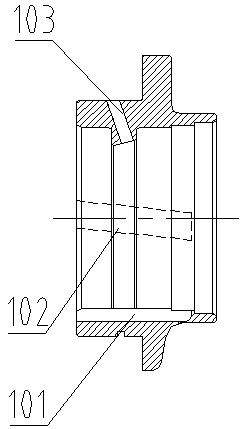

[0022] Example: as figure 1 - as shown in 4;

[0023] A main reducer of a rear drive axle of a new energy vehicle, which includes a housing 2, a differential assembly 001 and a driving gear assembly 002, the driving gear assembly 002 is fastened to the housing 2 through bolts 10, and the driving gear Assembly 002 includes bearing seat 1, driving gear 3, inner bearing 4, spacer sleeve 5, outer bearing 6, oil seal 7, flange 8 and flange nut 9, taking the axis of bearing seat 1 as the standard, in the bearing seat 1 A pair of horizontally arranged oil passage grooves 101, 102 are symmetrically arranged in the inner wall, and the oil passage grooves are inclined slot holes, and a pair of radially arranged inclined oil grooves are symmetrically arranged on the inner wall of the bearing housing 1 in the circumferential direction that is 45° different from the oil passage grooves 101, 102. The holes 103, 104 are symmetrically provided with a pair of oil passages on the inner wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com