Atomizing core and smoke cartridge

An atomizing core and atomizing liquid technology, which is applied in the field of electronic cigarettes, can solve the problems affecting the atomization of e-liquid, the rupture of heating wires, and oil leakage, so as to reduce the risk of oil leakage, reduce the number of sintering, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

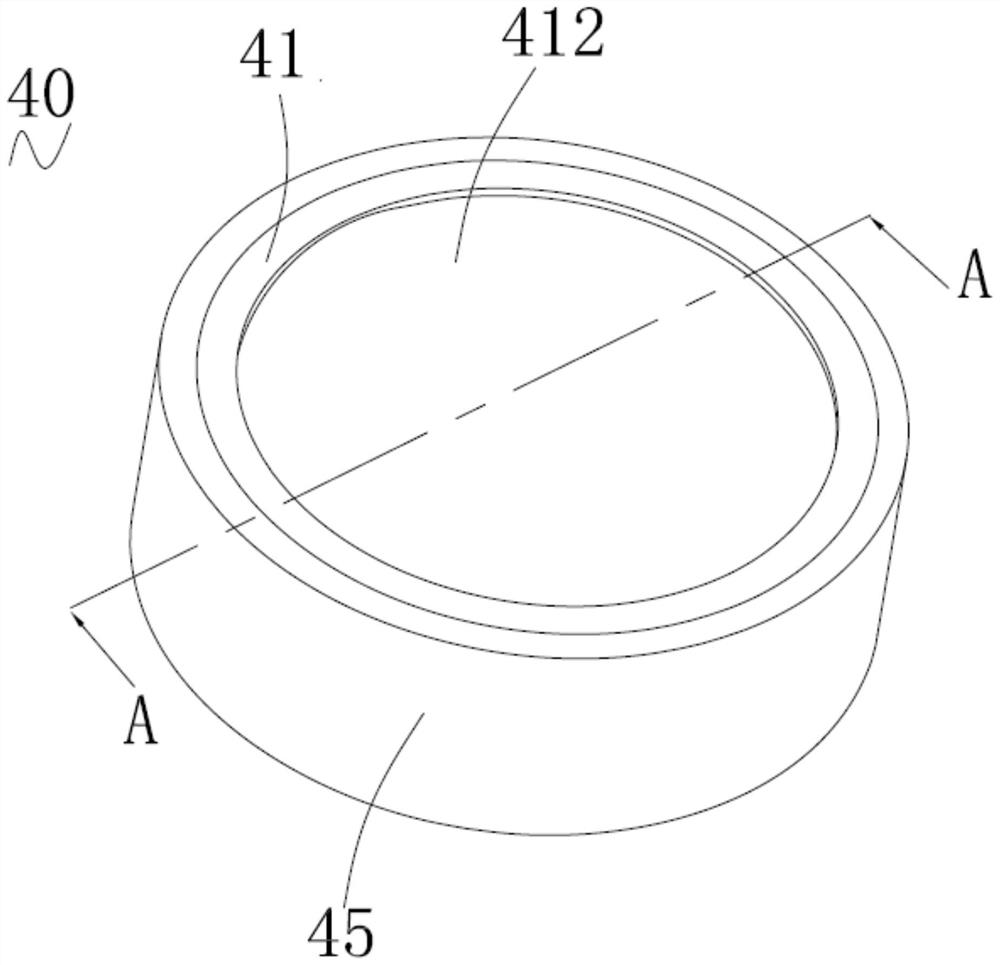

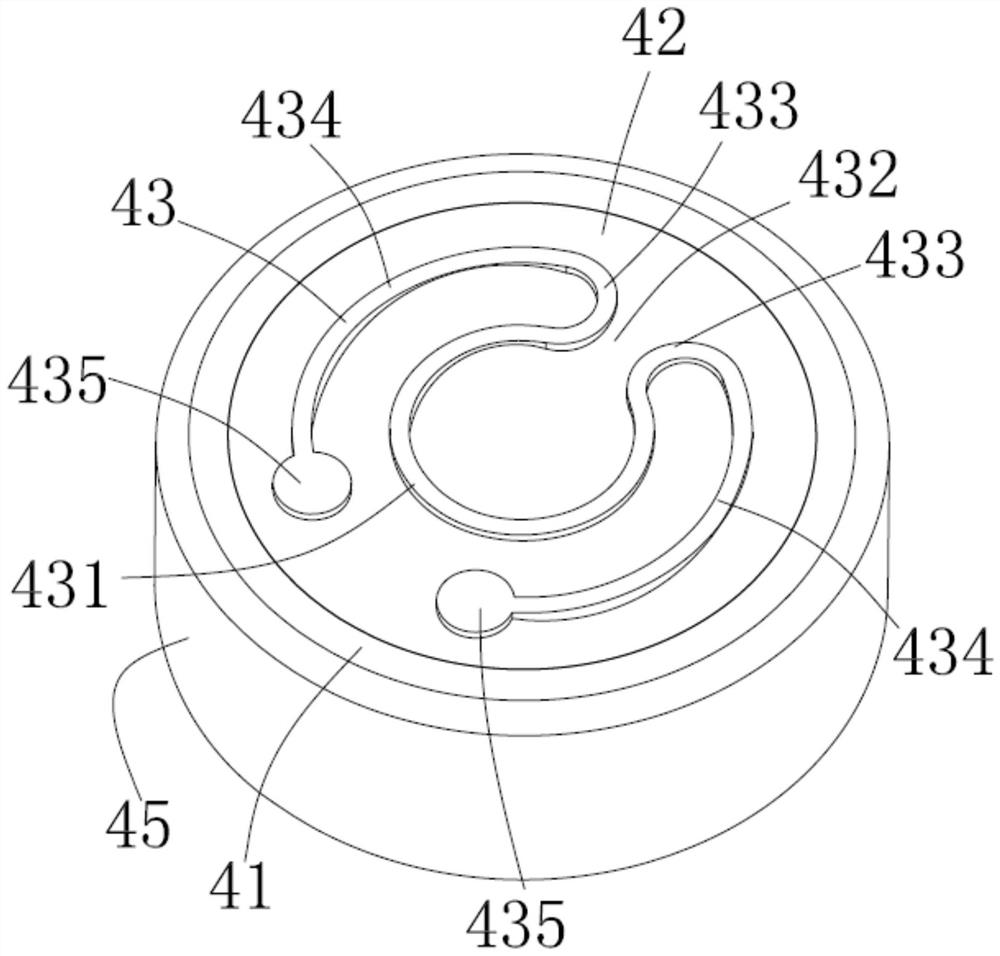

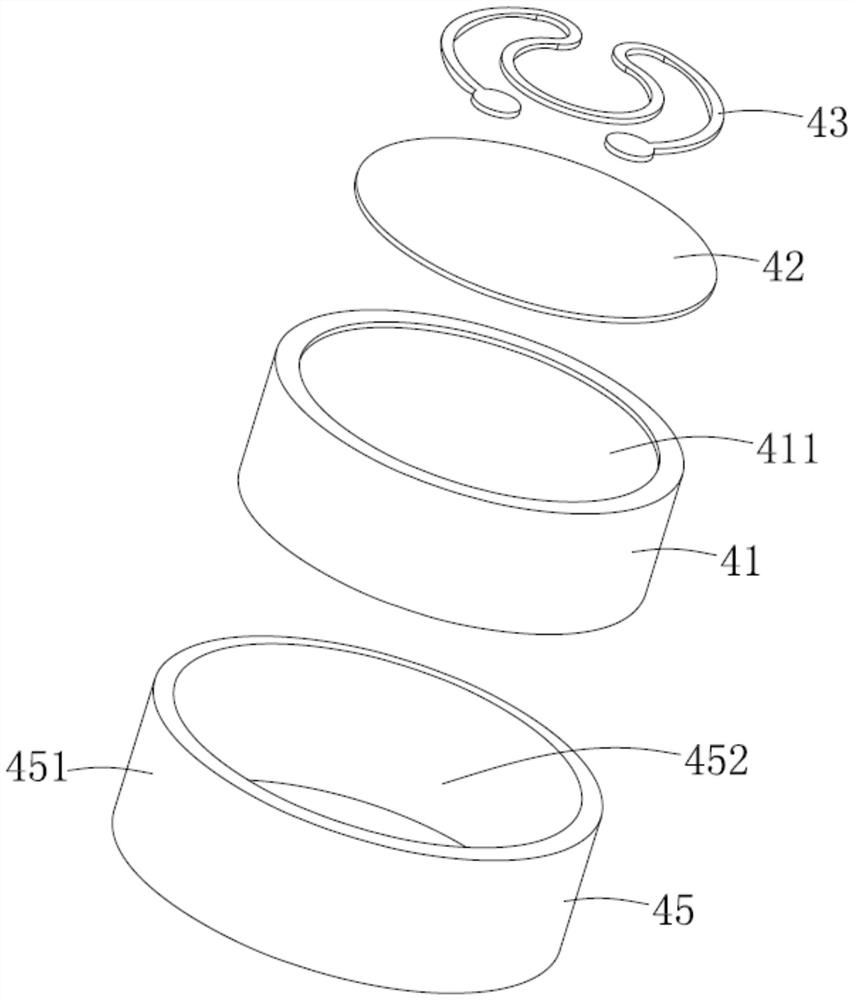

[0033] see Figure 1 to Figure 5 As shown, the atomizing core 40 of the present application includes a porous body 41, an insulating and heat-conducting layer 42 coated on one side of the porous body 41, a heating element 43 adhered to the surface of the insulating and heat-conducting layer 42, and wrapped in the A casing 45 around the periphery of the porous body 41 .

[0034] The porous body 41 is made of metal, which is sintered by mixing metal powder and organic material to form a mixture. The organic material is ablated and removed to form micropores. The pore diameter of the micropores is between 15-22um, and the porosity The range is between 50%-60%.

[0035] In one embodiment, the porous body 41 made of metal has a pore diameter ranging from 18-20um, and a porosity ranging from 54%-55%.

[0036] In one embodiment, the pore size of the metal porous body 41 is between 18-20um, and the porosity is between 54.87%-55.05%.

[0037] The porous body 41 includes a liquid-abs...

Embodiment 2

[0057] key reference Figure 9 As shown, compared with Embodiment 1, the difference of Embodiment 2 is that the porous body 41 is made of porous ceramic material instead of metal material, the insulation and heat conduction layer 42 is omitted, and the heating element 43 is directly arranged on the The bottom surface of the porous body 41 can be sintered and formed.

[0058] This embodiment can effectively solve the brittleness problem of the porous body 41 made of ceramic materials. By using the rigid shell 45 as a supporting force-bearing element, the shell 45 can effectively protect the porous body 41 from cracking due to force. The product is scrapped, or deformed due to force, resulting in product deformation and partial damage, resulting in serious oil leakage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com