NFC-based wireless intelligent electric power inspection system

An intelligent power and inspection system technology, applied in inspection time patrols, instruments, sensing record carriers, etc., can solve problems such as inability to update data in real time, many loopholes in inspection management, and easy duplication of QR codes, reducing inspection costs. cost, strengthen process control and supervision, and speed up the effect of informatization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

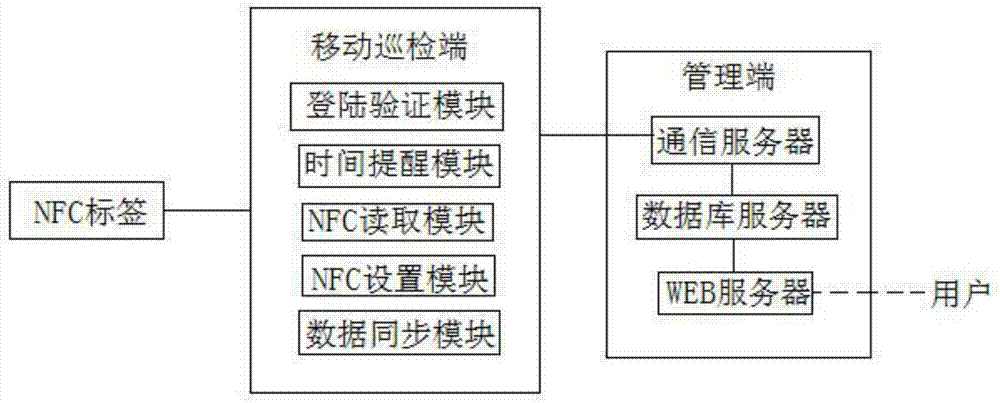

[0025] see figure 1 , a wireless intelligent power inspection system based on NFC, including an NFC tag, a mobile inspection terminal and a management terminal; the NFC tag is set at a corresponding inspection point, and the NFC tag is responsible for storing the inspection content of the corresponding inspection point ; Each inspection operation point adopts different forms of NFC tags according to the situation, and each NFC tag stores a different number.

[0026] The mobile inspection terminal is installed on a mobile phone terminal provided with NFC, carried by the inspection personnel, and is responsible for reading the inspection content information of the NFC tag at the inspection point, uploading the inspection record after the inspection, and performing the inspection. Information update reminder; the mobile inspection terminal includes a login verification module, a time reminder module, an NFC reading module, an NFC setting module, a data synchronization module, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com