Bearing box of heavy slurry pump and shafting transmission structure thereof

A transmission structure and bearing box technology, which is applied in the field of mechanical transmission, can solve the problems of difficult adjustment of the gap between the impeller and the flow-passing parts, difficulty in ensuring machining accuracy and coaxiality, and poor interchangeability of parts, so as to reduce the amount of processing and reduce leakage. Oil risk, effect of good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] specific implementation

[0027] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

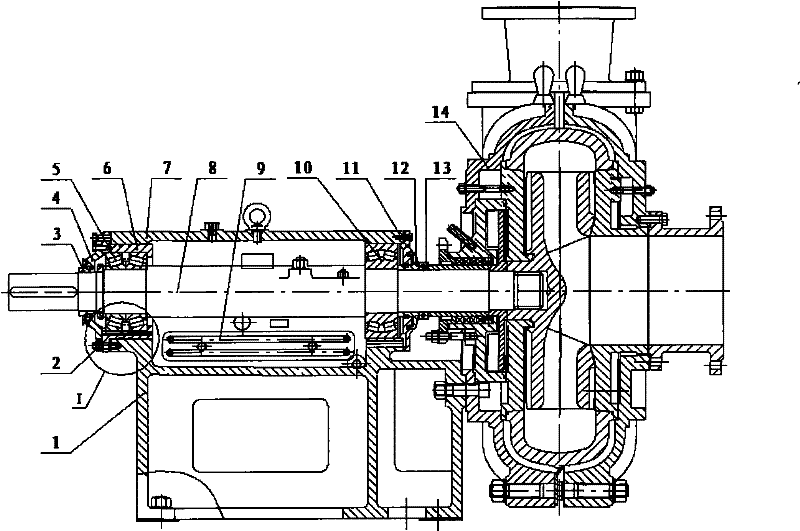

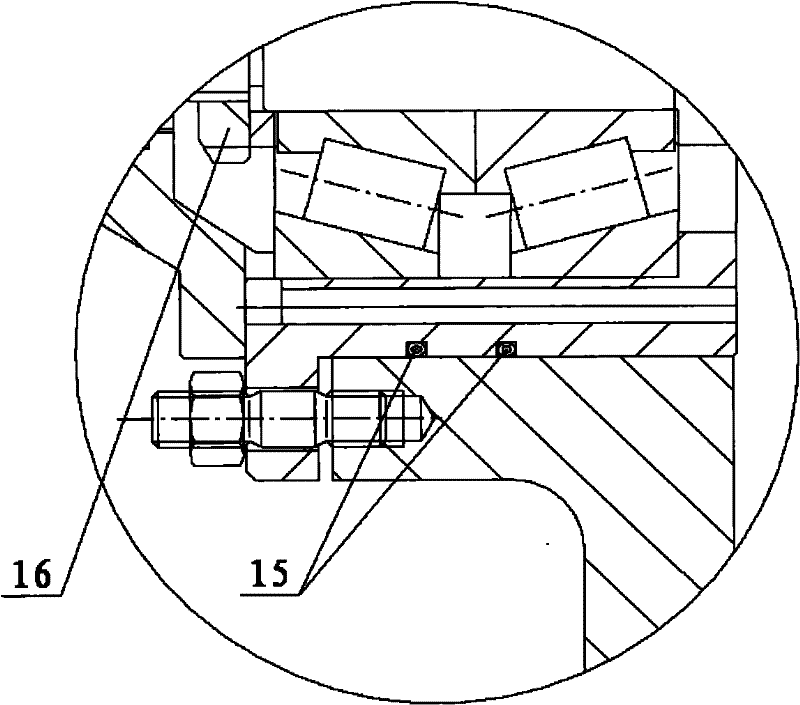

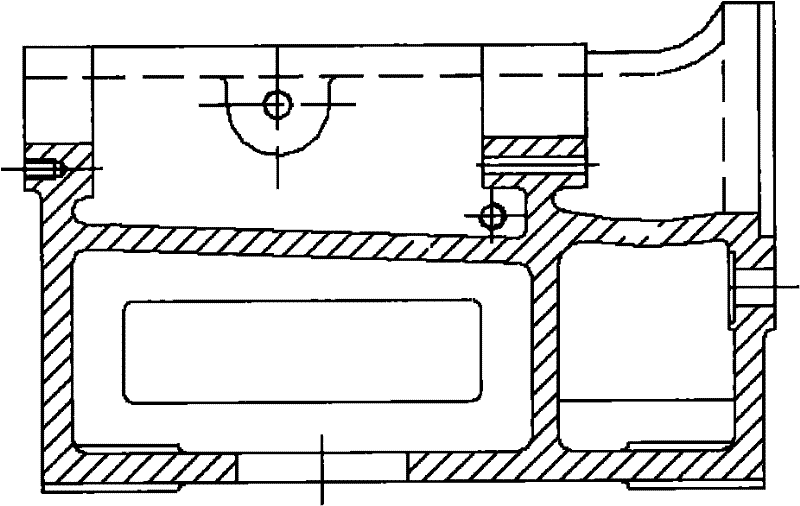

[0028] A heavy-duty slurry pump bearing box and its shaft transmission structure, which includes a pump shaft 8, a cooler 9, a front bearing cover 11, a rear bearing cover 4, a front dustproof plate 12, and a rear dustproof plate 3. It also includes bracket 17, bearing housing 20, second adjusting bolt 19, rear locking stud nut 18 and pressure ring 21; peripheral equipment includes: dismantling ring 13, flow-passing component 14; wherein, the structure diagram of bracket 17 is as follows Figure 10 , Figure 11 Shown, bracket 17 mainly bears radial force jointly with front, middle and rear three vertical stiffener plates and left and right two circular arc smooth design stiffeners, and the oil storage space has been canceled on bracket 17. The structural diagram of the bearing housing 20 is as follows: Figure 12 , Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com