Anti-leakage hydraulic valve for agricultural machine

An agricultural machinery, anti-leakage technology, applied in mechanical equipment, multi-port valves, valve devices, etc., can solve the problems of worn valve holes, difficult processing of O-rings, and stagnation of reversing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

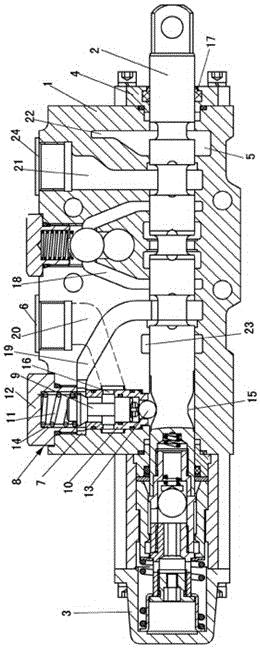

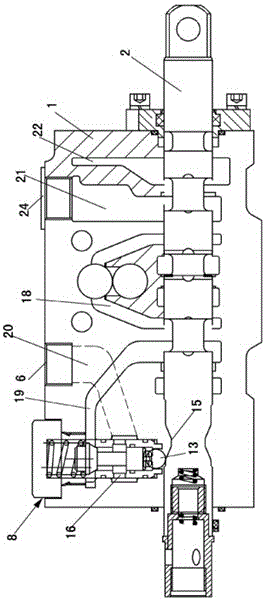

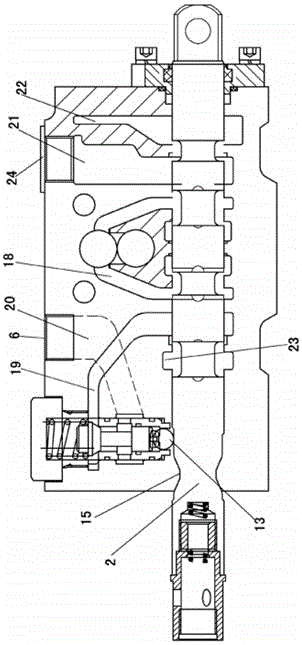

[0013] The anti-leakage hydraulic valve for agricultural machinery of the present invention includes a valve body 1, a valve stem 2, a back cover 3 and a bracket 4; a valve cavity 5 is arranged in the valve body 1, and the valve stem 2 is inserted into the valve In the chamber 5 and the valve stem 2 protrudes outside the valve body 1 at the right end, the bracket 4 is sleeved on the valve stem 2 and is located on the right end surface of the valve body 1; The rear cover 3 is located at the left end of the valve body 1; the valve body 1 is provided with a working oil port A6 and a hydraulic lock cavity 7, and the hydraulic lock cavity 7 and the working oil port A6 are connected through a third The oil passage 20 is connected, and the hydraulic lock chamber 7 is connected with the valve chamber 5 through the second oil passage 19; a hydraulic lock 8 is arranged in the hydraulic lock chamber 7; the hydraulic lock 8 includes a single One-way valve core 9, one-way valve sleeve 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com