Engine correct timing system inspection tool and method thereof

A timing system and engine technology, used in engine testing, measuring devices, internal combustion engine testing, etc., can solve problems such as oil leakage, reduced gasket sealing, and poor sealing, reducing workload, improving work efficiency, The effect of reducing the risk of oil spills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

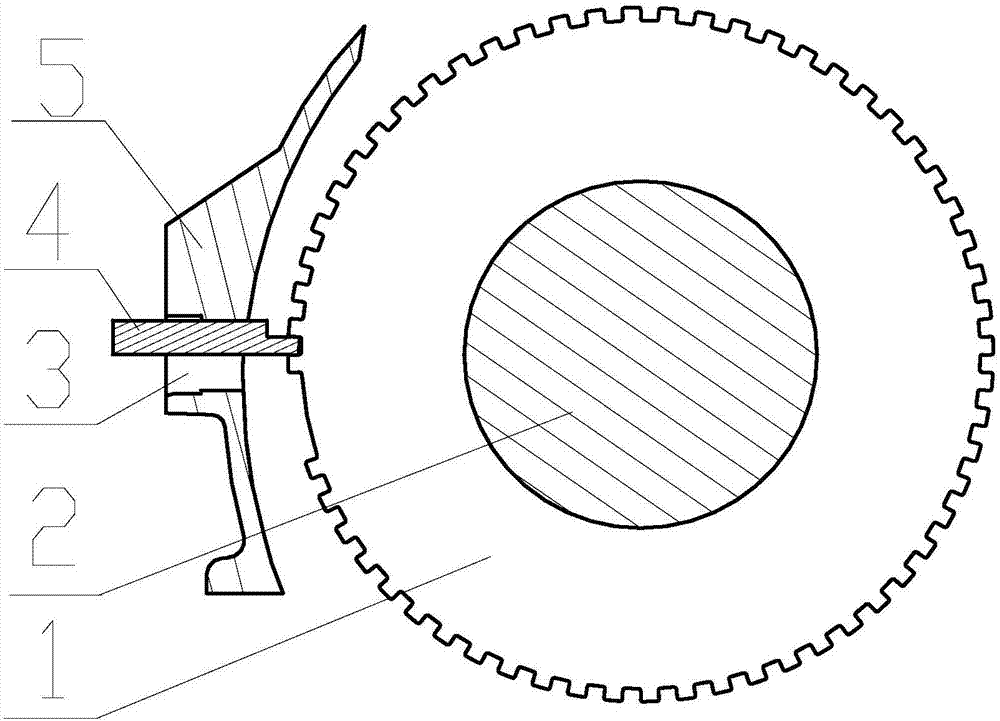

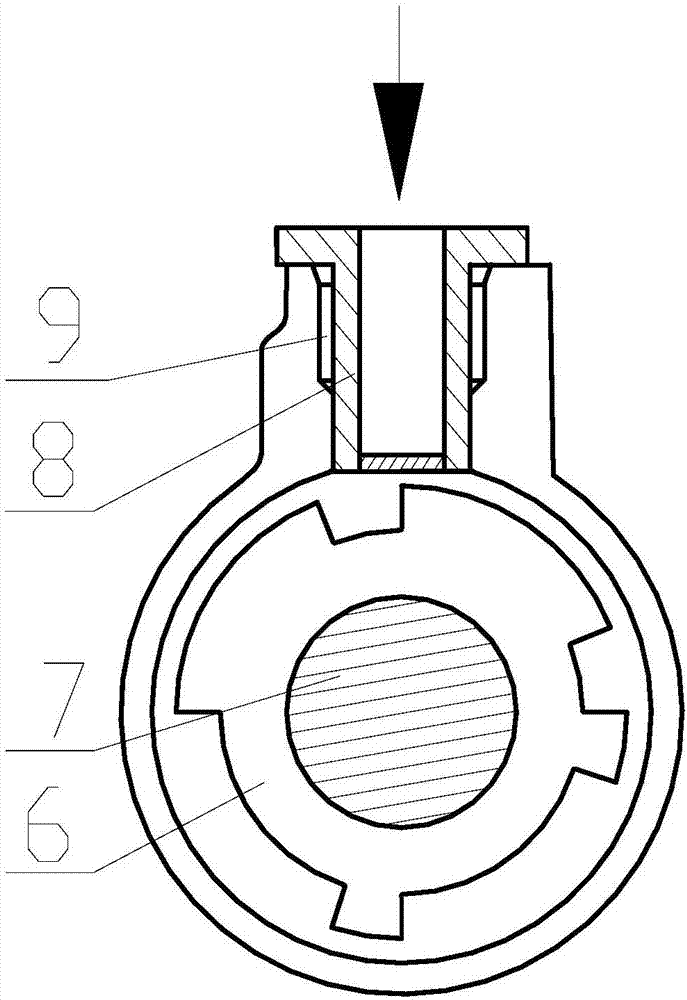

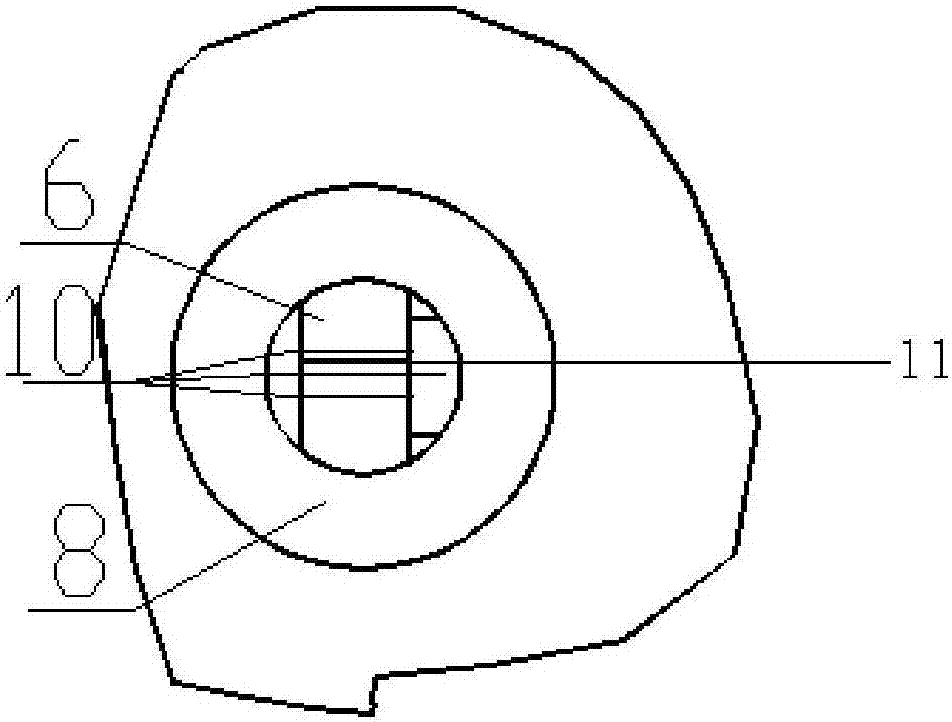

[0026] Such as Figure 1 to Figure 6 The engine timing system inspection tool shown includes a crankshaft position fixing part 4 and a camshaft phase inspection part 8 .

[0027] Such as Figure 4 As shown, the crankshaft position fixing member 4 includes a crankshaft position fixing body 43, and one end of the crankshaft position fixing body 43 is provided with a boss 41 matching the notch on the edge of the signal plate 1, and the top surface of the boss 41 is from The direction from the inside to the outside is inclined downward, so that the boss 41 can be inserted into the notch on the edge of the signal plate 1 conveniently. A projection 42 for fixing the position of the crankshaft 2 is provided on the top surface of the crankshaft position fixing body 43 .

[0028] Such as Figure 5 with Image 6 As shown, the camshaft phase inspection part 8 is a cylindrical bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com