Oil port sealing structure used for wind power gear box

A wind power gearbox and sealing structure technology, applied in belts/chains/gears, transmission parts, mechanical equipment, etc., can solve problems such as uneven thickness of adhesive layer, large oil leakage risk, and inability to fill small gaps, reducing The risk of oil spills, the effect of reducing maintenance costs, and reducing the risk of oil spills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the objects and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the examples; it should be understood that the following words are only used to describe one or several specific implementation modes of the present invention, and do not specifically request the present invention The scope of protection is strictly limited.

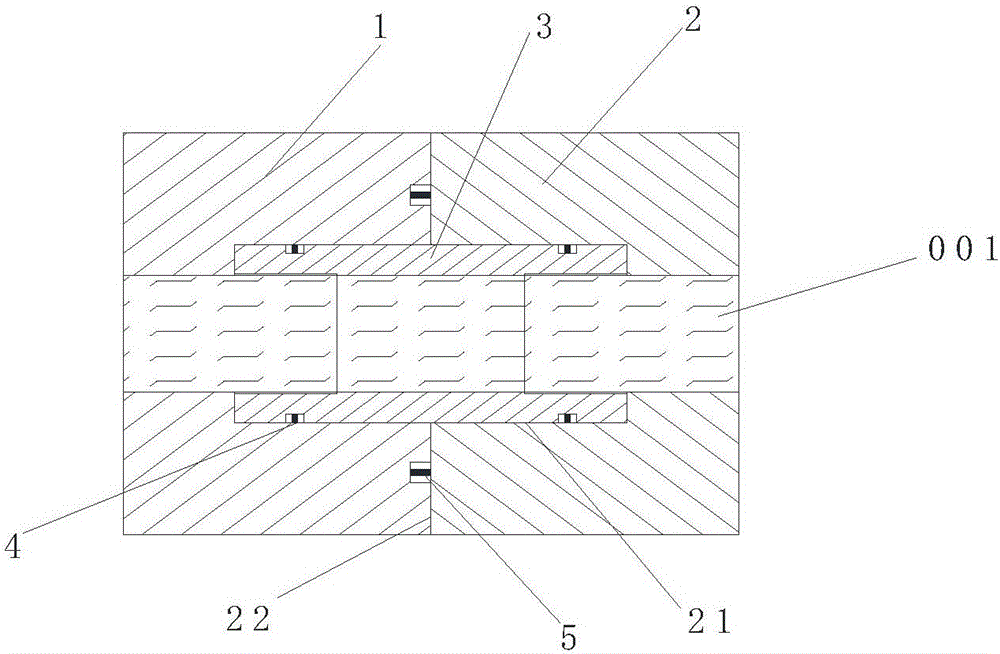

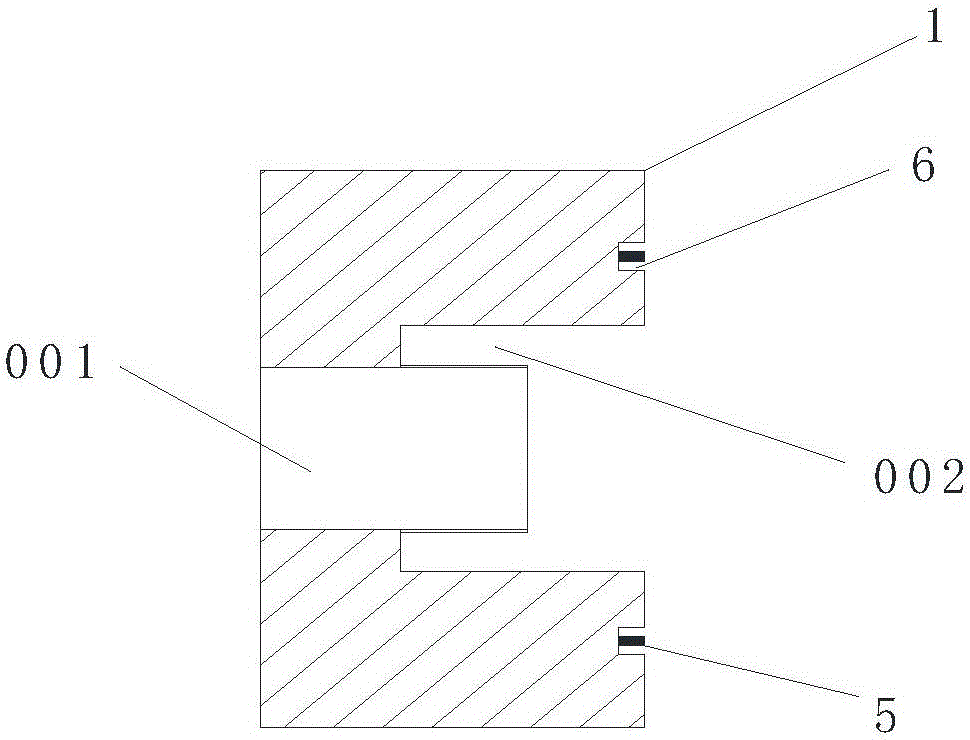

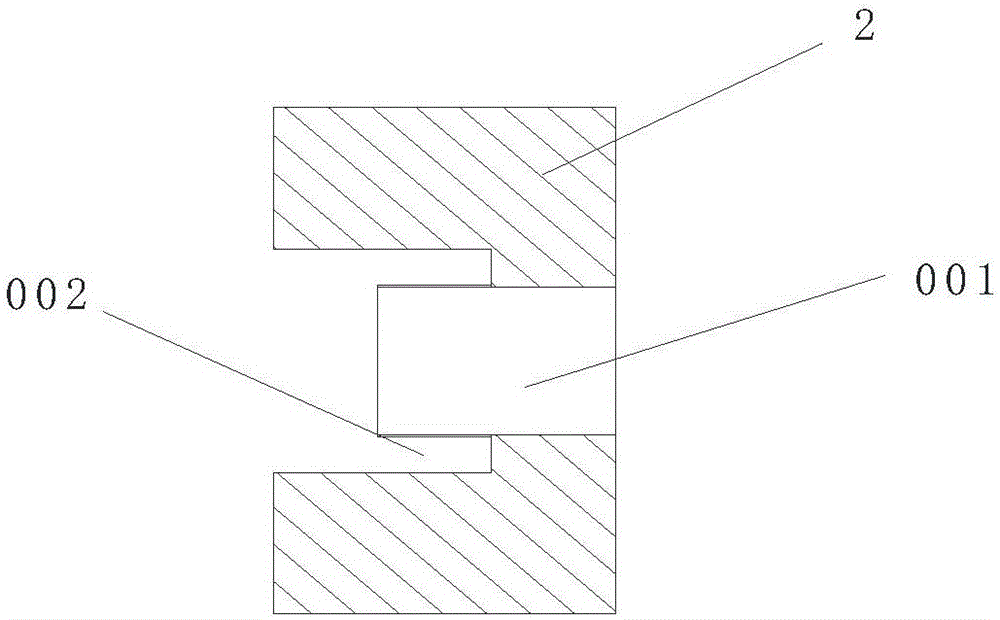

[0017] As shown in Figures 1, 2, 3, and 4, a schematic diagram of the oil port sealing structure of a wind power gearbox includes part I1, part II2 and sealing sleeve 3, part I1 oil hole 001 and part II2 oil hole 001 Connected by the sealing sleeve 3, an O-ring I4 is symmetrically provided between the outer wall surface of the shaft diameter of the sealing sleeve 3 and the contact surface 21 of the component I1 and the component II2; an O-ring I4 is arranged between the joint surface 22 of the component I1 and the component II2 Type seal ring II5;

[0018] Prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com