Sewing machine

A sewing machine and presser foot lifting technology, applied in the field of sewing equipment, can solve the problems of frequent use of electromagnet-driven presser foot, frequent movement of the ejector rod, and easy damage to the sealing cap, so as to reduce frequent movement, prevent aging and damage, and reduce The effect of the risk of oil spills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

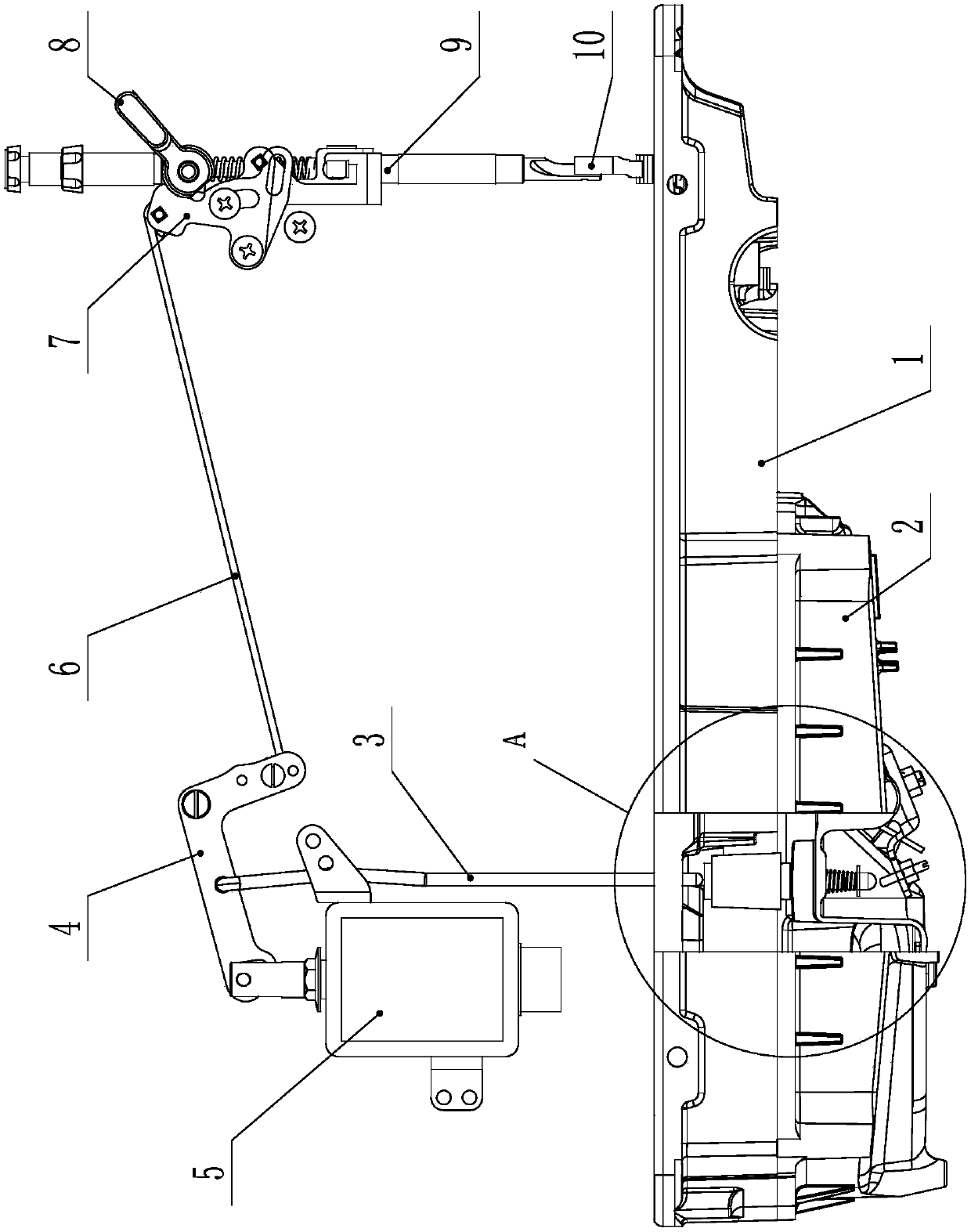

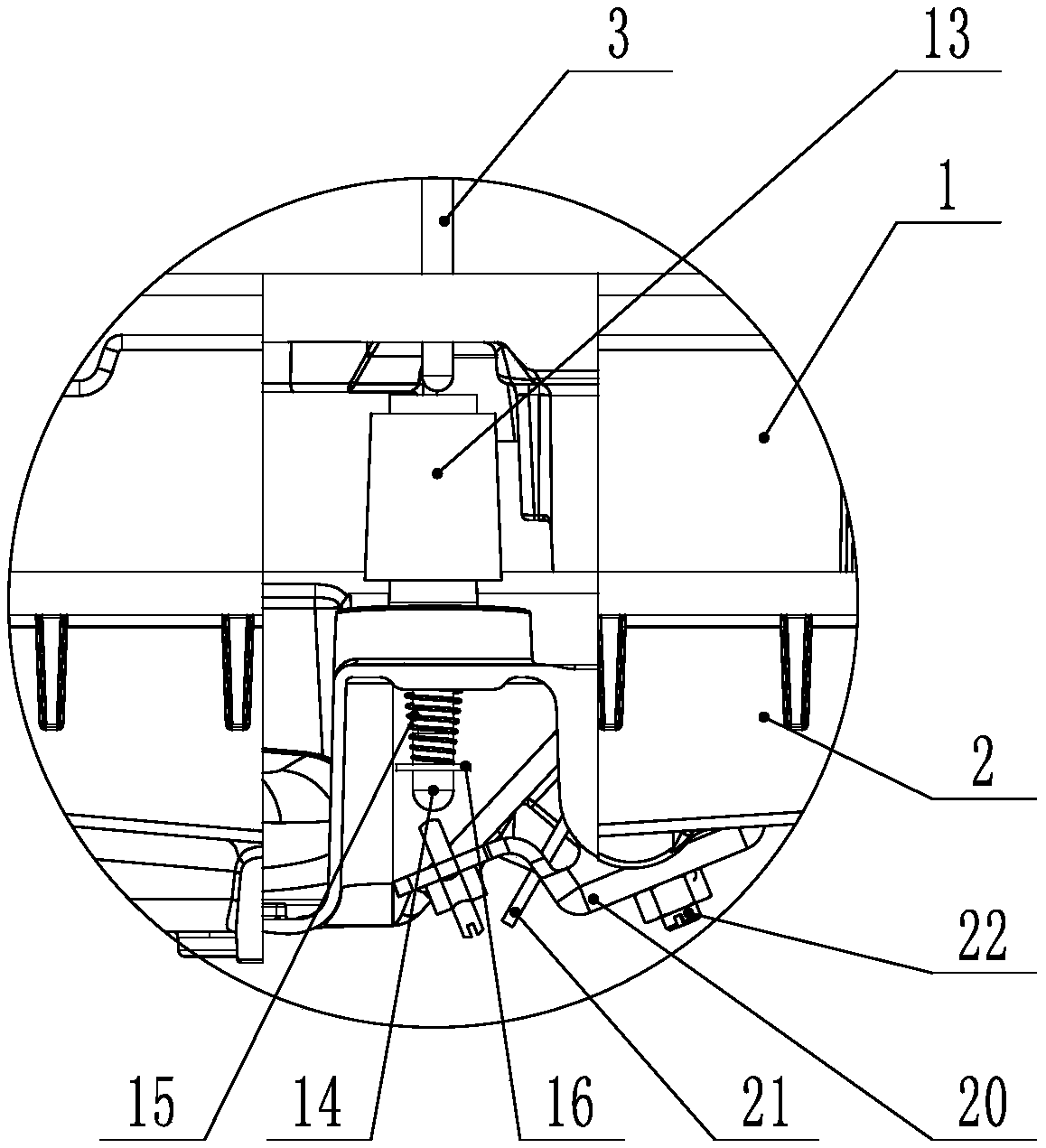

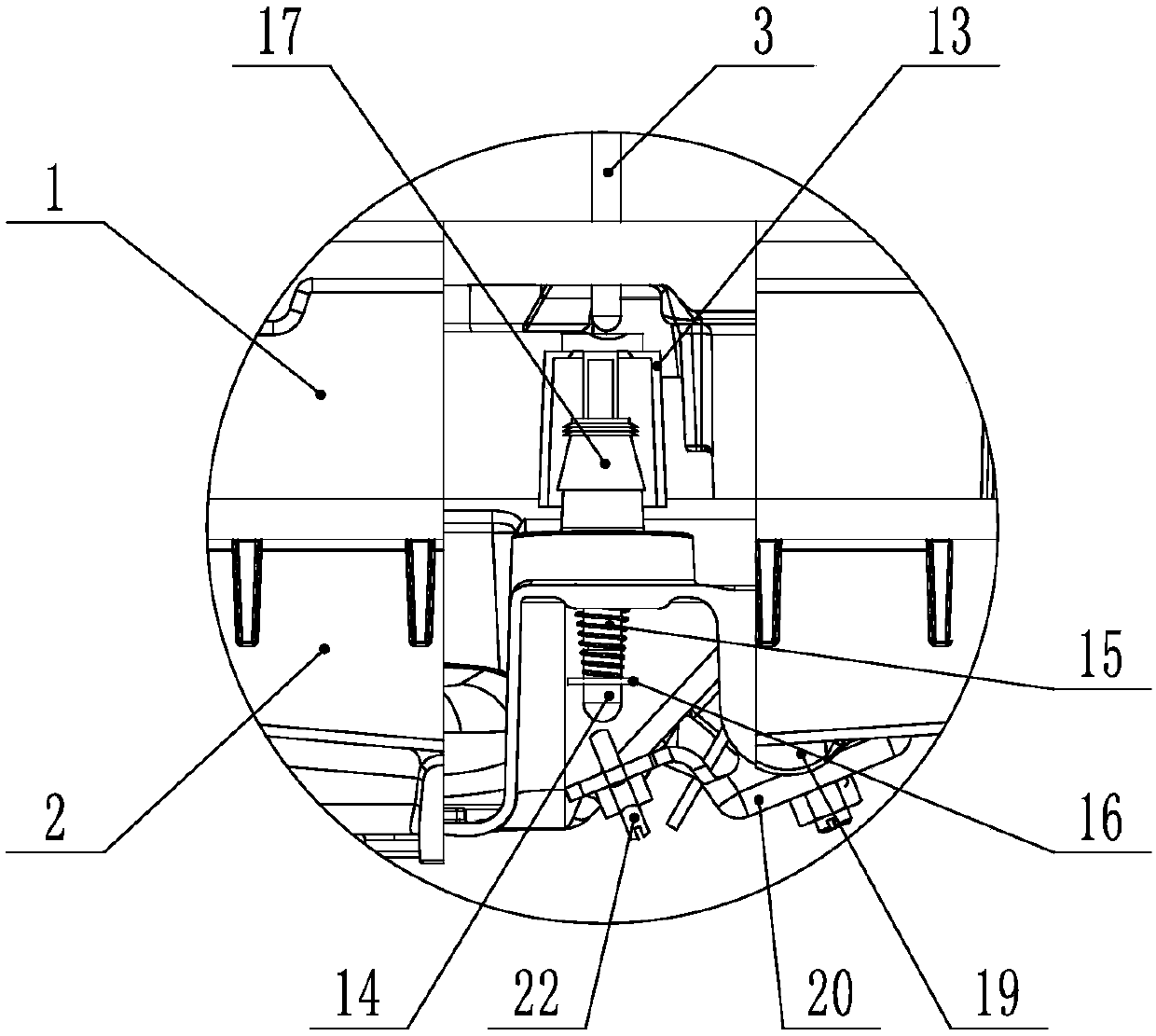

[0023] The present invention will be further described below with specific embodiment, see figure 1 -6:

[0024] A sewing machine, comprising a bottom plate 1, an oil seal plate 2, and a push rod 3, the upper end of the push rod 3 is connected to a presser foot rear lever 4 whose middle part is hinged on the casing, and the rear end of the presser foot rear lever 4 is connected to an electromagnet 5 connection, the front end is connected with the presser foot lifting front lever 7 through the pull rod 6, the presser foot lifting front lever 7 is connected with the presser foot lifting wrench 8 through the presser foot lifting cam, the presser foot lifting front lever 7 is connected through the presser foot lifting plate, the pressing rod guide The frame is connected with a pressing bar 9, and a presser foot 10 is arranged on the pressing bar 9. The action of lifting the presser foot can be driven by the electromagnet 5 and the presser foot lifting wrench 8 . The oil sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com