Oil pocket structure for rolling mill transmission shaft gear joint

A technology of transmission shaft and oil drum, which is applied to the driving device of metal rolling mill, metal rolling, metal rolling, etc., can solve the problems of entering the interlayer, high replacement cost, and delamination of exposed ends, etc. The frequency of replacement, not easy to aging and damage, the effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solutions and advantages of the present invention clearer, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings and specific embodiments. Obviously, the described embodiments are only the present invention. Some examples, but not all examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

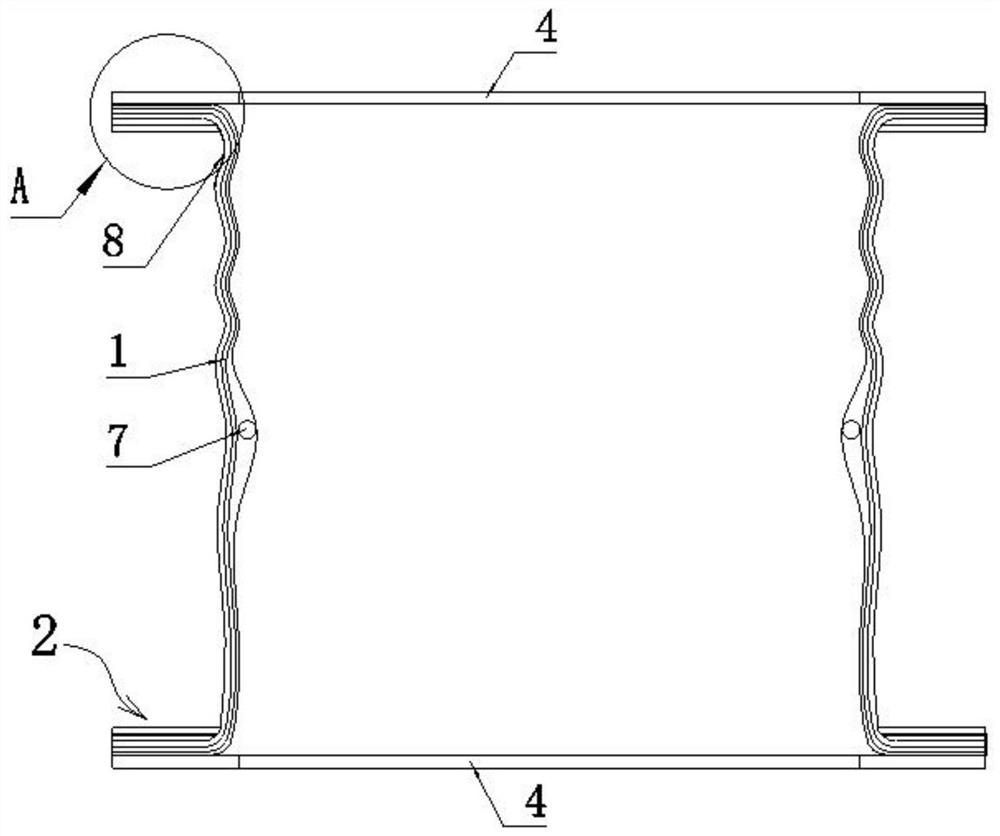

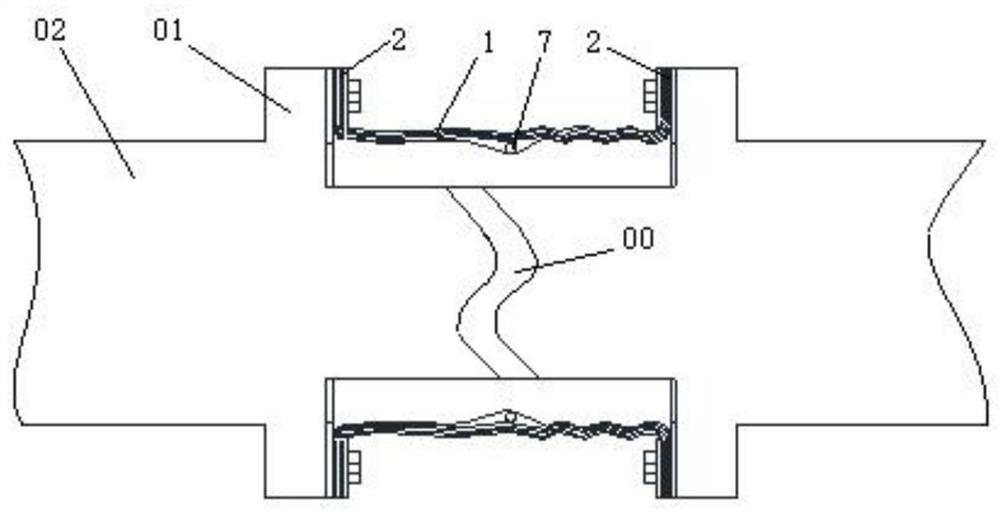

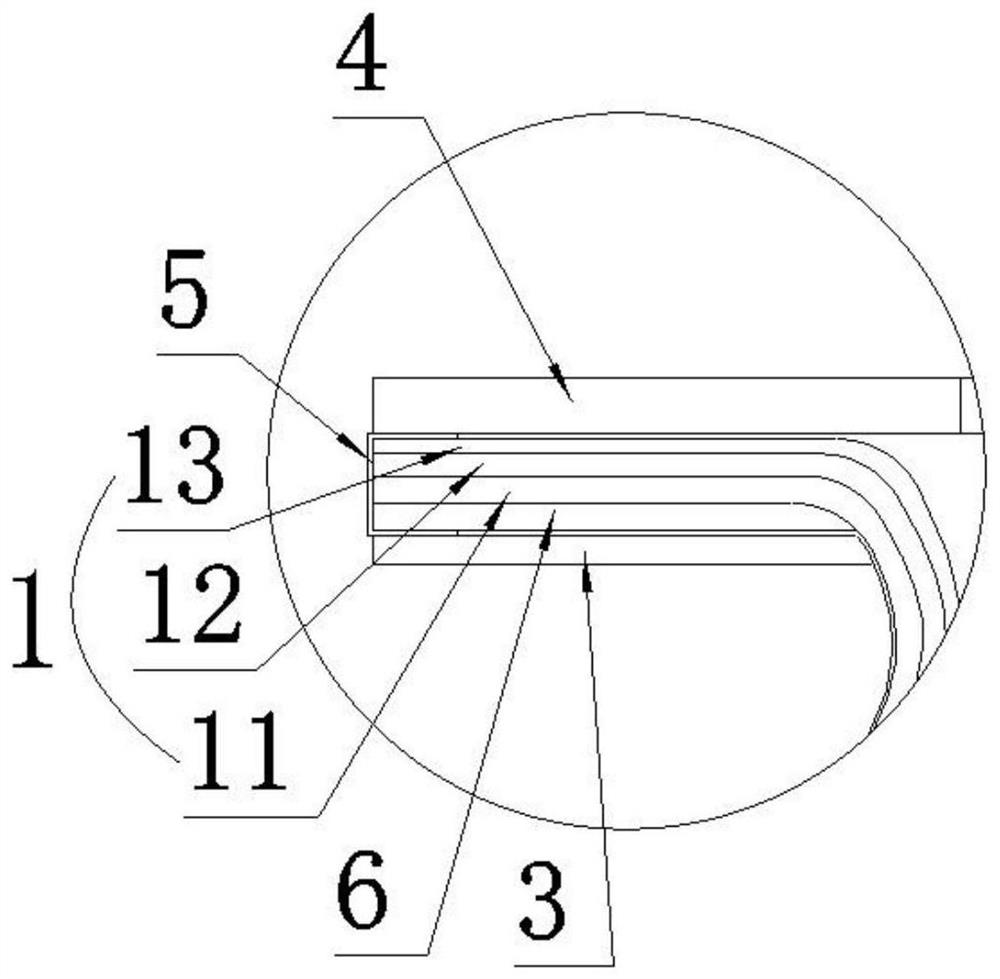

[0022] Such as figure 1 , 2 As shown, the present invention provides an oil bag structure for a gear joint of a rolling mill transmission shaft, comprising a flexible oil bag body 1 of a tubular structure, the oil bag body 1 is wrapped outside the gear joint 00 of a rolling mill transmission shaft, and the oil bag Both ends of the body 1 are respectively provided with flanges 2 for connecting with the flange 01 at the end of the transm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com